$38

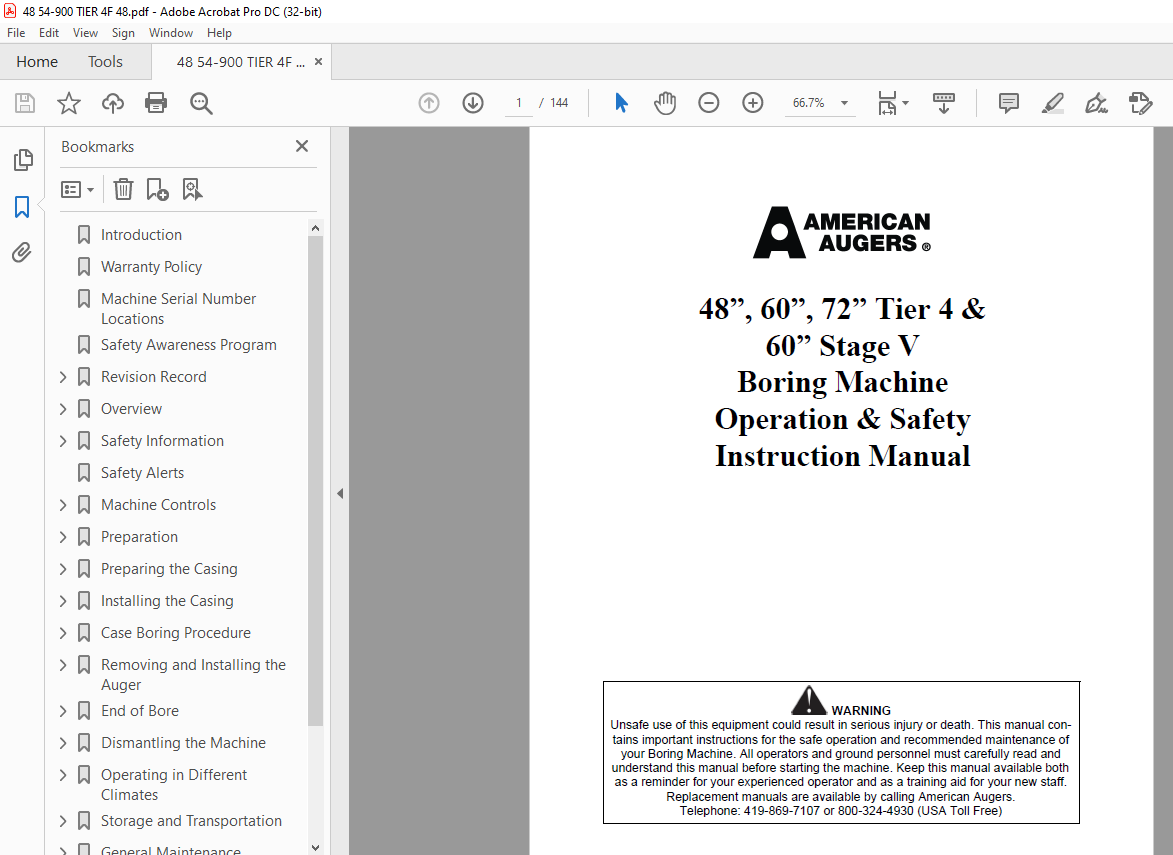

Ditch Witch 48”, 60”, 72” Tier 4 & 60” Stage V Boring Machine Operation & Safety Instruction Manual

Ditch Witch 48”, 60”, 72” Tier 4 & 60” Stage V Boring Machine Operation & Safety Instruction Manual – PDF DOWNLOAD

FILE DETAILS:

Ditch Witch 48”, 60”, 72” Tier 4 & 60” Stage V Boring Machine Operation & Safety Instruction Manual – PDF DOWNLOAD

Language : English

Pages : 144

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

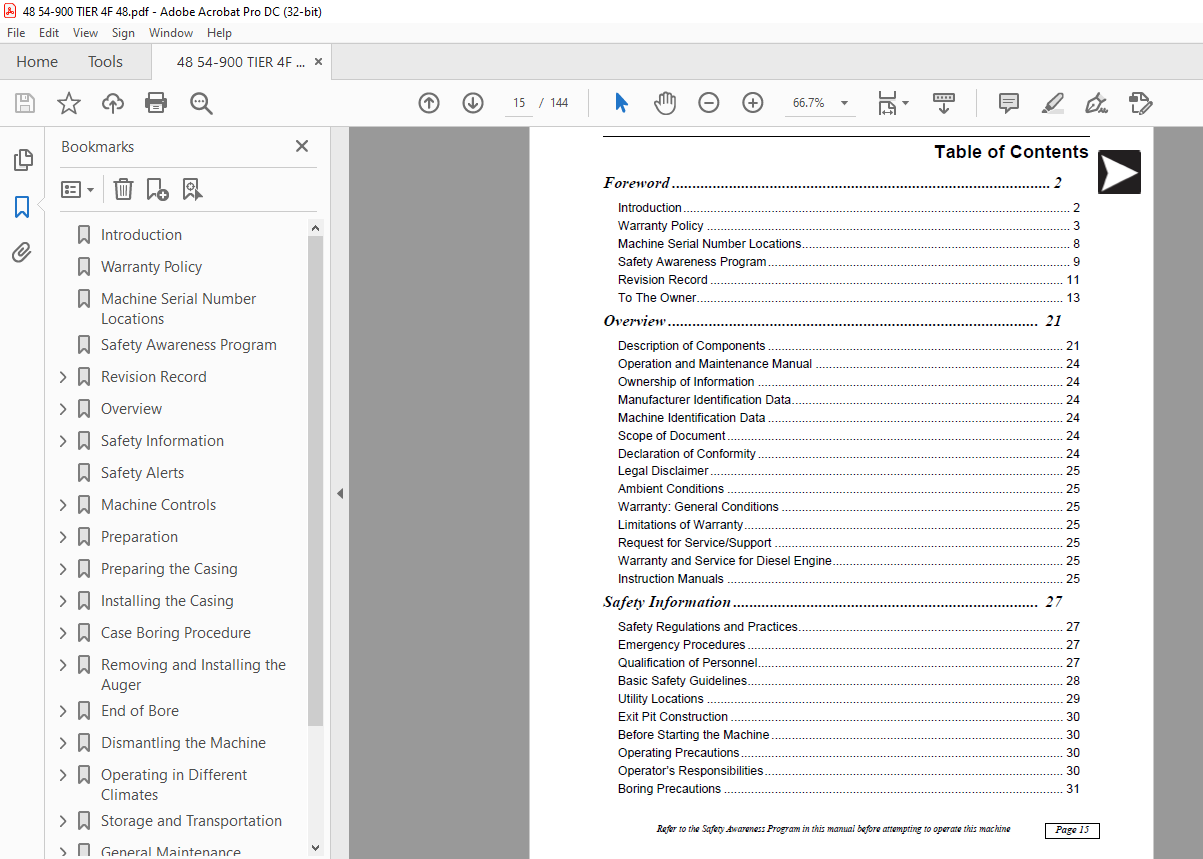

TABLE OF CONTENTS:

Ditch Witch 48”, 60”, 72” Tier 4 & 60” Stage V Boring Machine Operation & Safety Instruction Manual – PDF DOWNLOAD

Introduction 2

Warranty Policy 3

Machine Serial Number Locations 8

Safety Awareness Program 9

Revision Record 11

To The Owner 13

Overview 21

Description of Components 21

Operation and Maintenance Manual 24

Ownership of Information 24

Manufacturer Identification Data 24

Machine Identification Data 24

Scope of Document 24

Declaration of Conformity 24

Legal Disclaimer 25

Ambient Conditions 25

Warranty: General Conditions 25

Limitations of Warranty 25

Request for Service/Support 25

Warranty and Service for Diesel Engine 25

Instruction Manuals 25

Safety Information 27

Safety Regulations and Practices 27

Emergency Procedures 27

Qualification of Personnel 27

Basic Safety Guidelines 28

Utility Locations 29

Exit Pit Construction 30

Before Starting the Machine 30

Operating Precautions 30

Operator’s Responsibilities 30

Boring Precautions 31

Material Handling Precautions 31

Maintenance Precautions 31

Transporting Precautions 31

Noise Level Safety 32

Ladder Safety 32

Welding Safety 32

Refueling Safety 33

Lifting Sling Safety 34

Hazardous Chemicals 35

Crystalline Silica (Quartz) Dust Precautions 35

Danger Zones — Safe Distances 36

Grounding 36

Confined Space Entry 37

Preventing Boring Machine Accidents 37

Safety Alerts 45

Machine Controls 51

Safety Switches 51

Battery Switch 53

Service Lights 54

Operator Control Station 54

48/54-900NG Boring Machine Controls 55

60-1200NG and 72-1200NG Tier 4 Final & 60-1200NG Stage V Controls 56

Control Descriptions 57

Manual Clutch Override 59

Preparation 61

Classify Jobsite 61

Apply Precautions 61

Site Preparation 62

Designing the Job 63

Preparing the Entrance Pit 63

Preparing the Exit Pit 64

Daily Operations 64

Jobsite Lighting 64

Setting and Aligning the Track 65

Setting the Machine 66

Before Operating The Engine 68

Installing the Exhaust Extension 69

Starting the Engine 69

Test the Indicators, Engine Stop Buttons and all Controls 70

Normal Engine Shutdown 70

Emergency Engine Shutdown and Restart 70

Quik Tran Alignment 71

Operating the Quik Tran 72

Preparing the Casing 73

Preparing Casing 73

Constructing the Steering Head 74

Installing the Casing 80

Installing the Lead Casing and Auger in the Pit 80

Attaching the Casing to the Machine 81

Case Boring Procedure 83

Case Boring Check List 83

Measuring Casing 84

Collaring 85

Complete First Section of Casing 86

Adding Casing 87

Fast Work 90

Approaching the Exit Pit 90

Removing and Installing the Auger 91

Removing the Auger with Cutting Head Attached 91

Installing the Auger with Cutting Head Attached 93

End of Bore 95

Removing the Auger at the Completion of the Bore 95

Dismantling the Machine 96

To Quick Split The Machine 96

Removing the Machine from the Pit 96

Operating in Different Climates 97

Operating in Hot Weather 97

Operating in Cold Temperatures 97

Storage and Transportation 99

Minimum Storage Space Required 99

Storage Site Conditions 99

Preparations for Storage 99

Removal from Storage 99

Transportation 100

Lifting the Machine 100

Transportation Tie-Down Locations 101

General Maintenance 103

Qualification of the Technician 103

Cleaning 103

Replacing Hydraulic Hoses and Tubes 105

Welding 105

Tier 4 Diesel Engines 106

Stage V Diesel Engine 106

Approved Replacement Fluids 107

Scheduled Maintenance 108

Maintenance Schedule 108

After Removing from Storage (Before Starting the Machine) 109

Before First Use (and every 500 Hours Thereafter) 109

10 Hour Inspection and Maintenance 110

Check Connections 111

Check Oil in Gearbox 113

50 Hour Inspection and Maintenance 117

500 Hour Inspection and Maintenance 119

1000 Hour Inspection and Maintenance 119

After Each Use 119

Starting Each Job 120

Specifications 123

48/54-900 Specifications 123

60-1200 Tier 4 Final Specifications 124

60-1200 Stage V Specifications 125

72-1200 Specifications 126

Boring Machine Weights 127

Appendix A: List of Attachments 131

Appendix B: Force Charts 132

Appendix C: Entrance Pit 133

Appendix D: Ground Conditions Chart 134

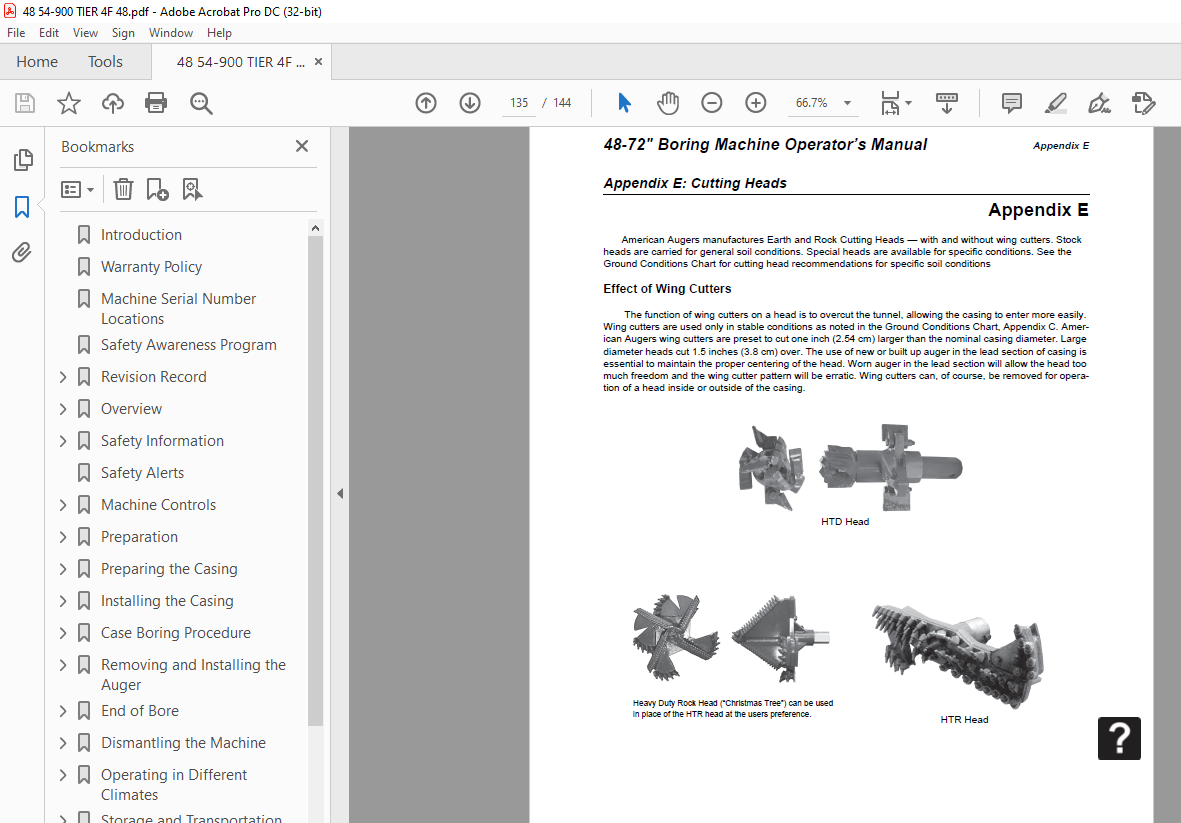

Appendix E: Cutting Heads 135

Appendix F: Auger Weight Chart 136

Appendix G: Casing Weight Chart 137

Appendix H: Torque Specifications 138

Sample Declaration of Conformity 141