$41

Crown Forklift IC Hamech D-4TNE98 DIESEL ENGINE Service Manual – PDF DOWNLOAD

Crown Forklift IC Hamech D-4TNE98 DIESEL ENGINE Service Manual – PDF DOWNLOAD

FILE DETAILS:

Crown Forklift IC Hamech D-4TNE98 DIESEL ENGINE Service Manual – PDF DOWNLOAD

Language : English

Pages :1291

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Crown Forklift IC Hamech D-4TNE98 DIESEL ENGINE Service Manual – PDF DOWNLOAD

GROUP 00 (D-4TNE98) DIESEL ENGINE 1

Section 1 GENERAL SERVICE INFORMATION 3

COMPONENT IDENTIFICATION 3

LOCATION OF LABELS 3

DIESEL FUEL 4

ENGINE OIL 5

ENGINE COOLANT 7

SPECIFICATIONS 9

ENGINE SERVICE INFORMATION 11

TIGHTENING TORQUES FOR STANDARD BOLTS AND NUTS 12

STANDARD TORQUE CHART 13

Section 2 Periodic Maintenance 15

PERIODIC MAINTENANCE PROCEDURES 17

Daily 17

Every 250 Hours of Operation 19

Every 500 Hours of Operation 23

Every 1000 Hours of Operation 25

Every 2000 Hours of Operation 30

Every 4000 Hours of Operation 31

Section 3 ENGINE 33

ENGINE SERVICE INFORMATION 34

ENGINE SPECIAL TORQUE CHART 40

SPECIAL SERVICE TOOLS 41

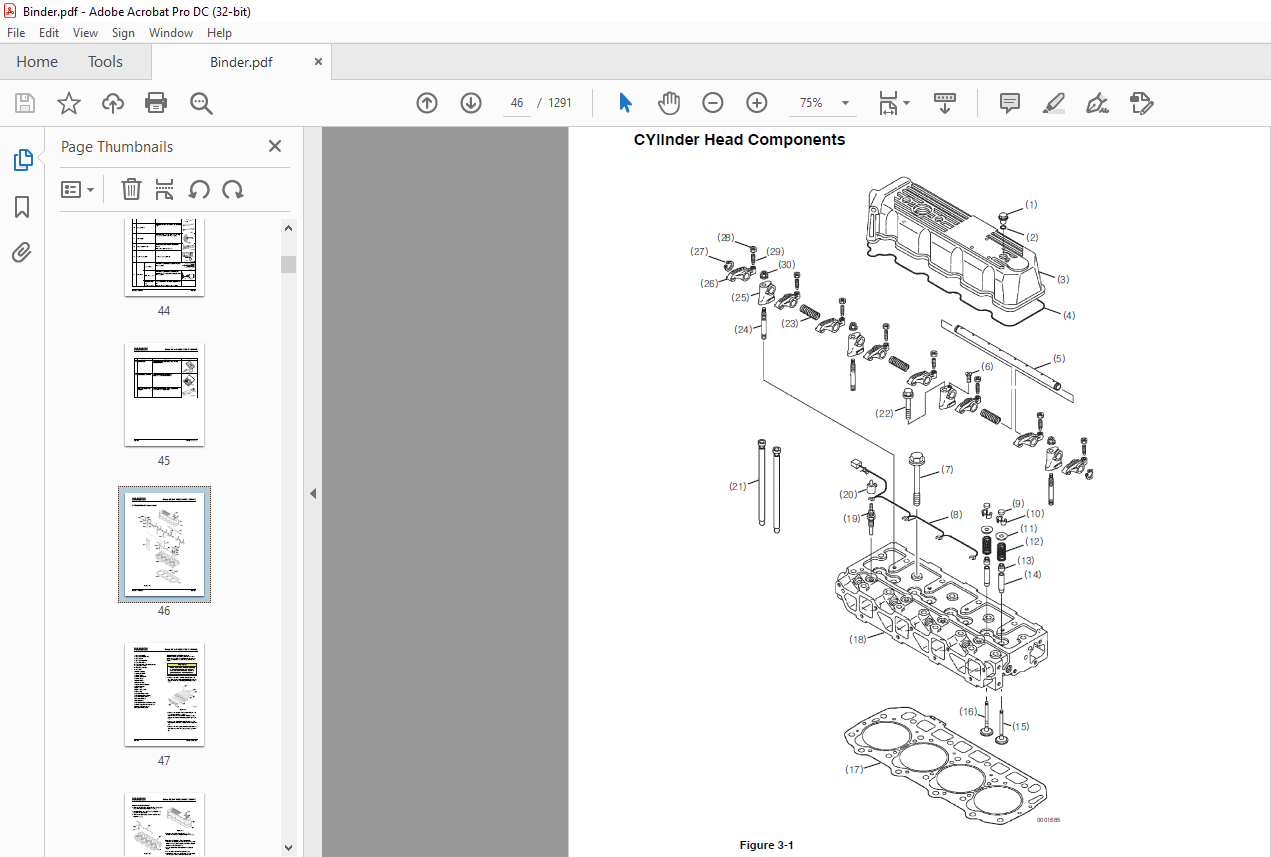

CYlinder Head Components 46

Disassembly of Cylinder Head 47

Removal of Glow Plugs 48

Removal of Valve Cover 48

Removal of Rocker Arm Assembly 48

Disassembly of Rocker Arm Assembly 49

Removal of Cylinder Head 49

Removal of Intake / Exhaust Valves 50

Removal of Valve Guides 50

Cleaning of Cylinder Head Components 51

Inspection of Cylinder Head Components 51

Assembly of Cylinder Head 54

Assembly of Intake and Exhaust Valves 54

Assembly of Cylinder Head 55

Assembly of Rocker Arm Assembly 56

Assembly of the Valve Cover 57

Assembly of Glow Plugs 57

MEASURING AND ADJUSTING VALVE CLEARANCE 58

DRIVE TRAIN AND CAMSHAFT COMPONENTS 60

Disassembly of Drive Train andCamshaft Components 61

Removal of Oil Pan 62

Removal of Oil Sump Pump 62

Removal of Timing Gears 63

Removal of Pistons 63

Removal of Crankshaft 64

Removal of Gear Case 66

Inspection of Drive Train and Camshaft Components 67

Honing and Boring 73

Assembly of Drive Train andCamshaft Components 74

Assembly of Pistons 74

Installation of Gear Case 75

Installation of Crankshaft 75

Installation of Pistons 76

Installation of Camshaft 77

Installation of Timing Gears 77

Installation of Gear Case Cover 78

Installation of Oil Sump Pump 78

Installation of Oil Pan 78

Section 4 FUEL SYSTEM 81

FUEL SYSTEM COMPONENTS 82

FUEL SYSTEM DIAGRAM 83

STRUCTURE AND OPERATION OF FUEL INJECTION PUMP 84

PLUNGER OPERATION 88

ALL -SPEED GOVERNOR 93

STRUCTURE AND OPERATION OF TIMER 100

REMOVAL OF FUEL INJECTION PUMP 102

INSTALLATION OF THE FUEL INJECTION PUMP 105

CHECKING / ADJUSTMENT OF FUEL INJECTION TIMING 107

SERVICING THE FUEL INJECTORS 108

Section 5 COOLING SYSTEM 113

ENGINE COOLANT PUMP COMPONENTS 114

ENGINE COOLANT SYSTEMCHECK 115

DISASSEMBLY OF ENGINE COOLANTPUMP 115

CLEANING AND INSPECTION 117

ASSEMBLY OF ENGINE COOLANTPUMP 118

Section 6 LUBRICATION SYSTEM 121

LUBRICATION SYSTEM DIAGRAM 122

CHECKING ENGINE OIL PRESSURE 123

Section 7 STARTER MOTOR 127

STARTER MOTOR TROUBLESHOOTING 128

STARTER MOTOR PRECAUTIONS 129

STARTER MOTOR SERVICING 130

Section 8 ALTERNATOR 141

ALTERNATOR TROUBLESHOOTING 142

ALTERNATOR COMPONENTS 143

Section 9 TROUBLESHOOTING 157

TROUBLESHOOTING BY MEASURING COMPRESSION PRESSURE 158

QUICK REFERENCE TABLE FOR TROUBLESHOOTING 160

Section 0 SAFETY 165

Safety Precautions 166

SERVICE AREA 166

WORK – WEAR (GARMENTS) 166

TOOLS 167

GENUINE PARTS and MATERIALS 167

FASTENER TORQUE 167

Electrical 168

WASTE MANAGEMENT 168

FURTHER PRECAUTIONS 169

Precautions for Service Work 170

How to Read this Manual 170

Section 1 GENERAL 173

Fuel Oil, Lubricating Oil andCooling Water 176

Exhaust gas emission regulation 178

Section 2 Inspection and Adjustment 183

Periodic Inspection and Maintenance Procedure 184

Inspection every 1,000 hours or one year 195

Section 3 Troubleshooting 211

Section 4 Disassembly, Inspection and Reassembly of Engines 219

Complete disassembly 224

Cylinder Head: Disassembly, Inspection and Reassembly 229

Gear Train and Camshaft 240

Cylinder Block 246

Section 5 LUBRICATION SYSTEM 261

Section 6 COOLING SYSTEM 265

Section 7 FUEL INJECTION PUMP/GOVERNOR 267

Section 8 ALTERNATOR 273

Section 9 ELECTRIC WIRING 277

Section 10 SERVICE STANDARDS 282

Engine Body 283

Gear train and camshaft 284

Cylinder block 285

Lubricating Oil System (Trochoid Pump) 288

Section 11 TIGHTENING TORQUE for BOLTS and NUTS 290

GROUP 00 (L-GM) ENGINE (GM 30 LPG) 292

Section 1 Specifications and Information 294

Section 2 Diagnostic Information and Procedures 298

Section 3 Engine Removal and Installation 302

Section 4 Description and Operation 362

Section 1 General Information 370

Section 2 Specification and Troubleshooting 378

Specifications 0

Tightening Torque 0

Compression Pressure Inspection 0

Valve Clearance and Adjustment 0

Troubleshooting 0

Special service tools 0

Section 3 Disassembly and Reassembly 394

TIMING SYSTEM 0

Removal 0

Inspection 0

Installation 0

CYLINDER HEAD ASSEMBLY 0

Removal 0

Disassembly 0

Inspection 0

Cylinder Head 0

Valve And Valve Spring 0

MLA 0

Camshaft 0

Reassembly 0

CYLINDER BLOCK ASSEMBLY 0

Disassembley 0

Inspection 0

Connecting Rod And Crankshaft 0

Cylinder Block 0

Piston And Rings 0

Piston Pins 0

Reassembly 0

COOLING SYSTEM 0

Removal 0

Water pump 0

Thermostat 0

Inspection 0

Water pump 0

Thermostat 0

Installation 0

Thermostat 0

Troubleshooting 0

Water pump 0

Thermostat 0

Intake manifold 0

Removal 0

Installation 0

Exaust manifold 0

Removal 0

Installation 0

Section 4 Lubrication System 442

Oil Pump 0

Engine Oil 0

Oil Pressure Switch 0

Selection Of Engine Oil 0

Section 5 Electrical System 448

Specification 0

Trouble Shooting 0

Special Service Tool 0

Ignition system 0

Description 0

Repair procedures 0

Spark Test 0

On-vehicle Inspection 0

Inspect Spark Plug 0

Inspect Ignition Coil 0

Charging system 0

Inspect Drive Belt 0

Inspect Charging System 0

Output Current Test 0

Regulated Voltage Test 0

Alternator 0

Starting system 0

Inspection 0

Description 0

Starter 0

Removal 0

Disassembly 0

Inspection 0

Armature Inspection And Test 0

Inspect Starter Brush 0

Starter Brush Holder Test 0

Inspect Overrunning Clutch 0

Cleaning 0

Starter relay 0

Section 6 Emission Control System 470

PCV(positive crankcase ventilation) VALVE 0

FUEL SYSTEM 0

Specifications 0

Sensor 0

Tightening torques 0

Troubleshooting 0

Basic inspection procedure 0

Engine control system 0

MAPS (Manifold Absolute Pressure Sensor) 0

IATS (Intake Air Temperature Sensor) 0

ECTS (Engine Coolant Temperature Sensor) 0

CMPS (Camshaft Position Sensor) 0

CKPS (Crankshaft Position Sensor) 0

HO2S (Heated Oxygen Sensor) 0

KS (Knock Sensor) 0

Injector 0

Section 1 LPG Fuel System 492

LPG FUEL SYSTEM 492

Section 2 Fuel System Component Details 494

Description of Regulator/Vaporizer Operating States 496

Liquid-Phase Filter & Shutoff Valve 498

Fuel Rail 499

Gaseous Fuel Filter 500

Engine Control Unit 501

Wire Harness 504

Emissions Catalyst 506

Oxygen Sensors 507

Ignition Control System 509

Power Transistors 509

Locations of Major Sensors & Components 510

Section 3 Recommended Maintenance 512

General Maintenance Guideline 513

Fuel System Leak Testing 514

General Fluid Leaks 514

Coolant System 514

Electrical System & Harness 514

Ignition System 517

LPG Regulator Service 517

LPG Shutoff Valve – Option 1, Valtek 520

LPG Liquid Filter – Option 1, Valtek 520

Maintenance Kit for LPG Liquid Filter 521

LPG Shutoff Valve – Option 2, AFC 522

LPG Rail & Injectors 523

Throttle Body & Intake Tubing 525

TMAP Sensor 525

Exhaust System & Catalyst 525

Section 4 Diagnostic Trouble Codes (DTC) 526

SUPPORTED DTCS 529

Section 5 General Trouble Shooting 536

Engine cranks but will not start 536

Engine does not provide expected power output, slow to accelerate, stalls when lifting load 537

Engine speed hunting at idle and other speed and load conditions 538

Engine backfires 539

Engine knocking 540

Engine run-on after shut down 541

Engine misfires 541

Poor fuel economy 542

High idle speed (above the set point of 750 rpm) 542

Engine knocking 543

Section 6 TROUBLE SHOOTING BY DTC 544

Section 7 DIAGNOSTIC SERVICE TOOL 570

Section 1 General Information 588

Section 2 Maintenance 590

Section 3 LPG Fuel System 598

Section 4 Fuel System Diagnosis 604

Section 5 Electrical Section 620

Diagnostic Trouble Codes (DTCs) 647

OBD System Check/MIL (MalfunctionIndicator Lamp) 652

HVS Ignition Control System Diagnostics 653

Ignition Control System DiagnosticChart 654

Section 6 Definitions 806

Section 1 Engine Cooling System 814

Section 2 Troubleshooting 816

Section 3 Testing and Maintenance 818

Engine Coolant Level Check 819

Adding Coolant 820

Cooling System Inspection 820

Cooling System Tests 821

Testing the Radiator Cap 821

Testing Radiator and Cooling System 822

Testing the Thermostat 822

Engine Coolant Change 822

Draining Radiator and Cooling System 822

Cleaning and Flushing Cooling System 823

Filling Cooling System 823

Section 4 Engine Cooling System and Alternator Belt Service 826

Belt Checks 827

Gas/LPG Truck Belt Removal 827

Fan Drive Belt Removal 827

Alternator/Water Pump Belt Removal 828

Gas/LPG Truck Belt Replacement 828

Alternator/Water Pump Belt Replacement (V47) 828

Fan Drive Belt Replacement 828

Alternator/Water Pump Belt Tension (Gas/LPG Engines) 829

Fan Drive Belt Tension (Gas/LPG Engines) 829

Diesel truck fan drive belt replacement 830

Section 5 Radiator Removal and Replacement 812

Radiator Removal 833

Radiator Replacement 835

Section 1 Specifications and Description 840

Section 2 Intake System Troubleshooting 842

Section 3 Intake System Service 844

Section 4 Exhaust Systems 848

Section 1 Cautions for working on the electrical system 856

Section 2 Electrical system Specifications and features 858

Section 3 Electrical Circuit Diagram & Electrical Parts Arrangement 860

VL30-VL40s WIRING DIAGRAM 861

INSTALL ELECTRICAL COMPONENT & HARNESS MAIN 867

VL30-40s LPG Tier 4 870

VL30-40s Diesel Tier 3 871

VL30-40s Diesel Tier 3 873

VL30-40s Diesel Tier 3 866

VL40-VL70 WIRING DIAGRAM 876

VL40-VL70 Diesel Tier 3 879

INSTALL ELECTRICAL COMPONENTS & HARNESS MAIN 882

VL40-70 LPG Tier 4 885

VL40-70 Diesel Tier 3 890

VL40-70 Diesel Tier 3 893

Section 4 Instrument Pod 898

1 Display Monitor 899

2 Explanation of function 900

3 Major function of truck 902

4 Functional setting and operation 904

41 Operating method for mode switch 904

42 Menu mode composition chart 905

# Menu Mode (Tree structure) 907

43 Menu mode check and adjusting method 908

44 Model set 910

45 Error history 910

46 Password change 911

47 Set on communication for option equipment 913

48 Optional function setting 913

49 DATE setting 921

5 Fault diagnosis 922

51 Self diagnostic function 922

52 Management of fault history 922

53 Error code 923

Section 5 Electrical Components Specification and Operation 924

Battery 925

Engine Accessories 926

Alternator 926

Starting Motor 927

Water Temp Sender 928

Switch-Eng Oil Pressure 929

LPG Pressure Switch 930

Switch-T/M Temp 931

Fuel Sender 932

Switches 933

Start Switch 933

Switch Fow & Rev 934

Switch – directional Indicator 935

Brake Stop Switch 936

Parking Brake Switch 937

Seat Switch 938

General Electrical Parts 939

Fuse / Relay Box 939

Engine Stop Relay 940

Flash Unit 941

Start and Preheat Relays 942

Horn 943

Backup Alarm 944

Lights 945

Lamp-Work 945

Lamp-Indicator 946

Combination Lamp 947

Lamp-Beacon 948

Directional Disable Function 949

1 Description of Operating the Neutral Shift Function 949

2 Description of Engine Shutdown Function action 950

Section 6 Troubleshooting of Electrical System 952

Fuel Gauge Malfunction 953

Hourmeter Malfunction 954

Coolant Temp Gage Malfunction 955

Transaxle Oil Malfunction 956

Engine Oil Gage Malfunction 957

Alternator Charge Malfunction 958

Preheat Plug Malfunction 959

Parking Brake Malfunction 960

Work Lamp Switch Malfunction 961

Rear Work Lamp Switch 962

All of Instrument Pod Lamps Fails to Turn On 963

Failure to Drive 964

Failure to engine shut down (Diesel-tier2) 965

Failure to engine shut down (GAS/LPG) 966

Failure to Start (GAS/LPG) 967

Failure to Start (Diesel) 968

Failure to Start (Diesel-Tier2) 969

Section 1 Specifications and Description 972

Section 2 Cushion Wheels and Tires 974

Section 3 Pneumatic Wheels and Tires 978

Pneumatic Tire Maintenance Precaution 979

General Tire Maintenance, Inspection, and Repair 980

Wheel Dismounting and Remounting 981

Drive and Steer Wheel Dismounting 981

Drive and Steer Wheel Remounting 982

Dual-Drive Wheel Dismounting(V47) 983

Dual-Drive Wheel Remounting(V47) 983

Wheel Disassembly and Tire Removal 984

Tire Replacement and Wheel Reassembly 986

Tire-to-Wheel Mounting 987

Filling Tires with Air 988

Filling Tires with Nitrogen 988

Checking and Adjusting Tire Pressure 989

Split-Rim Wheel Assemblies(V47) 990

Section 1 Steering System Specifications and Description 994

Section 2 Steering System Troubleshooting 996

Section 3 Steering Column and Component Removal and Replacement 0

Steering Column and Component Removal 0

Ignition Switch Removal 0

Hand Wheel, Horn Contact Ring, and Directional Control Assembly Removal 0

Column Tilt Lock Assembly Removal 0

Steering Gear and Lower Steering Column Removal 0

Steer Column and Component Replacement 0

Steering Gear and Lower Steering Column Replacement 0

Column Tilt Lock Assembly Replacement 0

Directional Control Assembly Reassembly 0

Directional Control Assembly and Ignition Switch Replacement 0

Steering Hand Wheel Replacement 0

Section 4 Steering System Relief Pressure Check and Adjustment 0

Section 5 Steering Gear Overhaul1012

Disassembly1013

Parts Inspection1015

Reassembly1015

Section 1 Steer Axle Specifications and Description 0

Section 2 Steer Axle Wheel Bearing Maintenance and Adjustment1024

Section 3 Steer Axle Removal and Replacement 0

Steer Axle Removal 0

Steer Axle Replacement 0

Section 4 Steer Axle Overhaul1034

Steer Axle Disassembly1035

Parts Inspection1036

Steer Axle Reassembly1036

Section 5 Steer Cylinder Removal and Replacement1038

Steer Cylinder Removal1038

Parts Inspection1039

Steer Cylinder Replacement1039

Section 6 Steer Cylinder Overhaul1042

Preparation for Steer Cylinder Disassemblyand Overhaul1043

Steer Cylinder Disassembly1043

Parts Inspection1043

Steer Cylinder Reassembly1044

Section 1 Hydraulic Sump, Filters, and Pump Specifications and Description 0

Section 2 Main Hydraulic Pump Troubleshooting1052

Section 3 Hydraulic Filters and Fluid Maintenance and Change 0

Section 4 Hydraulic Pump Removal and Replacement 0

Section 5 Hydraulic Pump Overhaul(Hanil Pump)-V471060

Pump Disassembly1061

Steering Priority and Steering Pressure Relief Valve Disassembly1064

Pump Reassembly1065

Steering Priority and Relief Valve Reassembly1066

Section 6 Hydraulic Pump Overhaul(Jinsung Pump)-V341070

Disassembly and Assembly1071

Inspection and Assessment1072

Trouble shooting1074

Start-up1075

Section 1 Hydraulic Control Valve/Lift Circuit Specifications and Description 0

Section 2 Hydraulic System Schematics1082

Section 3 Hydraulic System Troubleshooting1084

Section 4 Hydraulic System Pressure Checks and Adjustments 0

Relief Pressure Check 0

Main and Auxiliary Pressure Relief Adjustment 0

Flow Control Adjustment 0

Section 5 Hydraulic Control Valve Removal and Replacement1090

Hydraulic Control Valve Removal1091

Hydraulic Control Valve Replacement1092

Operational Checks1093

Section 6 Hydraulic Control Valve Overhaul For HANIL Valve (V47)1094

Preparation for Disassembly1094

Disassembly1095

Cleaning, Inspection, and Repair1096

Reassembly1097

Relief Valve Settings1097

Section 7 Hydraulic Control Valve Overhaul For EATON Valve (V34)1098

Precautions1098

Disassemble and reassemble1099

Trouble shooting1102

Section 1 Tilt Cylinder Specifications and Description1106

Section 2 Tilt Cylinder Checks and Adjustments1108

Section 3 Tilt Cylinder Removal and Replacement 0

Tilt Cylinder Removal 0

Parts Inspection 0

Tilt Cylinder Replacement 0

Section 4 Tilt Cylinder Overhaul 0

Preparation For Disassembly 0

Disassembly 0

Inspection 0

Reassembly 0

Section 1 Counterweight Specifications and Description1122

Section 2 Counterweight Removal and Replacement1124

Section 3 Overhead Guard/Operator’s Cell Removal and Replacement1128

Section 4 Floorboard, Cowls, and Seat Deck Removal and Replacement1130

Floor Plate Removal and Replacement1131

Cowl Removal and Replacement1131

Radiator Cover Removal and Replacement1132

Operator’s Seat Deck Removal and Replacement1132

Section 5 Operator’s Seat Removal and Replacement1136

Section 1 Nameplates and Decals1142

Truck Data and Capacity Plate1143

Operator Safety Warning Plate1143

General Safety Decal1144

Seat Belt/Tip-Over Warning Decal1145

Hand Safety Warning Decal1145

Keep Away from Forks Decal1145

Fan Warning Decal1145

Nameplate, Decal Locations1146

Section 2 General Specifications1148

Weights and Performance Specifications1149

Capacities1149

Truck Weights and Axle Weights1149

Parking Brake Test1149

Maximum Gradeability1150

Drawbar Pull1150

Travel Speeds1150

Turning Radius (outside)1150

Critical Fastener Torque Specifications1151

Group Specifications1152

Group 00, V34 LPG Engine Specifications1152

Group 00, V47 LPG Engine Specifications1152

Group 00(D), V47 – 4TNE98 Diesel Engine Specifications1153

Group 01, Cooling System Specifications1154

Group 02(LP), LPG Fuel System Specifications1154

Group 03, Intake and Exhaust Systems Specifications1154

Group 06(S), Standard Transaxle Specifications1154

Group 13, Instrument Pod & Electrical System Specifications1155

Group 22, Wheels and Tires Specifications1155

Group 23(G) brake/Inching System Specifications (Standard Transaxle)1156

Group 25, Steering Column and Gear Specifications1156

Group 26, Steer Axle Specifications1156

Group 29, Hydraulic Sump, Filters, and Pump Specifications1157

Group 30, Hydraulic Valve/Lift Circuit Specifications1157

Group 32, Tilt Cylinders Specifications1158

Group 34, Upright Specifications1158

Lift Speeds, Upright1159

Group 38, Counterweight and Chassis Specifications1159

Drift, Lift and Tilt Cylinders1159

Section 3 Hydraulic Fitting Tightening Procedure1160

Section1 Maintenance Schedulespdf1164

Maintenance Schedules1164

“Periodic Service” and “Planned Maintenance”1164

Determining Maintenance Intervals1164

Service Chart/Lubrication Points1165

Recommended Periodic Service Schedule1165

Section2 The Planned Maintenance Programpdf1170

Introduction to Planned Maintenance1171

PM Intervals1171

The PM Form1171

The Basic PM Procedures1171

The Recommended PM Task Chart1172

Listed by Service Manual Group1172

Visual Inspection1173

Functional Tests1175

Air Cleaning the Truck1177

Truck Chassis Inspection and Lubrication1178

Upright and Tilt Cylinder Lubrication1178

Lift Chain Lubrication1178

Under-the-Hood Inspection1178

Fluid Checks1178

Stall Test1179

Cranking Voltage Test1179

Critical Fastener Torque Checks1179

The Planned Maintenance Program1170

Section 1 Transaxle Specifications and Description 0

Construction 0

hydraulic circuit 0

SERVICE MAINTENANCE 0

Specification 0

Pressure specification 0

Pressure check points 0

Service brake adjustment 0

Section 2 Transaxle Disassembly1190

Wheel End1192

Brake Assembly Removal1194

Separation of Converter Housing and Adaptor Plate1195

Stator Support Removal From Adaptor Plate1196

Clutch Assembly, idler Gear & Pinion Shaft Removal1196

Section 3 Transaxle Reassembly1200

DIFFERENTIAL1201

Wheel End Final Assembly1209

Install brake assemblies1210

CLUTCH ASSEMBLY1212

Transmission assembly1214

Section 1 Transaxle Specifications and Description1220

Specifications1221

Description1223

Torque Converter1223

Charging Pump1224

Transmission1224

Forward/Reverse Clutch Packs1224

Solenoid Valves1224

Transaxle Control Valve1225

Differential1226

Drive Axle1227

Operation1228

Transaxle Hydraulic Schematic1230

Sectional View Along Turbine Shaft1231

Sectional View Along Drive Axle1232

Section 2 Transaxle Troubleshooting1234

Checks1236

Fluid Level Check1236

Fluid Leakage Checks1236

General Mechanical/Electrical Checks1236

Solenoid Valve Electrical Checks1236

Stall RPM Test1237

Transaxle Pressure Checks1237

Section 3 Transaxle Oil and Filter 1240

Section 4 Transaxle Oil Cooler1244

Flow Check1244

Pressure Check1244

Oil Cooler Removal1245

Oil Cooler Installation1246

Section 5 Transaxle Removal and Replacement1248

Transaxle Removal1249

Transaxle Replacement1251

Section 6 Transaxle Overhaul1254

General Practices to Follow1255

Disassembling Components1255

Cleaning Parts1255

Inspecting Parts1256

Repairing and Replacing Parts1256

Reassembling Components1257

Overhaul Procedures1258

Transaxle Disassembly1258

Differential Overhaul1266

Clutch Overhaul1267

Transaxle Control Valve Overhaul1271

Section 7 Drive Axle Ends Overhaul1286

Section 8 Transaxle Control Valve Overhaul1290

IMAGES PREVIEW OF THE MANUAL: