$38

Crown Forklift RC 5700 Counter Balanced Service Manual

Crown Forklift RC 5700 Counter Balanced Service Manual – PDF DOWNLOAD

FILE DETAILS:

Crown Forklift RC 5700 Counter Balanced Service Manual – PDF DOWNLOAD

Language : English

Pages :450

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Crown Forklift RC 5700 Counter Balanced Service Manual – PDF DOWNLOAD

Introduction 0

Cleaning of Material Handling Equipment 9

Operator’s Daily Checklist 25

Lubricants, Aerosols, and Service Supplies 0

SAE Torque Values 50

Grade 50

Componentry 0

Access 1 0

Access 2 0

Access 3™ 0

Access 7 0

ALM2-not shown 0

BRESL and BRESR 0

BRK1 0

BRK2 0

C KEY 0

DMS1, DMS2, and DMS3 0

DVR963 and DVR964 0

ECR1, not shown 0

ECR2 0

ECR3, not shown 0

ECR4 0

EDS 0

ENSL and ENSR 0

FNS, not shown 0

FAN1 0

FAN2 0

FS 0

FU1 0

FU2 0

FU11 and FU12 0

FU14 0

FU15 0

FU16 0

FU21 0

FU22 0

FU23 0

FU24 0

FU25 0

FU31 0

FU32 0

FU34 and FU35 0

FU36 0

HGTS1 0

HGTS2 0

HGTS3 0

HGTS4, not shown 0

HN1 0

HNS 0

K1 0

K11, not shown 0

K902, not shown 0

KYS 0

C Line 0

LCV 0

LGT1 and LGT2 0

ORS, not shown 0

RES1, not shown 0

RES2, not shown 0

RES3, not shown 0

RES4, not shown 0

RES5, not shown 0

RES6, not shown 0

RES7, not shown 0

TS1, not shown 0

TS2, not shown 0

TS3, not shown 0

THS1, not shown 0

Adjustment: Not applicable 0

THS2, not shown 0

Metric Torque Values 84

Grade 84

General Information 0

Avoid high-pressure fluids 0

High-pressure fluids can go through the skin and cause serious injury High-pressure fluid that goes into the skin can become a serious medical emergency even when the skin looks normal There is a delayed start of pain and serious tissue damage may 0

Release the pressure before you disconnect the hydraulic plumbing 0

Tighten all connections before you apply hydraulic pressure 0

Keep your hands away from pin-holes which eject high-pressure fluids 0

Use a piece of cardboard or paper to examine for leaks Do not use your hand 0

You must immediately get medical aid from a specialist who has experience with this type of injury 0

Hydraulic Lines and Fittings 0

Reservoir 0

Filter 0

Drift Test 0

Never stand or work under a suspended load 0

Lift Drift Test 0

1 Place maximum load (See the serial plate for rated capacity of your lift truck) on the forks at the rated load center, and mast tilted back 0

2 Elevate the test load above staging height 0

3 Turn off the lift truck 0

4 After 5 min, measure the distance the forks have drifted Load drift downward may not exceed 64 mm (25 in) over a 5 min period 0

Tilt Drift Test 0

Steering Slip 0

1 Turn on the lift truck 0

2 Stand, or place weight on the pedals and turn the tiller into the stop 0

3 Hold it against the stop with 1288–1627 N m (95– 120 ft lb) tiller knob speed for clockwise and counterclockwise directions, movement is not to exceed 10 rpm on lift trucks equipped with standard oil and 20 rpm on lift trucks equipped with f 0

Freezer Preparation 0

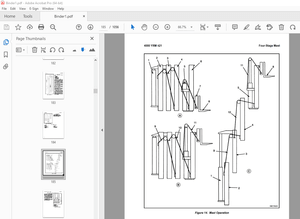

Fig 1 (35012) 0

Circuit Operation 0

Fig 2 (35013) 0

Hydraulic Circuits 0

Steering Circuit 0

Fig 3 (35014) 0

Hoist 0

Lift Circuit 0

Fig 4 (35015) 0

Lower Circuit 0

Fig 5 (35016) 0

Tilt and Accessory Flow 0

Fig 6 (35017) 0

Tilt 0

Tilt Down Circuit 0

Fig 7 (35018) 0

Tilt Back Circuit 0

Fig 8 (35019) 0

Tilt Position Assist 0

Sideshift-Left Circuit 0

Fig 9 (35020 0

Sideshift-Right Circuit 0

Fig 10 (35021) 0

Fourth Hydraulic Function (Second Accessory) 0

Fifth Hydraulic Function (Third Accessory) 0

Notes: 0

General Information 0

Avoid high-pressure fluids 0

High-pressure fluids can go through the skin and cause serious injury High-pressure fluid that goes into the skin can become a serious medical emergency even when the skin looks normal There is a delayed start of pain and serious tissue damage may 0

Release the pressure before you disconnect the hydraulic plumbing 0

Tighten all connections before you apply hydraulic pressure 0

Keep your hands away from pin-holes which eject high-pressure fluids 0

Use a piece of cardboard or paper to examine for leaks Do not use your hand 0

You must immediately get medical aid from a specialist who has experience with this type of injury 0

Hydraulic Lines and Fittings 0

Reservoir 0

Filter 0

Drift Test 0

Never stand or work under a suspended load 0

Lift Drift Test 0

1 Place maximum load (See the serial plate for rated capacity of your lift truck) on the forks at the rated load center, and mast tilted back 0

2 Elevate the test load above staging height 0

3 Turn off the lift truck 0

4 After 5 min, measure the distance the forks have drifted Load drift downward may not exceed 64 mm (25 in) over a 5 min period 0

Tilt Drift Test 0

Steering Slip 0

1 Turn on the lift truck 0

2 Stand, or place weight on the pedals and turn the tiller into the stop 0

3 Hold it against the stop with 1288–1627 N m (95– 120 ft lb) tiller knob speed for clockwise and counterclockwise directions, movement is not to exceed 10 rpm on lift trucks equipped with standard oil and 20 rpm on lift trucks equipped with f 0

Freezer Preparation 0

Fig 1 (35012) 0

Circuit Operation 0

Fig 2 (35013) 0

Hydraulic Circuits 0

Steering Circuit 0

Fig 3 (35014) 0

Hoist 0

Lift Circuit 0

Fig 4 (35015) 0

Lower Circuit 0

Fig 5 (35016) 0

Tilt and Accessory Flow 0

Fig 6 (35017) 0

Tilt 0

Tilt Down Circuit 0

Fig 7 (35018) 0

Tilt Back Circuit 0

Fig 8 (35019) 0

Tilt Position Assist 0

Sideshift-Left Circuit 0

Fig 9 (35020 0

Sideshift-Right Circuit 0

Fig 10 (35021) 0

Fourth Hydraulic Function (Second Accessory) 0

Fifth Hydraulic Function (Third Accessory) 0

Notes: 0

Hydraulic Schematic Symbols116

Electrical 0

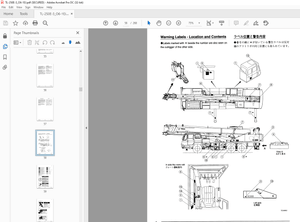

Fig 1 (34818) 0

Fig 2 (34819) 0

Notes: 0

Wiring Color Codes 0

Power Cables 0

Switches 0

Wiring Color Codes 0

Power Cables 0

Switches 0

Multi-Task Control Handle 0

Preparing the lift truck for maintenance 0

1 Follow all the safety procedures See the SAFETY chapter 0

2 Wear the appropriate personal protective equipment (PPE) 0

3 Move the lift truck to a maintenance area on a level floor 0

4 Fully lower the forks, platform, and attachments 0

5 Turn off the lift truck 0

6 Disconnect the battery 0

7 Secure the maintenance area 0

8 Lockout/tagout the lift truck 0

9 Put the chocks against the wheels 0

10 Remove the covers if necessary 0

Lubricating the multi-task control handle 0

1 Remove the multi-task control handle cover (1) and console 0

2 Tilt the handle down and lubricate the base (2) with clear silicone grease 0

Fig 1 (34839) 0

Replacing the handle wiring harness 0

1 Remove the console, the two screws (9), and the multi-task control handle cover (1) from the power unit 0

2 Remove the four screws (3) and the lower handle (4) from the upper handle (16) 0

3 Remove the cable ties from the dust cover (5) 0

4 Use the appropriate extraction tool to remove the wires from the connectors as needed, then remove the handle wiring harness 0

