$36

Crown Forklift M3000 Walkie Stacker Service Manual – PDF DOWNLOAD

Crown Forklift M3000 Walkie Stacker Service Manual – PDF DOWNLOAD

FILE DETAILS:

Crown Forklift M3000 Walkie Stacker Service Manual – PDF DOWNLOAD

Language : English

Pages :262

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Crown Forklift M3000 Walkie Stacker Service Manual – PDF DOWNLOAD

Introduction 0

Important Information 1

Service technician qualification 1

Ordering spare parts 1

Ordering documentation 1

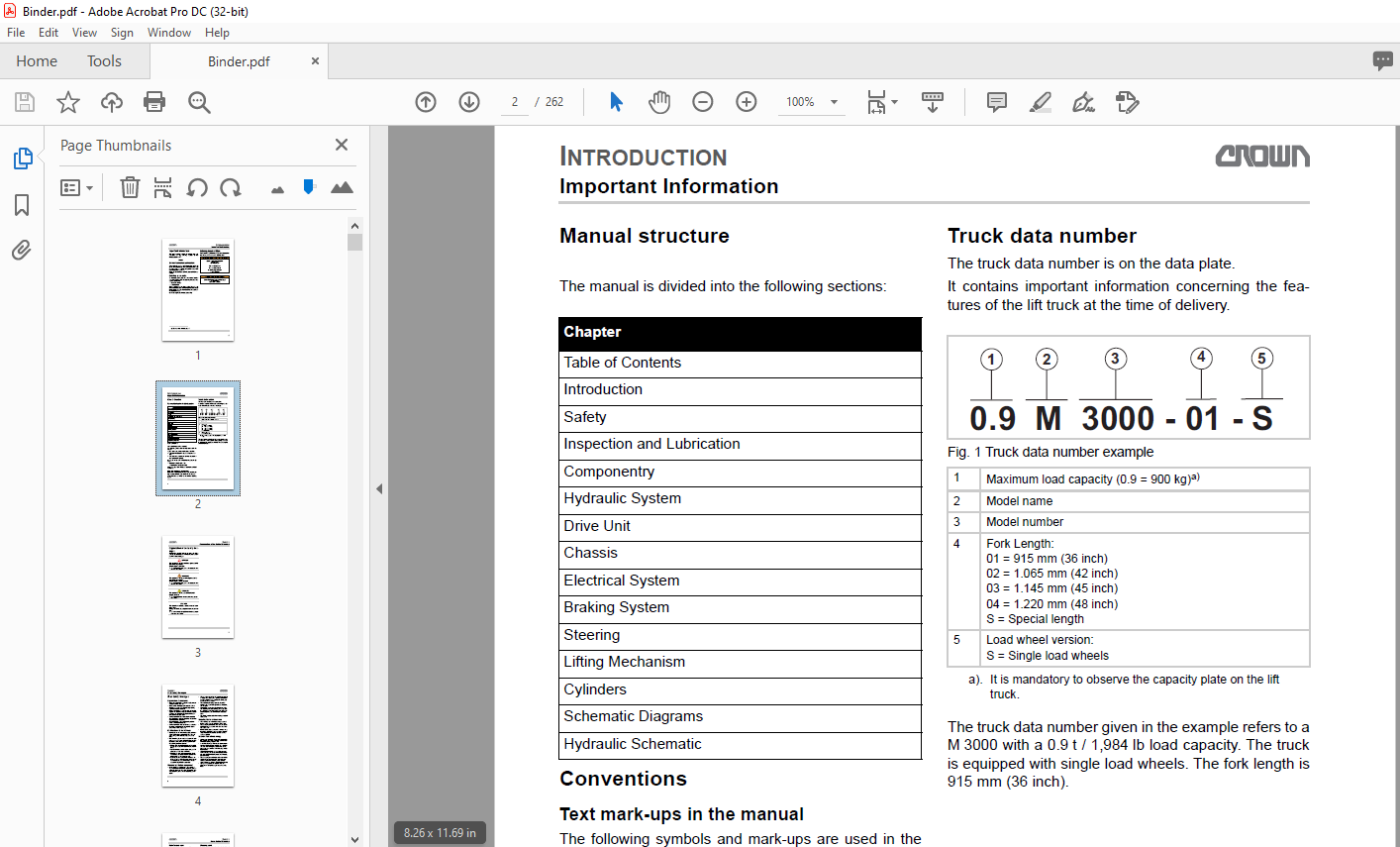

Manual structure 2

Conventions 2

Text mark-ups in the manual 2

Brief description of equipment 2

Truck data number 2

Safety 0

Organization of the Safety Messages 3

Basic Safety Messages 4

Organizational measures 4

Modifications to the lift truck 4

Personal protection equipment 4

Securing the hazardous area 4

Hazards from stored energy 4

Maintenance work 5

Restoring the lift truck to service after maintenance work 5

Cleaning work 5

Handling batteries 5

Warning and instruction decals 5

Lifting equipment and lifting accessories 6

Environmental protection 6

Safety Mechanisms and Protective Guards 7

Mast guard (standard) or mesh screen (optional) 7

Load backrest (optional) 7

Safety reverse switch 8

Battery disconnect (power disconnect) 8

Free-lift switch 8

Cleaning the Truck and Componentry 9

Effects of incorrect cleaning 9

Electrical components 9

Roller and slide bearings 9

Environmental protection 9

Cleaning the entire truck 9

Cleaning removed componentry 10

Cleaning other mechanical componentry 10

Storing and Returning the Truck to Service 11

Previous tasks 11

Returning the truck to service 11

Final tasks 11

Control of Hazardous Energy 12

(Lockout/Tagout) 12

Lockout/Tagout Procedures 12

Tagout Procedure 12

Lockout Procedure with the Battery Installed 13

Lockout Procedure Without the Battery Installed 13

Preparing the Lift Truck for Maintenance 13

Battery 14

Preparing the Battery for Removal 14

Removing the Batteries from the Lift Truck 14

Installing the Batteries in the Lift Truck 15

Maintenance free and wet cell 15

Final tasks 15

Discharge the Capacitor Voltage 15

The following procedure describes how to discharge the capacitors safely before performing maintenance near bus bars, power cables, or other electrical components on the lift truck 15

General Hot Work Instructions 16

Releasing the Hydraulic Pressure 16

Parking Brake 17

Releasing the Parking Brake 17

Towing the Lift Truck 20

Preparing for Towing the Lift Truck 20

Towing the Lift Truck in the Power Unit First Direction 20

Lifting and Blocking the Lift Truck 20

The following procedures describe how to lift and block the lift truck safely 20

Blocking the Inner Mast 23

Lifting the Lift Truck 23

Necessary equipment 23

Preparing for Lifting the Lift Truck 23

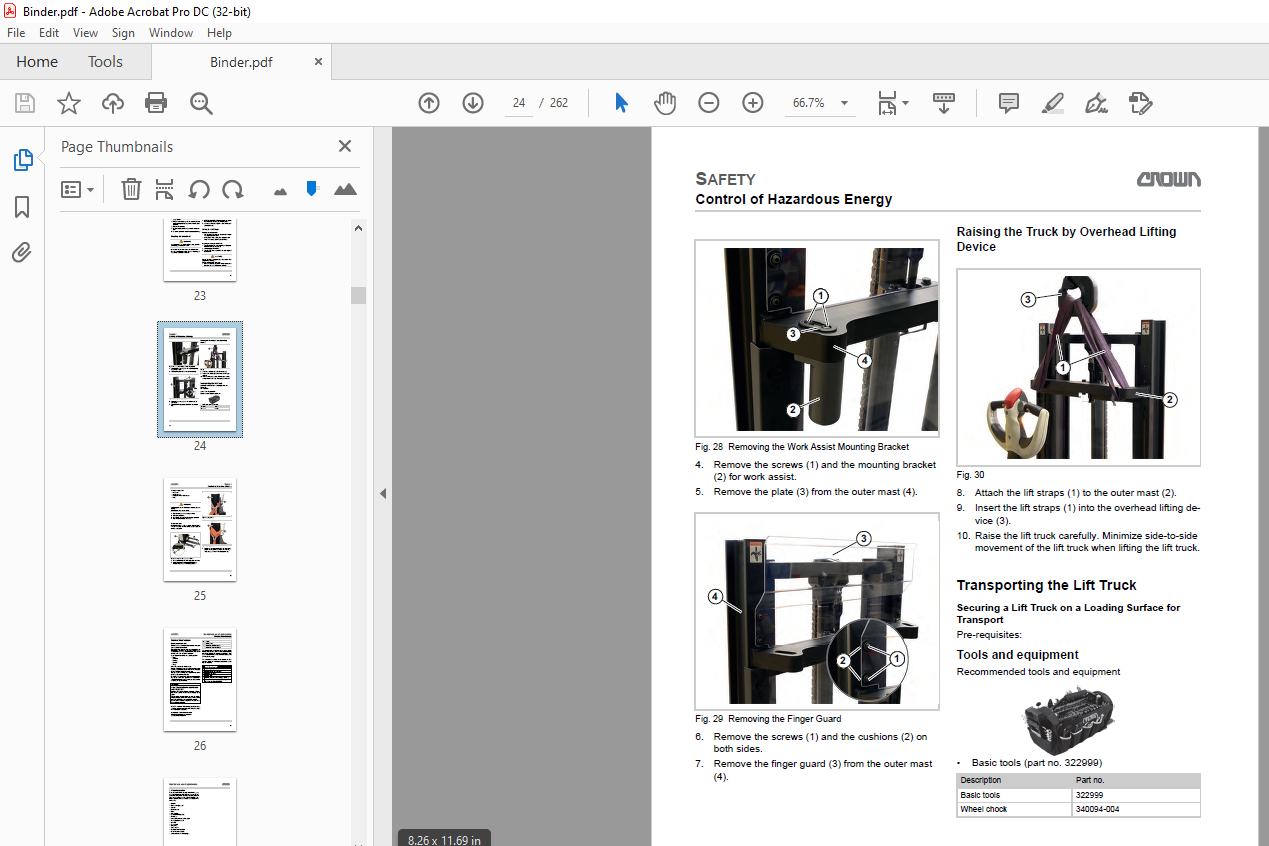

Raising the Truck by Overhead Lifting Device 24

Transporting the Lift Truck 24

Securing a Lift Truck on a Loading Surface for Transport 24

Tools and equipment 24

Additional equipment 25

Technican Tips 25

Inspection and Lubrication 0

Planned Maintenance 26

Maintenance schedule 26

Annual inspection in accordance with FEM 4004 26

Terms and abbreviations used 26

1 Visual Inspection 27

2 Functional test and test drive 28

3 Preparing the truck for maintenance 29

Take the truck out of service 29

Securing the work area and lift truck 29

Remove covers for maintenance 30

Removing the battery deck lid 30

Removing the left side cover 30

Removing the right side cover 31

Removing the motor compartment cover 31

Removing the knuckle cover 31

4 Maintenance schedule 33

5 Inspection with the lift truck jacked up 35

Jacking up the truck 35

Required tools: 35

Maintenance schedule (continued) 38

Lowering the truck 39

6 Clean and perform final test drive 42

Install knuckle cover 42

Install the motor compartment cover 42

Installing the right side cover 43

Installing the battery deck lid 43

Final tasks 43

Starting up the lift truck 43

Removing the lockout 44

Final test drive 45

Lubricants and Auxiliary Materials 46

Abbreviations 46

Standard Torque Values (Nm) 48

Standard Torque Values (in lb/ ft lb) 49

Componentry 0

Standard 50

“Soft lowering” option 51

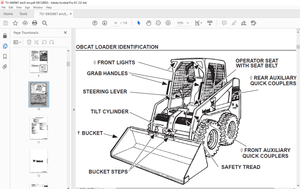

Lift truck overview 52

Hydraulic System 0

Drift Test 54

Preconditions for drift tests 54

Perform the lift truck drift test 54

Hydraulic system troubleshooting 55

M 3000 Standard 56

Replacing the hydraulic pump motor 57

Previous tasks 57

Removing the hydraulic unit with reservoir 57

Removing the hydraulic pump 58

Removing the hydraulic pump motor 58

Installing the hydraulic pump motor 59

Installing the hydraulic pump 59

Installing the hydraulic unit with reservoir 60

Final tasks 61

Hydraulic oil change 62

Previous tasks 62

Removing the hydraulic unit with reservoir 62

Draining the hydraulic reservoir and replacing the filter 63

Filling the hydraulic reservoir 64

Installing the hydraulic unit with hydraulic reservoir 64

Final tasks 65

Replacing the hydraulic pump 66

Previous tasks 66

Removing the hydraulic unit with reservoir 66

Draining the hydraulic reservoir and replacing the hydraulic pump 67

Installing the hydraulic pump 68

Filling the hydraulic reservoir 69

Installing the hydraulic unit with reservoir 69

Final tasks 70

Replace the hydraulic pump receptacle 71

Previous tasks 71

Removing the hydraulic unit with reservoir 71

Removing the hydraulic pump 72

Removing the hydraulic pump motor 73

Replace the hydraulic pump receptacle 73

Installing the hydraulic pump motor 75

Installing the hydraulic pump 76

Installing the hydraulic unit with reservoir 77

Final tasks 77

Check the hydraulic reservoir level 78

Requirement: 78

Bleeding the hydraulic system 79

Check the hydraulic reservoir level 79

Flushing the hydraulic system 79

Bleeding the hydraulic system 79

M 3000 Option Soft Lowering 81

Replacing the hydraulic pump motor 83

Previous tasks 83

Removing the hydraulic pump motor 83

Installing the hydraulic pump motor 83

Final tasks 84

Replacing the carbon brushes of the hydraulic pump motor 85

Previous tasks 85

Removing the cover for the carbon brushes 85

Removing the carbon brushes 85

Checking the carbon brushes and the armature 86

Installing the carbon brush 86

Installing the cover for the carbon brushes 87

Final tasks 87

Hydraulic oil change 88

Previous tasks 88

Removing the hydraulic pump with reservoir 88

Draining the hydraulic reservoir and replacing the filter 89

Installing the hydraulic pump with reservoir 89

Final tasks 90

Replacing the hydraulic pump 91

Previous tasks 91

Previous tasks 91

Draining the hydraulic reservoir 91

Replacing the hydraulic pump 91

Final tasks 93

Calibrating Access 2 94

Requirement: 94

Check the hydraulic reservoir level 96

Requirement: 96

Bleeding the hydraulic system 97

Check the hydraulic reservoir level 97

Flushing the hydraulic system 97

Bleeding the hydraulic system 97

Drive Unit 0

Overview of the Drive Unit 99

Changing the gearbox oil100

Previous tasks100

Changing the gearbox oil100

Permissible oil types100

Final tasks100

Checking the oil level101

Previous tasks101

Adding the oil101

Permissible oil types101

Final tasks101

Removing and Installing the Traction Motor M1102

Previous tasks102

Removing the traction motor102

Installing the traction motor103

Final tasks104

Chassis 0

Replacing the Battery Deck Lid105

Previous tasks105

Removing the battery deck lid105

Installing the battery deck lid105

Final tasks105

Replacing Left Side Cover106

Previous tasks106

Removing the left side cover106

Installing the left side cover106

Final tasks106

Replacing Right Side Cover107

Previous tasks107

Removing the right side cover107

Installing the right side cover107

Final tasks107

Replace the Main Cover108

Previous tasks108

Remove the main cover108

Install the main cover108

Final tasks108

Replace Knuckle Cover109

Previous tasks109

Removing the knuckle cover109

Installing the knuckle cover109

Final tasks109

Replace the Center Cover110

Previous tasks110

Remove the center cover110

Install the center cover110

Final tasks111

Replacing the Drive Wheel112

Previous tasks112

Loosening the screws on the drive wheel112

Jacking up the Truck112

Required tools:113

Removing the drive wheel115

Installing the drive wheel115

Lowering the Truck116

Tightening the drive wheel117

Final tasks117

Replacing the Load Wheel118

Previous tasks118

Removing the load wheel118

Installing the load wheel118

Final tasks118

Replacing Caster Wheel119

Previous tasks119

Removing the caster wheel unit119

Removing the caster wheel119

Check damper sheet119

Assembling the caster wheel120

Checking the caster wheel unit bearing120

Installing the caster wheel unit120

Final tasks121

Removing/ Installing Caster Wheel Unit122

Previous tasks122

Removing the caster wheel unit122

Checking the caster wheel unit bearing122

Installing the caster wheel unit122

Final tasks123

Replacing Caster Wheel Bearing124

Previous tasks124

Removing the caster wheel unit124

Removing caster wheel bearing124

Replacing caster wheel bearing124

Installing caster wheel bearing125

Installing the caster wheel unit125

Final tasks125

Adjusting the Caster Wheels126

General126

Previous tasks126

Adjusting the caster wheels126

Final tasks128

Adjusting of Outrigger129

Previous tasks129

Final tasks130

Braking System 0

Componentry and Operation131

Service brake131

Parking brake131

Control Handle Positions132

Travel and brake zone description132

Upper brake zone (1)132

Brake override zone (2)132

Drive zone (3)132

Lower brake zone (4)132

Traveling in vertical tiller mode133

Traveling in vertical tiller mode133

Auto deactivation of vertical tiller function133

Traveling in the brake override zone134

Testing the Stopping Distance135

Requirements135

Performing the test135

Table of stopping distances135

Check the Parking Brake136

Inspecting the Parking Brake137

Previous tasks137

Manually releasing the parking brake137

Inspecting the parking brake137

Activating the parking brake137

Final tasks138

Manually Releasing the Parking Brake139

Component overview139

Releasing the parking brake139

Previous tasks139

Activating the parking brake139

Final tasks140

Replacing Parking Brake141

Component overview141

Previous tasks141

Removing the parking brake141

Replacing parking brake141

Installing the parking brake142

Final tasks142

Troubleshooting Barking Brake143

Steering 0

X10® Control Handle144

Assembly overview144

Opening the panels of the X10 control handle145

Previous tasks145

Removing the switch unit145

Removing the horn switch145

Removing the handles146

Removing the shells146

Installing the shells146

Installing the handles146

Horn switch assembly147

Installing the switch unit147

Final tasks148

Replacing the switch unit of the X10® control handle149

Previous tasks149

Removing the switch unit149

Installing the switch unit149

Final tasks150

Replace the rabbit/turtle switch on the X10® control handle (HSS)151

Previous tasks151

Removing the switch unit151

Removing the rabbit/turtle switch (HSS)151

Replacing the rabbit/turtle switch (HSS)151

Installing the rabbit/turtle switch (HSS)152

Installing the switch unit152

Final tasks152

Replacing the hydraulic printed circuit board of the X10® control handle (HYD PCB)153

Previous tasks153

Removing the switch unit153

Removing the hydraulic printed circuit board (HYD PCB)153

Replacing the hydraulic printed circuit board (HYD PCB)153

Installing the hydraulic printed circuit board (HYD PCB)154

Installing the switch unit154

Final tasks154

Replacing the hydraulic printed circuit board of the X10® control handle (MAIN PCB)155

Previous tasks155

Removing the switch unit155

Removing the main circuit board155

Removing the main printed circuit board (MAIN PCB)155

Installing the main printed circuit board (MAIN PCB)156

Installing the switch unit156

Final tasks156

Replacing the traction potentiometer of the X10® control handle (POT)157

Previous tasks157

Removing the switch unit157

Removing the thumb wheels157

Removing the cover158

Removing the traction potentiometer (POT)158

Replacing the traction potentiometer (POT)158

Cover assembly159

Installing the thumb wheels159

Installing the switch unit159

Final tasks160

Replacing the safety reverse switch of the X10® control handle (SAS)161

Previous tasks161

Removing the switch unit161

Removing the thumb wheels161

Removing the cover162

Removing the safety reverse switch (SAS)162

Safety reverse switch (SAS) assembly162

Cover assembly162

Installing the thumb wheels163

Installing the switch unit163

Final tasks163

Replacing the horn switch of the X10® control handle (HNS)164

Previous tasks164

Removing the switch unit164

Removing the horn switch164

Installing the switch unit165

Final tasks166

Replacing the handles of the X10® control handle167

Previous tasks167

Removing the switch unit167

Removing the horn switch167

Removing the handles168

Installing the handles168

Horn switch assembly168

Installing the switch unit169

Final tasks169

Lifting Mechanism 0

Maintaining the Lift Chain and Chain Anchors170

Adapting the maintenance intervals to the application conditions170

Periodic replacement of chain anchors and lift chains170

Disconnecting lift chains171

Required tools and equipment171

Disconnecting171

Lift Chain172

Checking the chain anchor and lift chain service hours172

Clean lift chain172

Lubricating the lift chain172

Checking the Lift Chains for Wear and Damage174

Checking the lift chain elongation174

Tools required174

Test preparation174

Checking the lift chain elongation with the wear gauge175

Checking the lift chain elongation with the steel ruler176

Checking the chain for other damage177

Removing and Installing the Lift Chain (For Cleaning)180

Previous tasks180

Lift chain removal180

Clean lift chain181

Tools and equipment181

Clean lift chain181

Lubricating and preserving the lift chain181

Installing the lift chain181

Final tasks182

Removing the block from the fork carriage182

Adjusting the height of the forks182

Replacing the Lift Chains183

Previous tasks183

Lift chain removal183

Lubricating and preserving the lift chain184

Installing the lift chain184

Final tasks185

Removing the block from the fork carriage185

Adjusting the height of the forks185

Fork187

Terms and identification187

Identification187

Checking the Fork188

Checking the fork blades for cracks188

Checking the fork mount and weld seams for cracks188

Check the fork tip for straightness188

Checking the blade for warping189

Measuring the fork tip width189

Checking the fork height difference189

Checking the fork stop189

Measuring the fork blade wear190

Tools and equipment190

Replacing Fork Blades191

Previous tasks191

Removing fork blades191

Installing fork blades191

Final tasks192

Replacing the Fork Stop193

Previous tasks193

Removing the fork stop193

Installing the fork stop193

Final tasks194

Cylinders 0

Lift Cylinder Removal and Installation195

Previous tasks195

Releasing the lift chain from the chain anchor and chain roller195

Removing the block from the fork carriage195

Blocking inner mast195

Removing the yoke196

Removing the chain anchor196

Removing the lift cylinder197

Installing the lift cylinder198

Installing the chain anchor198

Installing the yoke199

Remove the block from the inner mast200

Blocking the fork carriage200

Secure the lift chain in the chain roller and chain anchor200

Removing the block from the fork carriage201

Adjusting the height of the forks201

Final tasks201

Table of Contents 0

Introduction 0

Important Information 2

Service technician qualification 2

Ordering spare parts 2

Ordering documentation 2

Manual structure 3

Conventions 3

Text mark-ups in the manual 3

Brief description of equipment 3

Truck data number 3

Safety 0

Organization of the Safety Messages 2

Basic Safety Messages 3

Organizational measures 3

Modifications to the lift truck 3

Personal protection equipment 3

Securing the hazardous area 3

Hazards from stored energy 3

Maintenance work 4

Restoring the lift truck to service after maintenance work 4

Cleaning work 4

Handling batteries 4

Warning and instruction decals 4

Lifting equipment and lifting accessories 5

Environmental protection 5

Safety Mechanisms and Protective Guards 6

Mast guard (standard) or mesh screen (optional) 6

Load backrest (optional) 6

Safety reverse switch 7

Battery disconnect (power disconnect) 7

Free-lift switch 7

Cleaning the Truck and Componentry 8

Effects of incorrect cleaning 8

Electrical components 8

Roller and slide bearings 8

Environmental protection 8

Cleaning the entire truck 8

Cleaning removed componentry 9

Cleaning other mechanical componentry 9

Storing and Returning the Truck to Service 10

Previous tasks 10

Returning the truck to service 10

Final tasks 10

Control of Hazardous Energy 13

(Lockout/Tagout) 13

Lockout/Tagout Procedures 13

Tagout Procedure 13

Lockout Procedure with the Battery Installed 14

Lockout Procedure Without the Battery Installed 14

Preparing the Lift Truck for Maintenance 14

Battery 15

Preparing the Battery for Removal 15

Removing the Batteries from the Lift Truck 15

Installing the Batteries in the Lift Truck 16

Maintenance free and wet cell 16

Final tasks 16

Discharge the Capacitor Voltage 16

The following procedure describes how to discharge the capacitors safely before performing maintenance near bus bars, power cables, or other electrical components on the lift truck 16

General Hot Work Instructions 17

Releasing the Hydraulic Pressure 17

Parking Brake 18

Releasing the Parking Brake 18

Towing the Lift Truck 21

Preparing for Towing the Lift Truck 21

Towing the Lift Truck in the Power Unit First Direction 21

Lifting and Blocking the Lift Truck 21

The following procedures describe how to lift and block the lift truck safely 21

Blocking the Inner Mast 24

Lifting the Lift Truck 24

Necessary equipment 24

Preparing for Lifting the Lift Truck 24

Raising the Truck by Overhead Lifting Device 25

Transporting the Lift Truck 25

Securing a Lift Truck on a Loading Surface for Transport 25

Tools and equipment 25

Additional equipment 26

Technican Tips 26

Inspection and Lubrication 0

Planned Maintenance 2

Maintenance schedule 2

Annual inspection in accordance with FEM 4004 2

Terms and abbreviations used 2

1 Visual Inspection 4

2 Functional test and test drive 5

3 Preparing the truck for maintenance 6

Take the truck out of service 6

Securing the work area and lift truck 6

Remove covers for maintenance 7

Removing the battery deck lid 7

Removing the left side cover 7

Removing the right side cover 8

Removing the motor compartment cover 8

Removing the knuckle cover 8

4 Maintenance schedule 10

5 Inspection with the lift truck jacked up 12

Jacking up the truck 12

Required tools: 12

Maintenance schedule (continued) 15

Lowering the truck 16

6 Clean and perform final test drive 19

Install knuckle cover 19

Install the motor compartment cover 19

Installing the right side cover 20

Installing the battery deck lid 20

Final tasks 20

Starting up the lift truck 20

Removing the lockout 21

Final test drive 22

Lubricants and Auxiliary Materials 23

Abbreviations 23

Standard Torque Values (Nm) 25

Standard Torque Values (in lb/ ft lb) 26

Componentry 0

Standard 2

“Soft lowering” option 3

Lift truck overview 4

Hydraulic System 0

Drift Test 2

Preconditions for drift tests 2

Perform the lift truck drift test 2

Hydraulic system troubleshooting 3

M 3000 Standard 4

Replacing the hydraulic pump motor 5

Previous tasks 5

Removing the hydraulic unit with reservoir 5

Removing the hydraulic pump 6

Removing the hydraulic pump motor 6

Installing the hydraulic pump motor 7

Installing the hydraulic pump 7

Installing the hydraulic unit with reservoir 8

Final tasks 9

Hydraulic oil change 10

Previous tasks 10

Removing the hydraulic unit with reservoir 10

Draining the hydraulic reservoir and replacing the filter 11

Filling the hydraulic reservoir 12

Installing the hydraulic unit with hydraulic reservoir 12

Final tasks 13

Replacing the hydraulic pump 14

Previous tasks 14

Removing the hydraulic unit with reservoir 14

Draining the hydraulic reservoir and replacing the hydraulic pump 15

Installing the hydraulic pump 16

Filling the hydraulic reservoir 17

Installing the hydraulic unit with reservoir 17

Final tasks 18

Replace the hydraulic pump receptacle 19

Previous tasks 19

Removing the hydraulic unit with reservoir 19

Removing the hydraulic pump 20

Removing the hydraulic pump motor 21

Replace the hydraulic pump receptacle 21

Installing the hydraulic pump motor 23

Installing the hydraulic pump 24

Installing the hydraulic unit with reservoir 25

Final tasks 25

Check the hydraulic reservoir level 26

Requirement: 26

Bleeding the hydraulic system 27

Check the hydraulic reservoir level 27

Flushing the hydraulic system 27

Bleeding the hydraulic system 27

M 3000 Option Soft Lowering 29

Replacing the hydraulic pump motor 31

Previous tasks 31

Removing the hydraulic pump motor 31

Installing the hydraulic pump motor 31

Final tasks 32

Replacing the carbon brushes of the hydraulic pump motor 33

Previous tasks 33

Removing the cover for the carbon brushes 33

Removing the carbon brushes 33

Checking the carbon brushes and the armature 34

Installing the carbon brush 34

Installing the cover for the carbon brushes 35

Final tasks 35

Hydraulic oil change 36

Previous tasks 36

Removing the hydraulic pump with reservoir 36

Draining the hydraulic reservoir and replacing the filter 37

Installing the hydraulic pump with reservoir 37

Final tasks 38

Replacing the hydraulic pump 39

Previous tasks 39

Previous tasks 39

Draining the hydraulic reservoir 39

Replacing the hydraulic pump 39

Final tasks 41

Calibrating Access 2 42

Requirement: 42

Check the hydraulic reservoir level 44

Requirement: 44

Bleeding the hydraulic system 45

Check the hydraulic reservoir level 45

Flushing the hydraulic system 45

Bleeding the hydraulic system 45

Drive Unit 0

Overview of the Drive Unit 2

Changing the gearbox oil 3

Previous tasks 3

Changing the gearbox oil 3

Permissible oil types 3

Final tasks 3

Checking the oil level 4

Previous tasks 4

Adding the oil 4

Permissible oil types 4

Final tasks 4

Removing and Installing the Traction Motor M1 6

Previous tasks 6

Removing the traction motor 6

Installing the traction motor 7

Final tasks 8

Chassis 0

Replacing the Battery Deck Lid 2

Previous tasks 2

Removing the battery deck lid 2

Installing the battery deck lid 2

Final tasks 2

Replacing Left Side Cover 3

Previous tasks 3

Removing the left side cover 3

Installing the left side cover 3

Final tasks 3

Replacing Right Side Cover 4

Previous tasks 4

Removing the right side cover 4

Installing the right side cover 4

Final tasks 4

Replace the Main Cover 5

Previous tasks 5

Remove the main cover 5

Install the main cover 5

Final tasks 5

Replace Knuckle Cover 7

Previous tasks 7

Removing the knuckle cover 7

Installing the knuckle cover 7

Final tasks 7

Replace the Center Cover 8

Previous tasks 8

Remove the center cover 8

Install the center cover 8

Final tasks 9

Replacing the Drive Wheel 10

Previous tasks 10

Loosening the screws on the drive wheel 10

Jacking up the Truck 10

Required tools: 11

Removing the drive wheel 13

Installing the drive wheel 13

Lowering the Truck 14

Tightening the drive wheel 15

Final tasks 15

Replacing the Load Wheel 17

Previous tasks 17

Removing the load wheel 17

Installing the load wheel 17

Final tasks 17

Replacing Caster Wheel 18

Previous tasks 18

Removing the caster wheel unit 18

Removing the caster wheel 18

Check damper sheet 18

Assembling the caster wheel 19

Checking the caster wheel unit bearing 19

Installing the caster wheel unit 19

Final tasks 20

Removing/ Installing Caster Wheel Unit 21

Previous tasks 21

Removing the caster wheel unit 21

Checking the caster wheel unit bearing 21

Installing the caster wheel unit 21

Final tasks 22

Replacing Caster Wheel Bearing 23

Previous tasks 23

Removing the caster wheel unit 23

Removing caster wheel bearing 23

Replacing caster wheel bearing 23

Installing caster wheel bearing 24

Installing the caster wheel unit 24

Final tasks 24

Adjusting the Caster Wheels 25

General 25

Previous tasks 25

Adjusting the caster wheels 25

Final tasks 27

Adjusting of Outrigger 28

Previous tasks 28

Final tasks 29

Electrical System 0

Replacing Access 3 2

Previous tasks 2

Removing Access 3 2

Installing Access 3 3

Final tasks 5

Status LED 6

Connecting the Programming Device to the Vehicle 7

General 7

Connecting the Controller Handset to the Lift Truck 8

Previous tasks 8

Final tasks 8

Operating Access 3 Menu 9

Menu structure 9

Menu functions 11

Functions Menu, general 11

Parameter change Menu 12

Settings and Alarms 13

Tester menu 14

TESTER menu 15

Alarms Menu 16

ALARMS Menu 17

PROGRAM V ACC Menu 19

Preparatory measures 19

Calibration 19

Config Menu 17

CONFIG Menu 17

SET MODEL 23

SET OPTIONS 17

ADJUSTMENTS 23

Menu functions 10

Parameter change 10

TESTER 10

ALARMS 10

PROGRAM VACC 10

CONFIG 10

Traction Control Module Safety Test (PMT Test) 24

Previous tasks 24

Final tasks 25

Battery Discharge Indicator (BDI) 27

Operation 27

General 27

Battery discharge indicator setting (BDI) 28

Calibration for wet batteries 28

Troubleshooting 29

Replacing the Battery Discharge Indicator (BDI) 30

Previous tasks 30

Loosen the mounting bracket of the battery discharge indicator 30

Removing the battery discharge indicator 30

Installing the battery discharge indicator 30

Attach the mounting bracket of battery discharge indicator 31

Final tasks 31

Replacing the Batteries 32

Previous tasks 32

Removing the batteries from the lift truck 32

Installing the batteries in the lift truck 32

(Maintenance free) 32

Final tasks 33

General DC Motor Maintenance Instructions 34

Carbon brushes 34

Rotor 34

Armature 34

Installing and Removing the Hydraulic Pump Contactor 35

Previous tasks 35

Removing the hydraulic pump contactor 35

Installing the hydraulic pump contactor 36

Final tasks 36

Repairing the Contactor 37

Dismantling the contactor 37

Checking contacts and springs 37

Checking the coil 38

Reassembling the contactor 38

On-board Charger 39

Assembly location 39

standard 39

“Soft Lowering” option 39

Functional monitoring 39

Display status of the yellow and green LEDs 39

General 40

Setting the charge curves 40

Battery charging phases 40

First phase (I1) 40

Second phase (P) 40

Third phase (U) 40

Fourth phase (I2) 40

End of normal charging 40

Special charging phases 40

Equalization charge 40

Float charge 41

Partial charging 41

Charging errors 42

Green LED not lit 42

Green LED flashing 42

Important technical data 42

Replacing the On-Board Battery Charger 43

Previous tasks 43

Loosen the mounting bracket of the battery discharge indicator 43

Removing the mounting bracket 43

Removing the on-board battery charger 44

Installing the on-board battery charger 46

Installing the mounting bracket 48

Attach the mounting bracket of battery discharge indicator 48

Final tasks 49

Replacing the On-Board Charger Cable 50

Previous tasks 50

Loosening the mounting bracket of the battery discharge indicator 50

Disconnecting charger cable 50

Connecting charger cable 50

Attach the mounting bracket of battery discharge indicator 51

Final tasks 51

Braking System 0

Componentry and Operation 2

Service brake 2

Parking brake 2

Control Handle Positions 3

Travel and brake zone description 3

Upper brake zone (1) 3

Brake override zone (2) 3

Drive zone (3) 3

Lower brake zone (4) 3

Traveling in vertical tiller mode 4

Traveling in vertical tiller mode 4

Auto deactivation of vertical tiller function 4

Traveling in the brake override zone 5

Testing the Stopping Distance 6

Requirements 6

Performing the test 6

Table of stopping distances 6

Check the Parking Brake 7

Inspecting the Parking Brake 8

Previous tasks 8

Manually releasing the parking brake 8

Inspecting the parking brake 8

Activating the parking brake 8

Final tasks 9

Manually Releasing the Parking Brake 10

Component overview 10

Releasing the parking brake 10

Previous tasks 10

Activating the parking brake 10

Final tasks 11

Replacing Parking Brake 12

Component overview 12

Previous tasks 12

Removing the parking brake 12

Replacing parking brake 12

Installing the parking brake 13

Final tasks 13

Troubleshooting Barking Brake 14

Steering 0

X10® Control Handle 2

Assembly overview 2

Opening the panels of the X10 control handle 3

Previous tasks 3

Removing the switch unit 3

Removing the horn switch 3

Removing the handles 4

Removing the shells 4

Installing the shells 4

Installing the handles 4

Horn switch assembly 5

Installing the switch unit 5

Final tasks 6

Replacing the switch unit of the X10® control handle 7

Previous tasks 7

Removing the switch unit 7

Installing the switch unit 7

Final tasks 8

Replace the rabbit/turtle switch on the X10® control handle (HSS) 9

Previous tasks 9

Removing the switch unit 9

Removing the rabbit/turtle switch (HSS) 9

Replacing the rabbit/turtle switch (HSS) 9

Installing the rabbit/turtle switch (HSS) 10

Installing the switch unit 10

Final tasks 10

Replacing the hydraulic printed circuit board of the X10® control handle (HYD PCB) 11

Previous tasks 11

Removing the switch unit 11

Removing the hydraulic printed circuit board (HYD PCB) 11

Replacing the hydraulic printed circuit board (HYD PCB) 11

Installing the hydraulic printed circuit board (HYD PCB) 12

Installing the switch unit 12

Final tasks 12

Replacing the hydraulic printed circuit board of the X10® control handle (MAIN PCB) 13

Previous tasks 13

Removing the switch unit 13

Removing the main circuit board 13

Removing the main printed circuit board (MAIN PCB) 13

Installing the main printed circuit board (MAIN PCB) 14

Installing the switch unit 14

Final tasks 14

Replacing the traction potentiometer of the X10® control handle (POT) 16

Previous tasks 16

Removing the switch unit 16

Removing the thumb wheels 16

Removing the cover 17

Removing the traction potentiometer (POT) 17

Replacing the traction potentiometer (POT) 17

Cover assembly 18

Installing the thumb wheels 18

Installing the switch unit 18

Final tasks 19

Replacing the safety reverse switch of the X10® control handle (SAS) 20

Previous tasks 20

Removing the switch unit 20

Removing the thumb wheels 20

Removing the cover 21

Removing the safety reverse switch (SAS) 21

Safety reverse switch (SAS) assembly 21

Cover assembly 21

Installing the thumb wheels 22

Installing the switch unit 22

Final tasks 22

Replacing the horn switch of the X10® control handle (HNS) 23

Previous tasks 23

Removing the switch unit 23

Removing the horn switch 23

Installing the switch unit 24

Final tasks 25

Replacing the handles of the X10® control handle 26

Previous tasks 26

Removing the switch unit 26

Removing the horn switch 26

Removing the handles 27

Installing the handles 27

Horn switch assembly 27

Installing the switch unit 28

Final tasks 28

Lifting Mechanism 0

Maintaining the Lift Chain and Chain Anchors 2

Adapting the maintenance intervals to the application conditions 2

Periodic replacement of chain anchors and lift chains 2

Disconnecting lift chains 3

Required tools and equipment 3

Disconnecting 3

Lift Chain 4

Checking the chain anchor and lift chain service hours 4

Clean lift chain 4

Lubricating the lift chain 4

Checking the Lift Chains for Wear and Damage 6

Checking the lift chain elongation 6

Tools required 6

Test preparation 6

Checking the lift chain elongation with the wear gauge 7

Checking the lift chain elongation with the steel ruler 8

Checking the chain for other damage 9

Removing and Installing the Lift Chain (For Cleaning) 12

Previous tasks 12

Lift chain removal 12

Clean lift chain 13

Tools and equipment 13

Clean lift chain 13

Lubricating and preserving the lift chain 13

Installing the lift chain 13

Final tasks 14

Removing the block from the fork carriage 14

Adjusting the height of the forks 14

Replacing the Lift Chains 15

Previous tasks 15

Lift chain removal 15

Lubricating and preserving the lift chain 16

Installing the lift chain 16

Final tasks 17

Removing the block from the fork carriage 17

Adjusting the height of the forks 17

Fork 19

Terms and identification 19

Identification 19

Checking the Fork 20

Checking the fork blades for cracks 20

Checking the fork mount and weld seams for cracks 20

Check the fork tip for straightness 20

Checking the blade for warping 21

Measuring the fork tip width 21

Checking the fork height difference 21

Checking the fork stop 21

Measuring the fork blade wear 22

Tools and equipment 22

Replacing Fork Blades 23

Previous tasks 23

Removing fork blades 23

Installing fork blades 23

Final tasks 24

Replacing the Fork Stop 25

Previous tasks 25

Removing the fork stop 25

Installing the fork stop 25

Final tasks 26

Cylinders 0

Lift Cylinder Removal and Installation 2

Previous tasks 2

Releasing the lift chain from the chain anchor and chain roller 2

Removing the block from the fork carriage 2

Blocking inner mast 2

Removing the yoke 3

Removing the chain anchor 3

Removing the lift cylinder 4

Installing the lift cylinder 5

Installing the chain anchor 5

Installing the yoke 6

Remove the block from the inner mast 7

Blocking the fork carriage 7

Secure the lift chain in the chain roller and chain anchor 7

Removing the block from the fork carriage 8

Adjusting the height of the forks 8

Final tasks 8

Schematic Diagrams 0

Electrical diagram for the standard 2

Traction control module 3

Traction control module 4

Power unit control module 5

X10® control handle control module 5

Hydraulic Schematic 0

Hydraulic symbols 2

M 3000 standard 6

“Soft lowering” M 3000 option 7

Schematic Diagrams 0

Electrical diagram for the standard252

Traction control module253

Traction control module254

Power unit control module255

X10® control handle control module255

Hydraulic Schematic 0

Hydraulic symbols257

M 3000 standard261

“Soft lowering” M 3000 option262

IMAGES PREVIEW OF THE MANUAL: