$43

Crown Forklift TSP 7000 Series Service Manual – PDF DOWNLOAD

Crown Forklift TSP 7000 Series Service Manual – PDF DOWNLOAD

FILE DETAILS:

Crown Forklift TSP 7000 Series Service Manual – PDF DOWNLOAD

Language : English

Pages :816

Downloadable : Yes

File Type : PDF

DESCRIPTION:

Crown Forklift TSP 7000 Series Service Manual – PDF DOWNLOAD

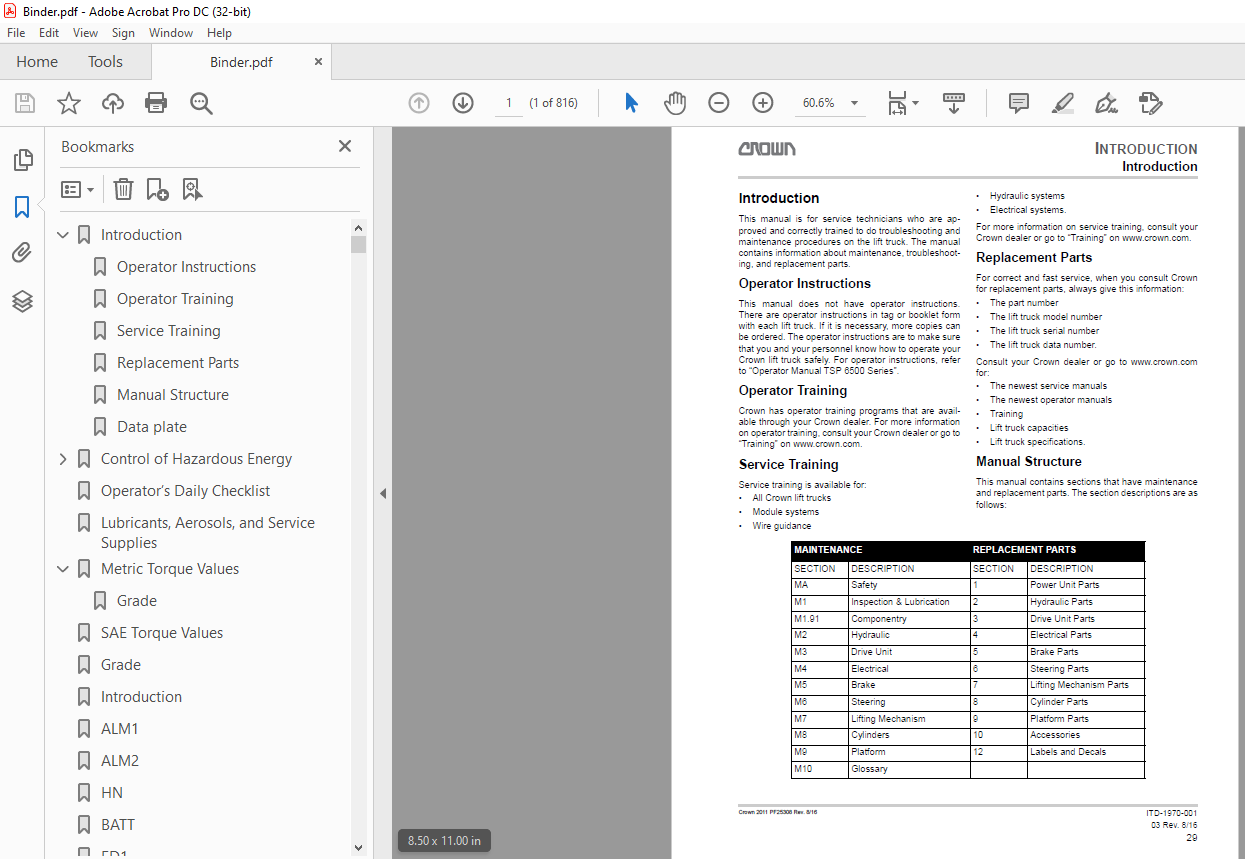

Introduction

This manual is for service technicians who are approved

and correctly trained to do troubleshooting and

maintenance procedures on the lift truck. The manual

contains information about maintenance, troubleshooting,

and replacement parts.

Operator Instructions

This manual does not have operator instructions.

There are operator instructions in tag or booklet form

with each lift truck. If it is necessary, more copies can

be ordered. The operator instructions are to make sure

that you and your personnel know how to operate your

Crown lift truck safely. For operator instructions, refer

to “Operator Manual TSP 6500 Series”.

TABLE OF CONTENTS:

Crown Forklift TSP 7000 Series Service Manual – PDF DOWNLOAD

Introduction 1

Operator Instructions 1

Operator Training 1

Service Training 1

Replacement Parts 1

Manual Structure 1

Data plate 2

Control of Hazardous Energy 0

Lockout/Tagout 0

Battery 0

Safety Rules 0

Battery Maintenance 0

Only personnel that have experience with batteries can do maintenance and repair on batteries 0

Battery Charging 0

Do not smoke or use a flame near the battery Gas made while you charge a battery is very explosive and can cause injury 0

Battery Removal 0

When you remove the battery, move the truck to an area that is used for battery maintenance The floor must be flat Lower the mast(s) fully, turn the truck OFF, and remove the key Disconnect the battery and lockout/tagout the truck (refer to SAFETY 0

Fig 1 (8251) 0

Battery Installation 0

Turn the truck OFF and remove the key If the battery was removed with the mast(s) raised, use a lift attached to the mast to supply tip over protection Do not metal objects to touch the top of the battery cells This may cause a short circuit when 0

Make sure the battery that you use agrees to the weight, capacity, amperage, and voltage requirements of the truck (refer to serial plate) NEVER operate the truck with a battery that does not agree with the requirements 0

Lockout/Tagout 0

Fig 2 (12723) 0

Capacitance 0

1 Move the truck to a maintenance area that has a flat and level floor 0

2 Turn the truck OFF and remove the key 0

3 Lockout/tagout the truck Refer to SAFETY>Control of Hazardous Energy>Lockout/Tagout 0

4 Wait for 2 minutes after you disconnect the battery for the capacitors to release 0

5 To make sure that the capacitors are released, put a volt-meter across the B+ and B- terminals of the ACCESS 2 and ACCESS 3 modules 0

Fig 3 (26141) 0

Hydraulic 0

AVOID HIGH PRESSURE FLUIDS 0

• High pressure fluid can go through the skin and cause serious injury 0

• Release the pressure before you disconnect the hydraulic lines 0

• Tighten all connections before you apply the pressure 0

• Keep your hands and body away from pin holes which eject high pressure fluids 0

• Use a piece of cardboard or paper to examine for leaks Do not use your hand 0

• High pressure fluid that goes into the skin can become a severe medical emergency even when the skin looks normal 0

• There is a delayed start of pain, and severe tissue damage may occur 0

• You must get medical aid from a specialist who has had experience with this type of injury 0

Fig 4 (26021) 0

Releasing the Brakes 0

To release the brakes through the Access 123 UTILITIES Menu 0

1 Lower the mast(s) fully 0

2 Lockout/tagout the truck Refer to SAFETY>Control of Hazardous Energy>Lockout/Tagout 0

3 Put chocks against the wheels of the truck to prevent unwanted movement of the truck when the brakes are released 0

4 When you tow the truck, make sure that the operator knows of the procedures to apply the brakes 0

5 Connect the battery and start the truck in the “Service” mode of ACCESS 1 and put in the password 0

6 Scroll the display of ACCESS 1 using the down arrow to the “UTILITIES” Menu and push the ENTER key 0

7 Use the up/down arrows to scroll to U2 “Active Tow Mode” and push the ENTER key 0

8 The operator can release the brakes at this time by closing the gates and then sit or stand-up with 2 feet on the presence pedals (DMS) and having the right hand on the right Multi-Task Handle 0

When the brakes are released the truck will be free to move 0

9 The truck can be towed and the operator can steer the truck (NOTE: If the operator opens a gate, removes a foot or the right hand, the brakes will apply) 0

10 Move the truck to a maintenance area that has a flat and level floor 0

11 Turn the truck off to disable tow mode 0

To release the brakes using the Drive/Tow Switch (DTS) 0

Use precaution when you use the Drive/Tow Switch (DTS) to release the brakes The truck will be free to move and the brake pedal in the operator compartment will have no effect on the brakes Also, the steering system will not operate The brakes wil 0

1 Lower the mast(s) fully 0

2 Lockout/tagout the truck Refer to SAFETY>Control of Hazardous Energy>Lockout/Tagout 0

3 Put chocks against the wheels of the truck to prevent unwanted movement of the truck when the brakes are released 0

4 When you tow the truck, make sure that all the operators and other personnel know the trucks brakes do not operate correctly 0

5 Disconnect the brake harness from the primary harness at connector PC407 and connect the brake harness to the distribution panel at CA203 0

6 Connect the battery and move the Drive/Tow Switch (DTS) from the Drive position to the Tow position 0

7 Remove the wheel chocks and move the truck to a level area that is used for maintenance 0

8 Move the Drive/Tow Switch (DTS) from the Tow position to the Drive position 0

9 Disconnect the battery 0

10 Disconnect the brake harness from the distribution panel and connect the brake harness to its first connection, CA407 0

Fig 5 (17675) 0

To release the brakes mechanically 0

Be careful when you use the manual brake procedure to release the brake The truck will be free to move and the brake pedal in the operator compartment will have no effect on the brakes With the truck OFF, the truck will not have traction or steerin 0

1 Lower the mast(s) fully 0

2 Lockout/tagout the truck Refer to SAFETY>Control of Hazardous Energy>Lockout/Tagout 0

3 Put chocks against the wheels of the truck to prevent unwanted movement of the truck when the brakes are released 0

4 Use a wrench, a punch or a screwdriver to turn the torque adjuster plate This will remove the spring preload 0

5 Remove the wheel chocks and move the truck to a maintenance area When you tow the truck, make sure all the operators and other personnel are told of the problem with the truck’s brake operation and steering Refer to SAFETY>Control of Hazardous E 0

6 To reapply the brake, turn the torque adjuster plate back to its first position to get the correct spring load 0

The truck will not have braking if you do not put the adjuster plate in its original position 0

7 Put a thin layer of lubricant on the top surface of the adjuster plate to decrease the likelihood of bending the compression springs 0

8 Refer to Torque Gap Adjustment in the Brake section of this manual for the factory adjustments 0

Towing the Truck 0

Towing by Pulling in Power Unit First Direction 0

• The towed truck must always have 3 points touching the floor and/or the towing device 0

• The maximum travel speed while you tow the truck is 16 km/h (1 mph) 0

• Do not make sharp turns when you lift and tow this truck 0

• The floor must be flat, level, and clean 0

Fig 6 (26147) 0

Towing by Pushing in Forks First Direction 0

• The towed truck must always have 3 points touching the floor and/or the towing device 0

• The maximum travel speed while you tow the truck is 16 km/h (1 mph) 0

• Do not make sharp turns when you lift and tow this truck 0

• The floor must be flat, level, and clean 0

Fig 7 (26148) 0

Jacking and Blocking 0

1 Move the truck to a maintenance area that has a flat and level floor 0

2 No load on forks 0

3 Lockout/tagout the truck Refer to SAFETY>Control of Hazardous Energy>Lockout/Tagout 0

4 To lift the mainframe, refer to Figure 8 To lift the power unit, refer to Figure 9 0

Fig 8 (26149) 0

Fig 9 (26150) 0

5 Put chocks against the load wheels if the power unit is being lifted 0

6 Put the hydraulic jack in the cutout of the component being lifted 0

Do not raise the operator platform component more than 450 mm (18 in) from the floor 0

Truck stability decreases dramatically if the load wheels are raised more than 13 mm (05 in) 0

Do not put hardwood blocks at the back of the power unit between the jack notches Doing so can result in damage to the guidance sensor 0

7 Use the hydraulic jack and lift the truck enough to put a hardwood block below the mainframe or the power unit Then lower the truck onto the hardwood block 0

Fig 10 (26151) 0

Main Mast – TF & TN 0

1 Move the truck to a maintenance area that has a flat and level floor 0

2 Put chocks against the wheels of the truck to prevent movement of the truck Refer to SAFETY>Control of Hazardous Energy>Jacking and Blocking 0

3 Connect the battery 0

4 Raise the main mast to get the necessary second stage height and then put the applicable length blocks in each mainframe rail 0

5 Hold the blocks on the mainframe with a strap or clamp 0

6 Lower the mast onto the blocks and make sure the platform is against the stops 0

7 Lockout/tagout the truck Refer to SAFETY>Control of Hazardous Energy>Lockout/Tagout 0

Fig 11 (26276) 0

Main Mast – TT 0

1 Move the truck to a maintenance area that has a flat and level floor 0

2 Put chocks against the wheels of the truck to prevent movement of the truck Refer to SAFETY>Control of Hazardous Energy>Jacking and Blocking 0

3 Connect the battery 0

4 Remove the screw and nut from one end of the locking tube tool and put the tool through the first stage mast Then install the screw and nut back through the locking tube tool to secure it in position 0

5 Lower the mast until the second stage is on the locking tube tool and the platform is fully lowered 0

6 Lockout/tagout the truck Refer to SAFETY>Control of Hazardous Energy>Lockout/Tagout 0

Fig 12 (20176) 0

Blocking Third Stage Mast Above Second Stage Mast 0

1 Move the truck to a maintenance area that has a flat and level floor 0

2 Put chocks against the wheels of the truck to prevent movement of the truck Refer to SAFETY>Control of Hazardous Energy>Jacking and Blocking 0

3 Connect the battery 0

4 Refer to Figure 13 Raise the mast until there is a sufficient distance to install the two 100 x 75 x 355 mm (4 x 3 x 14 in) hardwood blocks into the second stage mast rails (I-beams) and the two 100 x 75 x 1219 mm (4 x 3 x 48 in) hardwood blocks 0

5 Refer to Figure 13 Attach the hardwood blocks to the mast rails with clamps or straps 0

Fig 13 (26153) 0

6 Refer to Figure 13 Lower the mast so the third stage mast is on the two 355 mm (14 in) long blocks and the platform is on the two 1219 mm (48 in) long blocks 0

7 Lockout/tagout the truck Refer to SAFETY>Control of Hazardous Energy>Lockout/Tagout 0

Auxiliary Mast 0

1 Move the truck to a maintenance area that has a flat and level floor 0

2 Put chocks against the wheels of the truck to prevent movement of the truck Refer to SAFETY>Control of Hazardous Energy>Jacking and Blocking 0

3 Connect the battery 0

4 Raise the fork carriage to get the correct height and then put the correct length blocks in each of the mast rails 0

5 Hold the hardwood blocks on the mast rails with a strap or clamp 0

6 Lower the fork carriage so the carriage is on the blocks 0

7 Lockout/tagout the truck Refer to SAFETY>Control of Hazardous Energy>Lockout/Tagout 0

Fig 14 (26277) 0

Platform – TT 0

1 Move the truck to a maintenance area that has a flat and level floor 0

2 Put chocks against the wheels of the truck to prevent movement of the truck Refer to SAFETY>Control of Hazardous Energy>Jacking and Blocking 0

3 Connect the battery 0

4 Raise the platform enough in free lift to put the jack stands or hardwood blocks in the channels of the mast 0

5 Lower the platform onto the jack stands or hardwood blocks 0

6 Lockout/tagout the truck Refer to SAFETY>Control of Hazardous Energy>Lockout/Tagout 0

Fig 15 (20178) 0

Height Sensor 0

The spring is reverse wound and if it is not kept restrained, it will unwind fully and then wind in the opposite direction Personal injury is possible if you do not use extreme caution It is recommended to wear safety glasses and gloves when you re 0

Tool Fabrication 0

Fig 16 (17667) 0

Spring Removal 0

1 Remove the height sensor from the truck and lock the sensor in a vice 0

When you remove the last screw, turn the cover approximately 5 revolutions to release the spring force 0

2 Remove the four screws from the reel cover and let the spring force release through cover rotation 0

3 Pull the cover approximately 254 mm (10 in) from the housing Then, using a screwdriver, slowly remove the arbor off the square shaft of the cover 0

4 Remove the cover from the spacer Remove the grease 0

5 Carefully pull the arbor from the spring using a needle nose pliers 0

6 Move the opening in the inner spacer around until you have access to the spring retainer screws 0

7 Remove the spring retainer screws 0

The spring is reverse wound and if it is not kept restrained, it will unwind fully and then wind in the opposite direction Personal injury is possible if you do not use extreme caution It is recommended to wear safety glasses and gloves when you re 0

8 Use a fabricated rod or screwdriver, start to remove the spring approximately 127 mm (05 in) out of the reel 0

Fig 17 (17680) 0

9 Hold the spring with locking pliers near the end of the spring on the outside diameter While you hold the locking pliers with one hand, remove the spring from the reel with the fabricated tool 0

Fig 18 (17681) 0

10 Carefully put cable ties around the spring so the locking pliers can be removed Discard the spring 0

Spring Installation 0

1 When the height sensor is ready to have the spring installed, put a locking pliers carefully on the reel shaft and secure the locking pliers to keep the reel from turning Put a bolt through the reel housing to lock the reel 0

Fig 19 (17636) 0

2 The new spring is shipped with a rod wrapped partially around the circumference of the spring and is tied with cable ties Make sure the rod is in the center of the spring and then remove the cable ties 0

3 Move the shipping rod around the circumference of the spring so the end of the spring extends out between the ends of the rod 0

4 Assemble the hook of the spring retainer in the hole of the spring The retainer mounting tab must be on the opposite side of the spring as the diagonally cut corner at the end of the spring 0

5 Put the inner spacer between the spring and the spring retainer so the raised portion of the spacer is away from the spring 0

6 Put the assembly into the reel, spring retainer first, and work the shipping bar to the outer edge of the spring Move the assembly around until the holes in the spring retainer and reel align Start the screws to hold the spring retainer to the reel 0

7 Carefully push the spring into the reel and let it expand in the reel Tighten the screws holding the spring retainer 0

8 Fully soak the spring with lubricant 063001-009 Use lubricant 063002-059 for trucks used for operation in a freezer 0

9 Put the arbor into the center of the spring so when the arbor is turned clockwise, the flat on the arbor pulls the spring 0

10 Put a layer of lubricant (063001-009) on the surfaces of the end spacer and position it in the reel housing 0

11 Put the square shaft of the cover into the arbor and put the cover against the housing Turn the cover clockwise five revolutions Then put the screws in and tighten them 0

Platform and Load Handler Lifting 0

Load Handler 0

1 Move the truck to a maintenance area that has a flat and level floor 0

2 Lower the main and auxiliary masts fully No load on forks 0

3 Lockout/tagout the truck Refer to SAFETY>Control of Hazardous Energy>Lockout/Tagout 0

4 Put chocks against the wheels of the truck to prevent movement of the truck Refer to SAFETY>Control of Hazardous Energy>Jacking and Blocking 0

5 Remove the top and bottom traverse stop blocks from the left end of the top and bottom traverse gear racks 0

6 Put the display in “Shipping Mode” 0

7 Connect a lift to the auxiliary mast and raise the load handler enough to move the load handler weight from the platform to the lift 0

8 Slowly power the load handler off the left end of the traverse gear racks by requesting “traverse left” using the thumb ball on the right multi-task handle Use precaution to prevent damage to the gang hose and load handler wire harness 0

9 Disconnect the load handler wire harness 0

10 Disconnect the hoses and seal the hose ends to prevent hydraulic system contamination 0

11 Carefully move the load handler away from the truck 0

Platform 0

1 Move the truck to a maintenance area that has a flat and level floor 0

2 Lower all the masts fully No load on forks 0

3 Lockout/tagout the truck Refer to SAFETY>Control of Hazardous Energy>Lockout/Tagout 0

4 Put chocks against the wheels of the truck to prevent movement of the truck Refer to SAFETY>Control of Hazardous Energy>Jacking and Blocking 0

5 Remove the load handler 0

6 Remove the spotlights and overhead fan from the overhead guard, if applicable 0

7 Put a 100 x 100 mm (4 x 4 in) hardwood block below the overhead guard, tight against the back of the platform Make sure the hardwood block is a minimum of 305 mm (120 in) longer than the overhead guard and is on center8 Use a 3-point hook-up and attach a strap, chain, etc to the hardwood block and the back of the overhead guard Raise the platform to the necessary height 0

9 Block or remove the platform Refer to PLATFORM>Platform>Removing the Platform for procedures to remove the platform 0

Fig 20 (17670) 0

Operator’s Daily Checklist 27

Lubricants, Aerosols, and Service Supplies 0

Metric Torque Values 48

Grade 48

SAE Torque Values 52

Grade 52

Introduction 0

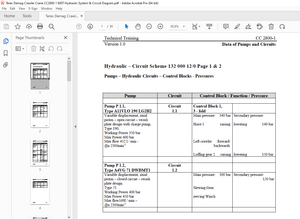

Hydraulic System119

General Information119

Hydraulic Plumbing and Fittings120

Reservoir and Filters120

Drift Tests122

Hydraulic Circuits123

Lift Circuit123

Lower Circuit124

Lower Circuit (MVL)125

Load Handler Circuit through the Mainframe Manifold Block126

Mainframe Manifold Auxiliary Circuit:126

Auxiliary Lift Circuit127

Auxiliary Lower Circuit128

Traverse Left Circuit129

Traverse Right Circuit130

Fork Extend Circuit132

Fork Retract Circuit134

Pivot Right Circuit136

Pivot Left Circuit138

Hydraulic Schematic Symbols141

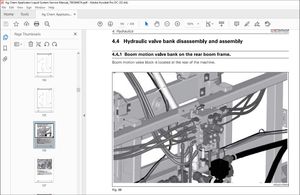

Manifolds148

Relief Valve (RV1)148

Manifold Block O-Ring Replacement148

Preparation Before Disassembly 0

Tools and Materials Required for Servicing 0

Reassembly 0

Final Checks 0

Traverse Motor170

Prepare the Traction Motor for Disassembly170

Traverse Motor Disassembly171

Traverse Motor Assembly178

Troubleshooting185

Drive Unit186

Drive Tire Replacement186

Changing the Oil187

Drive Unit Removal188

Drive Unit Installation189

Traction Motor Removal189

Traction Motor Installation189

Encoders190

Operation190

Wire designations190

Testing the encoders190

Channel feedback overview190

Index voltage overview191

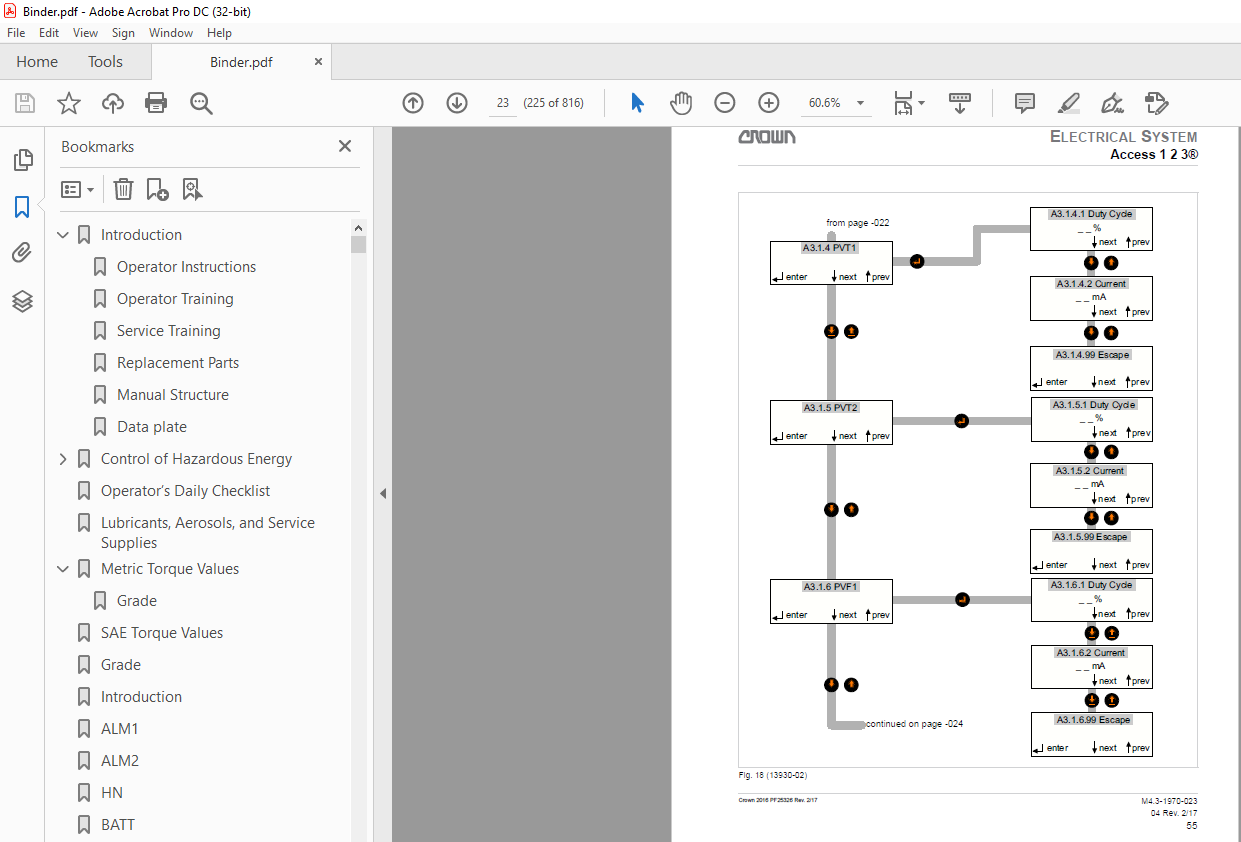

Access 1 2 3®203

Static Return to Off (SRO)203

Access 1 2 3® Menus203

User Codes204

Message Mode205

HOUR METERS Menu Description206

EVENT CODES Menu Description206

LEVEL 2 and LEVEL 3 Menu Description207

ANALYZER301

FEATURES Menus326

PERFORMANCE Menus345

PERFORMANCE Menu Overview345

CALIBRATION360

HOUR METERS377

EVENT CODES379

UTILITIES381

Guidance System384

Operation of the Wire Guidance System384

Steer Modes385

Sensors387

Line Driver Output387

Calibration389

Troubleshooting389

Contactors397

Emergency Disconnect Contactor (ED1)397

Contact Replacement398

Coil Replacement399

Logic Power Contactors (K2 & K3)399

Battery401

Safety Procedures402

Battery Inspection402

Battery Charging402

Battery Removal404

Battery Installation404

Battery Load Test405

Motors407

Event Codes408

Access Module Listing:408

Event Code 101409

Event Code 104410

Event Code 105411

Event Code 106412

Event Code 107413

Event Code 108413

Event Code 112414

Event Code 113414

Event Code 114414

Event Code 115414

Event Code 116414

Event Code 117414

Event Code 118415

Event Code 119415

Event Code 122415

Event Code 123415

Event Code 125415

Event Code 150415

Event Code 191416

Event Code 194416

Event Code 195416

Event Code 196416

Event Code 197416

Event Code 198416

Event Code 212416

Event Code 213417

Event Code 214417

Event Code 215417

Event Code 216417

Event Code 217418

Event Code 218418

Event Code 222418

Event Code 223418

Event Code 224419

Event Code 225419

Event Code 228420

Event Code 229420

Event Code 231420

Event Code 232421

Event Code 233422

Event Code 234424

Event Code 235425

Event Code 236426

Event Code 237426

Event Code 238427

Event Code 246427

Event Code 247427

Event Code 249427

Event Code 251427

Event Code 253427

Event Code 254427

Event Code 255428

Event Code 256428

Event Code 268428

Event Code 269428

Event Code 272429

Event Code 273429

Event Code 278430

Event Code 289430

Event Code 293430

Event Code 298430

Event Code 300430

Event Code 312431

Event Code 313431

Event Code 315431

Event Code 317431

Event Code 322432

Event Code 323433

Event Code 325433

Event Code 326434

Event Code 327434

Event Code 328435

Event Code 329435

Event Code 331435

Event Code 332436

Event Code 333436

Event Code 334437

Event Code 336437

Event Code 337438

Event Code 346438

Event Code 347438

Event Code 349438

Event Code 351438

Event Code 368438

Event Code 369439

Event Code 372439

Event Code 373440

Event Code 378440

Event Code 400440

Event Code 402441

Event Code 403442

Event Code 406443

Event Code 407443

Event Code 408444

Event Code 410445

Event Code 411445

Event Code 436446

Event Code 437446

Event Code 438446

Event Code 439447

Event Code 440447

Event Code 441448

Event Code 442448

Event Code 443449

Event Code 444449

Event Code 445449

Event Code 446450

Event Code 447451

Event Code 491451

Event Code 501451

Event Code 502452

Event Code 503453

Event Code 504453

Event Code 505454

Event Code 507454

Event Code 508455

Event Code 509455

Event Code 511456

Event Code 522456

Event Code 524457

Event Code 526457

Event Code 528458

Event Code 530458

Event Code 532459

Event Code 534459

Event Code 536460

Event Code 537460

Event Code 538461

Event Code 540461

Event Code 541462

Event Code 542463

Event Code 543463

Event Code 544464

Event Code 545464

Event Code 546464

Event Code 551465

Event Code 552465

Event Code 554465

Event Code 555465

Event Code 557466

Event Code 558466

Event Code 562467

Event Code 563468

Event Code 564468

Event Code 565468

Event Code 566469

Event Code 567469

Event Code 571469

Event Code 576470

Event Code 582470

Event Code 586471

Event Code 588472

Event Code 590473

Event Code 592473

Event Code 598473

Event Code 605474

Event Code 611474

Event Code 631474

Event Code 632474

Event Code 633475

Event Code 636476

Event Code 637476

Event Code 638476

Event Code 652477

Event Code 660478

Event Code 664478

Event Code 668478

Event Code 672478

Event Code 681479

Event Code 682479

Event Code 683479

Event Code 684479

Event Code 685480

Event Code 686480

Event Code 687480

Event Code 688480

Event Code 689480

Event Code 690481

Event Code 691481

Event Code 692481

Event Code 693481

Event Code 694481

Event Code 695481

Event Code 696482

Event Code 697482

Event Code 698482

Event Code 700483

Event Code 701484

Event Code 702485

Event Code 707486

Event Code 708487

Event Code 711488

Event Code 736488

Event Code 737488

Event Code 738489

Event Code 739489

Event Code 740490

Event Code 741490

Event Code 742491

Event Code 743491

Event Code 744492

Event Code 745492

Event Code 746493

Event Code 747494

Event Code 750494

Event Code 751495

Event Code 752496

Event Code 753496

Event Code 754497

Event Code 755498

Event Code 756498

Event Code 757499

Event Code 758500

Event Code 759500

Event Code 760501

Event Code 761501

Event Code 762502

Event Code 763502

Event Code 764503

Event Code 765503

Event Code 767504

Event Code 768504

Event Code 769505

Event Code 770505

Event Code 771505

Event Code 772506

Event Code 773506

Event Code 774507

Event Code 775507

Event Code 776507

Event Code 777508

Event Code 778509

Event Code 779509

Event Code 780509

Event Code 781510

Event Code 782511

Event Code 783512

Event Code 784512

Event Code 785513

Event Code 790513

Event Code 800513

Event Code 801514

Event Code 802515

Event Code 803516

Event Code 804517

Event Code 805518

Event Code 806519

Event Code 807520

Event Code 816521

Event Code 821521

Event Code 822521

Event Code 823521

Event Code 824522

Event Code 825522

Event Code 836523

Event Code 837523

Event Code 838524

Event Code 839524

Event Code 840525

Event Code 841526

Event Code 842526

Event Code 843526

Event Code 844527

Event Code 845527

Event Code 846527

Event Code 847528

Event Code 848529

Event Code 849531

Event Code 850532

Event Code 853532

Event Code 856533

Event Code 860533

Event Code 864534

Event Code 868534

Event Code 870535

Event Code 872536

Event Code 875537

Event Code 878538

Event Code Introduction540

Brake Force Adjustment 0

Torque Gap Adjustment 0

Air Gap Adjustment 0

Rotor and Brake Pad Replacement 0

Brake Assembly 0

Brake548

Stopping the Truck548

Stopping Distance Adjustment548

Torque Gap Adjustment548

Air Gap Adjustment551

Rotor and Brake Pad Replacement552

To Assemble the Brake554

Steering Gearbox558

Replacing Steering Gearbox558

Steer Motor563

Replacing the Steer Motor Brushes563

Steer Motor Replacement564

Steering Gearbox567

Steering Gearbox Replacement567

Hose Take-Up Cable574

Hose Take-Up Cable Replacement574

Mast 0

TN (Telescopic No Free Lift) Mast 0

TF (Telescopic Full Free Lift) Mast 0

TT (Triple Telescopic Full Free Lift) Mast 0

New Truck Installation Procedures 0

Second Stage Mast Removal and Installation – TF and TN 0

Second and Third Stage Mast Removal – TT 0

Second Stage Mast Installation – TF and TN 0

Second and Third Stage Mast Installation – TT 0

Side Thrust Roller Adjustment – TF, TN, and TT 0

Lift Chains614

Inspection614

Wear614

Corrosion615

Plates with Cracks615

Tight Joints616

Turned Pins616

Lift Chain Side Wear616

Lift Chain Lubrication617

Lift Chain Replacement617

Chain Leaf Disconnect617

Fork Inspection620

Abrasion620

Blade Measurement620

Hanger Bore Measurement621

Overloading623

Fatigue623

Bent or Twisted Forks623

Hanger624

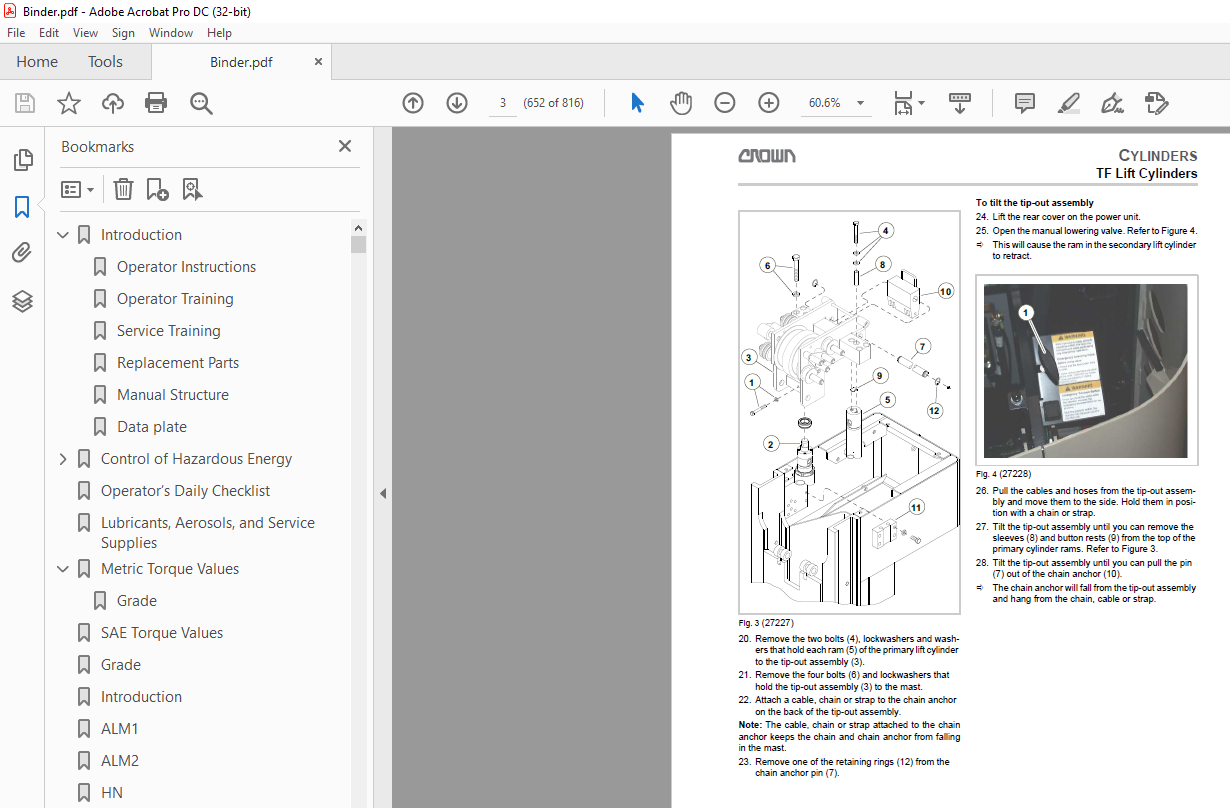

Pivoting The Tip-Out Assembly 0

Primary (Free) Lift Cylinder Repair 0

Cylinder Packing Installation 0

Reassembling Mast Tip-Out 0

Primary (Free) Lift Cylinder Removal 0

Secondary (Main) Lift Cylinder Removal 0

Primary (Free) Lift Cylinder Installation 0

Secondary (Main) Lift Cylinder Installation 0

Lift Cylinder Bleeding 0

Auxiliary Lift Cylinder Repair 0

Rod Packing Installation 0

Auxiliary Lift Cylinder Bleeding 0

Cylinder Disassembly 0

Piston Rod Disassembly 0

Cylinder Reassembly 0

Access to the Lift Cylinders650

To Replace the Seals in the PrimaryLift Cylinder653

Primary Lift Cylinder Removal656

Primary Lift Cylinder Installation657

Secondary Lift Cylinder Removal657

Secondary Lift Cylinder Installation658

To Bleed the Lift Cylinders659

Pivoting The Tip-Out Assembly 0

Lift Cylinder Repair 0

Cylinder Packing Installation 0

Reassembling Mast Tip-Out 0

Lift Cylinder Removal 0

Lift Cylinder Installation 0

Lift Cylinder Bleeding 0

Cylinder Removal 0

Cylinder Disassembly 0

Cylinder Reassembly 0

Cylinder Installation 0

Pivot Cylinder Bleeding 0

Access to the Lift Cylinder673

To Replace the Seals in the Lift Cylinder675

Lift Cylinder Removal678

Lift Cylinder Installation678

To Bleed the Lift Cylinders679

Pivot Cylinders695

General Information695

Basic Troubleshooting695

Pivot Cylinder Removal696

Pivot Cylinder Disassembly696

Assemble the Pivot Cylinder698

Pivot Cylinder Installation699

Pivot Cylinders Bleeding699

Inspection and Adjustment701

Lubrication702

Mast Shield702

Gates703

GTSL & GTSR704

Chain Anchor and Platform Height Adjustment704

Side Thrust Roller Adjustment – Platform (TF, TN and TT Mast)704

Traverse Hose Replacement705

Platform Removal706

Platform Assembly709

Seat Pivot Bearing Assembly710

Seat Rotate Switch Adjustment710

Seat Power Cable Installation711

Seat Up/Down Switch Adjustment712

Mirror Installation713

Mirror Adjustment715

Inspection and Adjustment 0

Lubrication 0

Mast Shield 0

Gates 0

GTSL & GTSR 0

Chain Anchor and Platform Height Adjustment 0

Side Thrust Roller Adjustment – Platform (TF, TN and TT Mast) 0

Traverse Hose Replacement 0

Platform Removal 0

Platform Assembly 0

Height Sensor Assembly – ECR5734

Height Sensor Assembly Removal734

Height Sensor Assembly Installation735

Height Sense Encoder (ECR5) Replacement736

Cable Replacement736

Height Sensor Assembly – ECR5738

Height Sensor Assembly Removal738

Height Sensor Assembly Installation739

Height Sense Encoder (ECR5) Replacement740

Cable Replacement740

Hydraulic Schematic813

IMAGES PREVIEW OF THE MANUAL: