$38

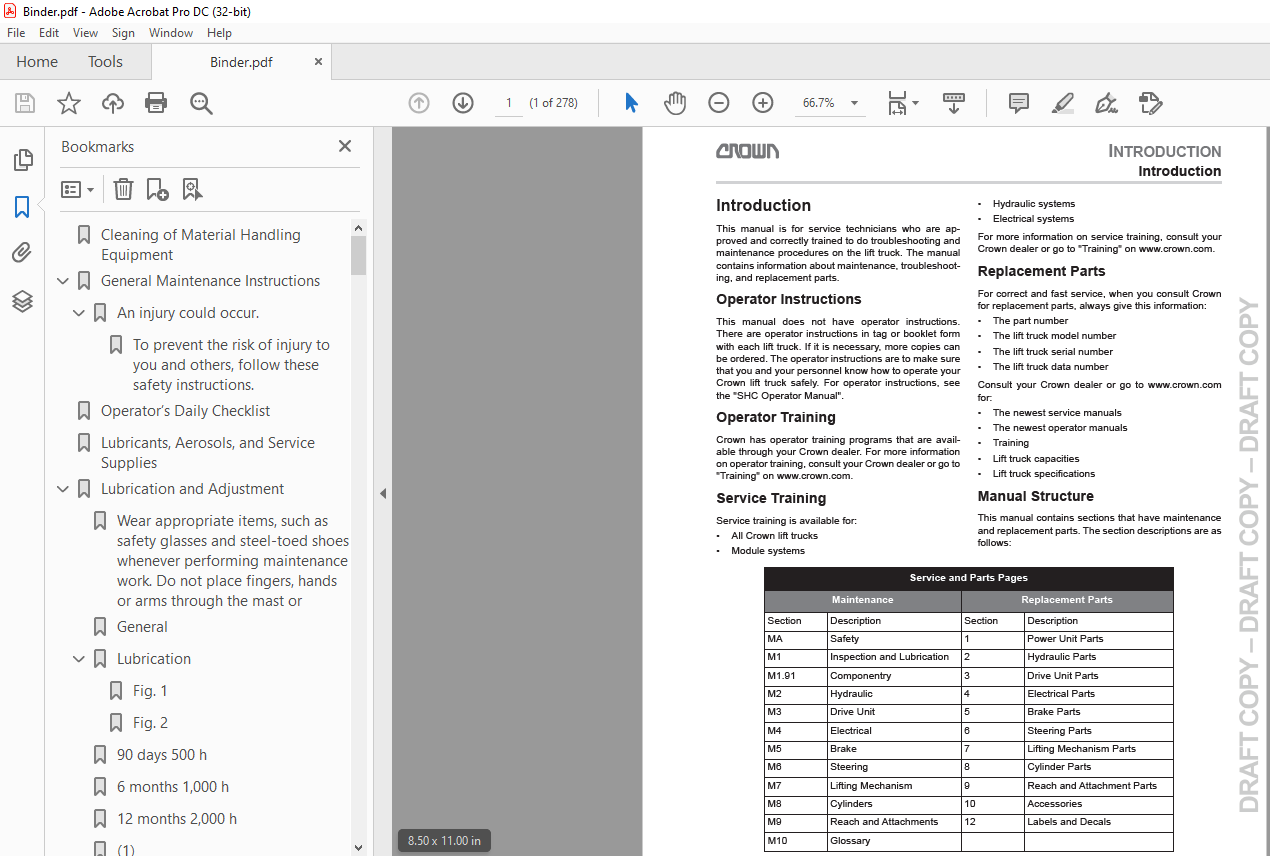

Crown Forklift SH SHR 5500 Walkie Stacker Service Manual – PDF DOWNLOAD

Crown Forklift SH SHR 5500 Walkie Stacker Service Manual – PDF DOWNLOAD

FILE DETAILS:

Crown Forklift SH SHR 5500 Walkie Stacker Service Manual – PDF DOWNLOAD

Language : English

Pages :278

Downloadable : Yes

File Type : PDF

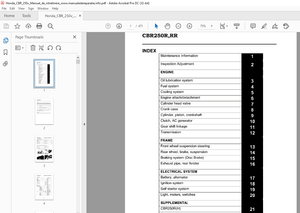

TABLE OF CONTENTS:

Crown Forklift SH SHR 5500 Walkie Stacker Service Manual – PDF DOWNLOAD

Cleaning of Material Handling Equipment 10

General Maintenance Instructions 0

An injury could occur 0

To prevent the risk of injury to you and others, follow these safety instructions 0

Operator’s Daily Checklist 22

Lubricants, Aerosols, and Service Supplies 0

Lubrication and Adjustment 0

Wear appropriate items, such as safety glasses and steel-toed shoes whenever performing maintenance work Do not place fingers, hands or arms through the mast or position them at pinch points In this section, you may be required to lift and block th 0

General 0

Lubrication 0

Fig 1 0

Fig 2 0

90 days 500 h 0

6 months 1,000 h 0

12 months 2,000 h 0

(1) 0

60 days 0

250 h 0

3 months 0

500 h 0

12 months 0

2,000 h 0

Notes: 0

Metric Torque Values 36

Grade 36

SAE Torque Values 40

Grade 40

Hydraulic System 0

Fig 1 (164964 A) 0

Reservoir 0

Fig 2 (34727) 0

Hydraulic lines and fittings 0

Hydraulic oils 0

Drift test 0

Never stand or work under a suspended load 0

Lift drift test 0

Tilt test 0

Hydraulic Schematic Symbols 72

Relief Valves 0

Relief Valve (RV) Operation 0

Relief Valve (RVA) Operation 0

Fig 1 (34733) 0

Fig 2 (34734) 0

Adjustment 0

Access 1 2 3® 0

Fig 1 (34700) 0

User Level 0

Message Mode 0

SOC – Message Mode 0

Hours – Message Mode 0

Hour 0

Events 0

Service 0

Manager 0

Performance 0

Operator menus 0

Fig 2 (34701) 0

Fig 3 (34702) 0

Analyzer menus 0

Fig 4 (34703) 0

Fig 5 (34704) 0

Fig 6 (34705) 0

Fig 7 (34706) 0

Fig 8 (34732) 0

Fig 9 (34707) 0

Calibration menus 0

Fig 10 (34708) 0

Fig 11 (34709) 0

Features menus 0

Fig 12 (34710) 0

Fig 13 (34711) 0

Fig 14 (34735) 0

Fig 15 (34736) 0

Hour menus 0

Fig 16 (34712) 0

Events menus 0

Fig 17 (34713) 0

Fig 18 (34738) 0

Performance menus 0

Fig 19 (34714) 0

Fig 20 (34715) 0

Fig 21 (34716) 0

Fig 22 (34717) 0

Utilities menus 0

Fig 23 (34719) 0

Fig 24 (34739) 0

Notes: 0

Upper and Lower Shell122

Fast/Slow Toggle Switch123

Hydraulic PC Board124

Main PC Board125

Traction Potentiometer Assembly125

Horn Switch127

Handle128

Control Modules 0

General 0

Display Control Module (ACCESS 1) 0

Fig 1 (34749) 0

Traction Control / Lift Control Module (ACCESS 2/3) 0

Fig 2 (34750) 0

Steering Control Module (ACCESS 5) 0

Fig 3 (34751) 0

Hydraulic Accessory Control (ACCESS 7) 0

Fig 4 (34752) 0

CAN Interface (ACCESS 8) 0

Fig 5 (34753) 0

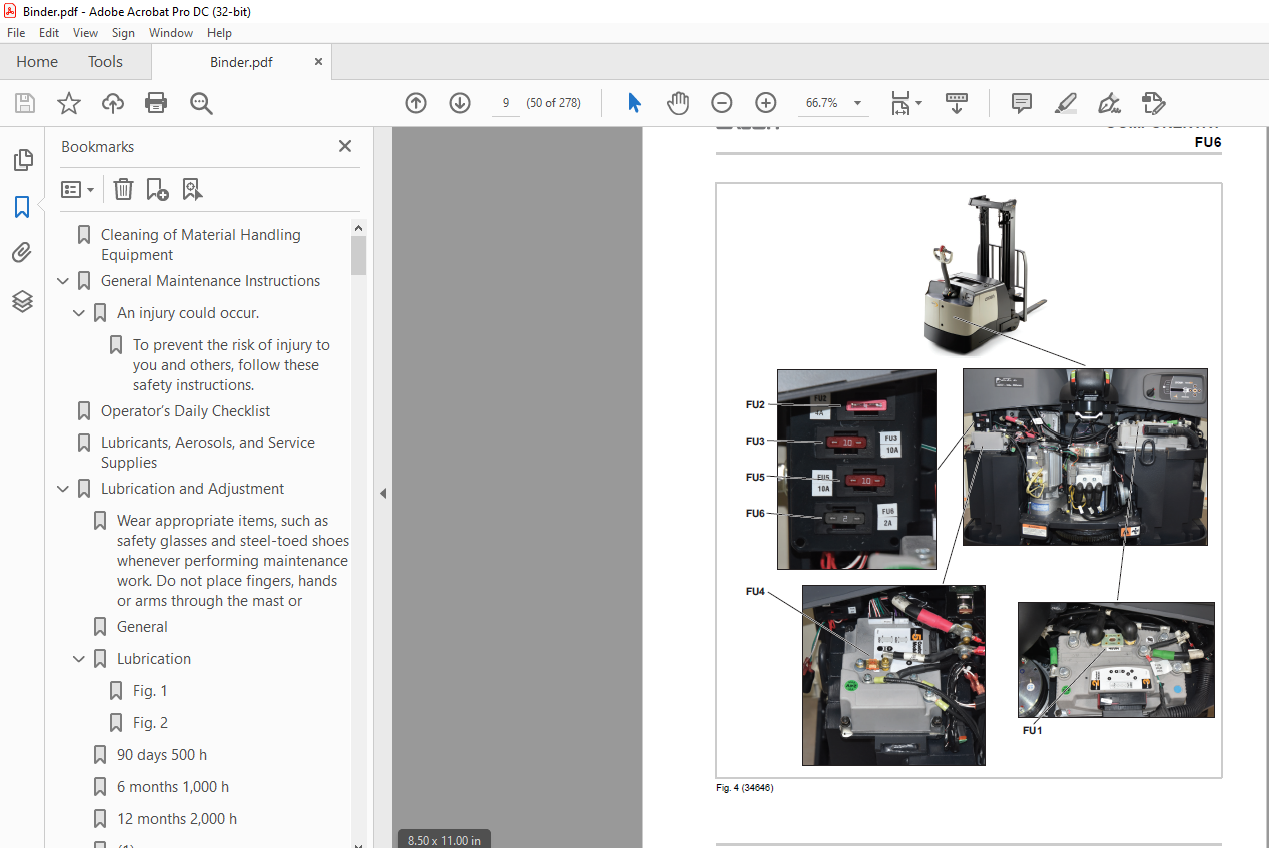

Power Fuses 0

Fig 6 (34754) 0

Servicing Control Modules 0

There are fire risks from short circuits Control modules operate at high currents Please note: 0

There is a risk of serious injury, avoid accidents by: 0

• Switching the lift truck off 0

• Disconnecting the battery 0

• Preventing the lift truck from being switched on again See the SAFETY / Control of Hazardous Energy section 0

Discharging Capacitors 0

Replacing Control Modules 0

Removing 0

When handling solvents lubricants, observe the manufacturer’s safe handling instructions See the INSPECTION AND LUBRICATION / Lubricants, Aerosols, and Service Supplies section 0

Assembling 0

Safety Rules 0

Checking 0

Battery Care 0

Onboard Charger 0

Troubleshooting 0

Onboard Charger 0

Battery Removal 0

Battery Installation 0

Battery Cleaning 0

Troubleshooting 0

Checking the Battery Under Load 0

Event Codes 0

Event Code 200 0

Event Code 201 0

Event Code 202 0

Event Code 203 0

Event Code 204 0

Event Code 205 0

Event Code 206 0

Event Code 207 0

Event Code 208 0

Event Code 209 0

Event Code 210 0

Event Code 211 0

Event Code 212 0

Event Code 213 0

Event Code 214 0

Event Code 215 0

Event Code 216 0

Event Code 217 0

Event Code 218 0

Event Code 219 0

Event Code 220 0

Event Code 221 0

Event Code 222 0

Event Code 223 0

Event Code 224 0

Event Code 225 0

Event Code 227 0

Event Code 228 0

Event Code 229 0

Event Code 230 0

Event Code 231 0

Event Code 250 0

Event Code 251 0

Event Code 252 0

Event Code 253 0

Event Code 254 0

Event Code 255 0

Event Code 256 0

Event Code 257 0

Event Code 258 0

Event Code 259 0

Event Code 301 0

Event Code 302 0

Event Code 303 0

Event Code 304 0

Event Code 305 0

Event Code 306 0

Event Code 307 0

Event Code 308 0

Event Code 309 0

Event Code 310 0

Event Code 311 0

Event Code 312 0

Event Code 313 0

Event Code 314 0

Event Code 315 0

Event Code 316 0

Event Code 317 0

Event Code 318 0

Event Code 319 0

Event Code 320 0

Event Code 321 0

Event Code 322 0

Event Code 323 0

Event Code 324 0

Event Code 325 0

Event Code 326 0

Event Code 327 0

Event Code 328 0

Event Code 329 0

Event Code 330 0

Event Code 331 0

Event Code 332 0

Event Code 333 0

Event Code 334 0

Event Code 335 0

Event Code 336 0

Event Code 337 0

Event Code 338 0

Event Code 339 0

Event Code 340 0

Event Code 341 0

Event Code 342 0

Event Code 343 0

Event Code 344 0

Event Code 345 0

Event Code 500 0

Event Code 501 0

Event Code 502 – 505 0

Event Code 506 0

Event Code 507 0

Event Code 508 0

Event Code 509 0

Event Code 510 – 512 0

Event Code 513 0

Event Code 514 0

Event Code 515 0

Event Code 516 0

Event Code 517 0

Event Code 518 0

Event Code 519 0

Event Code 520 0

Event Code 521 0

Event Code 522 0

Event Code 523 0

Event Code 524 0

Event Code 525 0

Event Code 526 0

Event Code 527 0

Event Code 528 0

Event Code 529 0

Event Code 530 0

Event Code 531 0

Event Code 532 0

Event Code 533 0

Event Code 534 0

Event Code 535 0

Event Code 536 0

Event Code 537 0

Event Code 538 0

Event Code 539 0

Event Code 540 0

Event Code 541 0

Event Code 542 0

Event Code 543 0

Event Code 544 0

Event Code 700 – 701 0

No Event Code 0

Event Code Introduction199

General 0

Servicing the Brake 0

Replacement 0

Steer Motor 0

Assemble Steer Motor 0

Assuring proper wiring and cabling connections 0

Adjusting Steer and Feedback Pot 0

Tiller Center Position 0

Drive Tire Position Adjustment 0

Torque Requirements 0

Fork Adjustments 0

Mast Testing (Assembled) 0

Flaking 0

Mast Staging Bumper Replacement 0

Disassembly 0

Assembly 0

Flushing 0

Bleeding 0

Fork Inspection 0

Cylinder Removal 0

Cylinder Replacement 0

Lift Cylinder 0

Seals 0

Rod U-Cup Installation 0

Cylinder U-cup Installation 0

Cylinder Assembly 0

Notes: 0

Reach Assembly 0

Reach Inspection 0

Steer Motor 0

Assemble Steer Motor 0

Assuring proper wiring and cabling connections 0

Adjusting Steer and Feedback Pot 0

Tiller Center Position 0

Drive Tire Position Adjustment 0

Sideshifter Inspection 0

Sideshifter Removal 0

Sideshifter Installation 0

Bearings 0

Troubleshooting 0

Supply Circuit Test 0

Electrical Diagrams Index 0

Schematic 0

Traction 0

Hydraulic 0

Steering / Handle 0

Strobe / Work Lights / Fan 0

Power Cables 0

Wiring Harnesses 0

IMAGES PREVIEW OF THE MANUAL: