$36

Cummins M11 Series Engines Shop Manual – PDF DOWNLOAD

Cummins M11 Series Engines Shop Manual – PDF DOWNLOAD

FILE DETAILS:

Cummins M11 Series Engines Shop Manual – PDF DOWNLOAD

Language : English

Pages : 585

Downloadable : Yes

File Type : PDF

Size: 14.5 MB

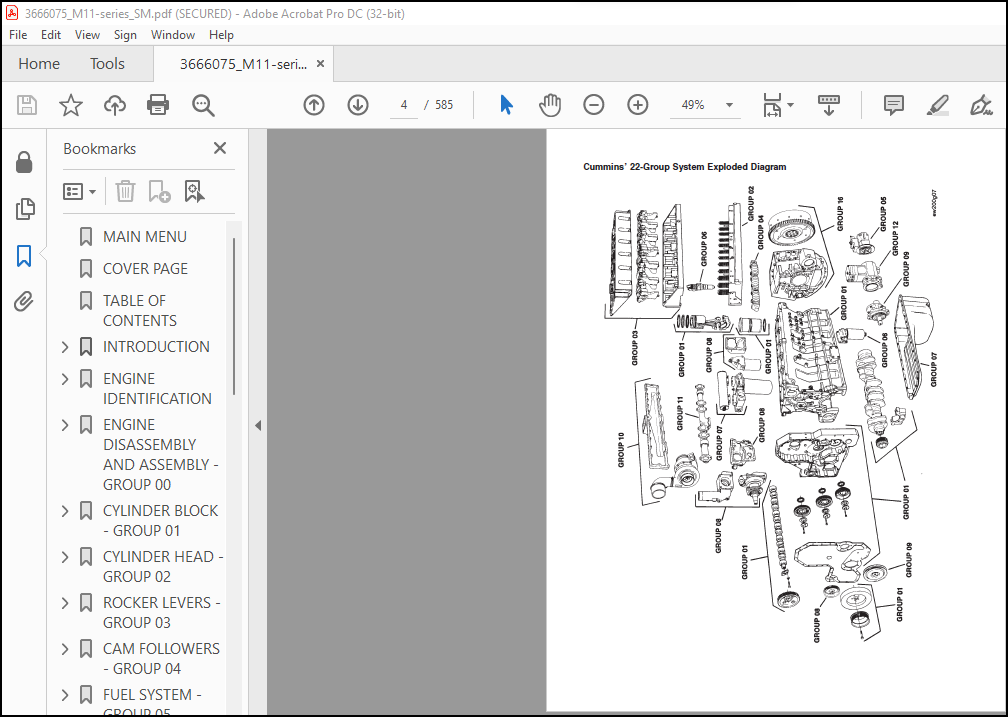

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Cummins M11 Series Engines Shop Manual – PDF DOWNLOAD

The Cummins M11 Series Engines Shop Manual is a technical reference guide designed to provide comprehensive information on the maintenance, repair, and overhaul of the Cummins M11 Series Engines. This engine series is a popular choice for heavy-duty applications such as construction equipment, mining, marine vessels, and on-highway trucks. The shop manual is an essential resource for mechanics, technicians, and service personnel who are responsible for servicing and maintaining these engines.

The Cummins M11 Series Engines Shop Manual covers all aspects of the engine, including the construction, operation, troubleshooting, and maintenance. It provides detailed instructions and specifications for disassembly, inspection, repair, assembly, and testing of engine components. The manual is organized into several sections, each of which covers a specific aspect of the engine. These sections include:

- Introduction: This section provides an overview of the M11 Series Engines, including specifications, application information, and general operating guidelines.

- Engine Disassembly and Assembly: This section provides detailed instructions for disassembling and assembling the engine, including removal and installation of major components such as the cylinder head, camshaft, crankshaft, pistons, and connecting rods. The manual includes detailed illustrations and specifications to help technicians perform these tasks safely and efficiently.

- Cylinder Block: This section provides information on the construction and maintenance of the engine block, including block disassembly and assembly, cylinder liner replacement, and bearing replacement.

- Cylinder Head: This section covers the removal and installation of the cylinder head, as well as cylinder head disassembly, inspection, and repair.

- Lubrication System: This section provides detailed information on the lubrication system, including oil pump removal and installation, oil filter replacement, and oil pressure testing.

- Cooling System: This section provides information on the engine’s cooling system, including water pump removal and installation, radiator removal and installation, and thermostat replacement.

- Fuel System: This section covers the engine’s fuel system, including fuel pump removal and installation, fuel injector replacement, and fuel system troubleshooting.

- Air Intake and Exhaust System: This section provides information on the engine’s air intake and exhaust system, including air filter replacement, turbocharger removal and installation, and exhaust manifold removal and installation.

- Electrical System: This section provides information on the engine’s electrical system, including alternator and starter motor removal and installation, as well as troubleshooting procedures for electrical faults.

The Cummins M11 Series Engines Shop Manual is an essential resource for maintaining and repairing these engines. It provides a comprehensive guide to servicing the engine and includes detailed instructions, specifications, and illustrations to help technicians perform tasks accurately and safely. The manual is a valuable tool for ensuring that Cummins M11 Series Engines continue to operate at peak performance, with maximum efficiency and reliability over their long service life.

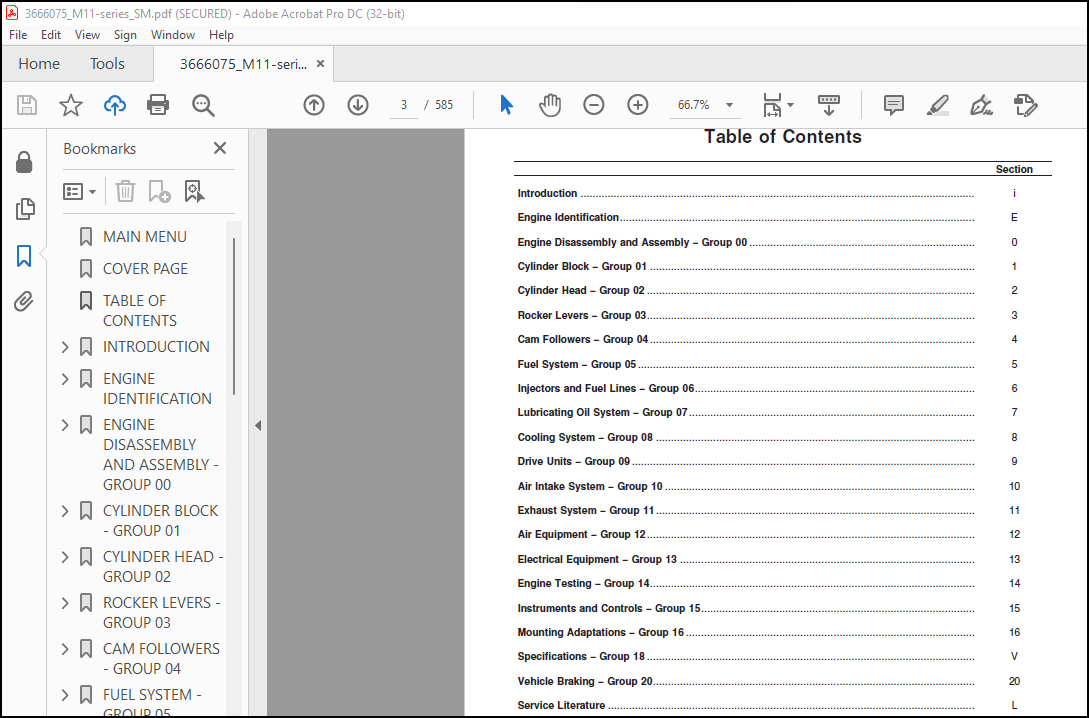

TABLE OF CONTENTS:

Cummins M11 Series Engines Shop Manual – PDF DOWNLOAD

MAIN MENU………………………………………………………………………….. 0

COVER PAGE…………………………………………………………………………. 1

TABLE OF CONTENTS…………………………………………………………………… 3

INTRODUCTION……………………………………………………………………….. 5

ABOUT THE MANUAL………………………………………………………………… 6

DEFINITION OF TERMS……………………………………………………………… 15

GENERAL CLEANING INSTRUCTIONS…………………………………………………….. 14

GLASS OR PLASTIC BEAD CLEANING………………………………………………… 14

SOLVENT OR ACID CLEANING……………………………………………………… 14

STEAM CLEANING………………………………………………………………. 14

GENERAL REPAIR INSTRUCTIONS………………………………………………………. 13

WELDING ON A CELECT CONTROLLED VEHICLE…………………………………………. 13

GENERAL SAFETY INSTRUCTIONS………………………………………………………. 12

IMPORTANT SAFETY NOTICE………………………………………………………. 12

HOW TO USE THE MANUAL……………………………………………………………. 6

ILLUSTRATIONS…………………………………………………………………… 11

SIMBOLOS……………………………………………………………………….. 8

SYMBOLE………………………………………………………………………… 9

SYMBOLES……………………………………………………………………….. 10

SYMBOLS………………………………………………………………………… 7

ENGINE IDENTIFICATION……………………………………………………………….. 19

ENGINE DIAGRAMS…………………………………………………………………. 24

ENGINE INDENTIFICATION…………………………………………………………… 20

ELECTRONIC CONTROL MODULE (ECM) DATAPLATE………………………………………. 20

ENGINE DATAPLATE…………………………………………………………….. 20

ENGINE SPECIFICATIONS……………………………………………………………. 21

AIR INTAKE SYSTEM……………………………………………………………. 22

BATTERIES (SPECIFIC GRAVITY)………………………………………………….. 23

COOLING SYSTEM………………………………………………………………. 22

ELECTRICAL SYSTEM……………………………………………………………. 23

EXHAUST SYSTEM………………………………………………………………. 22

FUEL SYSTEM…………………………………………………………………. 23

GENERAL ENGINE DATA………………………………………………………….. 21

LUBRICATING OIL SYSTEM……………………………………………………….. 22

ENGINE DISASSEMBLY AND ASSEMBLY – GROUP 00…………………………………………….. 25

ENGINE ASSEMBLY…………………………………………………………………. 74

ACCESSORY DRIVE ASSEMBLY – INSTALLATION…………………………………………110

ACCESSORY DRIVE OIL SEAL – INSTALLATION…………………………………………134

ACCESSORY DRIVE PULLEY – INSTALLATION…………………………………………..135

ACTUATOR HARNESS – INSTALLATION………………………………………………..145

AIR COMPRESSOR – INSTALLATION………………………………………………….150

AIR COMPRESSOR AIR SUPPLY TUBE – INSTALLATION……………………………………151

AIR COMPRESSOR COOLANT INLET TUBE FITTING – INSTALLATION………………………….149

AIR COMPRESSOR COOLANT OUTLET TUBE – INSTALLATION………………………………..155

AIR INTAKE MANIFOLD – INSTALLATION……………………………………………..163

ALTERNATOR – INSTALLATION……………………………………………………..166

ALTERNATOR AND BRACKET (BUS APPLICATIONS) – INSTALLATION………………………….167

ALTERNATOR BELT (NON BUS APPLICATIONS) – INSTALLATION…………………………….167

ALTERNATOR DRIVE BELT (BUS APPLICATIONS) – INSTALLATION…………………………..169

ALTERNATOR DRIVE PULLEY – INSTALLATION………………………………………….160

ALTERNATOR DRIVE SEAL – INSTALLATION……………………………………………160

AUTOMATIC BELT TENSIONER – INSTALLATION…………………………………………132

CAM FOLLOWER ASSEMBLIES – INSTALLATION………………………………………….114

CAMSHAFT AND GEAR ASSEMBLY – INSTALLATION……………………………………….106

CONNECTING ROD SIDE CLEARANCE MEASUREMENT……………………………………….103

COOLANT FILTER – INTSTALLATION…………………………………………………171

CRANKSHAFT – INSTALLATION…………………………………………………….. 81

CROSSHEADS – INSTALLATION……………………………………………………..137

CYLINDER BLOCK – INSTALLATION ON REBUILD STAND………………………………….. 74

CYLINDER HEAD – INSTALLATION…………………………………………………..116

CYLINDER LINERS – INSTALLATION………………………………………………… 74

DIPSTICK TUBE BRACKET – INSTALLATION……………………………………………162

DRAIN PLUGS – INSPECTION………………………………………………………171

ELECTRIC FAN CLUTCH (CUMMINS) – INSTALLATION…………………………………….156

ELECTRONIC CONTROL COOLING PLATE – INSTALLATION………………………………….153

ELECTRONIC CONTROL MODULE – INSTALLATION………………………………………..153

ENGINE – REMOVAL FROM THE REBUILD STAND…………………………………………157

EXHAUST MANIFOLD – INSTALLATION………………………………………………..162

FAN BELT – INSTALLATION……………………………………………………….169

FAN HUB (BELT DRIVEN) – INSTALLATION……………………………………………156

FAN HUB SUPPORT – INSTALLATION…………………………………………………155

FAN IDLER PULLEY – INSTALLATION………………………………………………..156

FAN PULLEY AND FAN – INSTALLATION………………………………………………169

FLYWHEEL – INSTALLATION………………………………………………………. 96

FLYWHEEL BORE RUNOUT – MEASUREMENT…………………………………………….. 96

FLYWHEEL FACE RUNOUT – MEASUREMENT…………………………………………….. 98

FLYWHEEL HOUSING – INSTALLATION……………………………………………….. 87

FLYWHEEL HOUSING BORE ALIGNMENT – MEASUREMENT…………………………………… 90

FLYWHEEL HOUSING FACE ALIGNMENT – MEASUREMENT…………………………………… 91

FLYWHEEL HOUSING, REPTO – INSTALLATION…………………………………………. 88

FRONT CRANKSHAFT OIL SEAL – INSTALLATION………………………………………..132

FUEL FILTER – INSTALLATION…………………………………………………….170

FUEL FILTER HEAD AND BRACKET – INSTALLATION……………………………………..154

FUEL PUMP PLUMBING – INSTALLATION………………………………………………154

FUEL PUMP SUPPORT BRACKET – INSTALLATION………………………………………..150

FUEL PUMP (WITH AIR COMPRESSOR) – INSTALLATION…………………………………..152

FUEL PUMP (WITHOUT AIR COMPRESSOR) – INSTALLATION………………………………..152

GEAR COVER – INSTALLATION……………………………………………………..130

GEAR HOUSING – INSTALLATION……………………………………………………104

HAND HOLE COVER (EXHAUST SIDE OF ENGINE ) – INSTALLATION………………………….162

HAND HOLE COVER (FUEL PUMP SIDE OF ENGINE ) – INSTALLATION………………………..149

HIGH OIL PRESSURE REGULATOR – INSTALLATION……………………………………… 85

HYDRAULIC PUMP DRIVE – INSTALLATION…………………………………………….109

IDLER GEAR ASSEMBLIES – INSTALLATION……………………………………………111

IDLER GEAR (REPTO) – INSTALLATION……………………………………………… 92

INJECTORS – INSTALLATION………………………………………………………136

JACOBS BRAKE HOUSING SPACER – INSTALLATION………………………………………148

JACOBS BRAKE OIL SUPPLY HOSE – INSTALLATION……………………………………..162

JACOBS ENGINE BRAKE – INSTALLATION……………………………………………..140

LUBRICATING OIL COOLER – INSTALLATION…………………………………………..161

LUBRICATING OIL FILTER – INSTALLATION…………………………………………..170

LUBRICATING OIL FILTER HEAD – INSTALLATION………………………………………160

LUBRICATING OIL PAN – INSTALLATION……………………………………………..105

LUBRICATING OIL PUMP – INSTALLATION…………………………………………….108

MAIN OIL PRESSURE REGULATOR – INSTALLATION……………………………………… 86

OVERHEAD – ADJUSTMENT…………………………………………………………141

PISTON AND CONNECTING ROD – ASSEMBLY…………………………………………… 99

PISTON AND CONNECTING ROD – INSTALLATION………………………………………..100

PISTON COOLING NOOZLE – INSTALLATION……………………………………………103

PUSH RODS AND TUBES – INSTALLATION……………………………………………..140

REAR CRANKSHAFT OIL SEAL – INSTALLATION………………………………………… 95

ROCKER LEVER ASSEMBLIES – INSTALLATION………………………………………….137

ROCKER LEVER COVER – INSTALLATION………………………………………………149

ROCKER LEVER HOUSING – INSTALLATION…………………………………………….135

ROCKER LEVER SIDE CLEARANCE – ADJUSTMENT………………………………………..138

SENSOR HARNESS – INSTALLATION………………………………………………….147

STARTING MOTOR – INSTALLATION………………………………………………….155

STATIC INJECTION TIMING – CHECKING……………………………………………..121

STATIC INJECTION TIMING – GENERAL INFORMATION……………………………………120

THERMOSTAT HOUSING – INSTALLATION………………………………………………166

THERMOSTAT HOUSING SUPPORT – INSTALLATION……………………………………….159

THRUST BEARING, LOWER BEARING SHELLS AND MAIN BEARING CAPS – INSTALLATION………….. 81

TORQUE CONVERTER COOLER DISC – INSTALLATION……………………………………..165

TURBOCHARGER – INSTALLATION……………………………………………………164

TURBOCHARGER DRAIN FITTING – INSTALLATION……………………………………….164

UPPER MAIN BEARING SHELLS – INFORMATION………………………………………… 80

VIBRATION DAMPER AND CRANKSHAFT PULLEY – INSTALLATION…………………………….133

VIBRATION DAMPER ECCENTRICITY – MEASUREMENT……………………………………..134

VIBRATION DAMPER FACE – RUNOUT MEASUREMENT………………………………………134

VISCOSITY SENSOR – INSTALLATION……………………………………………….. 86

WATER FILTER HEAD – INSTALLATION……………………………………………….158

WATER HEADER PLATE – INSTALLATION………………………………………………158

WATER HEATER HOUSING – INSTALLATION…………………………………………….158

WATER PUMP – INSTALLATION……………………………………………………..159

ENGINE DISASSEMBLY………………………………………………………………. 36

ACCESSORY DRIVE ASSEMBLY – REMOVAL…………………………………………….. 62

ACCESSORY DRIVE OIL SEAL – REMOVAL…………………………………………….. 62

ACCESSORY DRIVE PULLEY – REMOVAL………………………………………………. 61

AIR COMPRESSOR – REMOVAL……………………………………………………… 49

AIR COMPRESSOR AIR SUPPLY TUBE – REMOVAL……………………………………….. 48

AIR COMPRESSOR COOLANT TUBES – REMOVAL…………………………………………. 50

AIR INTAKE MANIFOLD – REMOVAL…………………………………………………. 41

ALTERNATOR ADJUSTING LINK (NON BUS APPLICATIONS) – REMOVAL……………………….. 39

ALTERNATOR AND BRACKET (NON BUS APPLICATIONS) – REMOVAL………………………….. 39

ALTERNATOR AND BRACKETS (BUS APPLICATIONS)……………………………………… 40

ALTERNATOR BELT (BUS APPLICATIONS) – REMOVAL……………………………………. 39

ALTERNATOR BELT (NON BUS APPLICATIONS) – REMOVAL………………………………… 38

ALTERNATOR DRIVE OIL SEAL – REMOVAL……………………………………………. 43

ALTERNATOR DRIVE PULLEY – REMOVAL……………………………………………… 43

BLOCK MOUNTED FRONT SUMP SUCTION TUBE – REMOVAL…………………………………. 57

CAM FOLLOWER ASSEMBLIES – REMOVAL……………………………………………… 56

CAMSHAFT – REMOVAL…………………………………………………………… 64

COOLANT – DRAINING…………………………………………………………… 36

COOLANT FILTER – REMOVAL……………………………………………………… 37

CRANKSHAFT AND UPPER MAIN BEARING SHELLS – REMOVAL………………………………. 70

CRANKSHAFT FRONT OIL SEAL – REMOVAL……………………………………………. 63

CRANKSHAFT PULLEY AND VIBRATION DAMPER – REMOVAL………………………………… 62

CRANKSHAFT REAR OIL SEAL – REMOVAL…………………………………………….. 59

CROSSHEADS – REMOVAL…………………………………………………………. 55

CYLINDER HEAD – REMOVAL………………………………………………………. 55

CYLINDER LINERS – REMOVAL…………………………………………………….. 71

ELECTRONIC CONTROL COOLING PLATE – REMOVAL……………………………………… 48

ELECTRONIC CONTROL MODULE – REMOVAL……………………………………………. 47

ENGINE – CLEANING……………………………………………………………. 36

ENGINE – INSTALLATION ON REBUILD STAND…………………………………………. 46

ENGINE – PREPARATION FOR CLEANING……………………………………………… 36

ENGINE BARRING TOOL – INSTALLATION…………………………………………….. 66

EXHAUST MANIFOLD – REMOVAL……………………………………………………. 41

FAN AND FAN HUB – REMOVAL…………………………………………………….. 38

FAN DRIVE BELT – REMOVAL……………………………………………………… 37

FAN HUB SUPPORT – REMOVAL…………………………………………………….. 47

FLYWHEEL – REMOVAL…………………………………………………………… 58

FLYWHEEL HOUSING – REMOVAL……………………………………………………. 59

FLYWHEEL HOUSING, REPTO – REMOVAL……………………………………………… 59

FRONT ENGINE SUPPORT BRACKET – REMOVAL…………………………………………. 63

FUEL FILTER – REMOVAL………………………………………………………… 37

FUEL LINES – REMOVAL…………………………………………………………. 49

FUEL PUMP – REMOVAL………………………………………………………….. 49

FUEL SUPPLY HOSE AND FILTER HEAD – REMOVAL……………………………………… 47

GEAR COVER – REMOVAL…………………………………………………………. 63

GEAR HOUSING – REMOVAL……………………………………………………….. 65

HAND HOLE COVER AND DIPSTICK TUBE BRACKET – REMOVAL……………………………… 45

HAND HOLE COVER (FUEL PUMP SIDE) – REMOVAL……………………………………… 50

HIGH OIL PRESSURE REGULATOR – REMOVAL………………………………………….. 71

HYDRAULIC PUMP DRIVE – REMOVAL………………………………………………… 50

HYDRAULIC PUMP OR COVER – REMOVAL……………………………………………… 50

IDLER GEAR ASSEMBLIES – REMOVAL……………………………………………….. 63

INJECTORS – REMOVAL………………………………………………………….. 55

INTERNAL ACTUATOR HARNESS – REMOVAL……………………………………………. 53

JACOBS ENGINE BRAKE – REMOVAL…………………………………………………. 52

LIFTING BRACKETS – REMOVAL……………………………………………………. 46

LUBRICATING OIL – DRAINING……………………………………………………. 36

LUBRICATING OIL COOLER – REMOVAL………………………………………………. 42

LUBRICATING OIL FILTER HEAD – REMOVAL………………………………………….. 42

LUBRICATING OIL FILTERS – REMOVAL……………………………………………… 37

LUBRICATING OIL PAN – REMOVAL…………………………………………………. 57

LUBRICATING OIL PUMP – REMOVAL………………………………………………… 64

LUBRICATING OIL TRANSFER TUBE – REMOVAL………………………………………… 57

MAIN BEARING CAPS, LOWER BEARING SHELLS AND THRUST BEARINGS – REMOVAL……………… 68

MAIN OIL PRESSURE REGULATOR – REMOVAL………………………………………….. 70

PISTON COOLING NOZZLES – REMOVAL………………………………………………. 66

PISTONS AND CONNECTING ROD – DISASSEMBLY……………………………………….. 72

PISTONS AND CONNECTING RODS – REMOVAL………………………………………….. 66

PUSH RODS – REMOVAL………………………………………………………….. 54

ROCKER LEVER ASSEMBLIES – REMOVAL …………………………………………….. 54

ROCKER LEVER COVER – REMOVAL………………………………………………….. 51

ROCKER LEVER HOUSING – REMOVAL………………………………………………… 55

ROCKER LEVER HOUSING SPACER – REMOVAL………………………………………….. 52

SENSOR HARNESS AND SENSORS REMOVAL…………………………………………….. 51

STARTING MOTOR – REMOVAL……………………………………………………… 48

THERMOSTAT HOUSING – REMOVAL………………………………………………….. 42

THERMOSTAT HOUSING SUPPORT – REMOVAL…………………………………………… 44

TORQUE CONVERTER COOLER DISC – REMOVAL…………………………………………. 42

TURBOCHARGER – REMOVAL……………………………………………………….. 40

TURBOCHARGER OIL DRAIN CONNECTION – REMOVAL…………………………………….. 45

VISCOSITY SENSOR – REMOVAL……………………………………………………. 70

WATER FILTER HEAD – REMOVAL…………………………………………………… 45

WATER HEADER PLATE – REMOVAL………………………………………………….. 45

WATER HEATER HOUSING – REMOVAL………………………………………………… 44

WATER PUMP – REMOVAL…………………………………………………………. 44

ENGINE DISASSEMBLY AND ASSEMBLY – GENERAL INFORMATION……………………………….. 34

ASSEMBLY……………………………………………………………………. 34

DISASSEMBLY…………………………………………………………………. 34

ENGINE LIFTING BRACKETS………………………………………………………. 35

SERVICE TOOLS – DISASSEMBLY AND ASSEMBLY…………………………………………… 28

CYLINDER BLOCK – GROUP 01…………………………………………………………….173

CAMSHAFT – CLEANING AND INSPECTION FOR REUSE………………………………………..220

CLEANING…………………………………………………………………….220

INSPECTION…………………………………………………………………..221

CAMSHAFT – MAGNETIC CRACK INSPECTION……………………………………………….226

BEARING JOURNAL – LIMITS OF ACCEPTANCE………………………………………….228

DEFINITIONS OF INDICATIONS…………………………………………………….227

VALVE AND INJECTOR LOBE – LIMITS OF ACCEPTANCE…………………………………..228

CAMSHAFT BUSHING – REPLACEMENT…………………………………………………….192

CLEANING…………………………………………………………………….192

INSPECTION…………………………………………………………………..193

INSTALLATION…………………………………………………………………193

REMOVAL……………………………………………………………………..192

CAMSHAFT GEAR – REPLACEMENT……………………………………………………….222

CLEANING…………………………………………………………………….223

INSPECTION…………………………………………………………………..223

INSTALLATION…………………………………………………………………225

REMOVAL……………………………………………………………………..222

CAMSHAFT OR IDLER GEAR – MAGNETIC CRACK INSPECTION…………………………………..229

CAMSHAFT OR IDLER GEAR – LIMITS OF ACCEPTANCE……………………………………230

DEFINITIONS OF INDICATION……………………………………………………..230

CONNECTING ROD – BEND AND TWIST INSPECTION………………………………………….218

ALIGNMENT INSPECTION………………………………………………………….220

FIXTURE CALIBRATION…………………………………………………………..218

TWIST INSPECTION……………………………………………………………..220

CONNECTING ROD – CLEANING AND INSPECTION FOR REUSE…………………………………..214

CLEANING…………………………………………………………………….214

INSPECTION…………………………………………………………………..215

CONNECTING ROD – MAGNETIC CRACK INSPECTION …………………………………………217

CONNECTING ROD – LIMITS OF ACCEPTANCE…………………………………………..218

CONNECTING ROD BEARINGS – CLEANING AND INSPECTION FOR REUSE…………………………..208

CLEANING…………………………………………………………………….208

INSPECTION…………………………………………………………………..208

CRANKSHAFT – CLEANING AND INSPECTIONS FOR REUSE……………………………………..200

CLEANING…………………………………………………………………….200

INSPECTION…………………………………………………………………..200

CRANKSHAFT GEAR – REPLACEMENT……………………………………………………..211

INSPECTION…………………………………………………………………..211

INSTALLATION…………………………………………………………………212

REMOVAL……………………………………………………………………..211

CRANKSHAFT MAGNETIC CRACK INSPECTION……………………………………………….202

COIL SHOT (CIRCUMFERENTAL MAGNETIZATION)………………………………………..203

HEAD SHOT (LONGITUDINAL MAGNETIZATION)………………………………………….202

MAGNETIC INSPECTION – LIMITS OF ACCEPTANCE………………………………………204

CRANKSHAFT PULLEY – CLEANING AND INSPECTION FOR REUSE………………………………..213

CLEANING…………………………………………………………………….213

INSPECTION…………………………………………………………………..214

CYLINDER BLOCK – EXPLODED VIEW…………………………………………………….178

CYLINDER BLOCK – GENERAL INFORMATION……………………………………………….179

CYLINDER BLOCK – INSPECTION FOR REUSE………………………………………………185

CAMSHAFT BUSHING INSIDE DIAMETER……………………………………………….192

CYLINDER LINER BORES – INSPECTION………………………………………………185

HIGH OIL PRESSURE REGULATOR SEAT DEPTH – MEASUREMENT……………………………..191

IDLER GEAR RING DOWEL BORE – MEASUREMENT………………………………………..191

MAIN BEARING BORE ALIGNMENT – INSPECTION………………………………………..186

MAIN BEARING BORE INSIDE DIAMETER – MEASUREMENT………………………………….190

MAIN OIL PRESSURE REGULATOR VALVE BORE – MEASUREMENT……………………………..191

THRUST BEARING SURFACE WIDTH – MEASUREMENT………………………………………190

CYLINDER BLOCK…………………………………………………………………..179

ASSEMBLY…………………………………………………………………….183

CAM FOLLOWER STUDS – INSTALLATION…………………………………………..184

DOWEL PINS – INSTALLATION………………………………………………….184

PIPE PLUGS – INSTALLATION………………………………………………….183

CLEANING…………………………………………………………………….181

DISASSEMBLY………………………………………………………………….179

CAM FOLLOWER STUDS – REMOVAL……………………………………………….181

DOWEL PINS – REMOVAL………………………………………………………180

IDLER SHAFT RING DOWELS – REMOVAL…………………………………………..181

PIPE PLUGS – REMOVAL………………………………………………………180

CYLINDER LINER – CLEANING AND INSPECTION FOR REUSE…………………………………..194

CLEANING…………………………………………………………………….194

INSPECTION…………………………………………………………………..195

DIPSTICK TUBE BRACKET – CLEANING AND INSPECTION FOR REUSE…………………………….237

CLEANING…………………………………………………………………….237

INSPECTION…………………………………………………………………..238

GEAR COVER – CLEANING AND INSPECTION FOR REUSE………………………………………236

CLEANING…………………………………………………………………….236

INSPECTION…………………………………………………………………..236

GEAR HOUSING – CLEANING AND INSPECTION FOR REUSE…………………………………….234

CLEANING…………………………………………………………………….234

INSPECTION…………………………………………………………………..235

NEEDLE BEARING INSTALLATION……………………………………………………235

HAND HOLE COVER – CLEANING AND INSPECTION FOR REUSE………………………………….237

CLEANING…………………………………………………………………….237

INSPECTION…………………………………………………………………..237

IDLER GEAR ASSEMBLY – CLEANING AND INSPECTION FOR REUSE………………………………197

CLEANING ……………………………………………………………………197

INSPECTION…………………………………………………………………..198

MAIN BEARINGS – CLEANING AND INSPECTION FOR REUSE……………………………………207

CLEANING…………………………………………………………………….207

INSPECTION…………………………………………………………………..207

PISTON – CLEANING AND INSPECTION FOR REUSE………………………………………….231

CLEANING…………………………………………………………………….231

INSPECTION…………………………………………………………………..232

PISTION RINGS – REMOVAL……………………………………………………….231

SERVICE TOOLS – CYLINDER BLOCK…………………………………………………….175

VIBRATION DAMPER (VISCOUS) – CLEANING AND INSPECTION FOR REUSE………………………..209

CLEANING…………………………………………………………………….209

INSPECTION…………………………………………………………………..209

CYLINDER HEAD – GROUP 02……………………………………………………………..239

CYLINDER HEAD – CLEANING AND INSPECTION FOR REUSE……………………………………245

CLEANING…………………………………………………………………….245

INSPECTION…………………………………………………………………..246

CYLINDER HEAD – EXPLODED VIEW……………………………………………………..244

CYLINDER HEAD – GENERAL INFORMATION………………………………………………..245

CYLINDER HEAD – PRESSURE TEST FOR REUSE…………………………………………….267

CYLINDER HEAD – REBUILD…………………………………………………………..246

ASSEMBLY…………………………………………………………………….256

DISASSEMBLY………………………………………………………………….246

INSPECTION…………………………………………………………………..248

VALVE SEATS – GRINDING………………………………………………………..255

CYLINDER HEAD – VACUUM TEST VALVE SEATING…………………………………………..269

CYLINDER HEAD – VALVE GRINDING…………………………………………………….263

INSPECTION…………………………………………………………………..263

CYLINDER HEAD INJECTOR SLEEVE – REPLACEMENT…………………………………………264

ASSEMBLY…………………………………………………………………….265

DISASSEMBLY………………………………………………………………….264

INSPECTION…………………………………………………………………..264

CYLINDER HEAD OVERSIZE VALVE SEAT INSERT – INSTALLATION………………………………262

CYLINDER HEAD VALVE GUIDE – REPLACEMENT…………………………………………….258

ASSEMBLY…………………………………………………………………….259

DISASSEMBLY………………………………………………………………….258

ASSEMBLY…………………………………………………………………….259

CYLINDER HEAD VALVE SEAT INSERT – REPLACEMENT……………………………………….260

ASSEMBLY…………………………………………………………………….261

DISASSEMBLY………………………………………………………………….260

INSPECTION…………………………………………………………………..260

CYLINDER HEAD VALVES – MAGNETIC CRACK INSPECTION…………………………………….271

SERVICE TOOLS – CYLINDER HEAD……………………………………………………..240

VALVE CROSSHEAD – CLEANING AND INSPECTION FOR REUSE………………………………….272

CLEANING…………………………………………………………………….272

INSPECTION…………………………………………………………………..272

VALVE CROSSHEAD – MAGNETIC CRACK INSPECTION…………………………………………272

ROCKER LEVERS – GROUP 03……………………………………………………………..275

CRANKCASE BREATHER (INTERNAL) – CLEANING AND INSPECTION………………………………290

ROCKER HOUSING AND COVER (AUTOMOTIVE) – EXPLODED VIEW………………………………..278

ROCKER LEVER – MAGNETIC CRACK INSPECTION……………………………………………289

ROCKER LEVER ASSEMBLY – CLEANING AND INSPECTION FOR REUSE…………………………….279

ASSEMBLY…………………………………………………………………….281

DISASSEMBLY………………………………………………………………….279

INSPECTION…………………………………………………………………..280

ROCKER LEVER ASSEMBLY – REBUILD……………………………………………………283

ASSEMBLY…………………………………………………………………….286

DISASSEMBLY………………………………………………………………….283

INSPECTION…………………………………………………………………..284

ROCKER LEVER BUSHING – REPLACEMENT…………………………………………………287

ASSEMBLY…………………………………………………………………….288

DISASSEMBLY………………………………………………………………….287

INSPECTION…………………………………………………………………..288

ROCKER LEVER COVER – CLEANING AND INSPECTION FOR REUSE……………………………….290

CLEANING…………………………………………………………………….290

INSPECTION…………………………………………………………………..290

ROCKER LEVER HOUSING – CLEANING AND INSPECTION FOR REUSE……………………………..289

CLEANING…………………………………………………………………….289

INSPECTION…………………………………………………………………..289

ROCKER LEVERS – EXPLODED VIEW……………………………………………………..277

ROCKER LEVERS – GENERAL INFORMATION………………………………………………..279

SERVICE TOOLS – ROCKER LEVERS……………………………………………………..276

CAM FOLLOWERS – GROUP 04……………………………………………………………..291

CAM FOLLOWER ASSEMBLY – CLEANING AND INSPECTION FOR REUSE…………………………….294

ASSEMBLY…………………………………………………………………….297

DISASSEMBLY………………………………………………………………….294

INSPECTION…………………………………………………………………..295

CAM FOLLOWER ASSEMBLY – EXPLODED VIEW ……………………………………………..293

CAM FOLLOWER ASSEMBLY – GENERAL INFORMATION…………………………………………294

CAM FOLLOWER ASSEMBLY – REBUILD……………………………………………………298

ASSEMBLY…………………………………………………………………….302

DISASSEMBLY………………………………………………………………….298

INSPECTION…………………………………………………………………..299

CAM FOLLOWER LEVER – MAGNETIC CRACK INSPECTION (ROLLER REMOVED)……………………….307

CAM FOLLOWER LEVER – ROLLER REPLACEMENT…………………………………………….303

ASSEMBLY…………………………………………………………………….305

DISASSEMBLY………………………………………………………………….303

INSPECTION…………………………………………………………………..304

CAM FOLLOWER LEVER SOCKET – REPLACEMENT (ROLLER REMOVED)……………………………..308

ASSEMBLY…………………………………………………………………….309

DISASSEMBLY………………………………………………………………….308

INSPECTION…………………………………………………………………..308

PUSH RODS AND TUBES – CLEANING AND INSPECTION FOR REUSE………………………………309

INSPECTION…………………………………………………………………..309

SERVICE TOOLS – CAM FOLLOWER ASSEMBLY………………………………………………292

FUEL SYSTEM – GROUP 05……………………………………………………………….311

FUEL PUMP – CLEANING AND INSPECTION FOR REUSE……………………………………….312

CLEANING…………………………………………………………………….312

INSPECTION…………………………………………………………………..313

FUEL PUMP – GENERAL INFORMATION……………………………………………………312

FUEL PUMP – REBUILD………………………………………………………………314

ASSEMBLY…………………………………………………………………….318

DISASSEMBLY………………………………………………………………….314

FUEL DAMPER – ASSEMBLY………………………………………………………..321

FUEL DAMPER – DISASSEMBLY AND INSPECTION………………………………………..321

FUEL SHUTOFF VALVE – ASSEMBLY………………………………………………….322

FUEL SHUTOFF VALVE – CLEANING AND INSPECTION…………………………………….322

FUEL SHUTOFF VALVE – DISASSEMBLY……………………………………………….321

FUEL SUPPLY PUMP – TEST……………………………………………………….323

INSPECTION…………………………………………………………………..316

INJECTORS AND FUEL LINES – GROUP 06……………………………………………………325

FUEL TUBES, FITTINGS AND MOUNTING PARTS – CLEANING AND INSPECTION FOR REUSE…………….330

INSPECTION…………………………………………………………………..330

INJECTOR – CELECT – EXPLODED VIEW………………………………………………….326

INJECTORS – CALIBRATION…………………………………………………………..329

INJECTORS – CLEANING AND INSPECTION FOR REUSE……………………………………….328

INSPECTION…………………………………………………………………..328

INJECTORS – GENERAL INFORMATION……………………………………………………327

INJECTORS – REBUILD………………………………………………………………329

LUBRICATING OIL SYSTEM – GROUP 07……………………………………………………..331

LUBRICATING OIL COOLER – CLEANING AND INSPECTION FOR REUSE……………………………342

CLEANING…………………………………………………………………….342

INSPECTION…………………………………………………………………..342

PRESSURE TEST THE OIL COOLER ELEMENT……………………………………………343

LUBRICATING OIL DIPSTICK – CALIBRATION……………………………………………..337

LUBRICATING OIL DIPSTICK AND DIPSTICK TUBE – CLEANING AND INSPECTION FOR REUSE………….337

CLEANING ……………………………………………………………………337

INSPECTION…………………………………………………………………..337

LUBRICATING OIL FILTER HEAD – CLEANING AND INSPECTION FOR REUSE……………………….338

CLEANING…………………………………………………………………….338

INSPECTION…………………………………………………………………..339

LUBRICATING OIL FILTER HEAD – REBUILD………………………………………………339

ASSEMBLY…………………………………………………………………….341

DISASSEMBLY………………………………………………………………….339

LUBRICATING OIL PAN – CLEANING AND INSPECTION FOR REUSE………………………………335

CLEANING…………………………………………………………………….335

INSPECTION…………………………………………………………………..335

LUBRICATING OIL PAN TRANSFER TUBE – CLEANING AND INSPECTION FOR REUSE………………….336

CLEANING…………………………………………………………………….336

INSPECTION…………………………………………………………………..336

LUBRICATING OIL PUMP – CLEANING AND INSPECTION FOR REUSE……………………………..344

ASSEMBLY…………………………………………………………………….347

CLEANING…………………………………………………………………….344

DISASSEMBLY………………………………………………………………….345

INSPECTION…………………………………………………………………..346

LUBRICATING OIL PUMP – REBUILD…………………………………………………….349

LUBRICATING OIL SYSTEM – EXPLODED VIEW……………………………………………..333

LUBRICATING OIL SYSTEM – GENERAL INFORMATION………………………………………..335

SERVICE TOOLS – LUBRICATING OIL SYSTEM……………………………………………..332

COOLING SYSTEM – GROUP 08…………………………………………………………….351

FAN HUB – CLEANING AND INSPECTION FOR REUSE…………………………………………373

CLEANING…………………………………………………………………….373

INSPECTION…………………………………………………………………..373

FAN HUB – EXPLODED VIEW…………………………………………………………..355

FAN HUB AND FAN IDLER PULLEY – GENERAL INFORMATION…………………………………..357

FAN HUB (BELT DRIVEN) – REBUILD……………………………………………………373

ASSEMBLY…………………………………………………………………….378

CLEANING…………………………………………………………………….375

DISASSEMBLY………………………………………………………………….373

INSPECTION…………………………………………………………………..376

FAN IDLER PULLEY – CLEANING AND INSPECTION FOR REUSE…………………………………383

CLEANING…………………………………………………………………….383

INSPECTION…………………………………………………………………..383

FAN IDLER PULLEY – REBUILD………………………………………………………..383

ASSEMBLY…………………………………………………………………….387

CLEANING…………………………………………………………………….386

DISASSEMBLY………………………………………………………………….383

INSPECTION…………………………………………………………………..386

FAN IDLER PULLEY AND BRACKET – EXPLODED VIEW………………………………………..356

HEATER HOUSING, THERMOSTAT SUPPORT AND WATER HEADER COVER – CLEANING AND INSPECTION……..390

CLEANING…………………………………………………………………….390

INSPECTION…………………………………………………………………..392

SERVICE TOOLS – COOLING SYSTEM…………………………………………………….352

THERMOSTAT – OPERATING TEMPERATURE INSPECTION……………………………………….394

TEST………………………………………………………………………..394

THERMOSTAT HOUSING ASSEMBLY – REBUILD………………………………………………392

ASSEMBLY…………………………………………………………………….393

CLEANING…………………………………………………………………….392

DISASSEMBLY………………………………………………………………….392

INSPECTION…………………………………………………………………..393

WATER FILTER HEAD ASSEMBLY – CLEANING AND INSPECTION FOR REUSE………………………..395

CLEANING…………………………………………………………………….395

INSPECTION…………………………………………………………………..395

WATER FILTER HEAD ASSEMBLY – REBUILD……………………………………………….395

ASSEMBLY…………………………………………………………………….397

CLEANING…………………………………………………………………….396

DISASSEMBLY………………………………………………………………….395

INSPECTION…………………………………………………………………..396

WATER PUMP – CLEANING AND INSPECTION FOR REUSE………………………………………358

CLEANING…………………………………………………………………….358

INSPECTION…………………………………………………………………..358

WATER PUMP – REBUILD……………………………………………………………..359

ASSEMBLY…………………………………………………………………….367

CLEANING…………………………………………………………………….363

DISASSEMBLY………………………………………………………………….359

INSPECTION…………………………………………………………………..364

WATER PUMP ASSEMBLY – EXPLODED VIEW………………………………………………..354

WATER PUMP ASSEMBLY – GENERAL INFORMATION…………………………………………..357

DRIVE UNITS – GROUP 09……………………………………………………………….399

ACCESSORY DRIVE PULLEY – CLEANING AND INSPECTION FOR REUSE……………………………415

CLEANING…………………………………………………………………….415

INSPECTION…………………………………………………………………..415

DRIVE UNITS – GENERAL INFORMATION………………………………………………….403

FUEL PUMP AND COMPRESSOR DRIVE…………………………………………………403

HYDRAULIC PUMP DRIVE………………………………………………………….403

FUEL PUMP AND COMPRESSOR DRIVE – CLEANING INSPECTION FOR REUSE………………………..404

CLEANING…………………………………………………………………….404

INSPECTION………………………………………………………………….404

FUEL PUMP AND COMPRESSOR DRIVE – EXPLODED VIEW………………………………………401

FUEL PUMP AND COMPRESSOR DRIVE – REBUILD……………………………………………405

ASSEMBLY…………………………………………………………………….409

CLEANING…………………………………………………………………….406

DISASSEMBLY………………………………………………………………….405

INSPECTION…………………………………………………………………..406

HYDRAULIC PUMP DRIVE – CLEANING AND INSPECTION FOR REUSE……………………………..411

CLEANING…………………………………………………………………….411

INSPECTION…………………………………………………………………..411

HYDRAULIC PUMP DRIVE – EXPLODED VIEW……………………………………………….402

HYDRAULIC PUMP DRIVE – REBUILD…………………………………………………….412

ASSEMBLY…………………………………………………………………….414

CLEANING…………………………………………………………………….412

DISASSEMBLY………………………………………………………………….412

INSPECTION…………………………………………………………………..413

SERVICE TOOLS – DRIVE UNITS……………………………………………………….400

AIR INTAKE SYSTEM – GROUP 10………………………………………………………….417

AIR INTAKE SYSTEM – GENERAL INFORMATION…………………………………………….420

CAC AIR INTAKE SYSTEM EXPODED VIEW………………………………………………..419

INTAKE MANIFOLD – CLEANING AND INSPECTION FOR REUSE………………………………….422

CLEANING…………………………………………………………………….422

INSPECTION…………………………………………………………………..422

SERVICE TOOLS – AIR INTAKE SYSTEM………………………………………………….418

TURBOCHARGER – CLEANING AND INSPECTION FOR REUSE……………………………………421

CLEANING ……………………………………………………………………421

INSPECTION…………………………………………………………………..421

EXHAUST SYSTEM – GROUP 11…………………………………………………………….423

EXHAUST MANIFOLD – CLEANING INSPECTION FOR REUSE…………………………………….425

CLEANING…………………………………………………………………….425

DISASSEMBLY………………………………………………………………….425

INSPECTION…………………………………………………………………..426

EXHAUST SYSTEM – EXPLODED VIEW…………………………………………………….424

EXHAUST SYSTEM – GENERAL INFORMATION……………………………………………….425

AIR EQUIPMENT – GROUP 12……………………………………………………………..429

AIR COMPRESSOR – CLEANING AND INSPECTION FOR REUSE…………………………………..434

CLEANING…………………………………………………………………….434

INSPECTION…………………………………………………………………..434

AIR EQUIPMENT – GENERAL INFORMATION………………………………………………..430

COMPRESSED AIR SYSTEMS FLOW DIAGRAMS……………………………………………….433

ELECTRICAL EQUIPMENT – GROUP 13……………………………………………………….437

ALTERNATOR ADJUSTING LINK – CLEANING AND INSPECTION FOR REUSE…………………………439

INSPECTION…………………………………………………………………..439

ALTERNATOR BRACKET – CLEANING AND INSPECTION FOR REUSE……………………………….439

INSPECTION…………………………………………………………………..439

ALTERNATOR BRACKET (BUS APPLICATIONS) – CLEANING AND INSPECTION FOR REUSE………………440

CLEANING…………………………………………………………………….440

INSPECTION…………………………………………………………………..440

AUTOMATIC BELT TENSIONER BRACKET (BUS APPLICATIONS) – CLEANING AND INSPECTION FOR REUSE….442

CLEANING…………………………………………………………………….442

AUTOMATIC BELT TENSIONER (BUS APPLICATIONS) – CLEANING AND INSPECTION FOR REUSE…………441

CLEANING…………………………………………………………………….441

INSPECTION…………………………………………………………………..441

ELECTRICAL EQUIPMENT – GENERAL INFORMATION………………………………………….438

STARTING MOTOR – CLEANING AND INSPECTION FOR REUSE…………………………………..439

CLEANING…………………………………………………………………….439

INSPECTION…………………………………………………………………..440

WIRING DIAGRAMS………………………………………………………………….439

ENGINE TESTING – GROUP 14…………………………………………………………….443

CHASSIS DYNAMOMETER………………………………………………………………479

GENERAL TEST PROCEDURE………………………………………………………..481

CHARGE AIR COOLER RESTRICTION………………………………………………488

COOLANT PRESSURE………………………………………………………….488

ENGINE BLOWBY…………………………………………………………….487

ENGINE SPEED (RPM) WITH A VERIFIED TACHOMETER………………………………..482

EXHAUST AIR RESTRICTION……………………………………………………487

FUEL DRAIN LINE RESTRICTION………………………………………………..484

FUEL INLET RESTRICTION…………………………………………………….483

FUEL RATE………………………………………………………………..483

INTAKE AIR RESTRICTION…………………………………………………….486

INTAKE AIR TEMPERATURE CONTROL – CHASSIS DYNAMOMETER TEST……………………..485

INTAKE MANIFOLD PRESSURE…………………………………………………..485

LUBRICATING OIL PRESSURE ………………………………………………….488

OPERATION……………………………………………………………………479

DYNAMOMETER WORKSHEET…………………………………………………………….461

ENGINE DYNAMOMETER – INSTALL ENGINE………………………………………………..464

AIR COMPRESSOR……………………………………………………………….470

AIR INLET RESTRICTION…………………………………………………………467

COOLANT PLUMBING……………………………………………………………..464

ENGINE BLOWBY………………………………………………………………..468

ENGINE SPEED (RPM) WITH A VERIFIED TACHOMETER……………………………………469

ENGINE THROTTLE CONTROL……………………………………………………….471

EXHAUST RESTRICTION…………………………………………………………..467

FUEL DRAIN LINE RESTRICTION …………………………………………………..470

FUEL INLET RESTRICTION………………………………………………………..469

FUEL PRESSURE………………………………………………………………..469

FUEL RATE……………………………………………………………………468

INTAKE AIR TEMPERATURE CONTROL…………………………………………………465

INTAKE MANIFOLD PRESSURE………………………………………………………468

LUBRICATING OIL PRESSURE………………………………………………………467

LUBRICATING OIL TEMPERATURE……………………………………………………467

STARTING MOTOR……………………………………………………………….471

ENGINE PAINTING………………………………………………………………….492

ENGINE RUN-IN PROCEDURE -CHASSIS DYNAMOMETER………………………………………..488

ENGINE RUN-IN PROCEDURE – ENGINE DYNAMOMETER………………………………………..475

ENGINE RUN-IN PROCEDURE – WITHOUT DYNAMOMETER……………………………………….491

ON-HIGHWAY…………………………………………………………………..491

ENGINE STORAGE – LONG TERM………………………………………………………..495

REMOVE THE ENGINE FROM LONG TERM STORAGE………………………………………..498

ENGINE STORAGE – SHORT TERM……………………………………………………….493

REMOVE THE ENGINE FROM SHORT TERM STORAGE……………………………………….495

ENGINE TESTING – GENERAL INFORMATION……………………………………………….444

CHASSIS DYNAMOMETER, PORTABLE DYNAMOMETER OR LOAD BANK RUN-IN……………………..444

DEFINITION OF TERMS ON ENGINE PERFORMANCE CURVE………………………………….445

ENGINE DYNAMOMETER RUN-IN……………………………………………………..444

FUEL FLOW MEASUREMENT ON ENGINE OR CHASSIS DYNAMOMETER……………………………447

INSTALLATION……………………………………………………………..447

OPERATION………………………………………………………………..448

GENERAL RUN-IN PROCEDURES……………………………………………………..446

IN-SERVICE RUN-IN…………………………………………………………….444

INTAKE MANIFOLD BOOST PRESSURE CORRECTION FACTORS………………………………..450

ENGINE TESTING – SPECIFICATIONS……………………………………………………460

SERVICE TOOLS – ENGINE TESTING…………………………………………………….462

INSTRUMENTS AND CONTROLS – GROUP 15……………………………………………………501

INSTRUMENTS AND CONTROLS – GENERAL INFORMATION………………………………………502

AIR HEATERS………………………………………………………………….502

COOLANT HEATERS………………………………………………………………502

FUEL WARMERS…………………………………………………………………502

GAUGES………………………………………………………………………502

OIL HEATERS………………………………………………………………….502

SAFETY CONTROLS………………………………………………………………503

MOUNTING ADAPTATIONS – GROUP 16……………………………………………………….505

FLYWHEEL – CLEANING AND INSPECTION FOR REUSE………………………………………..509

ASSEMBLY…………………………………………………………………….510

DISASSEMBLY………………………………………………………………….509

INSPECTION…………………………………………………………………..509

FLYWHEEL HOUSING – CLEANING AND INSPECTION FOR REUSE…………………………………511

CLEANING…………………………………………………………………….511

INSPECTION…………………………………………………………………..512

FLYWHEEL RING GEAR – REPLACEMENT…………………………………………………..510

ASSEMBLY…………………………………………………………………….511

DISASSEMBLY………………………………………………………………….510

INSPECTION…………………………………………………………………..510

FRONT ENGINE SUPPORT – CLEANING AND INSPECTIONS……………………………………..512

MOUNTING ADAPTATIONS – EXPLODED VIEW……………………………………………….507

MOUNTING ADAPTATIONS – GENERAL INFORMATION………………………………………….509

REAR ENGINE POWER TAKEOFF – EXPLODED VIEW…………………………………………..508

REAR ENGINE POWER TAKEOFF (REPTO) REBUILDING………………………………………..512

ASSEMBLY…………………………………………………………………….516

CLEANING…………………………………………………………………….514

DISASSEMBLY………………………………………………………………….512

INSPECTION…………………………………………………………………..514

SERVICE TOOLS – MOUNTING ADAPTATIONS……………………………………………….506

SPECIFICATIONS – GROUP 18…………………………………………………………….521

CAPSCREW MARKINGS AND TORQUE VALUES………………………………………………..566

CAPSCREW MARKINGS AND TORQUE VALUES – METRIC…………………………………….566

CAPSCREW MARKINGS AND TORQUE VALUES – U.S. CUSTOMARY……………………………..567

COMPONENT SPECIFICATIONS AND TORQUE VALUES………………………………………….523

AIR EQUIPMENT – INSPECTION SPECIFICATIONS……………………………………….559

AIR INTAKE SYSTEM – INSPECTION SPECIFICATIONS……………………………………559

CAM FOLLOWER ASSEMBLY – REBUILD SPECIFICATIONS…………………………………..550

COOLING SYSTEM – REBUILD SPECIFICATIONS…………………………………………554

COOLING SYSTEMS – TORQUE VALUES………………………………………………..556

CYLINDER BLOCK – REBUILD SPECIFICATIONS…………………………………………538

CYLINDER BLOCK – TORQUE VALUES…………………………………………………546

CYLINDER HEAD – REBUILD SPECIFICATIONS………………………………………….546

CYLINDER HEAD – TORQUE VALUES………………………………………………….549

DRIVE UNITS – REBUILD SPECIFICATIONS……………………………………………557

ELECTRICAL EQUIPMENT – INSPECTION SPECIFICATIONS…………………………………560

ENGINE ASSEMBLY – CAPSCREW TORQUE VALUES………………………………………..528

ENGINE ASSEMBLY – SPECIFICATIONS……………………………………………….523

ENGINE TESTING – TEST SPECIFICATIONS……………………………………………560

EXHAUST SYSTEM – TORQUE VALUES…………………………………………………559

FUEL PUMP – REBUILD SPECIFICATIONS……………………………………………..551

FUEL PUMP – TORQUE VALUES……………………………………………………..552

INJECTORS – REBUILD SPECIFICATIONS……………………………………………..553

LUBRICATING OIL SYSTEMS – SPECIFICATIONS………………………………………..553

LUBRICATING OIL SYSTEMS – TORQUE VALUES…………………………………………554

MOUNTING ADAPTATIONS – REBUILD SPECIFICATIONS……………………………………560

ROCKER LEVER ASSEMBLY – REBUILD SPECIFICATIONS…………………………………..549

VEHICLE BRAKING – REBUILD SPECIFICATIONS………………………………………..560

DRIVE BELT TENSION……………………………………………………………….562

INJECTIONS TIMING CODES…………………………………………………………..561

NEWTON-METER TO FOOT-POUND CONVERSTION CHART………………………………………..565

PIPE PLUG TORQUE VALUES…………………………………………………………..567

SPECIFICATIONS – GENERAL INFORMATION……………………………………………….522

TAP-DRILL CHART – U.S. CUSTOMARY & METRIC…………………………………………..568

WEIGHT AND MEASURES – CONVERSION FACTORS……………………………………………564

VEHICLE BRAKING – GROUP 20……………………………………………………………569

VEHICLE BRAKING – GENERAL INFORMATION………………………………………………570

SERVICE LITERATURE…………………………………………………………………..571

ADDITIONAL SERVICE LITERATURE……………………………………………………..572

SERVICE LITERATURE ORDERING LOCATION……………………………………………….573

COMPONENT MANUFACTURERS: NAMES AND ADDRESSES…………………………………………..577

COMPONENT MANUFACTURERS’ ADDRESSES…………………………………………………578

AIR COMPRESSORS………………………………………………………………….578

AIR CYLINDERS……………………………………………………………………578

AIR HEATERS……………………………………………………………………..578

AIR STARTING MOTORS………………………………………………………………578

ALTERNATORS……………………………………………………………………..578

AUXILIARY BRAKES…………………………………………………………………578

BELTS…………………………………………………………………………..578

CATALYTIC CONVERTERS……………………………………………………………..578

CLUTCHES………………………………………………………………………..578

COOLANT HEATERS………………………………………………………………….578

DRIVE PLATES…………………………………………………………………….578

ELECTRIC STARTING MOTORS………………………………………………………….579

ENGINE PROTECTION CONTROLS………………………………………………………..579

FAN CLUTCHES…………………………………………………………………….579

FANS……………………………………………………………………………579

FILTERS…………………………………………………………………………579

FLEXPLATES………………………………………………………………………579

FUEL WARMERS…………………………………………………………………….579

GAUGES………………………………………………………………………….579

GOVERNORS……………………………………………………………………….579

HEAT SLEEVES…………………………………………………………………….580

HYDRAULIC AND POWER STEERING PUMPS…………………………………………………580

OIL HEATERS……………………………………………………………………..580

TORQUE CONVERTERS………………………………………………………………..581

INDEX………………………………………………………………………………581