$43

Crown Forklift IC Hamech 2012 – V47 D-4TNE98 DIESEL ENGINE Service Manual – PDF DOWNLOAD

Crown Forklift IC Hamech 2012 – V47 D-4TNE98 DIESEL ENGINE Service Manual – PDF DOWNLOAD

FILE DETAILS:

Crown Forklift IC Hamech 2012 – V47 D-4TNE98 DIESEL ENGINE Service Manual – PDF DOWNLOAD

Language : English

Pages :1633

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Crown Forklift IC Hamech 2012 – V47 D-4TNE98 DIESEL ENGINE Service Manual – PDF DOWNLOAD

GROUP 00 (D-4TNE98) DIESEL ENGINE 1

Section 1 GENERAL SERVICE INFORMATION 3

COMPONENT IDENTIFICATION 3

LOCATION OF LABELS 3

DIESEL FUEL 4

ENGINE OIL 5

ENGINE COOLANT 7

SPECIFICATIONS 9

ENGINE SERVICE INFORMATION 11

TIGHTENING TORQUES FOR STANDARD BOLTS AND NUTS 12

STANDARD TORQUE CHART 13

Section 2 Periodic Maintenance 15

PERIODIC MAINTENANCE PROCEDURES 17

Daily 17

Every 250 Hours of Operation 19

Every 500 Hours of Operation 23

Every 1000 Hours of Operation 25

Every 2000 Hours of Operation 30

Every 4000 Hours of Operation 31

Section 3 ENGINE 33

ENGINE SERVICE INFORMATION 34

ENGINE SPECIAL TORQUE CHART 40

SPECIAL SERVICE TOOLS 41

CYlinder Head Components 46

Disassembly of Cylinder Head 47

Removal of Glow Plugs 48

Removal of Valve Cover 48

Removal of Rocker Arm Assembly 48

Disassembly of Rocker Arm Assembly 49

Removal of Cylinder Head 49

Removal of Intake / Exhaust Valves 50

Removal of Valve Guides 50

Cleaning of Cylinder Head Components 51

Inspection of Cylinder Head Components 51

Assembly of Cylinder Head 54

Assembly of Intake and Exhaust Valves 54

Assembly of Cylinder Head 55

Assembly of Rocker Arm Assembly 56

Assembly of the Valve Cover 57

Assembly of Glow Plugs 57

MEASURING AND ADJUSTING VALVE CLEARANCE 58

DRIVE TRAIN AND CAMSHAFT COMPONENTS 60

Disassembly of Drive Train andCamshaft Components 61

Removal of Oil Pan 62

Removal of Oil Sump Pump 62

Removal of Timing Gears 63

Removal of Pistons 63

Removal of Crankshaft 64

Removal of Gear Case 66

Inspection of Drive Train and Camshaft Components 67

Honing and Boring 73

Assembly of Drive Train andCamshaft Components 74

Assembly of Pistons 74

Installation of Gear Case 75

Installation of Crankshaft 75

Installation of Pistons 76

Installation of Camshaft 77

Installation of Timing Gears 77

Installation of Gear Case Cover 78

Installation of Oil Sump Pump 78

Installation of Oil Pan 78

Section 4 FUEL SYSTEM 81

FUEL SYSTEM COMPONENTS 82

FUEL SYSTEM DIAGRAM 83

STRUCTURE AND OPERATION OF FUEL INJECTION PUMP 84

PLUNGER OPERATION 88

ALL -SPEED GOVERNOR 93

STRUCTURE AND OPERATION OF TIMER 100

REMOVAL OF FUEL INJECTION PUMP 102

INSTALLATION OF THE FUEL INJECTION PUMP 105

CHECKING / ADJUSTMENT OF FUEL INJECTION TIMING 107

SERVICING THE FUEL INJECTORS 108

Section 5 COOLING SYSTEM 113

ENGINE COOLANT PUMP COMPONENTS 114

ENGINE COOLANT SYSTEMCHECK 115

DISASSEMBLY OF ENGINE COOLANTPUMP 115

CLEANING AND INSPECTION 117

ASSEMBLY OF ENGINE COOLANTPUMP 118

Section 6 LUBRICATION SYSTEM 121

LUBRICATION SYSTEM DIAGRAM 122

CHECKING ENGINE OIL PRESSURE 123

Section 7 STARTER MOTOR 127

STARTER MOTOR TROUBLESHOOTING 128

STARTER MOTOR PRECAUTIONS 129

STARTER MOTOR SERVICING 130

Section 8 ALTERNATOR 141

ALTERNATOR TROUBLESHOOTING 142

ALTERNATOR COMPONENTS 143

Section 9 TROUBLESHOOTING 157

TROUBLESHOOTING BY MEASURING COMPRESSION PRESSURE 158

QUICK REFERENCE TABLE FOR TROUBLESHOOTING 160

Section 0 SAFETY 165

Safety Precautions 166

SERVICE AREA 166

WORK – WEAR (GARMENTS) 166

TOOLS 167

GENUINE PARTS and MATERIALS 167

FASTENER TORQUE 167

Electrical 168

WASTE MANAGEMENT 168

FURTHER PRECAUTIONS 169

Precautions for Service Work 170

How to Read this Manual 170

Section 1 GENERAL 173

Fuel Oil, Lubricating Oil andCooling Water 176

Exhaust gas emission regulation 178

Section 2 Inspection and Adjustment 183

Periodic Inspection and Maintenance Procedure 184

Inspection every 1,000 hours or one year 195

Section 3 Troubleshooting 211

Section 4 Disassembly, Inspection and Reassembly of Engines 219

Complete disassembly 224

Cylinder Head: Disassembly, Inspection and Reassembly 229

Gear Train and Camshaft 240

Cylinder Block 246

Section 5 LUBRICATION SYSTEM 261

Section 6 COOLING SYSTEM 265

Section 7 FUEL INJECTION PUMP/GOVERNOR 267

Section 8 ALTERNATOR 273

Section 9 ELECTRIC WIRING 277

Section 10 SERVICE STANDARDS 282

Engine Body 283

Gear train and camshaft 284

Cylinder block 285

Lubricating Oil System (Trochoid Pump) 288

Section 11 TIGHTENING TORQUE for BOLTS and NUTS 290

Section1 Safety 294

Section2 Lifting, Jacking, and Blocking the Truck 298

Safe Parking 299

Lifting, Blocking, and Jacking Points 299

Raising Drive Wheels Off Floor 299

Raising Truck with A Hoist 300

Blocking the Upright In Raised Position 301

Raising Rear of Truck 301

Raising Entire Truck 302

Shipping Tie-Down Instructions 303

Section3 Towing 304

GROUP 00 (L-GM) ENGINE (GM 30 LPG) 308

Section 1 Specifications and Information 310

Section 2 Diagnostic Information and Procedures 314

Section 3 Engine Removal and Installation 318

Section 4 Description and Operation 378

Section 1 General Information 386

Section 2 Specification and Troubleshooting 394

Specifications 0

Tightening Torque 0

Compression Pressure Inspection 0

Valve Clearance and Adjustment 0

Troubleshooting 0

Special service tools 0

Section 3 Disassembly and Reassembly 410

TIMING SYSTEM 0

Removal 0

Inspection 0

Installation 0

CYLINDER HEAD ASSEMBLY 0

Removal 0

Disassembly 0

Inspection 0

Cylinder Head 0

Valve And Valve Spring 0

MLA 0

Camshaft 0

Reassembly 0

CYLINDER BLOCK ASSEMBLY 0

Disassembley 0

Inspection 0

Connecting Rod And Crankshaft 0

Cylinder Block 0

Piston And Rings 0

Piston Pins 0

Reassembly 0

COOLING SYSTEM 0

Removal 0

Water pump 0

Thermostat 0

Inspection 0

Water pump 0

Thermostat 0

Installation 0

Thermostat 0

Troubleshooting 0

Water pump 0

Thermostat 0

Intake manifold 0

Removal 0

Installation 0

Exaust manifold 0

Removal 0

Installation 0

Section 4 Lubrication System 458

Oil Pump 0

Engine Oil 0

Oil Pressure Switch 0

Selection Of Engine Oil 0

Section 5 Electrical System 464

Specification 0

Trouble Shooting 0

Special Service Tool 0

Ignition system 0

Description 0

Repair procedures 0

Spark Test 0

On-vehicle Inspection 0

Inspect Spark Plug 0

Inspect Ignition Coil 0

Charging system 0

Inspect Drive Belt 0

Inspect Charging System 0

Output Current Test 0

Regulated Voltage Test 0

Alternator 0

Starting system 0

Inspection 0

Description 0

Starter 0

Removal 0

Disassembly 0

Inspection 0

Armature Inspection And Test 0

Inspect Starter Brush 0

Starter Brush Holder Test 0

Inspect Overrunning Clutch 0

Cleaning 0

Starter relay 0

Section 6 Emission Control System 486

PCV(positive crankcase ventilation) VALVE 0

FUEL SYSTEM 0

Specifications 0

Sensor 0

Tightening torques 0

Troubleshooting 0

Basic inspection procedure 0

Engine control system 0

MAPS (Manifold Absolute Pressure Sensor) 0

IATS (Intake Air Temperature Sensor) 0

ECTS (Engine Coolant Temperature Sensor) 0

CMPS (Camshaft Position Sensor) 0

CKPS (Crankshaft Position Sensor) 0

HO2S (Heated Oxygen Sensor) 0

KS (Knock Sensor) 0

Injector 0

Section 1 General Information 506

Section 2 Maintenance 508

Section 3 LPG Fuel System 516

Section 4 Fuel System Diagnosis 522

Section 5 Electrical Section 538

Diagnostic Trouble Codes (DTCs) 565

OBD System Check/MIL (MalfunctionIndicator Lamp) 570

HVS Ignition Control System Diagnostics 571

Ignition Control System DiagnosticChart 572

Section 6 Definitions 724

Section 1 LPG Fuel System 732

LPG FUEL SYSTEM 732

Section 2 Fuel System Component Details 734

Description of Regulator/Vaporizer Operating States 736

Liquid-Phase Filter & Shutoff Valve 738

Fuel Rail 739

Gaseous Fuel Filter 740

Engine Control Unit 741

Wire Harness 744

Emissions Catalyst 746

Oxygen Sensors 747

Ignition Control System 749

Power Transistors 749

Locations of Major Sensors & Components 750

Section 3 Recommended Maintenance 752

General Maintenance Guideline 753

Fuel System Leak Testing 754

General Fluid Leaks 754

Coolant System 754

Electrical System & Harness 754

Ignition System 757

LPG Regulator Service 757

LPG Shutoff Valve – Option 1, Valtek 760

LPG Liquid Filter – Option 1, Valtek 760

Maintenance Kit for LPG Liquid Filter 761

LPG Shutoff Valve – Option 2, AFC 762

LPG Rail & Injectors 763

Throttle Body & Intake Tubing 765

TMAP Sensor 765

Exhaust System & Catalyst 765

Section 4 Diagnostic Trouble Codes (DTC) 766

SUPPORTED DTCS 769

Section 5 General Trouble Shooting 776

Engine cranks but will not start 776

Engine does not provide expected power output, slow to accelerate, stalls when lifting load 777

Engine speed hunting at idle and other speed and load conditions 778

Engine backfires 779

Engine knocking 780

Engine run-on after shut down 781

Engine misfires 781

Poor fuel economy 782

High idle speed (above the set point of 750 rpm) 782

Engine knocking 783

Section 6 TROUBLE SHOOTING BY DTC 784

Section 7 DIAGNOSTIC SERVICE TOOL 810

Section 1 General Information 828

Section 2 Maintenance 830

Section 3 LPG Fuel System 838

Section 4 Fuel System Diagnosis 844

Section 5 Electrical Section 860

Diagnostic Trouble Codes (DTCs) 887

OBD System Check/MIL (MalfunctionIndicator Lamp) 892

HVS Ignition Control System Diagnostics 893

Ignition Control System DiagnosticChart 894

Section 6 Definitions1046

Section 1 Engine Cooling System 1054

Section 2 Troubleshooting 1056

Section 3 Testing and Maintenance 1058

Engine Coolant Level Check1059

Adding Coolant1060

Cooling System Inspection1060

Cooling System Tests1061

Testing the Radiator Cap1061

Testing Radiator and Cooling System1062

Testing the Thermostat1062

Engine Coolant Change1062

Draining Radiator and Cooling System1062

Cleaning and Flushing Cooling System1063

Filling Cooling System1063

Section 4 Engine Cooling System and Alternator Belt Service 1066

Belt Checks1067

Gas/LPG Truck Belt Removal1067

Fan Drive Belt Removal1067

Alternator/Water Pump Belt Removal1068

Gas/LPG Truck Belt Replacement1068

Alternator/Water Pump Belt Replacement (V47)1068

Fan Drive Belt Replacement1068

Alternator/Water Pump Belt Tension (Gas/LPG Engines)1069

Fan Drive Belt Tension (Gas/LPG Engines)1069

Diesel truck fan drive belt replacement1070

Section 5 Radiator Removal and Replacement 1052

Radiator Removal1073

Radiator Replacement1075

Section 1 Specifications and Description1080

Section 2 Intake System Troubleshooting1082

Section 3 Intake System Service1084

Section 4 Exhaust Systems1088

Section 1 Cautions for working on the electrical system1096

Section 2 Electrical system Specifications and features1098

Section 3 Electrical Circuit Diagram & Electrical Parts Arrangement1100

VL30-VL40s WIRING DIAGRAM1101

INSTALL ELECTRICAL COMPONENT & HARNESS MAIN1107

VL30-40s LPG Tier 41110

VL30-40s Diesel Tier 31111

VL30-40s Diesel Tier 31113

VL30-40s Diesel Tier 31106

VL40-VL70 WIRING DIAGRAM1116

VL40-VL70 Diesel Tier 31119

INSTALL ELECTRICAL COMPONENTS & HARNESS MAIN1122

VL40-70 LPG Tier 41125

VL40-70 Diesel Tier 31130

VL40-70 Diesel Tier 31133

Section 4 Instrument Pod1138

1 Display Monitor1139

2 Explanation of function1140

3 Major function of truck1142

4 Functional setting and operation1144

41 Operating method for mode switch1144

42 Menu mode composition chart1145

# Menu Mode (Tree structure)1147

43 Menu mode check and adjusting method1148

44 Model set1150

45 Error history1150

46 Password change1151

47 Set on communication for option equipment1153

48 Optional function setting1153

49 DATE setting1161

5 Fault diagnosis1162

51 Self diagnostic function1162

52 Management of fault history1162

53 Error code1163

Section 5 Electrical Components Specification and Operation1164

Battery1165

Engine Accessories1166

Alternator1166

Starting Motor1167

Water Temp Sender1168

Switch-Eng Oil Pressure1169

LPG Pressure Switch1170

Switch-T/M Temp1171

Fuel Sender1172

Switches1173

Start Switch1173

Switch Fow & Rev1174

Switch – directional Indicator1175

Brake Stop Switch1176

Parking Brake Switch1177

Seat Switch1178

General Electrical Parts1179

Fuse / Relay Box1179

Engine Stop Relay1180

Flash Unit1181

Start and Preheat Relays1182

Horn1183

Backup Alarm1184

Lights1185

Lamp-Work1185

Lamp-Indicator1186

Combination Lamp1187

Lamp-Beacon1188

Directional Disable Function1189

1 Description of Operating the Neutral Shift Function1189

2 Description of Engine Shutdown Function action1190

Section 6 Troubleshooting of Electrical System1192

Fuel Gauge Malfunction1193

Hourmeter Malfunction1194

Coolant Temp Gage Malfunction1195

Transaxle Oil Malfunction1196

Engine Oil Gage Malfunction1197

Alternator Charge Malfunction1198

Preheat Plug Malfunction1199

Parking Brake Malfunction1200

Work Lamp Switch Malfunction1201

Rear Work Lamp Switch1202

All of Instrument Pod Lamps Fails to Turn On1203

Failure to Drive1204

Failure to engine shut down (Diesel-tier2)1205

Failure to engine shut down (GAS/LPG)1206

Failure to Start (GAS/LPG)1207

Failure to Start (Diesel)1208

Failure to Start (Diesel-Tier2)1209

Section 1 Specifications and Description1212

Section 2 Cushion Wheels and Tires1214

Section 3 Pneumatic Wheels and Tires1218

Pneumatic Tire Maintenance Precaution1219

General Tire Maintenance, Inspection, and Repair1220

Wheel Dismounting and Remounting1221

Drive and Steer Wheel Dismounting1221

Drive and Steer Wheel Remounting1222

Dual-Drive Wheel Dismounting(V47)1223

Dual-Drive Wheel Remounting(V47)1223

Wheel Disassembly and Tire Removal1224

Tire Replacement and Wheel Reassembly1226

Tire-to-Wheel Mounting1227

Filling Tires with Air1228

Filling Tires with Nitrogen1228

Checking and Adjusting Tire Pressure1229

Split-Rim Wheel Assemblies(V47)1230

Section 1 Braking / Inching System Specifications and Description1234

NOTE1234

Specifications1234

General Description1234

Service Brake and Inching System Arrangement1235

Inching Operation1236

Braking Operation1236

Service Requirements1236

Section 2 Service Brake Troubleshooting1238

Section 3 Brake/Inching Pedals and Linkages Adjustments1240

Section 4 Brake System Bleeding1244

Section 5 Brake Master Cylinder Service1246

Section 6 Service Brake Adjustment and Overhaul1250

External Inspection1250

Shoe-to-Drum Gap Adjustment1250

Internal Inspection and Repair1251

Brake Drum Removal and Replacement1251

Inspection1251

Brake Shoe Removal1251

Brake Shoe Replacement1251

Cylinder Removal and Replacement1252

Adjuster Removal and Replacement1252

Lubrication1252

Wheel Cylinder Overhaul1253

Operational Explanation of the Auto Adjuster1254

Section 7 Parking Brake Service1256

Operation1256

Adjustment1256

Removal and Replacement1256

Parking Brake Cable Removal and Installation1258

Section 1 Steering System Specifications and Description1262

Section 2 Steering System Troubleshooting1264

Section 3 Steering Column and Component Removal and Replacement 0

Steering Column and Component Removal 0

Ignition Switch Removal 0

Hand Wheel, Horn Contact Ring, and Directional Control Assembly Removal 0

Column Tilt Lock Assembly Removal 0

Steering Gear and Lower Steering Column Removal 0

Steer Column and Component Replacement 0

Steering Gear and Lower Steering Column Replacement 0

Column Tilt Lock Assembly Replacement 0

Directional Control Assembly Reassembly 0

Directional Control Assembly and Ignition Switch Replacement 0

Steering Hand Wheel Replacement 0

Section 4 Steering System Relief Pressure Check and Adjustment 0

Section 5 Steering Gear Overhaul1280

Disassembly1281

Parts Inspection1283

Reassembly1283

Section 1 Steer Axle Specifications and Description 0

Section 2 Steer Axle Wheel Bearing Maintenance and Adjustment1292

Section 3 Steer Axle Removal and Replacement 0

Steer Axle Removal 0

Steer Axle Replacement 0

Section 4 Steer Axle Overhaul1302

Steer Axle Disassembly1303

Parts Inspection1304

Steer Axle Reassembly1304

Section 5 Steer Cylinder Removal and Replacement1306

Steer Cylinder Removal1306

Parts Inspection1307

Steer Cylinder Replacement1307

Section 6 Steer Cylinder Overhaul1310

Preparation for Steer Cylinder Disassemblyand Overhaul1311

Steer Cylinder Disassembly1311

Parts Inspection1311

Steer Cylinder Reassembly1312

Section 1 Hydraulic Sump, Filters, and Pump Specifications and Description 0

Section 2 Main Hydraulic Pump Troubleshooting1320

Section 3 Hydraulic Filters and Fluid Maintenance and Change 0

Section 4 Hydraulic Pump Removal and Replacement 0

Section 5 Hydraulic Pump Overhaul(Hanil Pump)-V471328

Pump Disassembly1329

Steering Priority and Steering Pressure Relief Valve Disassembly1332

Pump Reassembly1333

Steering Priority and Relief Valve Reassembly1334

Section 6 Hydraulic Pump Overhaul(Jinsung Pump)-V341338

Disassembly and Assembly1339

Inspection and Assessment1340

Trouble shooting1342

Start-up1343

Section 1 Hydraulic Control Valve/Lift Circuit Specifications and Description 0

Section 2 Hydraulic System Schematics1350

Section 3 Hydraulic System Troubleshooting1352

Section 4 Hydraulic System Pressure Checks and Adjustments 0

Relief Pressure Check 0

Main and Auxiliary Pressure Relief Adjustment 0

Flow Control Adjustment 0

Section 5 Hydraulic Control Valve Removal and Replacement1358

Hydraulic Control Valve Removal1359

Hydraulic Control Valve Replacement1360

Operational Checks1361

Section 6 Hydraulic Control Valve Overhaul For HANIL Valve (V47)1362

Preparation for Disassembly1362

Disassembly1363

Cleaning, Inspection, and Repair1364

Reassembly1365

Relief Valve Settings1365

Section 7 Hydraulic Control Valve Overhaul For EATON Valve (V34)1366

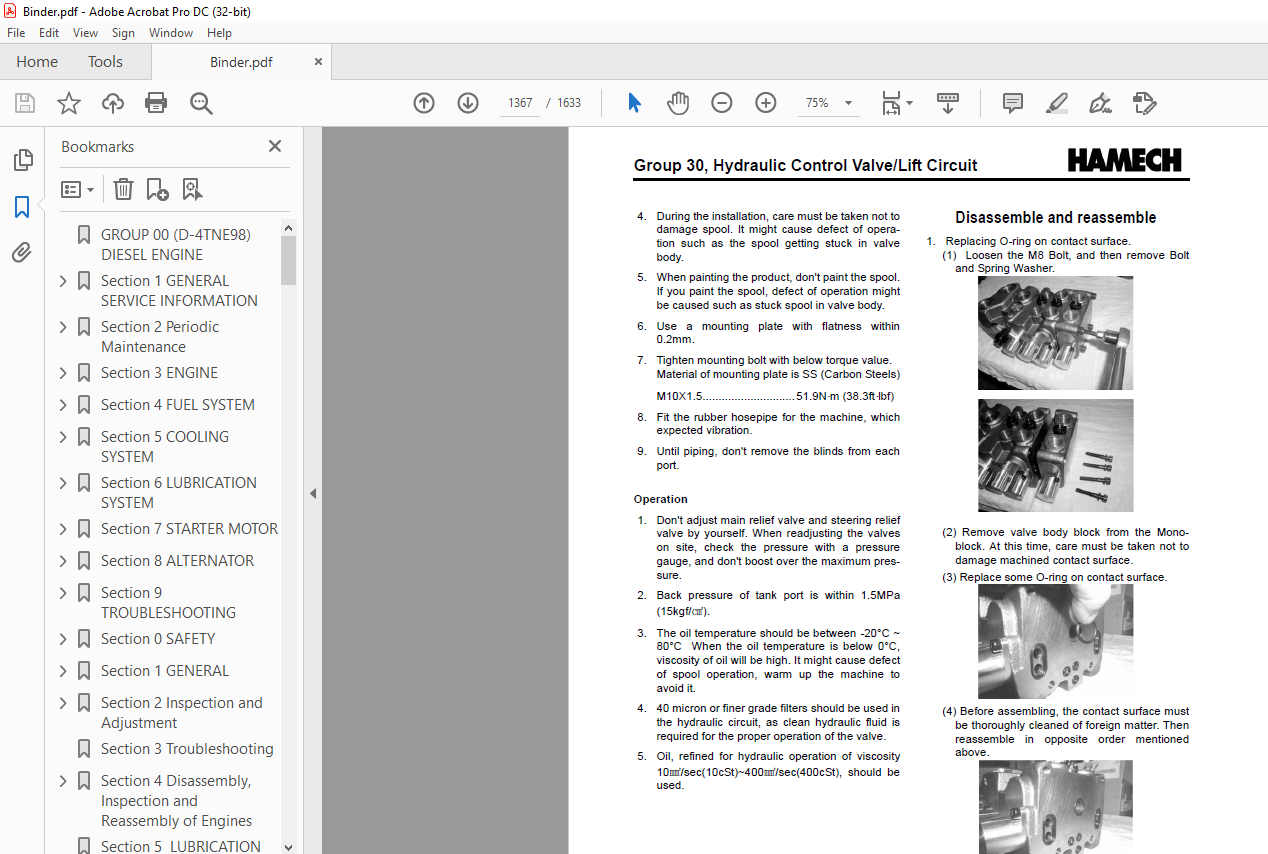

Precautions1366

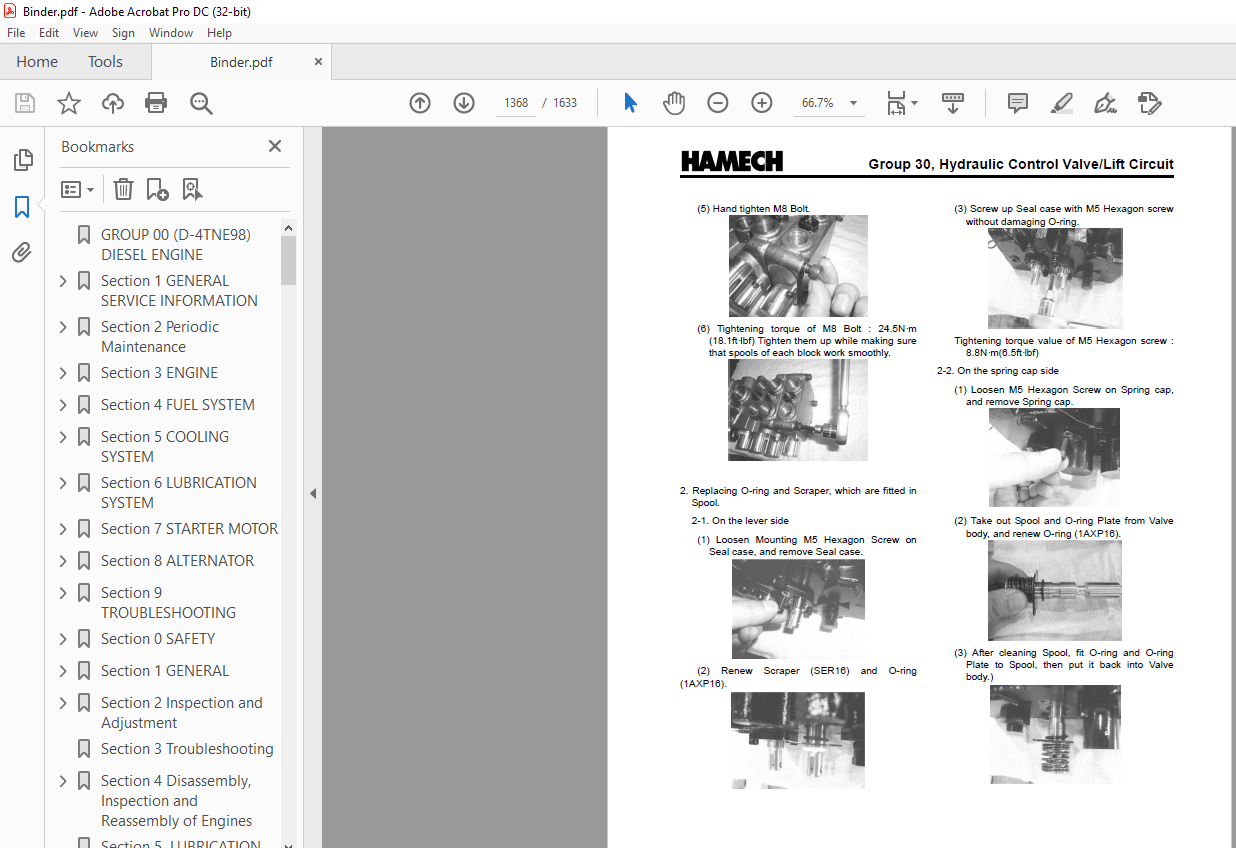

Disassemble and reassemble1367

Trouble shooting1370

Section 1 Tilt Cylinder Specifications and Description1374

Section 2 Tilt Cylinder Checks and Adjustments1376

Section 3 Tilt Cylinder Removal and Replacement 0

Tilt Cylinder Removal 0

Parts Inspection 0

Tilt Cylinder Replacement 0

Section 4 Tilt Cylinder Overhaul 0

Preparation For Disassembly 0

Disassembly 0

Inspection 0

Reassembly 0

Section 1 Upright Specifications and Description1390

General Specifications1390

Cylinder Types1390

Drift1390

Fastener and Fitting Torque Specifications1391

Service Intervals1391

Description1391

Section 2 Troubleshooting1406

Upright noise1406

No lift, tilt, or auxiliary function1406

No lift function but tilt operates1406

Load cannot be lifted to maximum height1407

Lift speed sluggish1407

Lowering speed sluggish1407

Load bounces excessively when lowering1407

Upright mis-staging (TSU lifting)1407

Upright mis-staging (TSU lowering)1408

Upright mis-staging (Standard and Hi-Lo upright lowering)1408

External leakage on primary cylinder1408

External leakage on lift (Standard) and secondary cylinder (TSUs and Hi-Lo)1409

Section 3 Upright Inspection1410

Basic Visual Inspection1411

Extended Inspection1412

Forks1412

Lift Chains1413

Carriage and Upright Weldments1414

Carriage and Upright Rollers1415

Cylinders1417

Hydraulic Plumbing1419

Upright Drift1419

Trunnion Bearings1420

Section 4 Carriage and Upright Roller Clearance Checks and Shim Adjustments1422

Introduction1422

Roller Side Clearance Checks1425

Internal Thrust Roller Adjustment(V47)1427

Oversize Rollers1428

Lift Roller Shimming1428

Carriage Roller Shimming1429

Upright Roller Shimming1429

Overshimming1432

Section 5 Cylinder Removal, Shimming, Overhaul, and Replacement1434

Cylinder Types1434

Lift Cylinder Shimming Procedure1434

Primary Cylinder Removal and Replacement (Hi-Lo & TSU)1435

Lift and Secondary Cylinder Removal and Replacement1436

Cylinder Overhaul1437

Section 6 Upright Chain Inspection, Adjustment, and Replacement1442

Periodic Inspections1444

Elongation1444

Edge Wear1444

Turning or Protruding Pins1444

Cracked Plates1444

Ultimate Strength Failure1445

Tight Joints1445

Chain Length Adjustments1446

Chain Lubrication1448

Chain Removal and Replacement1448

General Guidelines1448

Lift Chains (Standard and TSUs)1449

Primary Cylinder/Carriage Chains (TSU and Hi-Lo)1449

Other Chain Service Notes1450

Section 7 Fork and Carriage Removal and Replacement1452

Fork Removal1452

Fork Replacement1452

Carriage Removal1453

Carriage Replacement1454

Section 8 Upright Removal and Replacement1458

Upright Removal1459

Upright Replacement1460

Section 1 Counterweight Specifications and Description1464

Section 2 Counterweight Removal and Replacement1466

Section 3 Overhead Guard/Operator’s Cell Removal and Replacement1470

Section 4 Floorboard, Cowls, and Seat Deck Removal and Replacement1472

Floor Plate Removal and Replacement1473

Cowl Removal and Replacement1473

Radiator Cover Removal and Replacement1474

Operator’s Seat Deck Removal and Replacement1474

Section 5 Operator’s Seat Removal and Replacement1478

Section 1 Nameplates and Decals1484

Truck Data and Capacity Plate1485

Operator Safety Warning Plate1485

General Safety Decal1486

Seat Belt/Tip-Over Warning Decal1487

Hand Safety Warning Decal1487

Keep Away from Forks Decal1487

Fan Warning Decal1487

Nameplate, Decal Locations1488

Section 2 General Specifications1490

Weights and Performance Specifications1491

Capacities1491

Truck Weights and Axle Weights1491

Parking Brake Test1491

Maximum Gradeability1492

Drawbar Pull1492

Travel Speeds1492

Turning Radius (outside)1492

Critical Fastener Torque Specifications1493

Group Specifications1494

Group 00, V34 LPG Engine Specifications1494

Group 00, V47 LPG Engine Specifications1494

Group 00(D), V47 – 4TNE98 Diesel Engine Specifications1495

Group 01, Cooling System Specifications1496

Group 02(LP), LPG Fuel System Specifications1496

Group 03, Intake and Exhaust Systems Specifications1496

Group 06(S), Standard Transaxle Specifications1496

Group 13, Instrument Pod & Electrical System Specifications1497

Group 22, Wheels and Tires Specifications1497

Group 23(G) brake/Inching System Specifications (Standard Transaxle)1498

Group 25, Steering Column and Gear Specifications1498

Group 26, Steer Axle Specifications1498

Group 29, Hydraulic Sump, Filters, and Pump Specifications1499

Group 30, Hydraulic Valve/Lift Circuit Specifications1499

Group 32, Tilt Cylinders Specifications1500

Group 34, Upright Specifications1500

Lift Speeds, Upright1501

Group 38, Counterweight and Chassis Specifications1501

Drift, Lift and Tilt Cylinders1501

Section 3 Hydraulic Fitting Tightening Procedure1502

Section1 Maintenance Schedulespdf1506

Maintenance Schedules1506

“Periodic Service” and “Planned Maintenance”1506

Determining Maintenance Intervals1506

Service Chart/Lubrication Points1507

Recommended Periodic Service Schedule1507

Section2 The Planned Maintenance Programpdf1512

Introduction to Planned Maintenance1513

PM Intervals1513

The PM Form1513

The Basic PM Procedures1513

The Recommended PM Task Chart1514

Listed by Service Manual Group1514

Visual Inspection1515

Functional Tests1517

Air Cleaning the Truck1519

Truck Chassis Inspection and Lubrication1520

Upright and Tilt Cylinder Lubrication1520

Lift Chain Lubrication1520

Under-the-Hood Inspection1520

Fluid Checks1520

Stall Test1521

Cranking Voltage Test1521

Critical Fastener Torque Checks1521

The Planned Maintenance Program1512

Section 1 Transaxle Specifications and Description 0

Construction 0

hydraulic circuit 0

SERVICE MAINTENANCE 0

Specification 0

Pressure specification 0

Pressure check points 0

Service brake adjustment 0

Section 2 Transaxle Disassembly1532

Wheel End1534

Brake Assembly Removal1536

Separation of Converter Housing and Adaptor Plate1537

Stator Support Removal From Adaptor Plate1538

Clutch Assembly, idler Gear & Pinion Shaft Removal1538

Section 3 Transaxle Reassembly1542

DIFFERENTIAL1543

Wheel End Final Assembly1551

Install brake assemblies1552

CLUTCH ASSEMBLY1554

Transmission assembly1556

Section 1 Transaxle Specifications and Description1562

Specifications1563

Description1565

Torque Converter1565

Charging Pump1566

Transmission1566

Forward/Reverse Clutch Packs1566

Solenoid Valves1566

Transaxle Control Valve1567

Differential1568

Drive Axle1569

Operation1570

Transaxle Hydraulic Schematic1572

Sectional View Along Turbine Shaft1573

Sectional View Along Drive Axle1574

Section 2 Transaxle Troubleshooting1576

Checks1578

Fluid Level Check1578

Fluid Leakage Checks1578

General Mechanical/Electrical Checks1578

Solenoid Valve Electrical Checks1578

Stall RPM Test1579

Transaxle Pressure Checks1579

Section 3 Transaxle Oil and Filter 1582

Section 4 Transaxle Oil Cooler1586

Flow Check1586

Pressure Check1586

Oil Cooler Removal1587

Oil Cooler Installation1588

Section 5 Transaxle Removal and Replacement1590

Transaxle Removal1591

Transaxle Replacement1593

Section 6 Transaxle Overhaul1596

General Practices to Follow1597

Disassembling Components1597

Cleaning Parts1597

Inspecting Parts1598

Repairing and Replacing Parts1598

Reassembling Components1599

Overhaul Procedures1600

Transaxle Disassembly1600

Differential Overhaul1608

Clutch Overhaul1609

Transaxle Control Valve Overhaul1613

Section 7 Drive Axle Ends Overhaul1628

Section 8 Transaxle Control Valve Overhaul1632

IMAGES PREVIEW OF THE MANUAL: