$36

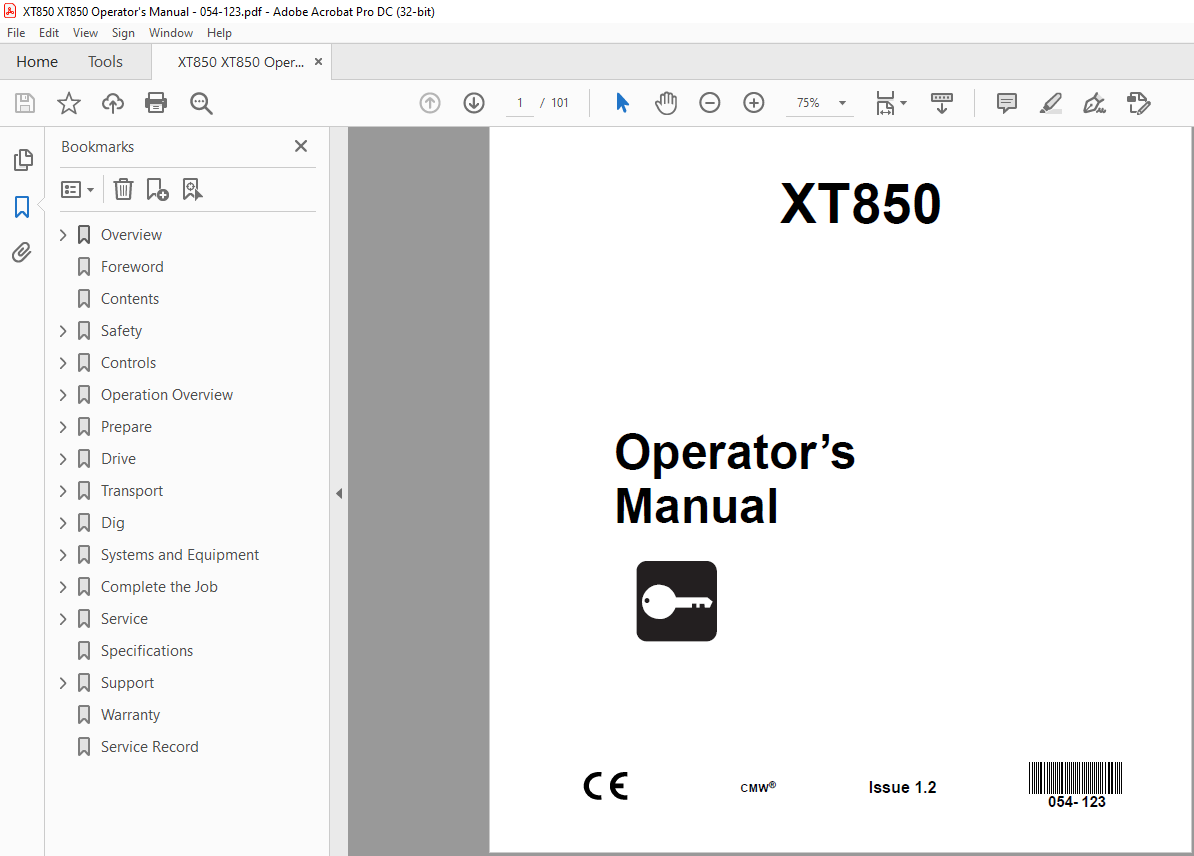

Ditch Witch XT850 Operator’s Manual PN 054-123 – PDF DOWNLOAD

Ditch Witch XT850 Operator’s Manual PN 054-123 – PDF DOWNLOAD

FILE DETAILS:

Ditch Witch XT850 Operator’s Manual PN 054-123 – PDF DOWNLOAD

Language : English

Pages : 101

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

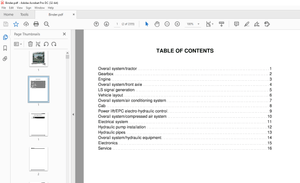

TABLE OF CONTENTS:

Ditch Witch XT850 Operator’s Manual PN 054-123 – PDF DOWNLOAD

Overview 2

Serial Number Location 3

Intended Use 4

Unit Components 4

Operator Orientation 5

About This Manual 5

Bulleted Lists 5

Numbered Lists 5

Foreword 6

Contents 8

Safety 10

Guidelines 11

Safety Alert Classifications 12

Safety Alerts 13

Emergency Procedures 16

Electric Strike Description 16

If an Electric Line is Damaged 17

If a Gas Line is Damaged 17

If a Fiber Optic Cable is Damaged 18

If Machine Catches on Fire 18

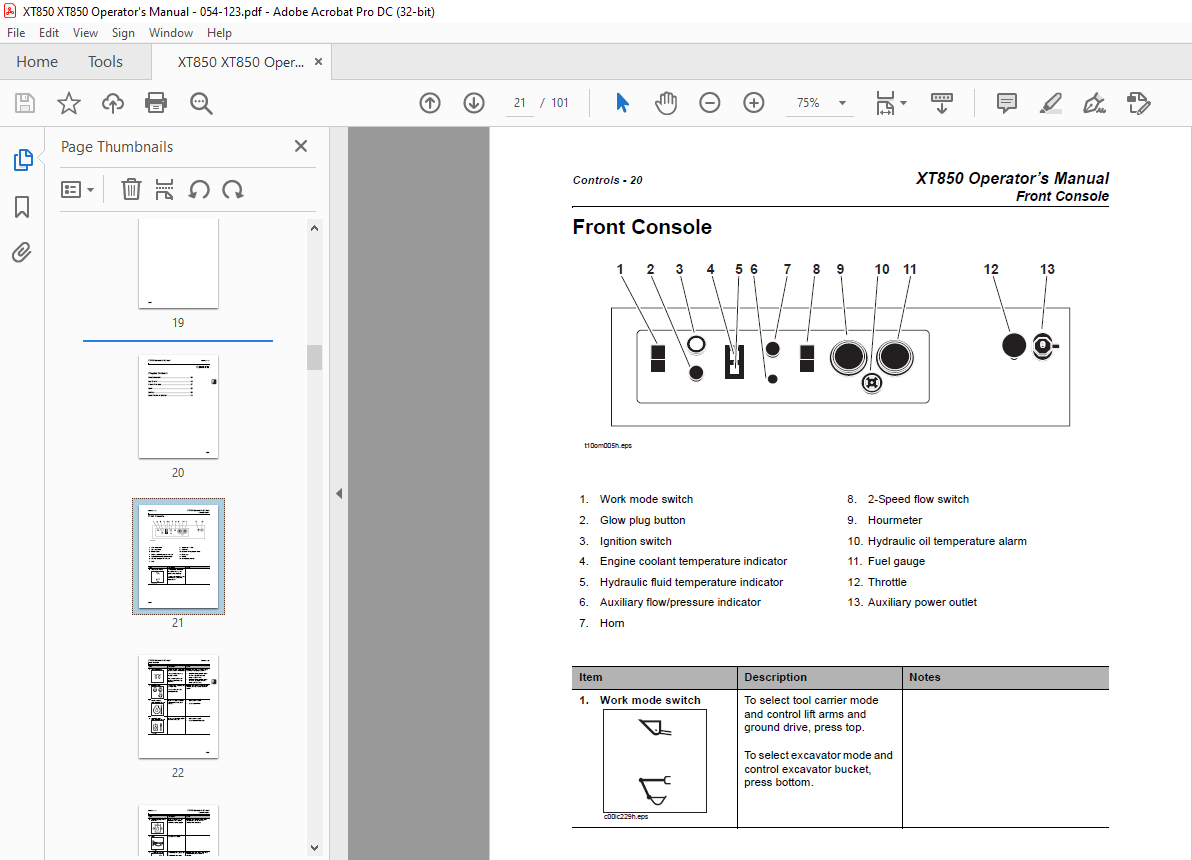

Controls 20

Front Console 21

Joysticks 25

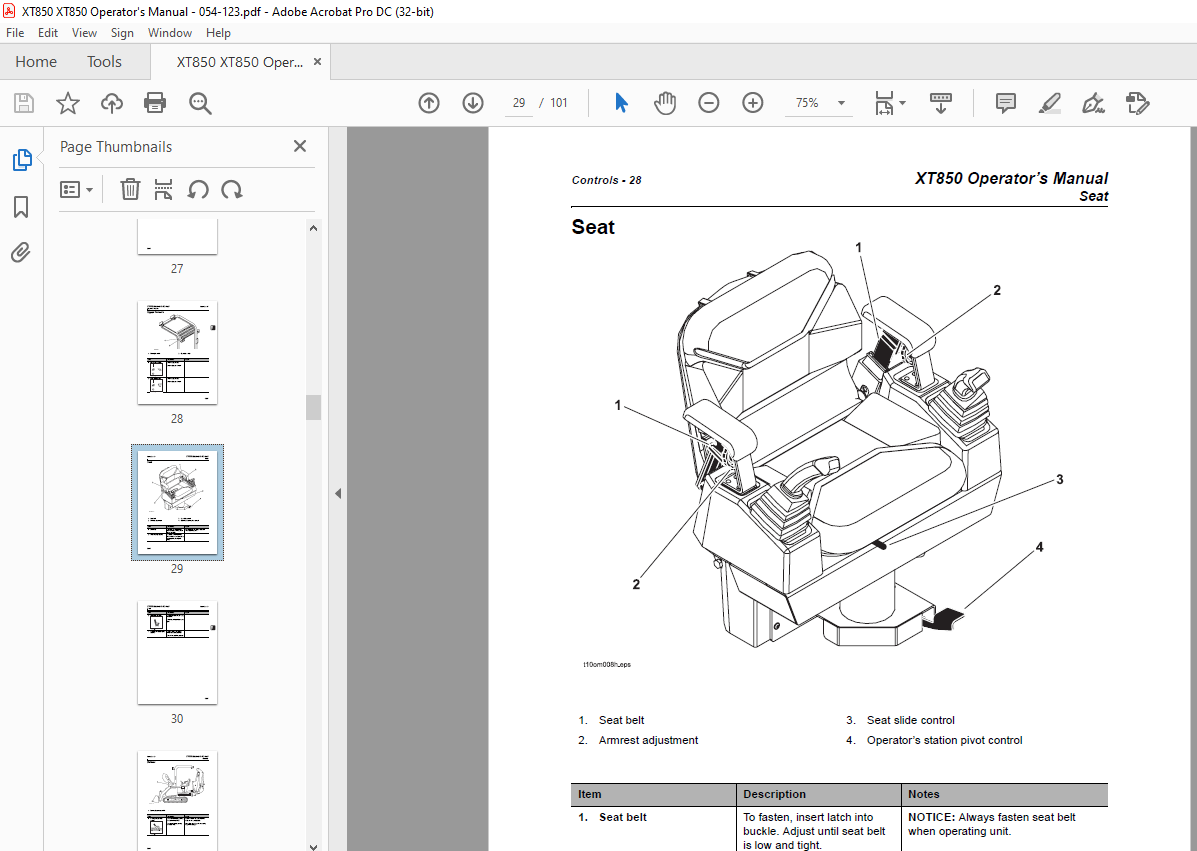

Upper Console 28

Seat 29

Battery 31

Tool Carrier Bucket 32

Operation Overview 34

Planning 35

Using Tool Carrier Mode 35

Using Excavator Mode 35

Leaving Jobsite 35

Prepare 36

Gather Information 37

Review Job Plan 37

Notify One-Call Services 37

Arrange for Traffic Control 37

Plan for Emergency Services 37

Inspect Site 38

Identify Hazards 38

Classify Jobsite 39

Inspect Jobsite 39

Select a Classification 39

Apply Precautions 40

Check Supplies and Prepare Equipment 41

Supplies 41

Fluid Levels 41

Condition and Function 41

Accessories 41

Drive 42

Start Unit 43

Drive 44

General Operation 44

Slope Operation Guidelines 44

Steer 45

Shut Down 45

Transport 46

Lift 47

Points 47

Procedure 47

Haul 48

Inspect Trailer 48

Hitch Trailer 48

Load 49

Tie Down 51

Unload 53

Unhitch Trailer 53

Tow 54

Procedure 54

Dig 56

Overview 57

Filling Bucket 57

Dumping Bucket 58

Digging 59

Single Inline Trench 59

Single Offset Trench 59

Multiple Trenches 60

Operating Tips 60

Systems and Equipment 62

Excavator Control Pattern 63

Change Pattern 63

Operate Controls 64

Front Attachments 65

Connect Attachment 65

Operate Attachment 67

Optional Equipment 67

Complete the Job 68

Rinse Equipment 69

Disconnect Attachment 69

Stow Tools 69

Service 70

Service Precautions 71

Working Under Raised Lift Arms 71

Opening Hood 72

Lubrication Overview 72

Recommended Lubricants/Service Key 73

Engine Oil Temperature Chart 74

Approved Coolant 74

10 Hour 75

Check coolant level every 10 hours Add coolant as needed to maintain as shown on overflow bottle 75

Check engine oil level at dipstick (2) every 10 hours Add DEO at fill (1) as needed to maintain oil level at highest line on dipstick 75

Check track tension every 10 hours Measure length of spring as shown When tracks are properly tensioned, dimension A should be 9 1/4” (235 mm) Adjust as needed (see page 85) 76

Check hydraulic fluid level every 10 hours Maintain level at halfway point on sight glass (2) Add THF as needed at fill (1) 77

50 Hour 78

100 Hour 80

150 Hour 82

250 Hour 83

500 Hour 84

1000 Hour 84

2000 Hour 85

As Needed 86

Specifications 90

Support 96

Procedure 96

Resources 96

Publications 96

Ditch Witch Training 96

Warranty 97

Service Record 100