$38

Crown Forklift SP 4000 Series Service Manual – PDF DOWNLOAD

Crown Forklift SP 4000 Series Service Manual – PDF DOWNLOAD

FILE DETAILS:

Crown Forklift SP 4000 Series Service Manual – PDF DOWNLOAD

Language : English

Pages :492

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Crown Forklift SP 4000 Series Service Manual – PDF DOWNLOAD

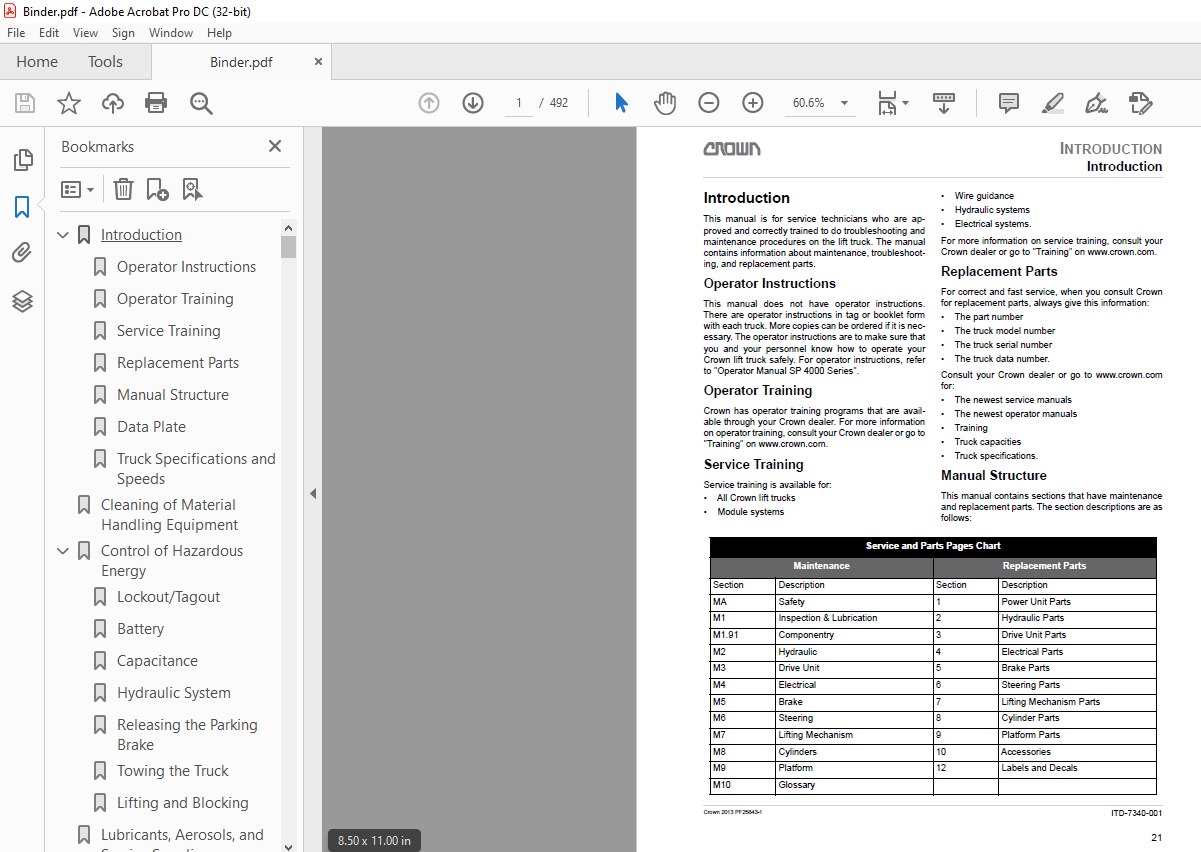

Introduction 1

Operator Instructions 1

Operator Training 1

Service Training 1

Replacement Parts 1

Manual Structure 1

Data Plate 2

Truck Specifications and Speeds 5

Cleaning of Material Handling Equipment 10

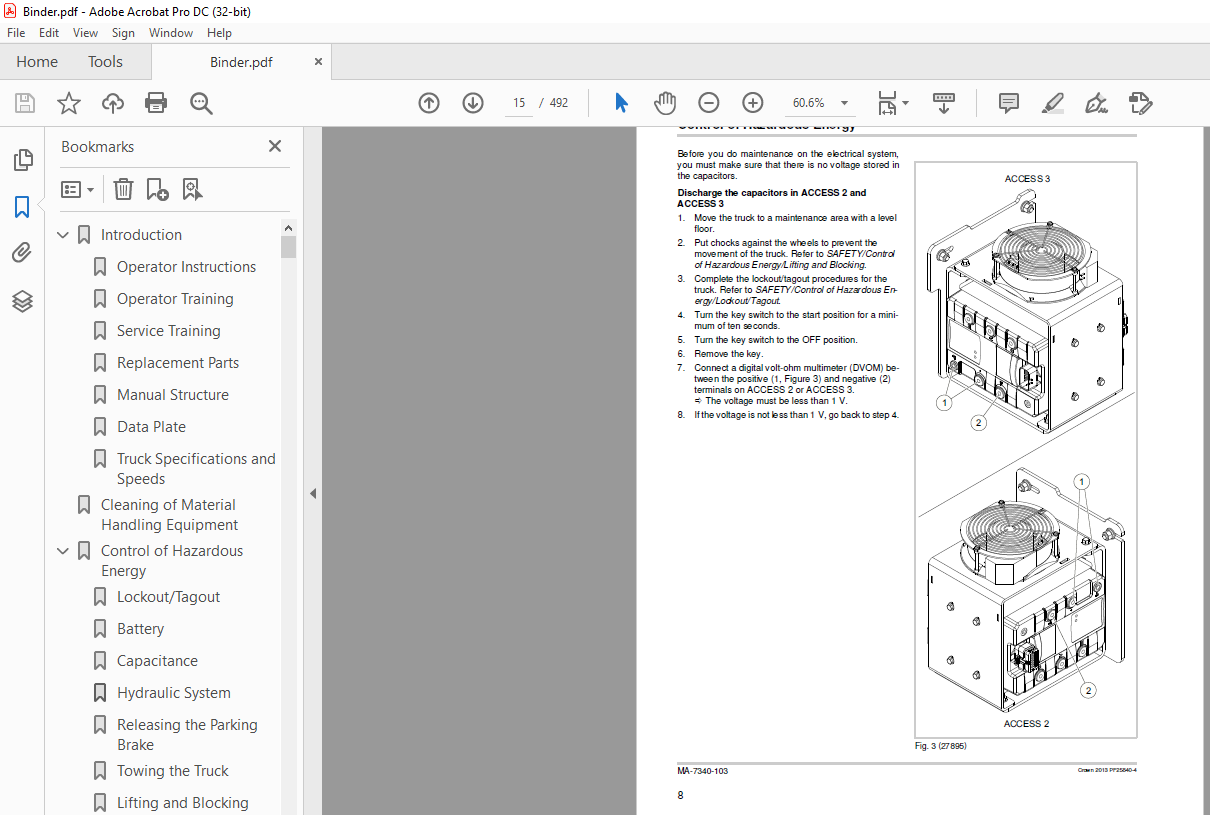

Control of Hazardous Energy 12

Lockout/Tagout 12

Battery 13

Capacitance 14

Hydraulic System 16

Releasing the Parking Brake 16

Towing the Truck 18

Lifting and Blocking 19

Lubricants, Aerosols, and Service Supplies 0

Metric Torque Values 57

Grade 57

SAE Torque Values 61

Grade 61

Componentry 63

Introduction 63

ACCESS 1 64

ACCESS 2 64

ACCESS 3 66

ACCESS 4 66

ACCESS 5 68

ACCESS 6 68

GTS1 and GTS2 94

GTS5 and GTS6 94

InfoLink® Module (Non-Windows) (Optional) 98

InfoLink® Control Module (Windows) (Optional) 98

LGT2 and LGT5104

LGT3 and LGT6104

LGT4 and LGT7104

LGT8 and LGT9104

PGS1108

PGLS1 and PGLS2110

RES2 and RES3112

RES5 and RES6112

RES7 and RES8114

RES9 and RES10114

RES11 and RES12114

RES13114

RES15116

RES16116

RES17116

RES18116

RES19 and RES20116

RES21 and RES22118

RES25118

RES50 and RES51118

RGSL and RGSR118

Lift Pump126

Lift Pump Overview126

Safety Notices126

P1 Priming127

Relief Valve Adjustment128

P1 Removal and Disassembly128

Parts Inspection129

P1 Assembly and Installation130

Hydraulic System131

Hydraulic System Overview131

Safety Notices131

Raise132

Lower134

Reservoir136

Hydraulic Plumbing136

Return Filter136

Drift Test136

Drive Unit139

Safety Notices139

Drive Tire Replacement139

Changing the Oil141

Oil Pump Disassembly and Assembly141

Traction Motor Removal and Installation142

Drive Unit Removal and Installation143

Access 1 2 3® Menus158

ANALYZER Menus179

FEATURES Menus197

PERFORMANCE Menus210

CALIBRATION Menus226

HOUR Menus233

EVENTS Menus237

UTILITIES Menus238

Wire Guidance242

Wire Guidance Inspections and Adjustments245

Control Module254

Safety Notices254

Traction Accelerator Potentiometer Adjustment254

Forward Switch and Reverse Switch Adjustment254

FS and RS Replacement255

POT1 Replacement256

Cam, Stop Assembly, and Torsion Spring Replacement256

Twist Grip Replacement258

Raise, Lower, and Horn Button Replacement259

Raise, Lower, and Horn Button Spring Replacement260

Emergency Disconnect Button and Spring Replacement260

Emergency Disconnect Switch Replacement261

Horn Switch Replacement262

Variable Raise Potentiometer and Variable Lower Potentiometer Replacement262

Troubleshooting263

Battery267

Event Codes 0

Access 1 2 3® Modules Overview 0

Symbols 0

Static Return to Off (SRO) Messages 0

Event Code 100 0

INVALID EVENT CODE FROM ACCESS 1 – NOT USED 0

Event Code 101 0

Event Code 103 0

ACCESS 1 CAN INITIALIZATION EVENT WITH Access 3™ 0

Event Code 104 0

ACCESS 1 CAN INITIALIZATION EVENT WITH ACCESS 4 0

Event Code 105 0

ACCESS 1 CAN INITIALIZATION EVENT WITH ACCESS 5 0

Event Code 106 0

ACCESS 1 CAN INITIALIZATION EVENT WITH ACCESS 6 0

Event Code 111 0

ACCESS 1 SOFTWARE PARAMETER EVENT 0

Event Code 113 0

Access 3™ SOFTWARE IS INCOMPATIBLE 0

Event Code 114 0

ACCESS 4 SOFTWARE IS INCOMPATIBLE 0

Event Code 115 0

ACCESS 5 SOFTWARE IS INCOMPATIBLE 0

Event Code 116 0

ACCESS 6 SOFTWARE IS INCOMPATIBLE 0

Event Code 123 0

Access 3™ CAN EVENT 0

Event Code 124 0

ACCESS 4 CAN EVENT 0

Event Code 125 0

ACCESS 5 CAN EVENT 0

Event Code 126 0

ACCESS 6 CAN EVENT 0

Event Code 131 0

ALM1 DRIVER HAS A SHORT CIRCUIT 0

Event Code 133 0

GUIDANCE STEER INDICATOR CAN EVENT 0

Event Code 134 0

ACCESS 4 CAN EVENT 0

Event Code 160 0

Access 1 COMMUNICATION ERROR WITH EPS 0

Event Code 161 0

Access 1 COMMUNICATION LOST FROM EPS 0

Event Code 162 0

Access 1 COMMUNICATION LOST FROM EPS 0

Event Code 163 0

Access 1 COMMUNICATION ERROR WITH EPS 0

Event Code 164 0

EPS Software is Incompatible 0

Event Code 165 0

Access 1 COMMUNICATION ERROR WITH EPS 0

Event Code 166 0

Load Shed Zero 0

Event Code 167 0

EPS ERROR STATE LOGGED 0

Event Code 168 0

EWS EVENT 0

Event Code 169 0

EPS/BRES Configuration Mismatch 0

Event Code 200 0

INVALID EVENT CODE FROM ACCESS 2 – NOT USED 0

Event Code 201 0

ACCESS 1 CAN EVENT WITH ACCESS 2 0

Event Code 205 0

ACCESS 5 CAN EVENT WITH ACCESS 2 0

Event Code 221 0

CURRENT SENSOR EVENT 0

Event Code 222 0

ACCESS 2 VOLTAGE IS TOO LOW 0

Event Code 223 0

ACCESS 2 VOLTAGE IS TOO HIGH 0

Event Code 224 0

ACCESS 2 INTERNAL TEMPERATURE IS LESS THAN -25 °C (-13 °F) 0

Event Code 225 0

ACCESS 2 INTERNAL TEMPERATURE IS LESS THAN -40 °C (-40 °F) 0

Event Code 226 0

ACCESS 2 INTERNAL TEMPERATURE IS MORE THAN 85 °C (185 °F) 0

Event Code 227 0

ACCESS 2 INTERNAL TEMPERATURE IS MORE THAN 105 °C (221 °F) 0

Event Code 228 0

M3 TEMPERATURE SENSOR (TS2) TEMPERATURE IS MORE THAN 165 °C (329 °F) 0

Event Code 229 0

TS2 TEMPERATURE IS TOO LOW OR TOO HIGH 0

Event Code 230 0

HYDRAULIC FEEDBACK ENCODER (ECR7) COUNT EVENT 0

Event Code 231 0

ACCESS 2 STALL IS DETECTED 0

Event Code 232 0

M3 ROTATION IS MORE THAN 4000 rpm 0

Event Code 233 0

ACCESS 2 VOLTAGE IS TOO LOW 0

Event Code 234 0

ACCESS 2 VOLTAGE IS VERY LOW 0

Event Code 235 0

ACCESS 2 VOLTAGE IS TOO HIGH 0

Event Code 236 0

ACCESS 2 VOLTAGE IS VERY HIGH 0

Event Code 237 0

ACCESS 2 VOLTAGE IS FLUCTUATING 0

Event Code 238 0

KEY SWITCH (KYS) VOLTAGE IS TOO LOW 0

Event Code 239 0

KYS VOLTAGE IS TOO HIGH 0

Event Code 240 0

MAIN CONTACTOR (ED1) COIL DRIVER HAS TOO MUCH CURRENT 0

Event Code 243 0

SOLENOID VALVE LOWER (SVL2) HAS TOO MUCH CURRENT 0

Event Code 244 0

FAN2/3 DRIVER HAS TOO MUCH CURRENT 0

Event Code 245 0

ED1 DRIVER HAS AN OPEN CIRCUIT 0

Event Code 248 0

SVL2 DRIVER HAS AN OPEN CIRCUIT 0

Event Code 249 0

FAN2/3 DRIVER HAS AN OPEN CIRCUIT 0

Event Code 250 0

ED1 DRIVER HAS A SHORT CIRCUIT 0

Event Code 253 0

SVL2 DRIVER HAS A SHORT CIRCUIT 0

Event Code 254 0

FAN2/3 DRIVER HAS A SHORT CIRCUIT 0

Event Code 255 0

ACCESS 2 PWM DRIVER HAS TOO MUCH VOLTAGE 0

Event Code 258 0

ACCESS 2 PRE-CHARGE POWER LIMIT IS TOO LOW OR TOO HIGH 0

Event Code 259 0

ACCESS 2 PRE-CHARGE TIME LIMIT HAS BEEN EXCEEDED 0

Event Code 260 0

ACCESS 2 PRE-CHARGE ELECTRICAL EVENT 0

Event Code 261 0

ACCESS 2 EVENT 0

Event Code 264 0

INTERNAL 5 V SUPPLY FOR ACCESS 2 IS TOO LOW OR TOO HIGH 0

Event Code 266 0

12 V SUPPLY VOLTAGE FOR ECR7 IS TOO LOW OR TOO HIGH 0

Event Code 268 0

15 V POWER SUPPLY FOR ACCESS 2 IS TOO LOW OR TOO HIGH 0

Event Code 270 0

5 V POWER SUPPLY FOR ACCESS 2 IS TOO LOW OR TOO HIGH 0

Event Code 272 0

INTERNAL 227 mV REFERENCE VOLTAGE FOR ACCESS 2 IS TOO LOW OR TOO HIGH 0

Event Code 274 0

INTERNAL 25 V REFERENCE VOLTAGE FOR ACCESS 2 IS TOO LOW OR TOO HIGH 0

Event Code 276 0

INTERNAL ANALOG GROUND VOLTAGE FOR ACCESS 2 IS TOO LOW OR TOO HIGH 0

Event Code 278 0

ACCESS 2 CURRENT IS TOO HIGH 0

Event Code 279 0

ACCESS 2 HAS AN INTERNAL SHORT CIRCUIT 0

Event Code 281 0

M3 HAS A SHORT CIRCUIT 0

Event Code 283 0

M3 HAS A SHORT CIRCUIT 0

Event Code 285 0

M3 HAS A SHORT CIRCUIT 0

Event Code 287 0

M3 HAS A SHORT CIRCUIT BETWEEN THE U TERMINAL AND THE V TERMINAL 0

Event Code 290 0

M3 HAS A SHORT CIRCUIT BETWEEN THE V TERMINAL AND THE W TERMINAL 0

Event Code 293 0

M3 HAS A SHORT CIRCUIT BETWEEN THE W TERMINAL AND THE U TERMINAL 0

Event Code 300 0

INVALID EVENT CODE FROM Access 3™ – NOT USED 0

Event Code 301 0

ACCESS 1 CAN EVENT WITH Access 3™ 0

Event Code 303 0

Access 3™ CAN EVENT 0

Event Code 304 0

ACCESS 4 CAN EVENT WITH Access 3™ 0

Event Code 305 0

ACCESS 5 CAN EVENT WITH Access 3™ 0

Event Code 306 0

ACCESS 6 CAN EVENT WITH Access 3™ 0

Event Code 310 0

HEIGHT ENCODER (ECR4) AND HEIGHT FEEDBACK ENCODER (ECR6) SOFTWARE INCOMPATIBILITY 0

Event Code 321 0

CURRENT SENSOR EVENT 0

Event Code 322 0

Access 3™ VOLTAGE IS TOO LOW 0

Event Code 323 0

Access 3™ VOLTAGE IS TOO HIGH (MORE THAN 63 V) 0

Event Code 324 0

Access 3™ INTERNAL TEMPERATURE IS LESS THAN -25 °C (-13 °F) 0

Event Code 325 0

Access 3™ INTERNAL TEMPERATURE IS LESS THAN -40 °C (-40 °F) 0

Event Code 326 0

Access 3™ INTERNAL TEMPERATURE IS MORE THAN 85 °C (185 °F) 0

Event Code 327 0

Access 3™ INTERNAL TEMPERATURE IS MORE THAN 105 °C (221 °F) 0

Event Code 328 0

M1 TEMPERATURE SENSOR (TS1) TEMPERATURE IS MORE THAN 165 °C (329 °F) 0

Event Code 329 0

TS1 TEMPERATURE IS TOO LOW OR TOO HIGH 0

Event Code 330 0

TRAVEL SPEED ENCODER (ECR3) COUNT EVENT 0

Event Code 331 0

Access 3™ STALL IS DETECTED 0

Event Code 332 0

M1 ROTATION IS MORE THAN 4000 rpm 0

Event Code 333 0

Access 3™ VOLTAGE IS TOO LOW 0

Event Code 334 0

Access 3™ VOLTAGE IS VERY LOW 0

Event Code 335 0

Access 3™ VOLTAGE IS TOO HIGH 0

Event Code 336 0

Access 3™ VOLTAGE IS VERY HIGH 0

Event Code 337 0

Access 3™ VOLTAGE IS FLUCTUATING 0

Event Code 338 0

KYS VOLTAGE IS TOO LOW (LESS THAN 7 V) 0

Event Code 339 0

KYS VOLTAGE IS TOO HIGH 0

Event Code 340 0

ED2 COIL DRIVER HAS TOO MUCH CURRENT 0

Event Code 343 0

SOLENOID VALVE LOWER (SVL1) HAS TOO MUCH CURRENT 0

Event Code 344 0

FAN2/3 DRIVER HAS TOO MUCH CURRENT 0

Event Code 345 0

ED2 DRIVER HAS AN OPEN CIRCUIT 0

Event Code 348 0

SVL1 DRIVER HAS AN OPEN CIRCUIT 0

Event Code 349 0

FAN2/3 DRIVER HAS AN OPEN CIRCUIT 0

Event Code 350 0

ED2 DRIVER HAS A SHORT CIRCUIT 0

Event Code 353 0

SVL1 DRIVER HAS A SHORT CIRCUIT 0

Event Code 354 0

FAN2/3 DRIVER HAS A SHORT CIRCUIT 0

Event Code 355 0

Access 3™ PWM DRIVER HAS TOO MUCH VOLTAGE 0

Event Code 356 0

ED2 WIRING HAS AN OPEN CIRCUIT 0

Event Code 357 0

ED2 CONTACTOR TIPS ARE WELDED 0

Event Code 358 0

Access 3™ PRE-CHARGE POWER LIMIT EVENT 0

Event Code 359 0

Access 3™ PRE-CHARGE TIME LIMIT HAS BEEN EXCEEDED 0

Event Code 360 0

Access 3™ PRE-CHARGE ELECTRICAL EVENT 0

Event Code 361 0

Access 3™ EVENT 0

Event Code 362 0

Access 3™ INTERNAL EVENT 0

Event Code 364 0

INTERNAL 5 V SUPPLY FOR Access 3™ IS TOO LOW OR TOO HIGH 0

Event Code 366 0

12 V SUPPLY VOLTAGE FOR ECR3 IS TOO LOW OR TOO HIGH 0

Event Code 368 0

15 V POWER SUPPLY FOR Access 3™ IS TOO LOW OR TOO HIGH 0

Event Code 370 0

5 V POWER SUPPLY FOR Access 3™ IS TOO LOW OR TOO HIGH 0

Event Code 372 0

INTERNAL 227 mV REFERENCE VOLTAGE FOR Access 3™ IS TOO LOW OR TOO HIGH 0

Event Code 374 0

INTERNAL 25 V REFERENCE VOLTAGE FOR Access 3™ IS TOO LOW OR TOO HIGH 0

Event Code 376 0

INTERNAL ANALOG GROUND VOLTAGE FOR Access 3™ IS TOO LOW OR TOO HIGH 0

Event Code 378 0

Access 3™ CURRENT IS TOO HIGH 0

Event Code 379 0

Access 3™ HAS AN INTERNAL SHORT CIRCUIT 0

Event Code 381 0

M1 HAS A SHORT CIRCUIT 0

Event Code 383 0

M1 HAS A SHORT CIRCUIT 0

Event Code 385 0

M1 HAS A SHORT CIRCUIT 0

Event Code 387 0

M1 HAS A SHORT CIRCUIT BETWEEN THE U TERMINAL AND THE V TERMINAL 0

Event Code 390 0

M1 HAS A SHORT CIRCUIT BETWEEN THE V TERMINAL AND THE W TERMINAL 0

Event Code 393 0

M1 HAS A SHORT CIRCUIT BETWEEN THE W TERMINAL AND THE U TERMINAL 0

Event Code 396 0

M3 TEMPERATURE IS TOO HIGH 0

Event Code 400 0

INVALID EVENT CODE FROM ACCESS 4 – NOT USED 0

Event Code 401 0

ACCESS 1 CAN EVENT WITH ACCESS 4 0

Event Code 405 0

ACCESS 5 CAN EVENT WITH ACCESS 4 0

Event Code 411 0

ACCESS 1 EVENT WITH ACCESS 4 0

Event Code 413 0

Access 3™ EVENT WITH ACCESS 4 0

Event Code 415 0

ACCESS 5 EVENT WITH ACCESS 4 0

Event Code 416 0

ACCESS 6 EVENT WITH ACCESS 4 0

Event Code 421 0

ACCESS 4 INTERNAL EVENT 0

Event Code 422 0

5 V POWER SUPPLY FOR TRACTION ACCELERATOR POTENTIOMETER (POT1) IS TOO LOW OR TOO HIGH 0

Event Code 423 0

POT1 ELECTRICAL RANGE IS TOO LOW OR TOO HIGH 0

Event Code 424 0

POT1 DOES NOT MATCH THE FORWARD SWITCH (FS) 0

Event Code 425 0

POT1 DOES NOT MATCH RS 0

Event Code 426 0

FS AND RS ARE CLOSED AT THE SAME TIME 0

Event Code 427 0

POT1 VOLTAGE IS TOO LOW OR TOO HIGH 0

Event Code 429 0

STEERING COMMAND ENCODERS (ECR1 AND ECR5) COUNT EVENT 0

Event Code 430 0

ECR1 AND ECR5 TURN RATE EVENT 0

Event Code 431 0

ECR1 AND ECR5 DIRECTION EVENT 0

Event Code 432 0

5 V POWER SUPPLY FOR HEIGHT ENCODER (ECR4) IS TOO LOW OR TOO HIGH 0

Event Code 433 0

5 V POWER SUPPLY RUNTIME EVENT 0

Event Code 435 0

THE HEIGHT SWITCH (HGTRS) DOES NOT CLOSE AT THE CORRECT TIME 0

Event Code 440 0

ZONE SELECT SWITCH (ZSS) WIRES HAVE AN OPEN CIRCUIT 0

Event Code 441 0

ZSS WIRES HAVE A SHORT CIRCUIT 0

Event Code 442 0

ZSS IS DETECTED BUT THE FEATURE IS NOT ENABLED 0

Event Code 448 0

TRAVEL ALARM (ALM2) DRIVER HAS A SHORT CIRCUIT 0

Event Code 452 0

ACCESS 4 INTERNAL DRIVER HAS A SHORT CIRCUIT 0

Event Code 460 0

ACCESS 5 CAN EVENT 0

Event Code 463 0

ACCESS 6 CAN EVENT 0

Event Code 466 0

ACCESS 1 CAN EVENT 0

Event Code 470 0

ACCESS 2 CAN EVENT 0

Event Code 474 0

Access 3™ CAN EVENT 0

Event Code 478 0

ACCESS 5 CAN EVENT 0

Event Code 480 0

ACCESS 6 CAN EVENT 0

Event Code 482 0

ACCESS 1 CAN EVENT 0

Event Code 485 0

ACCESS 2 CAN EVENT 0

Event Code 488 0

Access 3™ CAN EVENT 0

Event Code 500 0

INVALID EVENT CODE FROM ACCESS 5 – NOT USED 0

Event Code 501 0

ACCESS 1 CAN EVENT WITH ACCESS 5 0

Event Code 503 0

Access 3™ CAN EVENT WITH ACCESS 5 0

Event Code 504 0

ACCESS 4 CAN EVENT WITH ACCESS 5 0

Event Code 505 0

ACCESS 5 CAN EVENT 0

Event Code 506 0

ACCESS 6 CAN EVENT WITH ACCESS 5 0

Event Code 511 0

ACCESS 5 INTERNAL EVENT 0

Event Code 513 0

ACCESS 5 INTERNAL EVENT 0

Event Code 515 0

ACCESS 5 INTERNAL EVENT 0

Event Code 522 0

5 V POWER SUPPLY FOR ACCESS 5 IS TOO LOW OR TOO HIGH 0

Event Code 524 0

STEER MOTOR (M2) VOLTAGE IS TOO HIGH 0

Event Code 525 0

M2 VOLTAGE IS TOO LOW 0

Event Code 526 0

BRK VOLTAGE IS TOO HIGH OR TOO LOW 0

Event Code 528 0

BRK INNER COIL VOLTAGE IS TOO HIGH 0

Event Code 529 0

BRK INNER COIL VOLTAGE IS TOO LOW 0

Event Code 530 0

BRK OUTER COIL VOLTAGE IS TOO HIGH 0

Event Code 531 0

BRK OUTER COIL VOLTAGE IS TOO LOW 0

Event Code 532 0

CURRENT SENSOR (CS1) VOLTAGE IS TOO HIGH 0

Event Code 533 0

CS1 VOLTAGE IS TOO LOW 0

Event Code 534 0

BATTERY CURRENT IS TOO HIGH OR TOO LOW 0

Event Code 536 0

CS1 IS NOT INSTALLED CORRECTLY 0

Event Code 537 0

ZERO CURRENT IS TOO HIGH OR TOO LOW 0

Event Code 538 0

BATTERY VOLTAGE IS TOO HIGH OR TOO LOW 0

Event Code 540 0

INCORRECT BATTERY IS INSTALLED 0

Event Code 541 0

ED2 IS NOT CLOSED 0

Event Code 542 0

FUSE EVENT 0

Event Code 543 0

ED2 CONTACTOR TIPS ARE WELDED 0

Event Code 544 0

ED2 LOAD HAS AN OPEN CIRCUIT OR ED2 DRIVER HAS A SHORT CIRCUIT 0

Event Code 545 0

ED2 DRIVER DROPOUT EVENT 0

Event Code 546 0

Access 3™ ED2 PRE-CHARGE EVENT 0

Event Code 549 0

Access 3™ CHAIN SLACK 0

Event Code 551 0

ACCESS 5 PARAMETER EVENT 0

Event Code 552 0

ACCESS 5 PARAMETER EVENT 0

Event Code 554 0

ACCESS 5 EAC PARAMETER EVENT 0

Event Code 555 0

ECR2 FEEDBACK COUNTS ARE INCORRECT 0

Event Code 557 0

ECR2 INDEX EVENT 0

Event Code 558 0

ECR2 EVENT 0

Event Code 562 0

STEERING EVENT 0

Event Code 563 0

ACCESS 5 AND ACCESS 6 COMMUNICATION EVENT 0

Event Code 564 0

WIRE GUIDANCE ENABLE EVENT 0

Event Code 565 0

ECR3 EVENT 0

Event Code 566 0

EAC ENABLE EVENT 0

Event Code 567 0

END AISLE CONTROL SENSOR (EACA1) LATCHED ON EVENT 0

Event Code 568 0

END AISLE CONTROL SENSOR (EACB1) LATCHED ON EVENT 0

Event Code 569 0

END AISLE CONTROL SENSOR (EACA2) LATCHED ON EVENT 0

Event Code 570 0

END AISLE CONTROL SENSOR (EACB2) LATCHED ON EVENT 0

Event Code 571 0

EAC MAGNET EVENT 0

Event Code 573 0

ECR4 COUNT EVENT 0

Event Code 576 0

BRK CURRENT OR RESISTANCE EVENT 0

Event Code 582 0

BRK CURRENT IS TOO LOW OR TOO HIGH 0

Event Code 586 0

BRK INNER COIL HAS A SHORT CIRCUIT 0

Event Code 587 0

BRK OUTER COIL HAS A SHORT CIRCUIT 0

Event Code 588 0

BRK INNER COIL HAS AN OPEN CIRCUIT 0

Event Code 589 0

BRK OUTER COIL HAS AN OPEN CIRCUIT 0

Event Code 590 0

BRK DRIVER EVENT 0

Event Code 592 0

BRK DRIVER HAS A SHORT CIRCUIT 0

Event Code 600 0

INVALID EVENT CODE FROM ACCESS 6 – NOT USED 0

Event Code 601 0

ACCESS 1 CAN EVENT WITH ACCESS 6 0

Event Code 603 0

Access 3™ CAN EVENT WITH ACCESS 6 0

Event Code 604 0

ACCESS 4 CAN EVENT WITH ACCESS 6 0

Event Code 605 0

ACCESS 5 CAN EVENT WITH ACCESS 6 0

Event Code 606 0

ACCESS 6 CAN EVENT 0

Event Code 611 0

ACCESS 6 INTERNAL EVENT 0

Event Code 621 0

ACCESS 6 INTERNAL EVENT 0

Event Code 631 0

WIRE GUIDANCE SENSOR (GS1 OR GS2) AMPLIFIER SELF TEST 0

Event Code 632 0

GS2 EVENT 0

Event Code 633 0

GS1 EVENT 0

Event Code 636 0

LOSS OF WIRE GUIDANCE SIGNAL WHILE TRACKING 0

Event Code 637 0

LOSS OF WIRE GUIDANCE SIGNAL AT GS1 AND GS2 0

Event Code 638 0

LOSS OF WIRE GUIDANCE SIGNAL AT GS1 AND GS2 COILS WHILE TRACKING 0

Event Code 652 0

END AISLE CONTROL SENSOR SIGNAL IS TOO HIGH OR TOO LOW 0

Event Code 660 0

END AISLE CONTROL SENSOR DIGITAL SIGNAL EVENT 0

Event Code 664 0

EAC MAGNET FIELD STRENGTH IS TOO LOW 0

Event Code 668 0

END AISLE CONTROL SENSOR SELF TEST EVENT 0

Event Code 672 0

MANY END AISLE CONTROL SENSORS ARE ACTIVE 0

Event Code Introduction369

Brake371

Brake Overview371

Safety Notices371

Stopping Distance Adjustment372

Torque Gap Adjustment372

Air Gap Adjustment373

Rotor and Brake Pad Assembly Replacement374

Assemble BRK375

Troubleshooting376

Mast382

TL Mast382

TT Mast382

Shim Basics382

General Repair and Safety Instructions384

Mast Testing (Assembled)384

Mast Column Rollers and Shims386

Shim Removal (Mast Assembled)391

Mast Removal391

Mast Installation393

Fork Inspection 0

Lift Cylinder Operation406

General Repair and Safety Instructions408

Disassembling the Cylinders408

Assembling the Cylinders408

Inspection409

Accessing the Rod Packing in the Mast Cylinder411

Accessing the Rod Packing in the Free Lift Cylinder411

Rod Packing Replacement411

Mast Cylinder Removal414

Mast Cylinder Installation414

Free Lift Cylinder Removal416

Free Lift Cylinder Installation417

Mast and Free Lift Cylinders418

Lift cylinder operation418

General repair and safety instructions420

Cylinder Repair Tools421

Rod Packing Access and Replacement421

Replacing the rod packing422

Mast Cylinder Removal and Installation425

Platform431

Safety Notices431

Mat Replacement431

Shield Removal and Installation432

Fork Removal and Installation433

Fork Height Adjustment434

Pallet Grab435

Side Gates439

Full Body Harness and Lanyard440

Shim Installation on TL Masts, Platform Removal, and Platform Installation441

Shim Installation on TT Masts, Platform Removal, and Platform Installation442

Electrical Diagrams370

Schematic – Power Unit 0

Schematic – Platform 0

Platform Distribution Panel 0

Power Unit Distribution Panel 0

ACCESS 1 and ACCESS 4 0

Control Module 0

ACCESS 3 and ACCESS 5 0

ACCESS 2 0

Hydraulics 0

Overhead Guard – Light and Fan Assemblies 0

Overhead Guard – Optional Spotlights Only 0

ACCESS 6 and Wire Guidance 0

Mast Cable 3 0

Mast Cable 4 0

Power Cables 0

Wire Harnesses 0

IMAGES PREVIEW OF THE MANUAL: