$37

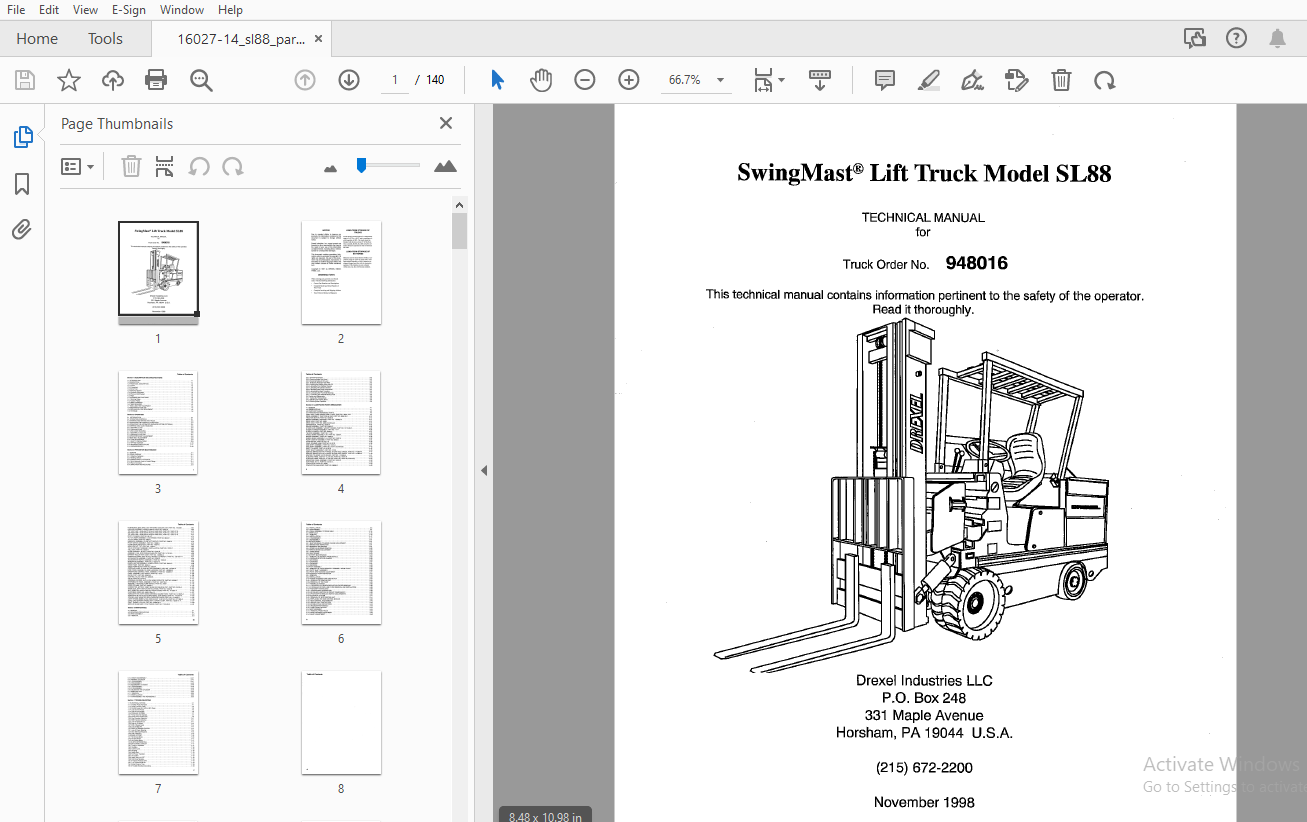

Drexel SL88 SwingMast Lift Truck Technical Manual 16027-14 – PDF DOWNLOAD

Drexel SL88 SwingMast Lift Truck Technical Manual 16027-14 – PDF DOWNLOAD

FILE DETAILS:

Language : English

Pages : 140

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Drexel SL88 SwingMast Lift Truck Technical Manual 16027-14 – PDF DOWNLOAD

Section 1 DESCRIPTION AND SPECIFICATIONS

1 1 INTRODUCTION 1-1

1 2DESCRIPTION 1-1

1 3 FUNCTIONAL DESCRIPTION 1-2

1 3 1 Frame 1-2

1 3 2 Powerplant 1-2

1 3 3 Drive Train 1-2

1 3 4 Electrical System 1-2

1 3 5 Hydraulic Subsystem 1-3

1 3 6 Pivot and Shift System 1-3

1 3 7 Mast 1-3

1 4 WARNINGS AND CAUTIONS 1-5

1 4 1 Warning Plates 1-5

1 4 2 Caution Plates 1-5

1 5 ITEMS FURNISHED 1-5

1 6 ITEMS REQUIRED 1-5

1 7 TOOLS AND TEST EQUIPMENT 1-5

1 8 PREPARATION FOR USE 1-5

1 9 PREPARATION FOR RESHIPMENT 1-5

1 10STORAGE 1-6

Section 2 OPERATION

2 1 INTRODUCTION 2-1

2 2 OPERATING CONTROLS 2-1

2 3 STARTING AND DRIVING THE TRUCK 2-3

2 4 OPERATING THE HYDRAULIC FUNCTIONS 2-3

2 5 OPERATING THE AUTOMATIC GUIDANCE SYSTEM (OPTIONAL) 2-4

2 6 NARROW-AISLE LOAD HANDLING 2-5

2 6 1 Depositing a Load 2-5

2 6 2 Retrieving a Load 2-5

2 7 LONG LOAD HANDLING 2-6

2 7 1 Depositing a Long Load 2-6

2 7 2 Retrieving a Long Load 2-7

2 8 OPERATOR’S SEAT ADJUSTMENT 2-8

2 9 SEAT BELT ADJUSTMENT 2-8

2 10 FORK ADJUSTMENT 2-8

2 11 SAFETY PRECAUTIONS 2-9

2 12TIPPING HAZARDS 2-10

2 13 SERVICING PRECAUTIONS 2-11

2 14 WARNING DECALS 2-12

Section 3 PREVENTIVE MAINTENANCE

3 1 GENERAL 3-1

3 2 VISUAL CHECKS 3-1

3 2 1 Defective Fasteners 3-1

3 2 2 Welding Defects 3-1

3 2 3 Defective Wires or Connectors 3-1

3 2 4 Worn Hydraulic Lines or Loose Fittings 3-1

3 2 5 Rust or Corrosion 3-2

3 3 LUBRICATION INSTRUCTIONS 3-2

3 3 1 General Procedures 3-2

3 3 2 Checking Brake Fluid Level 3-2

3 3 3 Checking Hydraulic Oil Level 3-2

3 3 4 Replacing Hydraulic Fluid Filter 3-3

3 3 5 Checking and Adding Drive Axle Oil 3-3

3 3 6 Lubricating Pivot Cylinder Clevises 3-3

3 3 7 Lubricating Tilt Cylinder Clevises 3-3

3 3 8 Lubricating Steer Axle Components 3-4

3 3 9 Lubricating the Mast Trunnions 3-5

3 3 1 O Lubricating the Pivot Shaft Bearings 3-5

3 3 11 Lubricating the Sideshift Bearing Pads 3-5

3 4 Checks and Adjustments 3-6

3 4 1 Testing the Parking Brake 3-6

3 4 2 Adjusting the Parking Brake , 3-6

3 4 3 Checking Mast Operation 3-6

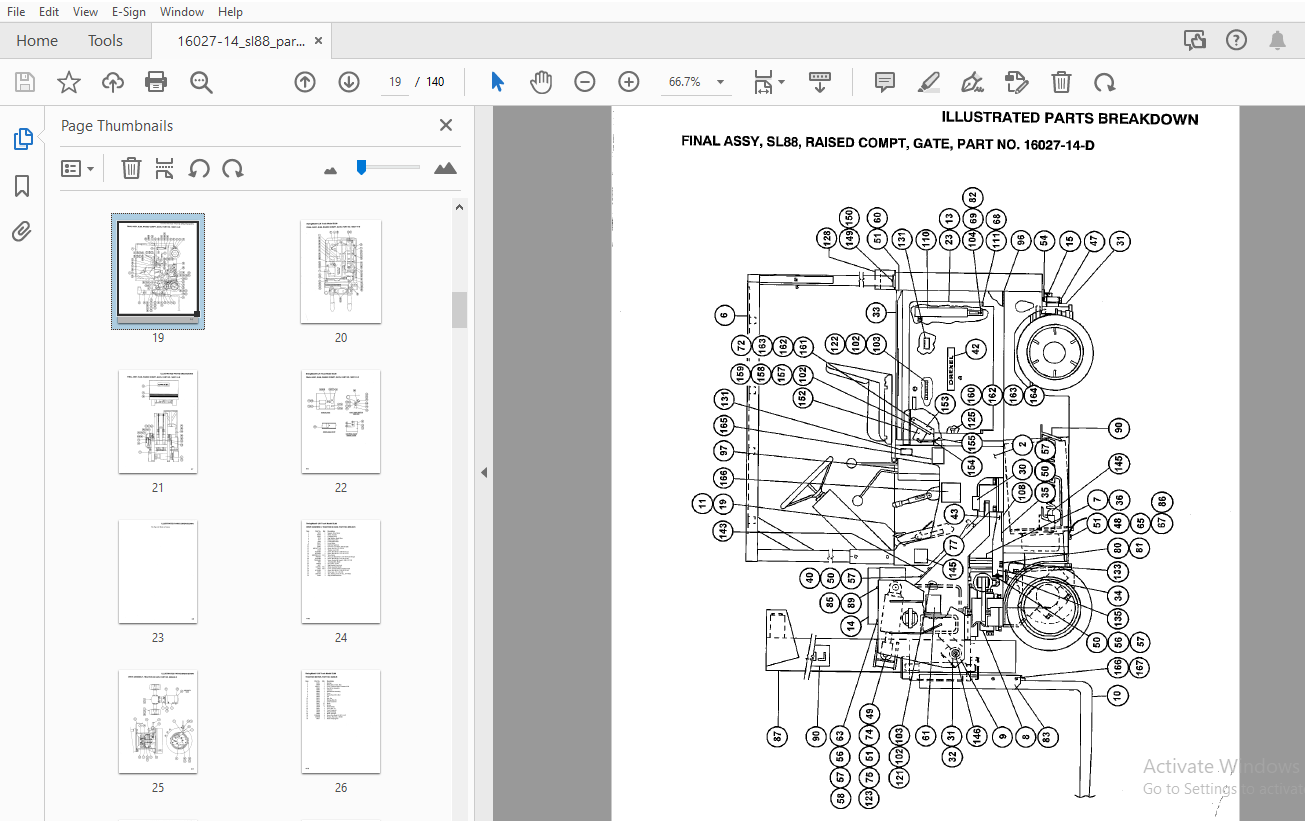

Section 4 ILLUSTRATED PARTS BREAKDOWN

4 1 GENERAL 4-1

4 2ABBREVIATIONS 4-1

4 3 PARTS NOT SHOWN 4-2

4 4 PHANTOM AND REFERENCE PARTS 4-2

FINALASSY, SL88, RAISED COMPT, GATE, PART NO 16027-14-D 4-4

DRIVE ASSEMBLY, TRACTION 56 OAW, PART NO 8856-02-K 4-10

TRACTION MOTOR, PART NO 50298-B 4-12

BRAKE ASSEMBLY MODIFIED, PART NO 1406982-B 4-14

DRIVE AXLE, PART NO 52994 4-15

DRIVE AXLE, PART NO 52994 (Continued) 4-16

DIFFERENTIAL, PART NO 20230-A 4-18

BRAKE ASSEMBLY, PART NO 53002-E 4-20

STEER AXLE ASSEMBLY w/KNOTT BRAKES, PART NO 13113-06-C 4-24

STEER CYLINDER ASSEMBLY, PART NO 11171 4-26

STEER CYLINDER, PART NO 50303-A 4-27

TIE ROD ASSEMBLY, PART NO 11158 4-28

WHEEL BRAKE ASSEMBLY, RH, PART NO 13596-A 4-29

BRAKE ASSEMBLY, PART NO 18062-D 4-30

WHEEL BRAKE ASSEMBLY, LH, PART NO 13597-A 4-32

PUMP & MOTOR ASSEMBLY, PART NO 9978-B 4-34

PUMP MOTOR, PART NO 9617-D 4-36

PUMP, DOUBLE VANE, PART NO 21197-D 4-38

SIDE SHIFT ASSEMBLY, PART NO 10273-J 4-41

SIDE SHIFT ASSEMBLY, PART NO 10273-J (Continued) 4-42

SHIFT CYLINDER, PART NO 6790-B 4-44

PIVOT SHAFT ASSEMBLY, PART NO 10133 4-45

SERVICE BRAKE SYS HYD 4 WHEEL 56 OAW AXLE w/KNOT, PART NO 1413804-A 4-47

SERVICE BRAKE SYS HYD 4 WHEEL 56 OAW AXLE w/KNOT, PART NO 1413804-A 4-48

MASTER CYLINDER 150 PSI RELIEF, PART NO 1413595-A 4-51

ELECTRIC PANEL ASSY EV-1 C, 36 VDC, PART NO 16075-R 4-53

ELECTRIC PANEL ASSY EV-1 C, 36 VDC, PART NO 16075-R (Continued) 4-54

MOUNTING PANEL ASSEMBLY, PART NO 16076-C 4-56

SCR PANEL EV-1C, PART NO 50741-B 4-58

CONTACTOR, PART NO 28888 4-60

CONT ACTOR, 300A SPNO, PART NO 28889-D 4-62

CONTACTOR, 300A, SPNO, STD TIP W/ARC COOLERS, 36V, PART NO 1413593 4-64

HARNESS ASSEMBLY POWER CABLES, PART NO 16203-D 4-68

TOP ASSY-GRP -SL88 w/BATT ROLLER AND GATE, PART NO 13401-07-N 4-72

TOP ASSY-GRP -SL88w/BATT ROLLER AND GATE, PART NO 13401-07-N 4-73

TOP ASSY-GRP -SL88 w/BATT ROLLER AND GATE, PART NO 13401-07-N 4-74

PIVOT CYLINDER, PART NO 6914-F 4-75

TILT CYLINDER ASSEMBLY 2 219 STROKE, PART NO 9822-01 4-76

TILT CYLINDER, PART NO 6982-K 4-77

UMBILICAL ASSEMBLY (3 LINE LIFT CIRCUIT), PART NO 10692-A 4-78

PIVOT SWITCH ASSEMBLY, PART NO 12360-A 4-79

COUNTER BALANCE ASSY, PART NO 10607-B 4-80

INDICATOR KIT, TILT, PART NO 11520-A 4-82

TAIL & STOPLIGHT ASSEMBLY INSTALLATION, PART NO 13707-C 4-83

TAIL LIGHT, PART NO 25055-B • 4-84

HORN ASSEMBLY, 36 VOLT, PART NO 10200-B 4-85

ASSEMBLY, FAN, SCR COOLING 24/56 voe, PART NO 1411316-A 4-86

BATTERY ROLLER TRAY ASSY, PART NO 1405800-A 4-88

OPERATOR COM PT ASSY 36 VOLT RAISED 3 5 HIGHER*, PART NO 13018-07-H 4-91

ACCELERATOR ASSEMBLY, PART NO 13522-C 4-93

ACCELERATOR SWITCH ASSEMBLY, PART NO 13523-C 4-94

RESERVOIR ASSEMBLY, PART NO 11750-01-B 4-96

PUMP & MOTOR ASSEMBLY, POWER STEER , PART NO 50454-A 4-98

STEER PUMP, PART NO 50654-A 4-99

STEER PUMP MOTOR, PART NO 50656-A 4-100

STEERING WHEEL & HORN BUTTON ASSEMBLY, PART NO 1410602-A 4-101

DASH PANEL ASSEMBLY & WIRE HARNESS, PART NO 1402690-B 4-102

OPERATOR’S CONTROL PANEL ASSEMBLY, PART NO 1402667-E 4-104

PANEL ASSEMBLY, KEY SWITCH, PART NO 16212 4-106

KNOB, PIVOT, PART NO 50382-03 4-108

CONTROL VALVE, PART NO 22065-B 4-110

VALVE, PART NO 23737-B 4-112

STEERING CONTROL UNIT,5 9 CU IN/REV OPEN CTR, PART NO 25763-C 4-114

INTERMEDIATE PANEL ASSEMBLY, PART NO 1402716-C 4-116

ASSEMBLY, RESISTOR, PUMP SWITCH, PART NO 37887 4-118

STEER COLUMN, PART NO 25040-C 4-119

CONNECTOR, BATTERY, GREY SB-350 2/0 CABLE 36 VOLT, PART NO 25165-A 4-120

INTERLOCK, SHIFT SWITCH (INSTALLATION), PART NO 13633-B 4-122

SEATw/BELTS & SWITCH INSTALLATION SL55/88, PART NO 1413607-A 4-124

CUSTOMER ORDER NO 948016 Rev 01 4-127

HEADLIGHT MTD BOTH SIDES OVERHEAD GUARD FRONT, PART NO 1412978-A 4-130

HEADLIGHT 36 VOLTS W/O GUARD MODEL 6700 SERIES, PART NO 1412924-A 4-132

STROBE LIGHT MOUNTED REAR OVERHEAD GUARD, PART NO 1412979-A 4-134

LIGHT STROBE AMBER w/180 LENS BLKOUT 12-80 VOLTS, PART NO 2771995-A 4-136

LONG LOAD SUPPORT RAISED BATT & OPER’S COMP, PART NO 16234-01-A 4-137

PAINT, ENAMEL YELLOW, PART NO 37260-04-A 4-139

BACK-UP ALARM ASSY 12119 TRUCKS, PART NO 17318-03-2 4-141

Section 5 MAINTENANCE

5-1 GENERAL 5-1

5-2 SERVICING PRECAUTIONS 5-1

5-3 DRIVE ASS EMBLY 5-2

5 3 1 REMOVAL 5-2

5 3 2 INSTALLATION 5-3

5 3 3 DISASSEMBLY 5-4

5 3 4 FINAL ASSEMBLY OF DRIVE AXLE 5-15

5-4 STEER AXLE 5-16

5 4 1 REMOVAL 5-16

5 4 2 INSTALLATION 5-17

5 4 3 DISASSEMBLY 5-17

5 4 4 REASSEMBLY 5-21

5-5 SERVICE BRAKE 5-21

5 5 1 MASTER BRAKE CYLINDER LINKAGE ADJUSTMENT 5-21

5 5 2 BRAKE SHOE INSPECTION 5-21

5 5 3 BLEEDING THE BRAKES 5-21

5 5 4 STEER AXLE BRAKE REMOVAL 5-22

5-6 PARKING BRAKE ADJUSTMENT 5-23

5 6 1 HAND BRAKE 5-23

5 6 2 SEAT BRAKE 5-23

5-7 BATTERY MAINTENANCE 5-23

5 7 1 REMOVAL OF BATTERY FROM VEHICLE 5-25

5 7 2 CHECKING STATE-OF-CHARGE 5-26

5 7 3 WATERING 5-26

5 7 4 CHARGING 5-27

5 7 5 CLEANING 5-27

5 7 6 RECORDS 5-28

5-8 PIVOT ASSEMBLY 5-28

5 8 1 REMOVAL OF PIVOT/SIDESHIFT ASSEMBLY FROM TRUCK 5-28

5 8 2 PIVOT SHAFT ASSEMBLY 5-30

5 8 3 PIVOT ARM RACKING ADJUSTMENT 5-31

5-9 HYDRAULIC PUMP AND MOTOR 5-31

5 9 1 REMOVAL 5-31

5 9 2 INSTALLATION 5-32

5-10 POWER STEERING PUMP AND MOTOR 5-34

5 10 1 REMOVAL OF PUMP MOTOR 5-34

5 10 2 REMOVAL OF THE PUMP 5-35

5-11 HYDRAULIC SYSTEM 5-35

5 11 1 HYDRAULIC OIL RESERVOIR SUCTION FILTER REMOVAL 5-35

5 11 2 HYDRAULIC RETURN LINE FILTER REMOVAL AND INSTALLATION 5-38

5-12 PIVOT/SHIFT INTERLOCKS 5-38

5 12 1 OPERATIONAL DESCRIPTION 5-38

5 12 2 DETAILED FUNCTION OF CIRCUIT COMPONENTS 5-39

5 12 3 PIVOT/SHIFT INTERLOCK SWITCH ADJUSTMENTS 5-40

5-13 ELECTRICAL SYSTEM 5-41

5 13 1 REMOVAL OF SCR CONTROL UNIT 5-41

5 13 2 REPLACING THE SCR CONTROL MODULE 5-42

5 13 3 SCR CONTROL ADJUSTMENTS 5-42

5 13 4 SINGLE POLE CONTACTORS 5-42

5 13 5 DOUBLE POLE CONTACTORS 5-43

5 13 6 ACCELERATOR MODULE 5-43

5 13 7 DASH PANEL MODULE 5-44

5-14 MAST ASSEMBLY 5-45

5 14 1 REMOVAL FROM TRUCK 5-45

5 14 2 MAST RACKING ADJUSTMENT 5-46

5 14 3 MAST ADJUSTMENT 5-46

5 14 4 MAST DISASSEMBLY 5-47

5-15 PRIMARY CYLINDER 5-47

5 15 1 DISASSEMBLY 5-47

5 15 2 REASSEMBLY 5-48

5-16 SECONDARY CYLINDER 5-48

5 16 1 DISASSEMBLY 5-48

5 16 2 REASSEMBLY 5-49

5 16 3 BLEEDING THE CYLINDER 5-49

5-17 ORBITROL UNIT 5-50

5 17 1 REMOVAL 5-50

5 17 2 INSTALLATION 5-50

5 17 3 DISASSEMBLY AND REASSEMBLY 5-50

Section 7 TROUBLESHOOTING

7 1 ELECTRICAL SYSTEM 7-1

7 1 1 TractionFuse1FUOpen 7-1

7 1 2 Pump Fuse 2FU Open 7-2

7 1 3 Control Fuses 3FU, 4FU or 5FU Open 7-3

7 1 4 Loss of Drive Power 7-4

7 1 5 Loss of Drive Speed 7-6

7 2 HYDRAULIC SYSTEM 7-7

7 2 1 Pump Does Not Operate 7-7

7 2 2 Pump Runs Continuously 7-9

7 2 3 Pivot Function Defective 7-11

7 2 4 Shift Function Defective 7-11

7 2 5 Loss of Hydraulic Lift 7-11

7 2 6 Loss of Lift Speed 7-13

7 2 7 Drift of Raised Load 7-14

7 2 8 Loss of Mast Tilt 7-14

7 3 POWER STEERING SYSTEM 7-14

7 3 1 Loss of Power Steering 7-14

7 3 2 Slow Steering Response 7-15

7 3 3 Drift of Steering 7-16

7 4 BRAKE SYSTEM 7-16

7 4 1 No Service Brake 7-16

7 4 2 No Seat Brake 7-17

7 4 3 No Parking Brake 7-17

7 5 NO-SPIN DIFFERENTIAL 7-17

7 6 SCR CONTROL CIRCUIT 7-17

7 6 1 Theory of Operation 7 -17

7 6 2 Oscillator 7-18

7 6 3 Current Limit 7-18

7 6 4 Plugging 7-18

7 6 5 Ramp Start 7-19

7 6 6 Full Power Transition 7-19

7 6 71A Control 7-19

7 6 8 Static Return to OFF 7-19

7 6 9 Coil Driver Modules 7-19

7 6 10 Thermal Protector (TP) 7-19

7 6 111AThermal Hold-Off 7-19

7 6 12 Must Pulse to Time 7-19

7 6 13 Trouble,Shooting Instructions 7-19