$33

Dana Spicer T12000 3,4,6-speed Intermediate Drop VDT12000 Transmission Service Manual 907397-b – PDF

Dana Spicer T12000 3,4,6-speed Intermediate Drop VDT12000 Transmission Service Manual 907397-b – PDF DOWNLOAD

FILE DETAILS:

Dana Spicer T12000 3,4,6-speed Intermediate Drop VDT12000 Transmission Service Manual 907397-b – PDF DOWNLOAD

Language : English

Pages : 338

Downloadable : Yes

File Type : PDF

Size: 41.1 MB

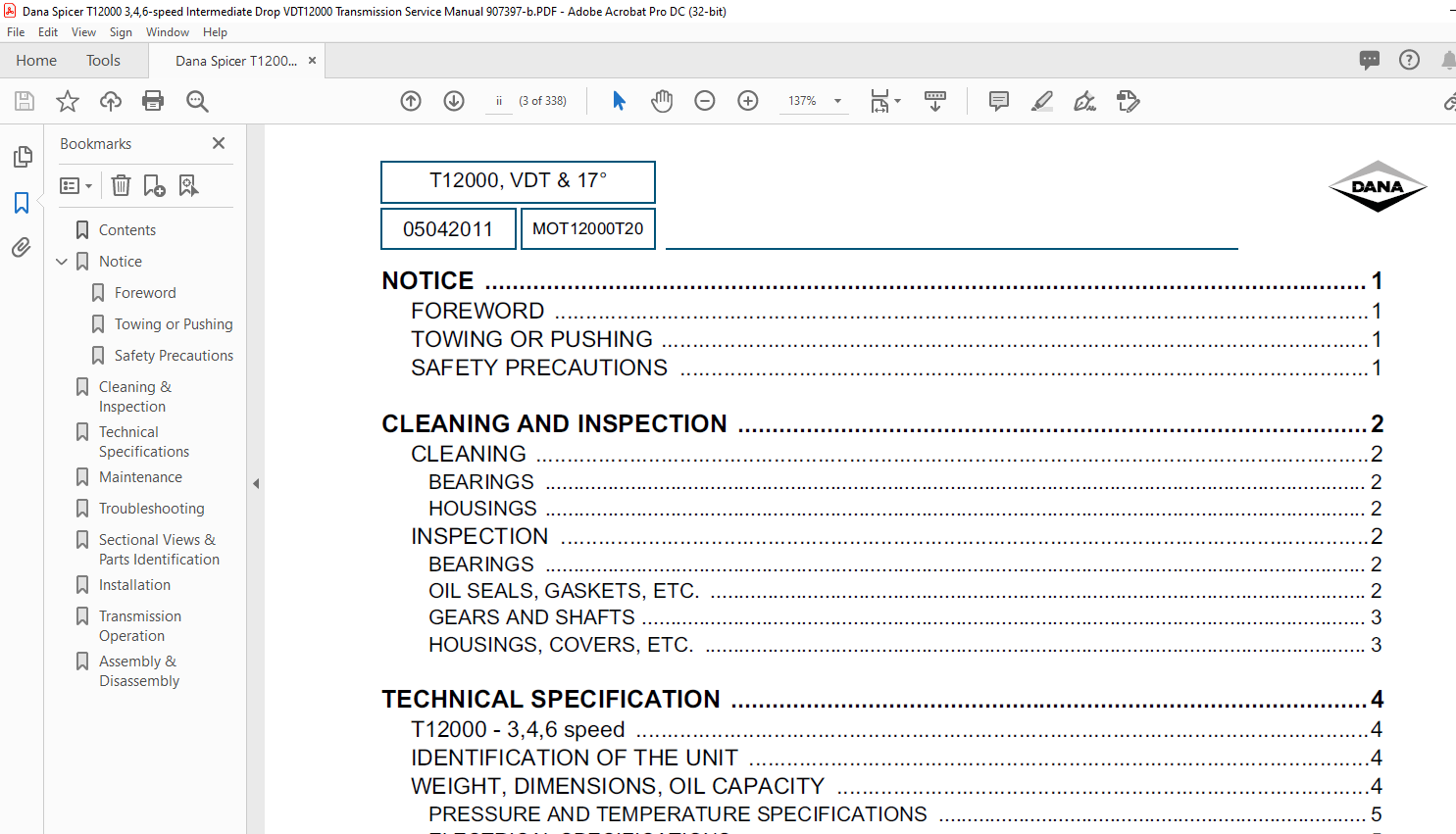

TABLE OF CONTENTS:

Dana Spicer T12000 3,4,6-speed Intermediate Drop VDT12000 Transmission Service Manual 907397-b – PDF DOWNLOAD

NOTICE 1

FOREWORD 1

TOWING OR PUSHING 1

SAFETY PRECAUTIONS 1

CLEANING AND INSPECTION 2

CLEANING 2

BEARINGS 2

HOUSINGS 2

INSPECTION 2

BEARINGS 2

OIL SEALS, GASKETS, ETC 2

GEARS AND SHAFTS 3

HOUSINGS, COVERS, ETC 3

TECHNICAL SPECIFICATION 4

T12000 – 3,4,6 speed 4

IDENTIFICATION OF THE UNIT 4

WEIGHT, DIMENSIONS, OIL CAPACITY 4

PRESSURE AND TEMPERATURE SPECIFICATIONS 5

ELECTRICAL SPECIFICATIONS 5

HYDRAULIC COOLER AND FILTER LINE SPECIFICATIONS 5

VDT12000 6

IDENTIFICATION OF THE UNIT 6

WEIGHT, DIMENSIONS, OIL CAPACITY 6

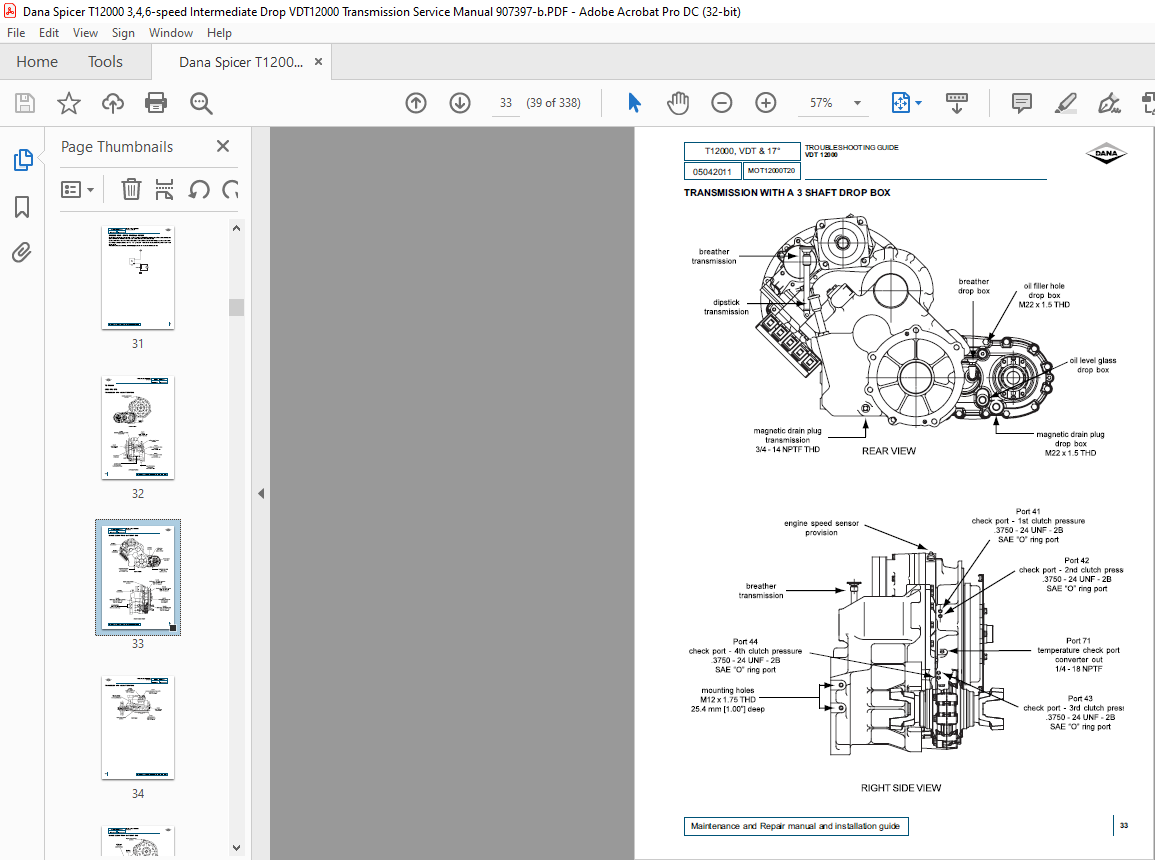

TRANSMISSION WITH A 3 SHAFT DROP BOX 6

TRANSMISSION WITH A 4 SHAFT DROP BOX 7

VDT 17 DEGREES 8

IDENTIFICATION OF THE UNIT 8

WEIGHT, DIMENSIONS, OIL CAPACITY 8

TIGHTENING TORQUES 9

COIL AND CARTIDGE TORQUE 10

MAINTENANCE 11

OIL SPECIFICATIONS 11

RECOMMENDED LUBRICANTS 11

VALID FOR: VDT12000 & T12000 12

VALID FOR: T12000 12

T12000 – 3, 4, 6 speed 13

MAINTENANCE INTERVALS 13

DAILY 13

NORMAL DRAIN PERIOD 13

SERVICING MACHINE AFTER COMPONENTS OVERHAUL 14

VDT12000 15

MAINTENANCE INTERVALS FOR THE 3 & 4 SHAFT DROP BOX 15

DAILY 15

NORMAL DRAIN PERIOD 15

MAINTENANCE INTERVALS FOR THE TRANSMISSION 15

INSTRUCTIONS FOR LINING REPLACEMENT AND ADJUSTMENT OF PARKING BRAKE ASSEMBLY

16

ASSEMBLY DIAGRAM 16

DISASSEMBLY 17

ASSEMBLY 18

05042011

T12000, VDT & 17°

MOT12000T20

3 Maintenance and Repair manual and installation guide

TROUBLESHOOTING GUIDE 22

T12000 – 3, 4, 6 speed 22

T12000 TRANSMISSION 22

TROUBLESHOOTING PROCEDURES 22

STALL TEST 22

TRANSMISSION PRESSURE CHECKS 22

MECHANICAL AND ELECTIRCAL CHECKS 23

HYDRAULIC CHECKS 23

TROUBLESHOOTING GUIDE 24

LOW CLUTCH PRESSURE 24

LOW CHARGING PUMP OUTPUT 24

OVERHEATING 24

NOISY CONVERTER 24

LACK OF POWER 24

CHECK POINTS 25

ELECTRICAL WIRING 28

3-SPEED TRANSMISSION 28

STANDARD 4-SPEED TRANSMISSION (1-3-5 6 SPEED) 29

ALTERNATIVE 4-SPEED TRANSMISSION (1-3-4-5 6 SPEED) 30

6-SPEED TRANSMISSION 30

SPEED SENSOR – STATIC STANDALONE TEST 31

VDT 12000 32

CHECK POINTS 32

TRANSMISSION WITH A 3 SHAFT DROP BOX 32

TRANSMISSION WITH A 4 SHAFT DROP BOX 35

VDT 17 DEGREES 38

CHECK POINTS 38

SECTIONAL VIEWS AND PARTS IDENTIFICATION 39

T12000 39

GROUP – CONVERTER HOUSING 39

GROUP -TRANSMISSION CASE AND PLATE 41

GROUP – TORQUE CONVERTER 43

GROUP – PUMP DRIVE 44

GROUP – CHARGING PUMP 45

GROUP – REVERSE IDLER 46

GROUP – FORWARD AND REVERSE SHAFT 47

GROUP – 3RD SHAFT (FOR 3-SPEED TRANSMISSION ONLY) 49

GROUP – HIGH (4TH) AND 3RD SHAFT 51

GROUP – 1ST AND 2ND SHAFT 53

GROUP – OUTPUT SHAFT (REAR ONLY) 55

GROUP – OUTPUT SHAFT (FRONT ONLY) 56

GROUP – OUTPUT SHAFT (FRONT & REAR) 57

GROUP – DISK BRAKE 58

GROUP – CALIPER ASSEMBLY 59

GROUP – ELECTRIC CONTROL 61

GROUP – DRIVE PLATE 63

VDT 12000 64

TRANSMISSION CASE & PLATE GROUP 64

3 SHAFT DROP BOX GROUP 66

4 SHAFT DROP BOX GROUP 67

T12000 INSTALLATION DETAILS 69

CONVERTER DRIVE COUPLING 69

TRANSMISSION TO ENGINE INSTALLATION PROCEDURE 70

Maintenance and Repair manual and installation guide 4

05042011

T12000, VDT & 17°

MOT12000T20

EXTERNAL PLUMBING 71

OPTIONAL REMOTE FILTER 72

COOLER & FILTER LINES SPECIFICATIONS 72

SPEED SENSOR INSTALLATION 73

OPERATION OF THE T12000 TRANSMISSION 75

THE TRANSMISSION ASSEMBLY 75

THE CONVERTER, PUMP DRIVE SECTION AND PRESSURE REGULATING VALVE 76

THE INPUT SHAFT AND DIRECTIONAL CLUTCHES 77

THE RANGE CLUTCHES 78

THE OUTPUT SECTION 78

THE TRANSMISSION CONTROLS (REFER TO HYDRAULIC DIAGRAM) 79

ELECTRIC SOLENOID CONTROLS 80

3-SPEED TRANSIMISSION 80

3-SPEED TRANSMISSION 80

STANDARD 4-SPEED TRANSMISSION (1, 3, 5, 6 6-SPEED) 80

ALTERNATIVE 4-SPEED TRANSMISSION, MODEL T12496 ONLY (1, 3, 4, 5 6-SPEED) 80

6-SPEED TRANSMISSION 81

POWERFLOWS, ACTIVATED SOLENOIDS AND HYDRAULIC CIRCUIT 82

3-SPEED TRANSMISSION 82

NEUTRAL AND 3RD CLUTCH ENGAGED 82

FORWARD 1ST SPEED 84

FORWARD 2ND SPEED 86

FORWARD 3RD SPEED 88

REVERSE 1ST SPEED 90

4-SPEED TRANSMISSION 92

STANDARD 4-SPEED TRANSMISSION 92

ALTERNATIVE 4-SPEED TRANSMISSION 105

6-SPEED TRANSMISSION 117

NEUTRAL AND 3RD CLUTCH ENGAGED 117

FORWARD 1ST SPEED 119

FORWARD 2ND SPEED 121

FORWARD 3RD SPEED 123

FORWARD 4TH SPEED 125

FORWARD 5TH SPEED 127

FORWARD 6TH SPEED 129

REVERSE 1ST SPEED 131

GEAR AND CLUTCH LAY-OUT (3-SPEED) 133

GEAR AND CLUTCH LAY-OUT (4-SPEED AND 6-SPEED) 134

ASSEMBLY INSTRUCTION 135

T12000 – 3, 4, 6 speed 135

TRANSMISSION COMPLETE 141

DISASSEMBLY 141

ASSEMBLY 155

1ST CLUTCH 172

DISASSEMBLY 172

ASSEMBLY 176

2ND CLUTCH 182

DISASSEMBLY 182

ASSEMBLY 187

4TH CLUTCH 194

DISASSEMBLY 194

ASSEMBLY 199

3RD CLUTCH 206

DISASSEMBLY 206

05042011

T12000, VDT & 17°

MOT12000T20

5 Maintenance and Repair manual and installation guide

ASSEMBLY 210

REVERSE CLUTCH 216

DISASSEMBLY 216

ASSEMBLY 220

FORWARD CLUTCH 225

DISASSEMBLY 225

ASSEMBLY 229

REGULATOR VALVE 234

DISASSEMBLY 234

ASSEMBLY 235

DUAL MODULATED VELVE ASSEMBLY 236

DISASSEMBLY 236

ASSEMBLY 237

SPACER PLATE 241

DISASSEMBLY 241

ASSEMBLY 246

FRONT OUTPUT FLANGE 252

DISASSEMBLY 252

ASSEMBLY 254

CONVERTER HOUSING 256

DISASSEMBLY 256

ASSEMBLY 259

SINGLE MODULATION AND HYDRAULIC REMOVAL 262

SINGLE MODULATED VALVE ASSEMBLY 265

DISASSEMBLY 265

ASSEMBLY 268

HYDRAULIC INCHING REMOVAL 270

DISASSEMBLY 270

ASSEMBLY 273

SINGLE MODULATION AND HYDRAULIC INCHING INSTALLATION 276

OPTIONS 279

ELECTRIC CONTROL-SINGLE MODULATION HYDRAULIC ACTUATED INCHING 279

SECTIONAL VIEWS AND PARTS IDENTIFICATION 279

MT SECTION 284

SECTIONAL VIEWS AND PARTS IDENTIFICATION 284

ASSEMBLY INSTRUCTIONS 284

MT CROSS SECTION AND ASSEMBLY INSTRUCTIONS 286

VDT 12000 287

3 SHAFT DROP BOX 287

4 SHAFT DROP BOX 288

3 SHAFT 289

4 SHAFT 290

4° SHAFT DROP BOX 291

DISASSEMBLY 291

ASSEMBLY 300

VDT 17 DEGREES 308

GENERAL BEARING INSTALLATION PROCEDURE 309

TAPER BEARING ADJUSTMENT 309

INPUT SHAFT TAPER BEARING ADJUSTMENT 312

17° DROP BOX 313

DISASSEMBLY 313

ASSEMBLY 320

INPUT SHAFT 330

DISASSEMBLY 330

ASSEMBLY 331

DESCRIPTION:

Dana Spicer T12000 3,4,6-speed Intermediate Drop VDT12000 Transmission Service Manual 907397-b – PDF DOWNLOAD

NOTICE:

All information mentioned in the and Service manual T12000 Powershift Transmission 3, 4 & 6 Speed Intermediate

Drop is valid, unless otherwise specified in this 17° Drop Box and VDT.

FOREWORD:

- This manual has been prepared to provide the customer and the maintenance personnel with information and instructions on the maintenance and repair of the SPICER OFF-HIGHWAY PRODUCTS product.

Extreme care has been exercised in the design, selection of materials, and manufacturing of these units. - The slight outlay in personal attention and cost required to provide regular and proper lubrication, inspection at stated intervals, and such adjustments as may be indicated will be reimbursed many times in low cost operation and trouble free service.

- In order to become familiar with the various parts of the product, its principle of operation, troubleshooting and

adjustments, it is urged that the mechanic studies the instructions in this manual carefully and uses it as a reference

when performing maintenance and repair operations. - Whenever repair or replacement of component parts is required, only SPICER OFF-HIGHWAY PRODUCTS approved

parts as listed in the applicable parts manual should be used. Use of “will-fit” or non-approved parts may endanger

proper operation and performance of the equipment. SPICER OFF-HIGHWAY PRODUCTS does not warrant repair

or replacement parts, nor failures resulting from the use of parts which are not supplied by or approved by SPICER

OFF-HIGHWAY PRODUCTS.

SAFETY PRECAUTIONS:

To reduce the chance of personal injury and/or property damage, the following instruction must be carefully observed.

Proper service and repair are important to the safety of the service technician and the safe, reliable operation of the

machine. If replacement parts are required the part must be replaced by a spare part which has the same part number

or with an equivalent part. Do not use a spare part of lesser quality.

- The service procedures recommended in this manual are effective methods for performing service and repair. Some

of these procedures require the use of tools specifically designed for the purpose. - Accordingly, anyone who intends to use a spare part, service procedure or tool, which is not recommended by SPICER

OFF-HIGHWAY PRODUCTS, must first determine that neither his safety nor the safe operation of the machine

will be jeopardized by the spare part, service procedure or tool selected.

IMAGES PREVIEW OF THE MANUAL: