$37

Drexel SwingMast Lift Truck R60SL (CBD) Series Service & Parts Maintenance Manual 1416841 – PDF

Drexel SwingMast Lift Truck R60SL (CBD) Series Service & Parts Maintenance Manual 1416841 – PDF DOWNLOAD

FILE DETAILS:

Drexel SwingMast Lift Truck R60SL (CBD) Series Service & Parts Maintenance Manual 1416841 – PDF DOWNLOAD

Language : English

Pages : 158

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Drexel SwingMast Lift Truck R60SL (CBD) Series Service & Parts Maintenance Manual 1416841 – PDF DOWNLOAD

Section 1 Description and Specifications

1 1 Introduction 1-1

1 2 Description 1-1

1 3 Functional Description 1-2

1 3 1 Frame 1-2

1 3 2 Power Plant 1-2

1 3 3 Drive Train 1-2

1 3 4 Electrical System 1-2

1 3:5 Hydraulic Subsystem 1-2

1 3 6 Pivot and Shift System 1-3

1 3 7 Mast 1-3

1 4 Items Furnished 1-4

1 5 Items Required 1-5

1 6 Tools and Test Equipment 1-5

1 7 Preparation for Use 1-5

1 8 Preparation for Re-shipment 1-5

1 9 Storage 1-6

Table 1-1: General Specifications 1-6

Table 1-2: Dimensions of Standard Masts 1-7

R60SL “CBD” Series, Service, p/n: 1416841 -b, 09/03 3

D Table of Contents

IPB Contents – continued Page

Section 2 Operating your Truck

2 1 Operation

2 1 1 Pre-operation checklist 2-5

2 1 2 Adjusting the driver’s seat 2-5

Figure 2-1: Driver’s seat 2-5

Seat belt 2-7

Figure 2-2: Belt release button 2-7

2 1 3 Tilt steering column 2-7

Figure 2-3: Adjust tilt steering 2-7

2 1 4 Fork adjustment 2-8

Manual fork adjust 2-8

Figure 2-4: Unlocking the forks 2-8

Fork positioner option – automatic 2-9

2 2 driving the truck

2 2 1 Starting diesel engines 2-1 O

Figure 2-5: Glow plugs button 2-1 O

Cold temperature starting 2-11

2 2 2 Practice sessions 2-11

Inching 2-13

2 3 the mast

2 3 1 Practice session 2-13

Figure 2-6: Lift and till function lever icon 2-13

Figure 2-7: Fork level gauge 2-14

Figure 2-8: Pivot and shift function lever icon • , • 2-14

2 4 handling standard loads

2 4 1 To pick up the load • 2-16

Figure 2-9: Aligning the truck to the pallet opening 2-17

Figure 2-1 O: Pivot the forks about 45° 2-17

Figure 2-11: Shifting the forks into the pallet 2-18

Figure 2-12: Pivot the load about 45° 2-19

2 4 2 To deliver a load 2-19

Figure 2-13: Align the load to the rack , 2-20

Figure 2-14: Pivot the load about 45° 2-21

Figure 2-15: Placing the load into the rack 2-21

Figure 2-16: Pivot the forks about 45° 2-22

Figure 2-17: Normal driving position 2-22

2 5 side loading (long loads)

2 5 1 To pick up a “long” load 2-24

Figure 2-18: Aligning the truck to the long load pallet 2-24

Figure 2-19: Shifting the forks into the pallet 2-25

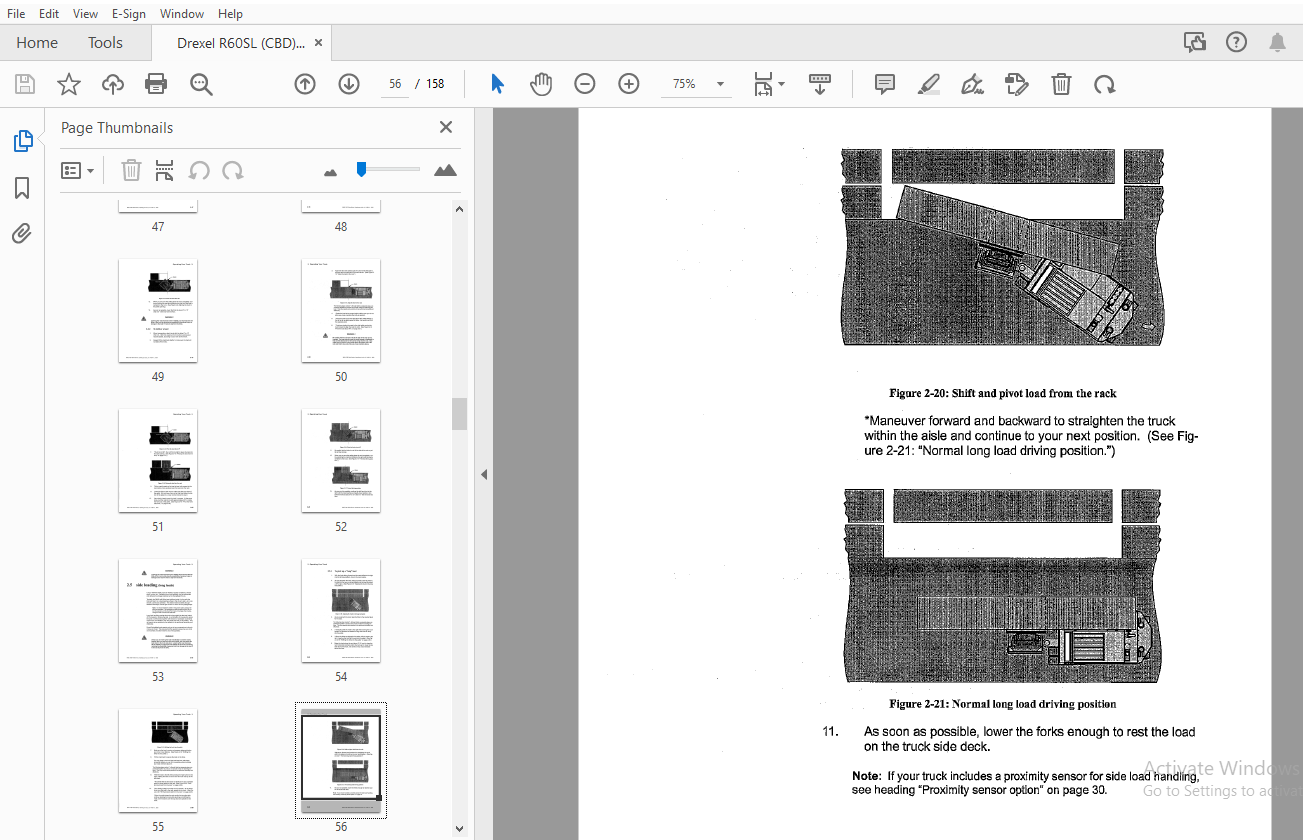

Figure 2-20: Shift and pivot load from the rack 2-26

Figure 2-21: Normal long load driving position 2-26

4 R60SL “CB □~ Serles, Service, p/n: 1416841 -b, 09/03

Table of Contents □

IPB Contents – continued Page

2 5 side loading (long loads) – continued

2 5 2 To deliver a “long” load 2-27

Figure 2-22: Aiming the load into the opening 2-27

Figure 2-23: Rotating the long load into the rack 2-28

Figure 2-24: Shifting the load into the opening 2-28

for more experienced driver’s 2-29

Figure 2-25: Backing the load into the slot 2-29

Figure 2-26: Pivoting the load into the opening 2-30

2 5 3 Proximity sensor option 2-30

Figure 2-27: Proximity sensor 2-31

Section 3 Preventive Maintenance

3 1 General 3-1

3 2 Visual Checks – 3-1

Defective Fasteners 3-1

Welding Defects 3-1

Defective Wires or Connectors 3-1

Worn Hydraulic Lines or Loose Fittings 3-2

Rust or Corrosion 3-2

3 3 Lubrication Instructions 3-1

3 4 Procedures 3-2

Check Engine Oil Level 3-2

Adding Engine Oil 3-2

Replacing Engine Oil Filter 3-2

Checking Transmission Fluid Level 3-2

Adding Transmission Fluid 3-3

Replacing Transmission Filter 3-3

Check and Adding Hydraulic Oil 3-3

Replacing Hydraulic Oil Filter 3-3

Check and Adding Drive Axle Oil 3-3

Check Brake Fluid 3-3

Lubricating Pivot Cylinder Clevis 3-4

Lubricating Shift Spherical Bearings and Sheave Block 3-5

Lubricating Side Shift Cam Rollers 3-5

Lubricating Steer Axle Components 3-5

Lubricating Tilt Cylinder Clevis 3-5

Lubricating Side Shift Bearing Housing 3-6

Lubricating Mast Trunnions 3-6

Lubricating Pivot Shaft Bearings 3-7

Check the Parking Brake 3-7

Adjusting the Parking Brake 3-7

R60SL “CBD” Serles, Service, p/n: 1416841 -b, 09/03 5

D Table of Contents

IPB Contents – continued Page

Section 3 Preventive Maintenance – continued

Checking the Air Filter 3-7

Cleaning the Air Filter 3-8

Replacing the Air Filler Element 3-8

Testing Broken Belt Indicator 3-8

Checking Mast Operation 3-8

Table 3-1: Daily Preventive Maintenance Checks 3-9

Table 3-2: Weekly Preventive Maintenance Checks 3-10

Table 3-3: Lubrication Chart 3-11

Section 4 Not Used

Section 5 Maintenance

5-1 Introduction 5-1

5-2 Servicing Precautions 5-1

5-3 General Maintenance 5-2

5 3 1 Replacement of Air Filter , 5-2

5 3 2 Replacement of Engine Oil Filter 5-2

5 3 3 Replacement of Hydraulic Oil Filter • 5-3

5 3 4 Replacement of Transmission Fluid Filter 5-3

5 3 5 Replacement of Alternator Belt 5-3

5 3 6 Replacement of Blower Belt , 5-4

5-4 Overhead Guard Removal 5-4

5-5 Drive Axle Maintenance 5-4

5 5 1 Removal 5-4

5 5 2 Installation 5-5

5 5 3 Removal and Replacement of Disk Brakes 5-5

5 5 4 Disassembly and Assembly of Planetary System 5-5

5 5 5 Adjustment of Bevel Gear Set ; 5-5

5 5 6 Disassembly of Differential 5-5

5 5 7 Assembly of Differential 5-5

5-6 Removal of Engine and Transmission 5-5

5-7 Installation of Engine and Transmission 5-6

5-8 Engine Maintenance 5-6

5-9 Transmission Maintenance 5-6

6 RSOSL •cso· Serles, Service, pin: 1416841 -b, 09/03

Table of Contents □

IPB · Contents – continued Page

Section 5 Maintenance – continued

5-10 Steer Axle Maintenance 5-6

5 10 1 Removal of Steer Axle 5-6

5 10 2 Installation of Steer Axle 5-7

5 10 3 Disassembly of Wheel Hub 5-7

5 10 4 Reassembly of Wheel Hub 5-7

5 10 5 Disassembly of Steering Knuckle 5-8

5 10 6 Reassembly of Steering Knuckle 5-8

5 10 7 Removal of Steering Cylinder 5-9

5 10 8 Installation of Steering Cylinder 5-9

5-11 Brake System Maintenance 5-9

5 11 1 Bleeding the Brakes 5-9

5 11 2 Adjustment of Brake Linkage 5-10

5 11 3 Adjustment of Service Brake 5-10

5 11 4 Adjustment of Parking Brake 5-1 0

5-12 Battery Maintenance 5-10

5-13 Pivot/Side Shift Maintenance 5-1 0

5 13 1 Removal of Pivot Arm 5-10

5 13 2 Installation of Pivot Arm 5-10

5 13 3 Removal of Pivot Cylinder 5-11

5 13 4 Installation of Pivot Cylinder 5-11

5 13 5 Adjustment of Side Shift Chain 5-11

5 13 6 Removal of Side Shift Cylinder 5-12

5 13 7 Installation of Side Shift Cylinder 5-12

5 13 8 Replacement of Side Shift Bearings 5-12

5-14 Hydraulic Pump Maintenance 5-15

5 14 1 Removal 5-15

5 14 2 Installation 5-15

5-15 Power Steering Unit Maintenance 5-15

5 15 1 Removal 5-15

5 15 2 Installation 5-15

5 15 3 Disassembly and Assembly 5-15

5-16 Mast Maintenance 5-15

5 16 1 Removal 5-15

5 16 2 lnstallation 5-16

5 16 3 Till Cylinder Adjustment 5-16

5 16 4 Adjustment of Carriage Side Rollers 5-16

5 16 5 Adjustment of Rail Guide Rollers 5-16

R60SL ·cso• Serles, Service, pin: 1416841 -b, 09/03 7

□ Table of Contents

IPB Contents – continued Page

Section 5 Maintenance – continued

5-16 Mast Maintenance – continued

5 16 6 Adjustment of Chain 5-16

5 16 7 Disassembly of Rail Guide Rollers 5-16

5 16 8 Disassembly of Primary Cylinder 5-17

5 16 9 Reassembly of Primary Cylinder 5-17

5 16 10 Disassembly of Secondary Cylinder 5-18

5 16 11 Reassembly of Secondary Cylinder 5-18

5 16 12 Bleeding the Mast Cylinder 5-18

Section 6 Troubleshooting

6 1 Introduction 6-1

6 2 Hydraulic System, Pivot and Shift 6-1

Pivot Function Defective 6-1

Shift Function Defective 6-1

Steering Drift 6-1

6 3 Hydraulic System, Pivot and Shift 6-2

Steering Power Loss 6-2

6 4 Hydraulic System, Mast 6-2

Mast Will Not Lift 6-2

Lift Cylinder Does Not Move 6-2

Lifts Load Slowly or Stops 6-2

Lift Cylinder Leak 6-3

Jerky or Spongy Lifting Action 6-3

Sudden Increase in Lift Speed , 6-3

Extended Mast Fails to Lower Completely 6-4

Load DriftsDownward After Control is in Neutral 6-4

Unable to Extend Mast 6-4

Excessive Side Movement 6-4

Carriage Binds in Rails 6-4

Carriage Side Bars Hit or Scrape 6-4

Rails Move Before Carriage 6-4

Carriage Lower Before Rails Retract 6-4

Excessive Spalling on Inner Rail 6-5

Extended Mast Drifts Downward , 6-5

6 5 Hydraulic System, Brake System

Parking Brake Inoperative 6-6

Service Brake Inoperative 6-6

8 R60SL “CB □” Serles, Service, p/n: 1416841 -b, 09/03

Table of Contents D

IPB Contents – continued Page

Section 6 Troubleshooting – continued

6 6 Drive System 6-7

Wheel Studs Shearing Off 6-7

Drive Tries Scuffing 6-7

Broken Axle Shaft 6-7

Load Snapping or Cracking Noises 6-7

Grinding Noises 6-7

Clicking Noises 6-7

Excessive Tire Wear 6-7

Locking Up 6-8

Backlash in Drive Train 6-8

Section 7 Mast IPB

Section 7 “Mast IPB” (illustrated parts breakdown) includes a Mast Assembly and a Mast

Installation manual, each having its own separate “Table of Contents ”

Section 8 Base Unit IPB

Section 8, “Base Unit IPB” (illustrated Parts Breakdown) includes a parts breakdown of the

main body of the SwingMast® Lift Truck This section includes a separate “Table of Contents ”

Section 9 Options IPB

Section 9, “Options IPB” (illustrated parts breakdown) includes a parts breakdown of the most

commonly used option features ordered on Drexel SwingMast Lift Trucks