$38

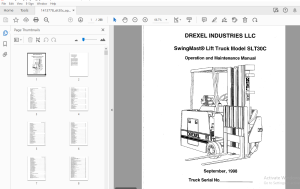

DREXEL SwingMast Lift Truck SLT30C Operation & Maintenance Manual 1413778 - PDF DOWNLOAD

DREXEL SwingMast Lift Truck SLT30C Operation & Maintenance Manual 1413778 - PDF DOWNLOAD

FILE DETAILS:

DREXEL SwingMast Lift Truck SLT30C Operation & Maintenance Manual 1413778 - PDF DOWNLOAD

Language : English

Pages : 268

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

DREXEL SwingMast Lift Truck SLT30C Operation & Maintenance Manual 1413778 - PDF DOWNLOAD

Section 1 DESCRIPTION AND SPECIFICATIONS

11 INTRODUCTION 1-1

12 DESCRIPTION 1-1

13 FUNCTIONAL DESCRIPTION 1-2

131 Frame 1-2

132 Powerplant 1-2

133 Drive Train 1-2

134 Electrical System 1-2

Battery J -2

SCR Controller 1-2

Solenoid Contactors 1-2

Transit01ized Motor Controller 1-2

Safety Interlocks 1-3

Meters 1-3

14 Hydraulic Subsystem 1-3

141 Steering · , 1-3

1 42 Mast Positioning • 1-3

1 43 Brake System 1-4

144 Pivot and Shift System 1-4

1 45 Mast 1-4

15 WARNINGS AND CAUTIONS 1-5

151 Warning Plates 1-6

152 Caution Plates 1-6

16 ITEMS FURNISHED 1-6

17 ITEMS REQUIRED 1-6

18 TOOLS AND TEST EQUIPMENT 1-6

19 PREPARATION FOR USE , 1-6

110 PREPARATION FOR RESHIPMENT 1-6

111 STORAGE 1-6

Section 2 PREPARATION FOR USE

21 RECEIVING INSPECTION 2-1

22 PREPARATION FOR USE 2-1

23 CHARGING BATTERIES 2-1

24 PREPARING DRY-CHARGE BATTERIES 2-2

25 OPERATIONAL CHECKS 2-3

26 PROGRAMMING THE SCR CONTROLLER 2-3

27 OPERATION 2-4

28 DESCRIPTION OF FUNCTIONS 2-5

281 Function 1: Display Stored Fault 2-5

282 Function 2: Set Creep Speed 2-5

283 Function 3: Set Controlled Acceleration 2-5

284 Function 4: Set Current Limit 2-5

285 Function 5: Set Plugging Current 2-5

286 Function 6: 1 A Dropout 2-6

287 Function 7: Field Weakening Pickup 2-6

288 Function 8: Field Weakening Dropout 2-6

289 Function 9: Regenerative Braking Current Limit 2-6

2810 Function 1 O: Regenerative Braking Start 2-6

2811 Function 11: Speed Limit 1 2-6

2812 Function 12: Speed Limit 2 2-6

Table of Contents

2813 Function 13: Speed Limit 3 2-6

2814 Function 14: Internal Resistance Compensation 2-6

2815 Function 15: Battery Voltage 2-7

2816 Function 16: Pedal Position Plugging 2-7

2817 Function 17: Card Type Selection 2-7

2818 Function 18: Seat Time Delay 2-8

29 PROGRAMMING THE PUMP SPEED CONTROL 2-8

Section 3 OPERATION

31 OVERVIEW 3-1

32 SAFETY SUMMARY 3-1

321 Before Operating 3-1

322 Using Dock Boards 3-1

323 Moving a Load 3-1

33 PRE-OPERATION CHECKLIST 3-2

34 OPERATING CONTROLS 3-2

35 OPERATING LIMITATIONS 3-3

36 ADJUSTING THE SEAT 3-4

37 RUNNING FORWARD AND BACKWARD 3-4

38 MANEUVERING THE MAST 3-5

39 FORK ADJUSTMENT 3-5

310 PICKING UP A LOAD 3-6

311 DEPOSITING A LOAD 3-6

Section 4 PRINCIPLES OF OPERATION

41 GENERAL 4-1

42 HYDRAULIC SYSTEM , 4-1

421 Steering System 4-1

422 Mast Systems 4-1

423 Pivot-Tilt System 4-2

424 Lift-Shift System 4-3

43 ELECTRICAL CONTROL SYSTEM 4-3

431 General 4-3

432 Plugging 4-3

433 Accelerator Operation 4-3

434 Power Bypass 4-4

435 Direction Control 4-4

436 Interlocks 4-4

Section 5 PREVENTIVE MAINTENANCE

51 OVERVIEW 5-1

511 Standard Tools Required 5-2

512 Special Tools Required 5-2

51 3 Safety Equipment Required 5-2

52 DAILY CHECKS AND INSPECTIONS 5-2

521 Check Batteries 5-2

522 Check Power Steering 5-3

523 Check Pump Contactor Delay 5-3

524 Check Return-To-Neutral 5-3

525 Daily Lift Chain Inspection 5-3

ii

Table of Contents

526 Inspect Tires , , 5-3

53 WEEKLY CHECKS 5-3

531 Check Hydraulic Oil Level 5-3

532 Check Master Cylinder Fluid Level 5-4

533 Check Pivot Alignment 5-4

534 Check Tilt Alignment , 5-4

54 SIX-WEEK CHECKS 5-4

541 Lubricate Truck 5-4

542 Check Lift Operation 5-4

55 TWELVE-WEEK CHECKS 5-4

551 Check Bolts 5-4

552 Change Hydraulic Oil Filter 5-4

56 SEMI-ANNUAL CHECKS 5-6

561 Adjust Lift Chain 5-6

562 Adjust Shift Chain 5-6

563 Inspect Electrical Connections 5-6

564 Fork Inspection 5-6

565 Inspect the Lift Chain 5-7

566 Hydraulic Pump Motor Brush Replacement , , 5-7

567 Power Steering Motor Brush Replacement 5-8

568 Traction Motor Brush Replacement 5-8

57 ANNUAL CHECKS • 5-9

571 Change Hydraulic Oil , , 5-9

57 2 Change Reservoir Sump Filter 5-9

573 Lubricate Front Wheel Bearings 5-1 O

Section 6 TROUBLESHOOTING

61 GENERAL , 6-1

62 PRELIMINARY PROCEDURES 6-1

63 VISIBLE PROBLEMS 6-1

631 Cracks in Forks 6-1

632 Leaking Fluid , 6-1

633 Fluid Puddled Near Drive Wheel 6-1

634 Fluid Puddled Near Front Wheels 6-1

635 Fluid Puddled Near Mast 6-1

636 Frayed or Broken Wires 6-2

637 Lights Inoperative 6-2

638 Loose Electrical Connections 6-2

639 639 Scraped Rails on Mast 6-2

64 64 AUDIBLE PROBLEMS 6-2

641 641 Backup Alarm Inoperative 6-2

642 Noise when truck moves 6-2

643 High RPM in Drive Motor 6-2

644 Horn Inoperative 6-2

645 Main Pump Runs Continuously 6-2

646 Rubbing Noise at Front Wheels 6-2

647 Scraping Noise When Mast is Lifted 6-2

65 OPERATIONAL PROBLEMS 6-2

651 Brakes Do Not Stop the Truck 6-2

652 Hydraulic Functions Do Not Shut Off , , 6-3

653 Mast Does Not Lift 6-3

654 Mast Does Not Pivot 6-3

iii

Table of Contents

655 Mast Does Not Shift 6-3

656 Mast Does Not Tilt 6-3

657 Mast Drifts Downward 6-3

658 Mast Lifts Slowly 6-3

659 Parking Brake Does Not Hold the Truck 6-3

651 O Power Steering Motor Does Not Start 6-4

6511 Steering Drifts or is Erratic 6-4

6512 Truck Does Not Move 6-4

6513 Truck Does Not Turn 6-4

6514 Truck Moves Slowly 6-4

6515 Truck Turns Slowly 6-4

Section 7 CORRECTIVE MAINTENANCE

71 GENERAL 7-1

72 ADJUSTMENTS 7-1

721 Brake Adjustment 7-1

722 Brake Pedal Adjustment 7-1

723 Main Pump Relief Valve Adjustment : \ 7-1

724 Parking Brake Adjustment • 7-3

725 Stack Valve Switch Adjustment 7-3

726 Steering Pump Relief Valve Adjustment 7-3

727 Brake System Bleeding 7-4

728 Lift Cylinder Bleeding 7-4

729 Brake Shoe Cleaning 7-4

721 O Commutator Cleaning 7-4

73 REMOVAL PROCEDURES 7-4

7 31 Brake Master Cylinder Removal 7-4

732 Drive Unit Removal 7-4

733 Main Pump and Motor Removal 7-5

734 Mast Removal 7-5

735 Pivot Cylinder Removal 7-6

736 Shift Cylinder Removal 7-6

737 Steering Head Removal 7-6

738 Steering Pump and Motor Removal 7-7

739 Tilt Cylinder Removal 7-7

731 O Traction Motor Removal 7-7

74 INSTALLATION PROCEDURES 7-8

741 Brake Master Cylinder Installation 7-8

742 Drive Unit Installation 7-8

743 Main Pump and Motor Installation 7-8

744 Mast Installation 7-8

745 Pivot Cylinder Installation 7-8

746 Shift Cylinder Installation 7-8

747 Steering Head Installation 7-8

748 Steering Pump and Motor Installation 7-8

749 Tilt Cylinder Installation 7-8

7410 Traction Motor Installation 7-8

75 DISASSEMBLY PROCEDURES 7-8

751 Brake Master Cylinder Disassembly 7-8

752 Drive Unit Servicing 7-8

753 Lift Cylinder Disassembly 7-9

754 Main Pump Disassembly 7-9

iv

Table of Contents

755 Mast Disassembly 7-10

756 Steering Control Unit 7-10

757 Steering Motor Servicing 7-10

758 Tilt Cylinder Disassembly 7-10

76 ASSEMBLY PROCEDURES 7-10

761 Brake Master Cylinder Assembly 7-10

762 Lift Cylinder Assembly 7-10

763 Main Pump Assembly • 7-11

764 Mast Assembly , 7-11

765 Tilt Cylinder Assembly 7-11

77 REPLACEMENT PROCEDURES 7-11

771 Accelerator Assembly Replacement 7-11

772 Brake Line Replacement 7-11

773 Brake Assembly Replacement 7-11

774 Brake Switch Replacement 7-11

775 Control Fuse Replacement 7-12

776 Bulb Replacement 7-12

777 Centering Spring Replacement (Valve Stack) 7-12

778 Directional Control Switch Replacement 7-12

779 Drive Wheel Replacement 7-13

7 7 10 Emergency Stop Switch Replacement 7-13

7 7 11 Fork Replacement 7-13

7712 Front Wheel Replacement 7-13

7713 Hash Filter Replacement 7-13

7714 Horn Assembly Replacement 7-14

7715 Horn Hash Filter Replacement 7-14

7716 Hydraulic Fitting Replacement : 7-14

7717 Hydraulic Hose Replacement 7-14

7 7 18 Key Switch Replacement 7 -15

7719 Power Fuse Replacement 7-15

7720 Relief Valve Replacement 7-15

7721 Rocker Switch Replacement 7-15

7722 Seat Switch Replacement 7-15

7723 Wheel Cylinder Replacement 7-15

7724 Valve Stack Replacement 7-16

Section 8 PARTS LIST

81 GENERAL 8-1

82 WELDMENTS 8-1

Section 9 ILLUSTRATED PARTS BREAKDOWN

91 GENERAL 9-1

92 REVISION LEVELS 9-1

93 ABBREVIATIONS 9-1

94 PARTS NOT SHOWN 9-2

95 PHANTOM AND REFERENCE PARTS 9-2

96 TASK GROUPS AND ASSEMBLIES 9-2

DRIVE GROUP DA1 9-3

MOTOR, TRACTION, REAR DRIVE, PART NO1412757-A 9-4

STEER IDLER ASSEMBLY, PART NO1412460-A 9-6

DRIVE WHEEL DA2 9-7

V

Table of Contents

DRIVE UNIT SU BASS EMBLY DAB 9-8

DRIVE UNIT, DUAL CHAIN, PART NO 1400695-A 9-9

DRIVE UNIT, DUAL CHAIN, PART NO 1400695-A (Continued} 9-10

CHAIN ASSY FOR STEER, PART NO1400109-B 9-12

LOWER DRIVE UNIT DA 11 9-13

STEER IDLER DA9 9-14

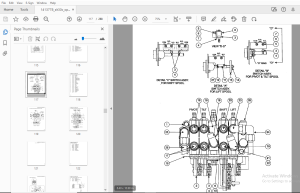

CONTROL VALVE HY15 9-15

HYDRAULIC SPOOL VALVE ASSEMBLY, PART NO 1411868-D 9-16

VALVE CONTROL ASSYWITH CAMS SLT-30C, PART NO 1413566-A 9-18

HYDRAULIC PUMP/MOTOR HY16 9-22

HYDRAULIC PUMP/MOTOR ASSEMBLY, PART NO 1411872-B 9-24

MAIN PUMP, PART NO 1400269 9-26

MAIN PUMP MOTOR, PART NO 1400268 9-28

HYDRAULIC TANK HY6 9-31

HYDRAULIC TANK SUBASSY HY44 9-32

POWER STEER HYDRAULIC ASSY HY14 9-35

STEER PUMP/MOTOR SUBASSY HY12 9-37

PUMP & MOTOR ASSEMBLY, STEER, SLT-30C, PART NO 1413444-A 9-38

STEERING PUMP, PART NO 51734 9-39

STEERING PUMP MOTOR, PART NO 51735 9-40

UMBILICAL ASSY HY8 9-42

SIDESHIFT HOSE HY? 9-44

STEER PUMP/MOTOR HY11 9-45

STEER MOTOR SUBASSEMBLY HY21 9-46

MOTOR, HYDRAULIC, S SERIES, PART NO 25950 9-47

UMBILICAL TRAY HY22 9-49

PIVOT & TILT HOSE HY19 9-50

JOYSTICK SUBASSEMBLY HY24 9-52

HOSE HY23 9-53

OPERATOR CONSOLE OH6 9-55

DOLL-UP 103 9-56

INSTRUMENT PANEL ASSEMBLY, PART NO 1413057-C 9-58

LEVER ASS EMBLY, PART NO 10417-B 9-60

SIDE CONSOLE OH? 9-62

KEY SWITCH EL 14 9-64

SIDE CONSOLE SU BASS EMBLY HY20 9-65

CONSOLE COVER SUBASSY OH9 9-66

ACCELERATOR UNIT EL15 9-68

STEERING WHEEL 104 9-70

STACK VALVE COVER 105 9-71

BRAKE WELDMENT ASSEMBLY SB2 9-72

BRAKE PEDAL SB3 9-74

MASTER CYLINDER SB4 9-76

SERVICE BRAKE SB5 9-78

STEER COLUMN HY5 9-80

FLOORPLATE SUBASSEMBLY CO2 9-81

HORN BUTTON OH2 9-82

FLOORPLATE OH3 9-83

BATTERY DOOR OH4 9-85

BATTERY DOOR SUBASSEMBLY OHS 9-86

LEVEL INDICATOR MA2 9-87

FLUIDS FL 1 9-89

vi

Table of Contents

REAR COMPARTMENT COVERS CO1 9-92

SCR PANEL EL 16 9-96

PANEL, CONTACTOR w/O BOX, PART NO 1405740-A 9-99

PANEL, CONT ACTOR w/O BOX, PART NO 1405740-A (Continued) 9-100

CONTACTOR, 150A, DPDT, 24V, PART NO 1401978-A 9-102

CONTACTOR,300A,SPNO 24V, PART NO 1401979-A 9-104

CONTACTOR, 100A,SPNO 24V, PART NO 1401980-A 9-106

CONTACTOR,SPNO, 300A, 36VDC COIL, PART NO 28889-D 9-107

BATTERY CONNECTOR SUBASSEMBLY EL 17 9-109

WIRE HARNESS EL18 9-110

CABLE EL 19 9-111

PARKING BRAKE PB1 9-114

EQUALIZER PB2 9-116

BRAKE CABLE PB3 9-118

OVERHEAD GUARD OH1 : 9-122

SPINDLE LW3 9-126

LOAD WHEEL LW6 , 9-128

SEATBELTST1 9-129

SEAT ST2 9-130

PIVOT & SHIFT PS10 9-131

CROSSHEAD BEARINGS PS1 , 9-132

PIVOT STOP PAD PS3 9-133

PIVOT ARM PS2 9-134

PIVOT CYLINDER PS4 9-136

CYLINDER PIVOT, PART NO 1400601-A 9-138

SIDE SHIFT CHAINS PSS , 9-140

SHIFT CYLINDER PS6 " 9-142

LOWER BAR SUBASSEMBLY PS? 9-143

LOWER BAR PSS 9-144

SHIFT CYLINDER SUBASSY PS9 9-145

CYLINDER, SHIFT SLT30C, PART N01412889-A 9-146

TILT CYLINDER MA52 9-147

CYLINDER TILT 300 BORE, PART NO1400153-A 9-148

PUMP SPEED CONTROL HY1 9-149

PORTEC-MTG PLATES INSTALL EL22 9-152

PORTEC BOARD INSTALL EL23 9-154

PORTEC GROUND STRAP INST EL24 9-157

PORTEC-STEER IDLER INST EL26 9-158

PORTEC PANEL SUBASSEMBLY EL29 9-160

PORTEC WIRE HARNESS INST EL30 9-162

SWITCH COVER INSTALL EL31 9-164

PORTEC HOSES INSTALL HY45 9-166

vii

IMAGES PREVIEW OF THE MANUAL:

S.S 05/24