$34

Drexel SL44/4 Swingmast Lift Truck Parts Manual 942396 - PDF DOWNLOAD

Drexel SL44/4 Swingmast Lift Truck Parts Manual 942396 - PDF DOWNLOAD

FILE DETAILS:

Drexel SL44/4 Swingmast Lift Truck Parts Manual 942396 - PDF DOWNLOAD

Language : English

Pages : 112

Downloadable : Yes

File Type : PDF

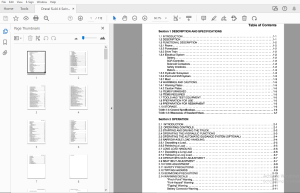

TABLE OF CONTENTS:

Drexel SL44/4 Swingmast Lift Truck Parts Manual 942396 - PDF DOWNLOAD

Section 1 DESCRIPTION AND SPECIFICATIONS

11 INTRODUCTION 1-1

12 DESCRIPTION 1-1

13 FUNCTIONAL DESCRIPTION 1-2

131 Frame 1-2

132 Powerplant 1-2

133 Drive Train 1-2

134 Electrical System 1-2

Battery 1-2

SCR Controller 1-2

Solenoid Contactors 1-2

Safety Interlocks 1-2

Meters 1-3

135 Hydraulic Subsystem 1-3

136 Pivot and Shift System : 1-3

137 Mast 1-3

14 WARNINGS AND CAUTIONS 1-5

141 Warning Plates 1-5

142 Caution Plates 1-5

15 ITEMS FURNISHED 1-5

16 ITEMS REQUIRED 1-5

17 TOOLS AND TEST EQUIPMENT 1-5

18 PREPARATION FOR USE 1-5

19 PREPARATION FOR RESHIPMENT , 1-5

110 STORAGE 1-6

Table 1-1: General Specifications 1-6

Table 1-2: Dimensions of Standard Masts 1,7

Section 2 OPERATION

21 INTRODUCTION 2-1

22 OPERATING CONTROLS 2-1

23 STARTING AND DRIVING THE TRUCK 2-2

24 OPERATING THE HYDRAULIC FUNCTIONS 2-3

25 OPERATING THE AUTOMATIC GUIDANCE SYSTEM (OPTIONAL) 2-4

26 NARROW-AISLE LOAD HANDLING 2-4

261 Depositing a Load 2-5

262 Retrieving a Load 2-5

27 LONG LOAD HANDLING 2-6

271 Depositing a Long Load 2-6

272 Retrieving a Long Load 2-7

28 OPERATOR'S SEAT ADJUSTMENT 2-7

29 SEAT BELT ADJUSTMENT 2-7

210 FORK ADJUSTMENT 2-8

211 SAFETY PRECAUTIONS 2-8

212 TIPPING HAZARDS 2-9

213 SERVICING PRECAUTIONS 2-10

214 WARNING DECALS 2-11

"Pinch-Point" Warning 2-11

"Fork-Hazard" Warning 2-11

"Tipping" Warning 2-11

Battery Connector Warning 2-11

Table of Contents

Battery Hazard Warning 2-12

Block-Up Warning 2-12

Use Handbrake Warning 2-12

Battery Replacement Warning 2-13

Tire Replacement Warning 2-13

Don't Paint Notice 2-13

General Warnings 2-13

Capacity Plate 2-13

Figure 2-1 Location of Controls and Indicators 2-2

Figure 2-2 Lift Control Symbol 2-3

Figure 2-3 Tilt Control Symbol 2-3

Figure 2-4 Pivot Control Symbol 2-3

Figure 2-5 Shift Control Symbol 2-4

Figure 2-6 Aligning Truck with Rack Opening 2-5

Figure 2-7 Pivoting the Load into Load Position 2-5

Figure 2-8 Load Shifted Right into Rack 2-5

Figure 2-9 Positioning Truck at Slot 2-6

Figure 2-10 Rotating the Load Into the Slot (Forward) 2-6

Figure 2-11 Pnshing the Load into the Slot 2-6

Figure 2-12 Backing the Truck into the Slot 2-7

Figure 2-13 Rotating the Load into the Slot (Rearward) 2-7

Figure 2-14 Operator's Seat Adjnstments 2-7

Figure 2-15 Fork Latch in Release Position 2-8

Figure 2-16 Fork Latch in Lock Position 2-8

Figure 2-17 Pinch Point Warning, P/N 1408792 (small) or 1408793 (large) 2-11

Figure 2-18 Fork Hazard, PIN 1408791 2-12

Figure 2-18 Tipping Warning, PIN 1409832 2-12

Figure 2-19 Battery Connector, P/N 50367-Y 2-12

Figure 2-20 Battery Hazard, PIN 50366-Y 2-12

Figure 2-21 Block-Up Warning, PIN 50690 2-12

Figure 2-22 Use Handbrake Warning, P/N 30300 2-13

Figure 2-23 Battery Replacement, PIN 51023-R 2-13

Figure 2-24 Tire Replacement, PIN 37433 2-13

Figure 2-25 Don't Paint Notice, PIN 50368-Y 2-13

Figure 2-26 General Warnings, PIN 50365-Y 2-14

Figure 2-27 Capacity Plate (Unique to Truck No PIN) 2-15

Section 3 PREVENTIVE MAINTENANCE

31 GENERAL 3-1

32 VISUAL CHECKS 3-1

321 Defective Fasteners 3-1

322 Welding Defects 3-1

323 Defective Wires or Connectors 3-1

324 Worn Hydraulic Lines or Loose Fittings 3-2

325 Rust or Corrosion 3-2

33 LUBRICATION INSTRUCTIONS 3-2

331 General Procedures 3-2

332 Checking Brake Fluid Level 3-2

333 Checking Hydraulic Oil Level 3-2

334 Replacing Hydraulic Fluid Filter 3-2

335 Checking and Adding Drive Axle Oil 3-3

336 Lubricating Pivot Cylinder Clevises 3-3

337 Lubricating Tilt Cylinder Clevises 3-3

338 Lubricating Steer Axle Components 3-4

339 Lubricating the Mast Trunnions 3-4

3310 Lubricating the Pivot Shaft Bearings 3-4

34 Checks and Adjustments 3-5

341 Testing the Parking Brake 3-5

342 Adjusting the Parking Brake 3-5

343 Checking Mast Operation 3-5

Table 3-1: Daily Preventive Maintenance Checks 3-6

Table 3-2: Weekly Preventive Maintenance Checks 3-6

Table 3-3: Lubrication Chart 3-6

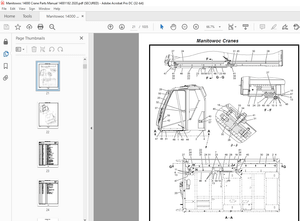

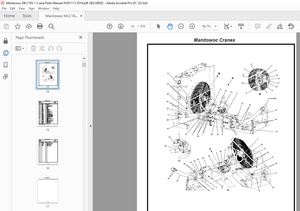

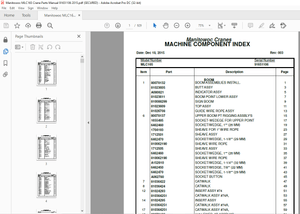

Section 4 ILLUSTRATED PARTS BREAKDOWN

41 GENERAL 4-1

42ABBREVIATIONS 4-1

43 PARTS NOT SHOWN 4-2

44 PHANTOM AND REFERENCE PARTS 4-2

BASE UNIT SL44/4, 48 voe, PART NO 1413338-A 4-3

SERVICE BRAKE GROUP, PART NO 1412402-A 4-5

SERVICE BRAKE PARTS GROUP, PART NO 15507-E 4-6

CYLINDER, MASTER, 3/4 BORE 1-1/4 STROKE, PART NO 20210-A 4-9

HAND BRAKEASSY, PARTNO17395 , 4-10

DRIVEASSY, SL33HP STD, PART NO 10712-05-K , 4-12

AXLE, DRIVE WITH KNOTT BRAKE, PART NO 17133-8 4-15

AXLE, DRIVE WITH KNOTT BRAKE, PART NO 17133-S (Continued) 4-16

DIFFERENTIAL, NO-SPIN, PART NO 20230-A 4-20

MOTOR, TRACTION, PART NO 51367-8 4-21

BRAKE ASSY MODIFIED 6" DIAMETER, PART NO 30677-8 4-22

FLUIDS & GREASE GROUP, PART NO 30760-01-C 4-23

COVER GROUP SL-44/4 STD, PART NO 1412273-A 4-25

SEAT GROUP, PART NO 1412286-A 4-27

SEAT BELT ASSY MODIFIED, PART NO 17585-8 4-28

ELECTRICAL GP SL44/4 STD 48 VOL TS, PART NO 1413361-C 4-29

ELECTRICAL PANEL ASSY 48 VOL TS, PART NO 1413362-A 4-30

FUSE PANEL SUB ASSY 48 VOL TS SL33/44, PART NO 1413364-A 4-32

ELECTRICAL DOOR ASSY 48 VOLTS, PART NO 15512-12-C 4-35

ELECTRICAL DOOR ASSY 48 VOL TS , PART NO 15512-12-C (Continued) 4-36

SCR TRACTION CONTROL UNIT, PART NO 51170-C 4-40

CONTACTOR,300A,DPDT, 48V, PART NO 28888-50-8 4-42

CONTACTOR,300A, SPNO, 48V, PART NO 28889-50-8 4-44

BATTERY CONNECTOR SBE320 BLUE FOR 3/0 WIRE 48 VOLT, PART NO 1413425 4-46

CAPACITORASSY, PART NO 15547-A 4-47

FOOT CONTROLLER ASSY (EV-100), PART NO 17065-D 4-48

SWITCH ASSY, SEAT, PART NO 15659- 4-50

HORN ASS'Y 48V DC 48VOLT, PART NO 10200-01-A 4-51

INSTALLATION TAIL LAMP 48, PART NO 10902-01- 4-52

LIGHT,STOP & TAIL,48 V, PART NO 25055-2-A 4-54

STEER PUMP & MOTOR ASSY 48V, w/O THERMOSTAT, PART NO 50661-04-C 4-55

PUMP, POWER STEERING, PART NO 50654-A 4-56

MOTOR, POWER STEER DC 48 VOLT, PART NO 50656-02-A 4-57

ARTICULATED STEER AXLE ASSY, PART NO 14221-05-F 4-60

CYLINDER ASSY, STEER, PART NO 10834-G 4-63

CYLINDER ASSY, MODIFIED, PART NO 9767-01-B 4-64

CROSSHEAD AND PIVOT ASSY, PART NO 17512-01-E 4-66

COMMON PARTS GROUP SL33/44, PART NO 1412401-C 4-70

COMMON PARTS GROUP SL33/44, PART NO 1412401-C (Continued) 4-71

COMMON PARTS GROUP SL33/44, PART NO 1412401-C (Continued) 4-72

KNOB, LIFT, PART NO 50382-01 4-78

DOOR ASSY GROUP w/o STEER PUMP & MOTOR, PART NO 11748-05-A 4-80

CHAIN ANCHOR ASSY, PART NO 17393-B 4-81

INDICATOR, FORK LEVEL, PART NO 36560 4-82

BATTERY RETAINER & SPACER PLTINSTALL GP SL443-44, PART NO 1413324-A 4-83

CUSTOMER ORDER NO 942396 REV 00 4-85

DRIVE TIRE GP NON MARKING 18 X 10 X 1213, PART NO 1412261-A 4-87

OPERATOR CONSOLEASSY & COVER HYO CONTROLS STD, PART N01412398-A 4-89

OPERATOR CONSOLEASSY STD SL-33/44, PART NO17372-12-A 4-90

COVER PANEL ASSEMBLY, PART NO 17371-01 4-92

DASH PANEL, WIRE HARNESS ASSY & JUMPER SL33/44HP, PART NO 1411615-A 4-93

PANEL ASSY, INSTRUMENT, PART NO 17369-G 4-94

LEVERASSY, PARTNO10417-B 4-96

ORBITROL SUB-ASSY, PART NO 17430-C 4-97

STEERING CONTROL UNIT, PART NO 25715-B 4-98

COLUMN, STEER w/2 HORN WIRES, PART NO 25040-C 4-100

STEERING WHEEL & HORN BUTTON ASSY, PART NO 1410602-A 4-101

HYDRAULIC ASSY 48Vw/O LIFT- SHIFT & PIVOT, PART NO 1413365-C 4-103

HYDRAULIC ASSY 48Vw/O LIFT- SHIFT & PIVOT, PART NO 1413365-C (Continued) 4-104

CONTROL PANEL ASSY "E" & "EE" 36 & 48 VOL TS, PART NO 15593-08-A 4-108

VALVEASSY, CONTROL, PART NO11777 4-111

VALVE, CONTROL, MODIFIED, PART NO 50700-B 4-112

VALVEASSY, CONTROL, PARTNO15592-01-A 4-115

VALVE, CONTROL, MODIFIED, PART NO 50701-01-A 4-116

PUMP AND MOTOR ASSEMBLY SL44/4 ESS "E", PART NO 14051-01-A 4-118

MOTOR, PUMP, PART NO 21000-A 4,120

PUMP, DOUBLE VANE, 13GPM/5GPM OUTLET 1 OPP INPUT, PART NO 21150-A 4-122

HOSE KIT, PART NO 1413454-A 4-124

HOSE KIT, PART NO1413455-B 4-125

RESERVOIR ASSY, PART NO 10845-02-J 4-126

FILTER ASSY, HYDRAULIC, PART NO17397-B 4-128

CYLINDER-SHIFT ASSY 11 STROKE, PART NO 17394-01-B 4-129

CYLINDER-SHIFT 1107 STROKE, PART NO 51398-01-D 4-130

UMBILICALASSY, PART NO 1411667-A 4-131

CYLINDER, PIVOT, PART NO 30071-A 4-132

CYLINDER, TILT, PART NO 30340-02-B 4-133

QUAD GP 855-240-63 1400 SERIES, PART NO 1412516-A 4-135

INTER GP QUAD MAST 48V w/LIFT-SHIFT & PIVOT, PART NO 1413371-A 4-137

PARTS GROUP HYO 48 VOLTS w/LIFT-SHIFT & PIVOT, PART NO 1413373-B 4-138

SWITCH GROUP, LIFT, SHIFT & PIVOT QUAD MAST, PART NO 1412481-A 4-140

LIFT LIMIT SWITCH MODIF ABOVE 192 FH QUAD MAST, PART NO 1412404-B 4-142

SIDESHIFT SWITCH MODIF 16 SHIFT, PART NO 17365-01-B 4-144

PIVOT SWITCH INSTALLATION SL33/44, PART NO 1412314-B 4-146

PAINT, ENAMEL YELLOW, PART NO 37260-04-A 4-149

DECALS & MARKINGS, PLATES 15019 DUTCH, PART NO 15647-07-C 4-152

Table of Contents

Section 5 MAINTENANCE

5-1 GENERAL 5-1

5-2 SERVICING PRECAUTIONS 5-1

5-3 DRIVE ASSEMBLY 5-2

531 REMOVAL 5-2

532 INSTALLATION 5-3

533 DISASSEMBLY 5-4

SATISFACTORY TOOTH CONTACT 5-14

HIGH TOOTH CONTACT 5-14

LOW TOOTH CONTACT 5-15

534 FINAL ASSEMBLY OF DRIVE AXLE 5-15

5-4 STEER AXLE 5-16

541 REMOVAL 5-16

542 INSTALLATION 5-17

543 DISASSEMBLY 5-17

544 REASSEMBLY 5-21

5-5 SERVICE BRAKE 5-21

551 MASTER BRAKE CYLINDER LINKAGE ADJUSTMENT 5-21

552 BRAKE SHOE INSPECTION 5-21

553 BLEEDING THE BRAKES 5-21

554 STEER AXLE BRAKE REMOVAL 5-22

5-6 PARKING BRAKE ADJUSTMENT 5-23

561 HAND BRAKE 5-23

562 SEAT BRAKE 5-23

5-7 BATTERY MAINTENANCE 5-23

571 REMOVAL OF BATTERY FROM VEHICLE 5-25

572 CHECKING STATE-OF-CHARGE 5-26

573 WATERING 5-26

574 CHARGING 5-27

575 CLEANING 5-27

576 RECORDS 5-28

5-8 PIVOT ASSEMBLY 5-28

581 REMOVAL OF PIVOT/SIDESHIFT ASSEMBLY FROM TRUCK 5-28

582 PIVOT SHAFT ASS EMBLY : 5-30

583 PIVOT ARM RACKING ADJUSTMENT 5-31

5-9 HYDRAULIC PUMP AND MOTOR 5-31

591 REMOVAL 5-31

592 INSTALLATION 5-32

5-10 POWER STEERING PUMP AND MOTOR 5-34

5101 REMOVAL OF PUMP MOTOR 5-34

5102 REMOVAL OF THE PUMP 5-35

5-11 HYDRAULIC SYSTEM 5-35

5111 HYDRAULIC OIL RESERVOIR SUCTION FILTER REMOVAL 5-35

5112 HYDRAULIC RETURN LINE FILTER REMOVALAND INSTALLATION 5-38

5-12 PIVOT/SHIFT INTERLOCKS 5-38

5121 OPERATIONAL DESCRIPTION 5-38

5122 DETAILED FUNCTION OF CIRCUIT COMPONENTS 5-39

5123 PIVOT/SHIFT INTERLOCK SWITCH ADJUSTMENTS 5-40

5-13 ELECTRICAL SYSTEM 5-41

5131 REMOVAL OF SCR CONTROL UNIT 5-41

5132 REPLACING THE SCR CONTROL MODULE 5-42

5133 SCR CONTROL ADJUSTMENTS 5-42

Table of Contents

5134 SINGLE POLE CONTACTORS 5-42

5135 DOUBLE POLE CONTACTORS 5-43

5136ACCELERATOR MODULE 5-43

513 7 DASH PANEL MODULE 5-44

5-14 MAST ASSEMBLY 5-45

5141 REMOVAL FROM TRUCK 5-45

5142 MAST RACKING ADJUSTMENT 5-46

5143 MAST ADJUSTMENT 5-46

5144 MAST DISASSEMBLY 5-47

5-15 PRIMARY CYLINDER 5-47

5151 DISASSEMBLY 5-47

5152 REASSEMBLY 5-48

5-16 SECONDARY CYLINDER 5-48

5161 DISASSEMBLY 5-48

5162 REASSEMBLY 5-49

5163 BLEEDING THE CYLINDER 5-49

5-17 ORBITROL UNIT 5-50

5171 REMOVAL 5-50

5172 INSTALLATION 5-50

5173 DISASSEMBLY AND REASSEMBLY 5-50

Table 5-1: Standard Torque Values for "English" Fasteners 5-51

Table 5-2: Standard Torque Values for Metric Fastener 5-52

Section 6 PARTS LIST

61 GENERAL 6-1

62 WELDMENTS 6-1

Section 7 TROUBLESHOOTING

71 ELECTRICAL SYSTEM 7-1

71 1 Traction Fuse 1 FU Open 7-1

7 12 Pump Fuse 2FU Open 7-2

713 Control Fuses 3FU, 4FU or 5FU Open 7-3

7 14 Loss of Drive Power 7-4

715 Loss of Drive Speed 7-6

72 HYDRAULIC SYSTEM 7-7

721 Pump Does Not Operate 7-7

722 Pump Runs Continuously 7-9

723 Pivot Function Defective 7-11

7 24 Shift Function Defective 7-11

7 25 Loss of Hydraulic Lift 7-11

Table 7-1: Normal Hoist Pressures 7-12

Table 7-2: No-Load Function Pressures 7-13

Table 7-3: Function Pressures @2500 lb Load 7-13

726 Loss of Lift Speed 7-13

727 Drift of Raised Load 7-14

7 28 Loss of Mast Tilt 7-14

73 POWER STEERING SYSTEM 7-14

731 Loss of Power Steering 7-14

732 Slow Steering Response 7-15

733 Drift of Steering 7-16

74 BRAKE SYSTEM 7-16

Table of Contents

741 No Service Brake 7-16

742 No Seat Brake 7-17

743 No Parking Brake 7-17

75 NO-SPIN DIFFERENTIAL 7-17

76 SCR CONTROL CIRCUIT 7-17

761 Theory of Operation 7-17

762 Oscillator · 7-18

763 Current Limit 7-18

764 Plugging 7-18

765 Ramp Start 7-19

7 66 Full Power Transition 7-19

767 1A Control 7-19

768 Static Return to OFF 7-19

7 69 Coil Driver Modules 7 -19

7 61 O Thermal Protector (TP) 7-19

7 611 1 A Thermal Hold-Off 7-19

7612 Must Pulse to Time 7-19

7613 Trouble-Shooting Instructions 7-19

Table 7-4: Control Card Component Checks 7-21

Table 7-5: Troubleshooting Pump 7-24

Table 7-6: Troubleshooting NoSPIN Differential 7-26

S.S 05/24