$38

EATON Roadranger Fuller® Heavy Duty Transmissions TRSM1500 Service Manual – PDF DOWNLOAD

EATON Roadranger Fuller® Heavy Duty Transmissions TRSM1500 Service Manual – PDF DOWNLOAD

FILE DETAILS:

EATON Roadranger Fuller® Heavy Duty Transmissions TRSM1500 Service Manual – PDF DOWNLOAD

Language : English

Pages : 256

Downloadable : Yes

File Type : PDF

Fuller® Heavy Duty Transmissions

Service Manual

TRSM1500

July 2010

RTO-11707LL

RTO-11708LL

RTOF-11707LL

RTOF-11708LL

RTOF-14708LL

RTX-11708LL

RTX-14708LL

RTXF-11708LL

RTXF-14708LL

RTO-11707DLL

RTO-11709MLL

RTO-11908LL

RTO-11909ALL

RTO-11909MLL

RTO-13707DLL

RTO-13707MLL

RTO-14709MLL

RTO-14908LL

RTO-14909ALL

More time on the road®

RTO-14909MLL

RTO-16908LL

RTO-16909ALL

RTOF-11709MLL

RTOF-11908LL

RTOF-11909ALL

RTOF-11909MLL

RTOF-13707DLL

RTOF-13707MLL

RTOF-14709MLL

RTOF-14908LL

RTOF-14909ALL

RTOF-14909MLL

RTOF-16908LL

RTOF-16909ALL

RTX-11715

RTX-14715

RTXF-11715

RTXF-14715

RTXF-15715

RT- 8908LL

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

EATON Roadranger Fuller® Heavy Duty Transmissions TRSM1500 Service Manual – PDF DOWNLOAD

Warnings and Precautions 2

Transmission Overview 3

Purpose and Scope of Manual 7

How to use this Manual 7

Disassemble Precautions 7

Inspection Precautions 8

Assembly Precautions 10

Serial Tag Information and Model Nomenclature 11

Model Options 12

Lubrication Specifications 13

Buy from a reputable dealer 13

Transmission Operating Angles 13

Operating Temperatures with Oil Coolers 13

Oil Cooler Chart 14

Transmission Operation 15

Shift Patterns 15

Initial Start-Up 16

Double-Clutching Procedure 16

Lever Shifts 17

Range Shifts 17

Deep Reduction Shifts 17

Special Notes 18

Additional Operating Information 18

Tool Specifications 19

General Tools 19

Eaton Aftermarket Parts 22

Preventive Maintenance Inspection 23

Preventative Maintenance Check Points 23

Oil Leak Inspection Process 26

Power Flow Diagrams 27

Front Section Power Flow 28

Front Section Power Flow – Direct Gear 29

Front Section Power Flow – Reverse Gear 30

Auxiliary Section Power Flow- Low Range 31

Auxiliary Section Power Flow- High Range 32

RTO-1X707LL/DLL/MLL 33

RTO-1X707LL/DLL/MLL Continued 34

RTO/X-1XX08LL 35

RTO/X-1XX08LL Continued 36

RTO-1XX09MLL 37

RTO-1XX09MLL Continued 38

RT/O/X-1XX15 39

RT/O/X-1XX15 Continued 40

Air System Overview 41

Air System Components 41

Shift Knob 42

Air Filter/Regulator 43

Slave Valve 44

Slave Valve Preselection System 45

Range Cylinder 46

Deep Reduction Cylinder 46

Insert valve 47

Low Range 48

High Range 49

Deep Reduction 51

General Troubleshooting Chart 53

General Troubleshooting Chart (cont) 54

General Troubleshooting Chart (cont) 55

Air System Troubleshooting 56

Procedure 1: Symptom – Air leak at shift knob 57

Procedure 2: Symptom – Air leak at slave valve 59

Procedure 3: Symptom – Air Leak from Transmission Breather or Transmission Case is Pressurized 60

Procedure 4: Symptom: Air leak at deep reduction cylinder cover exhaust port 61

Procedure 5: Symptom – No or Slow Range Shift into Low 62

Procedure 6: Symptom – No or Slow Range Shift into High 65

Procedure 7: Symptom – No or slow shift into Deep Reduction 68

Procedure 8: Symptom – Range shifts with shift lever in gear 71

Timing Procedures 72

How to Disassemble Roadranger Valve A-4900 76

How to Assemble Roadranger Valve A-4900 78

How to Remove the Air Lines and Hoses 80

How to Install the Air Lines and Hoses 82

How to Remove Compression Type Fittings 84

How to Install Compression Type Fittings 85

How to Remove Push-To-Connect Type Fittings 86

How to Install Push-To-Connect Type Fittings 87

How to Remove Rubber 1/4″ Air Hoses 88

How to Install Rubber 1/4″ Air Hoses 89

How to Remove the Air Filter/Regulator 90

How to Install the Air Filter/Regulator 91

How to Remove a Roadranger Valve 92

How to Install a Roadranger Valve 93

How to Remove a Slave Valve 94

How to Install a Slave Valve 95

How to Remove the Gear Shift Lever/Remote Shift Control 96

How to Install the Gear Shift Lever/Remote Shift Control 97

How to Adjust the Remote Shift Control (LRC Type) 98

Neutral Switch Operation and Testing 100

How to Remove the Neutral Switch 101

How to Install the Neutral Switch 102

Reverse Switch Operation and Testing 103

How to Remove the Reverse Switch 104

How to Install the Reverse Switch 105

How to Remove the Shift Bar Housing 106

How to Install the Shift Bar Housing 108

How to Remove the Oil Seal – Mechanical Speedometer 110

How to Install the Oil Seal – Mechanical Speedometer 112

How to Remove the Oil Seal – Magnetic Speedometer 113

How to Install the Oil Seal – Magnetic Speedometer 116

How to Remove the Output Yoke/Companion Flange and Nut 118

How to Install the Output Yoke/Companion Flange and Nut 120

How to Remove the Output Yoke / Flange and Retaining Capscrews 122

How to Install the Output Yoke / Flange and Retaining Capscrews 123

How to Remove the Auxiliary Section in Chassis 124

How to Install the Auxiliary Section in Chassis 126

How to Remove the Combination Cylinder Assembly 129

How to Install the Combination Cylinder Assembly 131

How to Disassemble the Gear Shift Lever 133

How to Assemble the Gear Shift Lever 135

How to Remove the Shift Bar Housing 137

How to Install the Shift Bar Housing 139

How to Disassemble the Standard Shift Bar Housing 141

How to Assemble the Standard Shift Bar Housing 144

How to Disassemble the Forward Shift Bar Housing 147

How to Assemble the Forward Shift Bar Housing 150

How to Remove the Input Shaft Assembly (without main case disassembly) 153

How to Install the Input Shaft Assembly (without main case disassembly) 155

How to Remove the Auxiliary Section with Tapered Bearings 157

How to Remove the Combination Cylinder Assembly 159

How to Remove the Auxiliary Countershaft Assembly 161

How to Disassemble the Output Shaft Assembly 164

How to Disassemble the Synchronizer Assembly 168

How to Assemble the Synchronizer Assembly 169

How to Assemble the Output Shaft Assembly 171

How to Install the Combination Cylinder Assembly 177

How to Install the Auxiliary Countershaft Assembly 179

How to Remove the Clutch Housing 183

How to Remove the Auxiliary Drive Gear Assembly 185

Standard Torque Capacity Models 185

High Torque Capacity Models 186

How to Disassemble the Upper Reverse Idler Gear Assembly 188

How to Disassemble the Lower Reverse Idler Gear Assembly 190

How to Remove the Upper and Lower Countershaft Bearings 191

How to Remove the Mainshaft Assembly 193

How to Remove the Countershaft Assemblies 194

How to Disassemble the Countershaft Assemblies 196

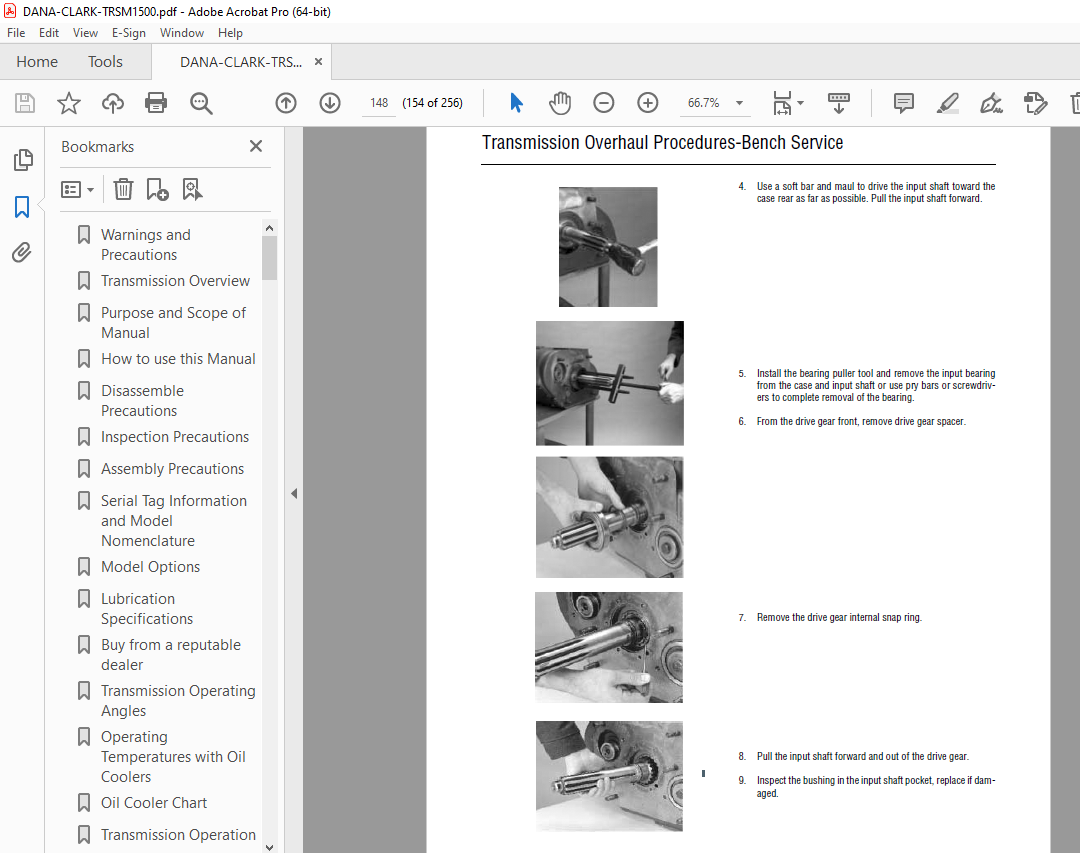

How to Remove the Input Shaft and Main Drive Gear 198

How to Disassemble the Mainshaft Assembly 201

How to Disassemble the Mainshaft Assembly with Low Force Gearing 203

How to Assemble the Mainshaft Assembly with Selective (Adjustable) Thickness Tolerance Washers 205

How to Assemble the Mainshaft Assembly with Non-Selective (Non-Adjustable) Tolerance Washers 211

How to Assemble the Mainshaft Assembly with Low Force Gearing 214

How to Prepare the Main Case for Assembly 217

How to Assemble the Countershaft Assemblies 218

How to Assemble the Lower Reverse Idler Gear Assembly 220

How to Install Countershaft Assemblies 223

How to Install the Lower Countershaft Bearings 224

How to Install the Input Shaft and Main Drive Gear 226

How to Install the Mainshaft Assembly 228

How to Install the Upper Countershaft Bearings 230

How to Assemble the Upper Reverse Idler Gear Assembly 233

How to Install the Auxiliary Drive Gear Assembly 236

How to Install the Clutch Housing 239

How to Disassemble the Integral Oil Pump without Auxiliary Oil Tube 240

How to Assemble the Integral Oil Pump without Auxiliary Oil Tube 243

How to Remove the Integral Oil Pump 246

How to Install the Integral Oil Pump 248

How to Install the Auxiliary Section with Tapered Bearings 250

Shim Procedure without a Shim Tool for Tapered Bearings 252