5 See Figure 2 Route the handle wiring harness as necessary 0

6 Secure the handle wiring harness with cable ties 0

7 Install the wires that were previously removed into the connectors 0

8 Put the lower handle (4) on the upper handle (16) and secure with the four screws (3) 0

9 Remove the wheel chocks 0

10 Connect the battery 0

11 Turn on the lift truck 0

12 Make sure that the multi-task control handle operates correctly 0

13 Turn off the lift truck 0

14 Disconnect the battery 0

15 Put the wheel chocks against the wheels 0

16 Put the dust cover (5) on the multi-task control handle and secure with cable ties 0

17 Put the multi-task control handle cover (1) on the power unit and secure with the two screws (9) 0

18 Install the console on the power unit 0

Replacing POT1 or POT2 0

1 Remove the console, the two screws (9), and the multi-task control handle cover (1) from the power unit 0

2 Remove the four screws (7) to remove the handle from the support (8) 0

3 Remove the cable ties from the dust cover (5) 0

4 Use the appropriate extraction tool to remove the wires from the connectors, then remove the potentiometer harness 0

5 Remove the screw (12) and POT1 (13) from the bracket (14) and replace as needed 0

6 Remove the screw (15) and POT2 (10) from the bracket (14) and replace as needed 0

7 See Figure 2 Route the replacement wires as necessary 0

8 Secure the wires with the cable ties 0

9 Install the wires that were previously removed into the connectors 0

10 Assemble the handle to the support (8) 0

11 Torque the screws (7) removed in Step 2 to 3 N m (27 in lb) 0

12 Remove the wheel chocks 0

13 Connect the battery 0

14 Turn on the lift truck 0

15 Make sure that the multi-task control handle operates correctly 0

16 Turn off the lift truck 0

17 Disconnect the battery 0

18 Put the wheel chocks against the wheels 0

19 Put the dust cover (5) on the multi-task control handle and secure with cable ties 0

20 Put the multi-task control handle cover (1) on the power unit and secure with the two screws (9) 0

21 Install the console on the power unit 0

Preparing the lift truck for operation 0

1 Install the covers if necessary 0

2 Remove the chocks from the wheels 0

3 Remove the lockout/tagout device 0

4 Connect the battery 0

5 Turn on the lift truck 0

6 Make sure that the lift truck operates correctly 0

Fig 2 (34840) 0

Event Code Introduction388

Mast 0

Torque Requirements 0

Fork Adjustments 0

TT (Triple Telescopic Full Free Lift) Mast 9

Mast Flaking 0

Mast Testing (Assembled) 0

Mast Inspection 0

Mast Disassembly 0

Removal From The Power Unit 0

Mast Reassembly 0

Lift Chain Tension 0

Quad (Four Stage) Mast 0

Mast Flaking 0

Mast Testing (Assembled) 0

Mast Inspection 0

Mast Removal 0

Carriage Removal 0

Carriage Inspection 0

Lift Chain Tension 0

Fork Inspection 0

Cylinders 0

Avoid high pressure fluids – escaping fluids under pressure can penetrate the skin, causing serious injury Relieve pressure before disconnecting hydraulic lines Tighten all connections before applying pressure Keep hands and body away from pin-hol 0

Any fluid injected into the skin under high pressure should be considered a serious medical emergency despite an initial normal appearance of the skin There is a delayed onset of pain, and serious tissue damage may occur Medical attention should be 0

Preparing the lift truck for maintenance 0

Mast cylinder 0

Inspecting the mast cylinder 0

Fig 1 (15293-01) 0

Disassembling the mast cylinder 0

Fig 2 (15962-03) 0

Repairing the mast cylinder 0

Avoid high pressure fluids – escaping fluids under pressure can penetrate the skin, causing serious injury Relieve pressure before disconnecting hydraulic lines Tighten all connections before applying pressure Keep hands and body away from pin-hol 0

Any fluid injected into the skin under high pressure should be considered a serious medical emergency despite an initial normal appearance of the skin There is a delayed onset of pain, and serious tissue damage may occur Medical attention should be 0

Fig 3 (15963-02) 0

Fig 4 (15964-02) 0

Close inspection of seal seating critical areas should be made before the new seal is installed 0

Fig 5 (15970-02) 0

Reassembling the mast cylinder 0

Care should be taken when inserting the cylinder cap to prevent threads and sharp edges from damaging new seals and packings Packings can also be damaged by forcing air past seals 0

Bleeding and flushing the mast cylinder 0

Avoid high pressure fluids – escaping fluid under pressure can penetrate the skin causing serious injury Relieve pressure before disconnecting hydraulic lines Tighten all connections before applying pressure Keep hands and body away from pin-holes 0

Any fluid injected into the skin under high pressure should be considered as a serious medical emergency despite an initial normal appearance of the skin There is a delayed onset of pain, and serious tissue damage may occur Medical attention should 0

Do not attempt to bleed a line by cracking an O-ring face seal fitting This will result in damaging the O-ring which then must be replaced to prevent hydraulic fluid leakage 0

Bleeding the mast cylinder 0

Flushing the mast cylinder 0

Never stand or work under a suspended load 0

Carriage cylinder 0

Inspecting the carriage cylinder 0

Fig 6 (15296-01) 0

Disassembling the carriage cylinder 0

Fig 7 (15962-03) 0

Repairing the carriage cylinder 0

Avoid high pressure fluids – escaping fluids under pressure can penetrate the skin, causing serious injury Relieve pressure before disconnecting hydraulic lines Tighten all connections before applying pressure Keep hands and body away from pin-hol 0

Any fluid injected into the skin under high pressure should be considered a serious medical emergency despite an initial normal appearance of the skin There is a delayed onset of pain, and serious tissue damage may occur Medical attention should be 0

Fig 8 (15963-02) 0

Fig 9 (15964-02) 0

Close inspection of seal seating critical areas should be made before the new seal is installed 0

Fig 10 (15970-02) 0

Reassembling the carriage cylinder 0

Care should be taken when inserting the cylinder cap, to prevent threads and sharp edges from damaging new seals and packings Packings can also be damaged by forcing air past seals 0

Bleeding and flushing the carriage cylinder 0

Avoid high pressure fluids – escaping fluid under pressure can penetrate the skin causing serious injury Relieve pressure before disconnecting hydraulic lines Tighten all connections before applying pressure Keep hands and body away from pin-holes 0

Any fluid injected into the skin under high pressure should be considered as a serious medical emergency despite an initial normal appearance of the skin There is a delayed onset of pain, and serious tissue damage may occur Medical attention should 0

Do not attempt to bleed a line by cracking a seal fitting This will result in damaging the seal which then must be replaced to prevent hydraulic fluid leakage 0

Bleeding the carriage cylinder 0

Flushing the carriage cylinder 0

Never stand or work under a suspended load 0

Tilt cylinder 0

Inspecting the tilt cylinder 0

Fig 11 (15301) 0

Disassembling the tilt cylinder 0

Fig 12 (15966) 0

Disassembling the rod 0

Repairing the tilt cylinder 0

Never use a screwdriver to remove seals, as irreparable damage and leakage may occur 0

Reassembling the tilt cylinder and rod 0

Care should be taken when inserting the rod guide to prevent sharp edges from damaging the new seals and packings 0

Adjusting the tilt cylinder 0

Fig 13 (15967-01) 0

Shimming the tilt cylinder 0

Fig 14 (19830) 0

Adjusting the tilt cylinder spacing 0

Fig 15 (19831-01) 0

Bleeding and flushing the tilt cylinder 0

Avoid high pressure fluids – escaping fluid under pressure can penetrate the skin causing serious injury Relieve pressure before disconnecting hydraulic lines Tighten all connections before applying pressure Keep hands and body away from pin-holes 0

Any fluid injected into the skin under high pressure should be considered as a serious medical emergency despite an initial normal appearance of the skin There is a delayed onset of pain, and serious tissue damage may occur Medical attention should 0

Do not attempt to bleed a line by cracking an O-ring face seal fitting This will result in damaging the O-ring which then must be replaced to prevent hydraulic fluid leakage 0

Preparing the lift truck for operation 0

Notes: 0

IMAGES PREVIEW OF THE MANUAL: