$36

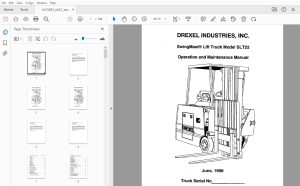

Drexel SwingMast Lift Truck SLT22 Operation & Maintenance Manual 1412883 – PDF DOWNLOAD

Drexel SwingMast Lift Truck SLT22 Operation & Maintenance Manual 1412883 - PDF DOWNLOAD

FILE DETAILS:

Drexel SwingMast Lift Truck SLT22 Operation & Maintenance Manual 1412883 - PDF DOWNLOAD

Language : English

Pages : 134

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Drexel SwingMast Lift Truck SLT22 Operation & Maintenance Manual 1412883 - PDF DOWNLOAD

Section 1 DESCRIPTION AND SPECIFICATIONS

11 INTRODUCTION 1-1

12DESCRIPTION 1-1

13 FUNCTIONAL DESCRIPTION 1-2

131 Frame 1-2

132 Powerplant 1-2

133 Drive Train 1-2

134 Electrical System 1-2

Battery 1-2

Motor Controllers 1-2

Safety Interlocks 1-3

Meters 1-3

14 Hydraulic Subsystem 1-3

141 Steering 1-3

142 Mast Positioning 1-3

1 43 Brake System 1-4

1 44 Pivot and Shift System 1-4

145 Mast 1-4

15 WARNINGS AND CAUTIONS 1-5

151 Warning Plates 1-6

152 Caution Plates 1-6

16 ITEMS FURNISHED 1-6

17 ITEMS REQUIRED 1-6

18 TOOLS AND TEST EQUIPMENT 1-6

19 PREPARATION FOR USE 1-6

110 PREPARATION FOR RESHIPMENT 1-6

111 STORAGE 1-6

Figure 1-1 Rails in "Collapsed" Position 1-4

Figure 1-2 Mast in Free Lift Position 1-5

Figure 1-3 Mast in Extended Position 1-5

Figure 1-4 Quadplex Mast in Collapsed Position 1-5

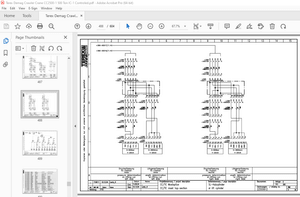

Table 1-1: Basic Truck Specifications 1-7

Table 1-2: Standard Masts Available for Truck 1-8

Section 2 PREPARATION FOR USE

21 RECEIVING INSPECTION 2-1

22 PREPARATION FOR USE 2-1

23 CHARGING BATTERIES , 2-1

24 PREPARING DRY-CHARGE BATTERIES 2-2

25 OPERATIONAL CHECKS 2-3

26 PROGRAMMING THE DRIVE MOTOR CONTROLLER 2-3

27 PROGRAMMING THE PUMP MOTOR CONTROLLER 2-4

Figure 2-1 Handset for Programming Motor Controllers 2-3

Table 2-1: Specific Gravity Corrections for Electrolyte Temperature 2-2

Table of Contents

Table 2-2: Recommended Function Values for Drive Motor Controller 2-4

Table 2-3: Recommended Function Values for Pump Motor Controller 2-5

Section 3 OPERATION

31 OVERVIEW 3-1

32 SAFETY SUMMARY 3-1

321 Before Operating 3-1

322 Using Dock Boards • 3-1

323 Moving a Load 3-1

33 PRE-OPERATION CHECKLIST 3-2

34 OPERATING CONTROLS 3-2

35 OPERATING LIMITATIONS 3-3

36 ADJUSTING THE SEAT 3-4

37 RUNNING FORWARD AND BACKWARD 3-4

38 MANEUVERING THE MAST 3-5

39 FORK ADJUSTMENT 3-5

310 PICKING UP A LOAD 3-6

311 DEPOSIT! NG A LOAD 3-6

Figure 3-1 Location of Controls and Indicators 3-3

Figure 3-2 Location of Seat Adjustment Controls : 3-4

Figure 3-3 Unlatching the Forks 3-5

Figure 3-4 Latching the Forks 3-6

Figure 3-5 Aligning the Truck to the Rack 3-7

Figure 3-6 Shifting and Pivoting a Load in or Out of the Rack 3-7

Figure 3-7 Inserting a Load Into or Removing a Load from the Rack 3-8

Section 4 PRINCIPLES OF OPERATION

41 GENERAL 4-1

42 HYDRAULIC SYSTEM 4-1

421 Steering System 4-1

422 Mast Systems 4-1

423 Pivot-Tilt System 4-2

424 Lift-Shift System 4-3

43 ELECTRICAL CONTROL SYSTEM 4-3

431 General 4-3

432 Plugging 4-3

433 Accelerator Operation 4-3

434 Power Bypass 4-4

435 Direction Control 4-4

436 Interlocks 4-4

Figure 4-1 Basic Hydraulic Flow, Power Steering 4-1

Figure 4-2 Steering at "Zero" Position (Valve Closed) 4-2

Figure 4-3 Pressure Relief System 4-2

Figure 4-4 "Boost'' Power to Lift-Shift System 4-2

Figure 4-5 Tilt System Anti-Cavitation Circuit 4-2

Figure 4-6 Lift System, Simplified Diagram 4-3

Figure 4-7 Shift System, Simplified Diagram 4-3

ii

Table of Contents

Section 5 PREVENTIVE MAINTENANCE

51 OVERVIEW 5-1

511 Standard Tools Required 5-2

512 Special Tools Required 5-2

513 Safety Equipment Required 5-2

52 DAILY CHECKS AND INSPECTIONS 5-2

521 Check Batteries 5-2

522 Check Power Steering 5-3

523 Check Pump Contactor Delay 5-3

524 Check Return-To-Neutral '' 5-3

525 Daily Lift Chain Inspection 5-3

526 Inspect Tires 5-3

53 WEEKLY CHECKS 5-3

531 Check Hydraulic Oil Level 5-3

532 Check Master Cylinder Fluid Level 5-4

533 Check Pivot Alignment 5-4

534 Check Tilt Alignment 5-4

54 SIX-WEEK CHECKS 5-4

541 Lubricate Truck 5-4

542 Check Lift Operation 5-4

55 TWELVE-WEEK CHECKS 5-4

551 Check Bolts 5-4

552 Change Hydraulic Oil Filter 5-4

56 SEMI-ANNUAL CHECKS 5-6

561 Adjust Lift Chain 5-6

562 Adjust Shift Chain 5-6

563 Inspect Electrical Connections 5-6

564 Fork Inspection 5-6

565 lnspectthe Lift Chain · 5-7

566 Hydraulic Pump Motor Brush Replacement 5-7

567 Power Steering Motor Brush Replacement 5-8

568 Traction Motor Brush Replacement 5-8

57 ANNUAL CHECKS 5-9

571 Change Hydraulic Oil 5-9

572 Change Reservoir Sump Filter 5-9

573 Lubricate Front Wheel Bearings 5-1 O

Figure 5-1 Truck Lubrication Points 5-5

Figure 5-2 Measuring Fork Wear 5-6

Figure 5-3 Measuring Fork Distortion 5-7

Figure 5-4 Maximum Chain Elongation 5-7

Figure 5-5 Brush Rigging 5-8

Table 5-1: Preventive Maintenance Schedule 5-1

Table 5-2: Maximum Y Values, 2,000 lb Trucks 5-6

Table 5-3: Maximum Y Values, 3,000 lb Trucks 5-7

Section 6 TROUBLESHOOTING

61 GENERAL 6-1

iii

Table of Contents

62 PRELIMINARY PROCEDURES 6-1

63 VISIBLE PROBLEMS 6-1

631 Cracks in Forks &-1

632 Leaking Fluid 6-1

633 Fluid Puddled Near Drive Wheel 6-1

634 Fluid Puddled Near Front Wheels 6-1

635 Fluid Puddled Near Mast 6-1

636 Frayed or Broken Wires 6-2

63 7 Lights Inoperative 6-2

638 Loose Electrical Connections 6-2

639 639 Scraped Rails on Mast 6-2

64 64 AUDIBLE PROBLEMS 6-2

641 641 Backup Alarm Inoperative 6-2

642 Noise when truck moves 6-2

643 High RPM in Drive Motor 6-2

644 Horn Inoperative 6-2

645 Main Pump Runs Continuously 6-2

646 Rubbing Noise at Front Wheels 6-2

64 7 Scraping Noise When Mast is Lifted 6-2

65 OPERATIONAL PROBLEMS 6-2

651 Brakes Do Not Stop the Truck 6-2

652 Hydraulic Functions Do Not Shut Off 6-3

653 Mast Does Not Lift 6-3

654 Mast Does Not Pivot 6-3

655 Mast Does Not Shift 6-3

656 Mast Does Not Tilt 6-3

657 Mast Drifts Downward 6-3

658 Mast Lifts Slowly 6-3

659 Parking Brake Does Not Hold the Truck 6-3

651 O Power Steering Motor Does Not Start 6-4

6511 Steering Drifts or is Erratic 6-4

6512 Truck Does Not Move 6-4

6513 Truck Does Not Turn 6-4

6514 Truck Moves Slowly 6-4

6515 Truck Turns Slowly 6-4

Section 7 CORRECTIVE MAINTENANCE

71 GENERAL 7-1

72 ADJUSTMENTS 7-1

721 Brake Adjustment 7-1

722 Brake Pedal Adjustment 7-1

723 Main Pump Relief Valve Adjustment 7-1

724 Parking Brake Adjustment 7-3

725 Stack Valve Switch Adjustment 7-3

726 Steering Pump Relief Valve Adjustment 7-3

727 Brake System Bleeding 7-4

728 Lift Cylinder Bleeding 7-4

729 Brake Shoe Cleaning 7-4

7 21 O Commutator Cleaning 7-4

73 REMOVAL PROCEDURES 7-4

731 Brake Master Cylinder Removal 7-4

732 Drive Unit Removal 7-4

iv

Table of Contents

733 Main Pump and Motor Removal 7-5

734 Mast Removal 7-5

735 Pivot Cylinder Removal 7-6

736 Shift Cylinder Removal 7-6

737 Steering Head Removal 7-6

738 Steering Pump and Motor Removal 7-7

739 Tilt Cylinder Removal 7-7

7 310 Traction Motor Removal 7-7

74 INSTALLATION PROCEDURES 7-8

7 41 Brake Master Cylinder Installation 7-8

742 Drive Unit Installation 7-8

743 Main Pump and Motor Installation 7-8

744 Mast Installation 7-8

745 Pivot Cylinder Installation 7-8

746 Shift Cylinder Installation 7-8

747 Steering Head Installation 7-8

748 Steering Pump and Motor Installation 7-8

749 Tilt Cylinder Installation 7-8

7410 Traction Motor Installation 7-8

75 DISASSEMBLY PROCEDURES 7-8

751 Brake Master Cylinder Disassembly 7-8

752 Drive Unit Servicing 7-8

753 Lift Cylinder Disassembly 7-9

754 Main Pump Disassembly 7-9

7 55 Mast Disassembly , 7-1 O

756 Steering Control Unit 7-10

757 Steering Motor Servicing 7-10

7 58 Tilt Cylinder Disassembly 7-1 O

76ASSEMBLY PROCEDURES 7-10

761 Brake Master Cylinder Assembly 7-10

762 Lift Cylinder Assembly 7-10

763 Main Pump Assembly 7-11

7 64 Mast Assembly 7-11

765 Tilt Cylinder Assembly 7-11

77 REPLACEMENT PROCEDURES 7-11

771 Accelerator Assembly Replacement 7-11

772 Brake Line Replacement 7-11

773 Brake Assembly Replacement 7-11

774 Brake Switch Replacement ~ 7-11

775 Control Fuse Replacement 7-12

776 Bulb Replacement 7-12

777 Centering Spring Replacement (Valve Stack) 7-12

778 Directional Control Switch Replacement 7-12

779 Drive Wheel Replacement 7-13

7710 Emergency Stop Switch Replacement 7-13

7711 Fork Replacement 7-13

7712 Front Wheel Replacement 7-13

7 7 13 Hash Filter Replacement 7-13

7714 Horn Assembly Replacement , : 7-14

7715 Horn Hash Filter Replacement 7-14

7716 Hydraulic Fitting Replacement 7-14

7717 Hydraulic Hose Replacement 7-14

V

Table of Contents

7718 Key Switch Replacement 7-15

7719 Power Fuse Replacement 7-15

7720 Relief Valve Replacement 7-15

7721 Rocker Switch Replacement 7-15

7722 Seat Switch Replacement 7-15

7723 Wheel Cylinder Replacement 7-15

7724 Valve Stack Replacement 7-16

Figure 7-1 Brake Pedal Adjustments 7-2

Figure 7-2 Control Valve Connections for Relief Valve Adjustments 7-2

Figure 7-3 Suggested Support Fixture and Cradle 7-5

Figure 7-4 Mast Lifting 7-6

Figure 7-5 Blocking the Mast 7-6

Figure 7-6 Steering Head Hydraulic Lines 7-7

Figure 7-7 Lifting the Drive Motor 7-8

Figure 7-8 Brake Assembly Replacement 7-12

Figure 7-9 Removing the Directional Control Switch 7-13

Section 8 PARTS LIST

81 GENERAL 8-1

82 WELDMENTS 8-1

Section 9 ILLUSTRATED PARTS BREAKDOWN

91 GENERAL 9-1

92 ABBREVIATIONS 9-1

93 PARTS NOT SHOWN 9-2

94 PHANTOM AND REFERENCE PARTS 9-2

SLT22 BASE UNIT, SPECIAL PAYLESS SHOE, PART NO 1412883-A 9-3

DRIVE GROUP, PART NO 1413283-A 9-5

DRIVE ASSEMBLY, PART NO 1400645-E 9-8

DRIVE UNIT, DUAL CHAIN, PART NO 1400695-A: 9-11

DRIVE UNIT, DUAL CHAIN, PART NO 1400695-A (Continued) 9-12

CHAIN ASSY FOR STEER, PART NO 1400109-8 9-14

MOTOR, DRIVE SHUNT, PART NO 1412772 9-15

IDLER ASSY FOR STEER CHAIN, PART NO 1401239-C 9-16

HYDRAULIC GROUP, PORTEC, PART NO 1413285-A 9-17

HYDRAULIC GROUP, PORTEC, PART NO 1413285-A (Continued) 9-18

HYDRAULIC SPOOL VALVE ASSY GE PUMP CONTROLLER, PART NO 1413387-A 9-22

STACK VALVE, PART NO 1400270-A 9-24

HYDRAULIC PUMP/MOTOR ASSEMBLY, PART NO 1413284-A 9-27

PUMP, TANDEM, PART NO 1410451 9-28

MOTOR,PUMP-MODIFIED, PART NO 1413625-A 9-29

MOTOR, PUMP SERIES, PART NO 1412771- 9-30

PUMP & MOTOR ASSEMBLY POWER STEERING ASSEMBLY, PART NO 37506-A 9-31

PUMP, HYDRAULIC, STEER, PART NO 51734-A 9-32

MOTOR, ELECTRIC STEER PUMP, PART NO 51735-8 9-34

HYDRAULIC RESERVOIR ASSY, PART NO 1400258-E 9-36

FILLER CAP ASSY w/ STRAINER,SIDE-MOUNT, PART NO 1400263-A 9-38

OIL FILTER ASSY, PART NO 1400646-E 9-39

HYDRAULIC ASSY, POWER STEER, PART NO 1400649-C 9-40

vi

Table of Contents

MOTOR, HYDRAULIC, S SERIES, PART NO 25950-A 9-41

ASSEMBLY, MANIFOLD, PART NO 1402869-C 9-42

HOSE ASSY,UMBILICAL IMPERIAL HYTRON SB, PART NO 1405392-A 9-44

HOSE KIT, PART NO 1400603-F 9-45

OPERATOR CONSOLE GROUP, PART NO 1413288-A 9-48

CONSOLE PANELASSY, PART NO 1400498-D 9-52

SERVICE BRAKE COMPONENTS, PART NO1400648-M , 9-54

CYLINDER, MASTER 3/4 BORE 1 1/4 STROKE, PART NO 20210-A 9-56

STEERING COMPONENTS, PART NO1400650-H 9-58

STEERING COLUMN, 1 O" w/ 2 WIRE, PART NO 1400968-A 9-60

STEERING CONTROL UNIT 73 CU IN/REV OPEN CTR, PART NO 25975-A 9-62

ELECTRICAL COMPONENTS (CONSOLE GROUP), PART NO 1401464-F 9-64

INSTRUMENT PANELASSY, PART NO 1413287-A 9-66

LEVERASSY, PARTNO10417-B 9-68

SIDE CONSOLE ASSY, PART NO 1400931-F 9-70

JOYSTICK CONTROL PIVOT & SHIFT, PART NO 1406119-A 9-72

JOYSTICK CONTROL LIFT & TILT, PART NO 1406120-A 9-74

COVER PLATE ASSY (STANDARD), PART NO 1401930-C 9-75

CONSOLE COVER ASSY, PART NO 1401860-A 9-76

CATCH & KEEPER ASSY 5# PULL FORCE, PART NO 1401800-A 9-78

FINAL ASSEMBLY GROUP, PART NO 1400639-P 9-80

BATTERY DOOR ASSY, PART NO 1401378-B , 9-82

FLOOR PLATE ASSEMBLY, PART NO 1400660-E , 9-83

LEVEL INDICATOR ASSY, PART NO 1409561-C 9-84

FLUIDS GROUP, PART NO 1400640-D 9-87

REAR COMPARTMENT GROUP, PART NO 1401777-H 9-89

REAR COVERASSY, PART NO 1401755-A 9-90

GAS SPRING ASSY, PART NO 1410120-A 9-91

ELECTRICAL GROUP PORTEC w/TRANSISTOR CONTROLS, PART NO 1413300-B 9-93

ELECTRICAL GROUP PORTEC w/TRANSISTOR CONTROLS, PART NO 1413300-B (Cont) 9-94

CONTROL PANEL MODIF FOR GE SX CONTROL, PART NO 1413417-A 9-96

CONTACTOR PANEL, PART NO 1413294 9-97

ASSEMBLYPANEL PORTEC PATHFINDER, PART NO 1403854-C 9-98

KIT, WIRE GUIDANCE 36 VDC, 625 KHZ - 22/30, PART NO 1402034-D 9-99

PORTEC IDLER ASSY FOR STEER CHAIN, PART NO 1403041-B 9-100

PORTEC GUIDANCE SL T 22/30, PART NO 1403001 9-101

PARKING BRAKE GROUP GE SX TRACTION CONTROL, PART NO 1413377-A 9-104

OVERHEAD GUARD GROUP, PART NO 1400634-D 9-108

SEAT GROUP, PART NO 1400635-K 9-111

SEAT ASSY, GRAMMER WITH ARMS, PART NO 1410161-A 9-112

SEAT, GRAMMER WITH ARMS, PART NO 1402680-A 9-113

SERVICE BREAKDOWN GRAMMER GS12 SEAT, PART NO 1412457-A 9-114

SERVICE PARTS, SEAT, GRAMMER WITH ARMS, PART NO 1410162-A 9-115

SEAT BELT KIT SLT22/30, PART NO 1412363-A 9-116

LOADWHEELGROUPSLT22/30, PARTNO1400636-E 9-118

BRAKE ASSY, 105 X 25 w/RH PARK LEVER, PART NO 51082-01-A 9-120

BRAKE ASSY, 105 X 25 w/LH PARK LEVER, PART NO 51082-02-A 9-122

CUSTOMER ORDER NO 940069 Rev 02 9-125

IDENTIFICATION GROUP, STANDARD, PART NO 1400641-M 9-128

PAINT GROUP ENAMEL YELLOW, PART NO 1401997-A 9-131

TRIPLEX GROUP 95/214/75-31, PART NO 1402465-B 9-133

PIVOT/SHIFT GROUP STD QUAD MAST TO LIMIT REACH*, PART NO 1401784-F 9-135

vii

Table of Contents

SHIFT CYLINDER COMPONENTS, PART NO 1405452-D 9-136

SHIFT CYLINDER ASSY, PART NO 1401785-C 9-138

SHIFT CYLINDER ASSY, PART NO 1401786-F 9-140

TILT CYLINDER COMPONENTS, PART NO 1400604-B 9-142

CYLINDER TILT 300 BORE, PART NO 1400153-A 9-144

PIVOT CYLINDER COMPONENTS, PART NO 1400605-C 9-146

CYLINDER PIVOT, PART NO 1400601-A 9-148

CROSSHEAD AND PIVOT ASSY, PART NO 1400653-H 9-150

MIRROR GROUP OVERHEAD GUARD, PART NO 1410902-A 9-154

SEAT BELTS, PART NO 1402011-A 9-155

viii

S.S 05/24