$35

Epson Stylus Color 980 Service Manual - PDF DOWNLOAD

Epson Stylus Color 980 Service Manual - PDF DOWNLOAD

FILE DETAILS:

Epson Stylus Color 980 Service Manual - PDF DOWNLOAD

Language :English

Pages :193

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Epson Stylus Color 980 Service Manual - PDF DOWNLOAD

PREFACE

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of Stylus Color 980. The instructions and procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page. The chapters are organized as follows:

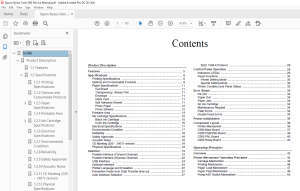

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the

product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved

lubricants and adhesives required for servicing the product.

CHAPTER 7. APPENDIX

Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Exploded diagram

• Electrical circuit boards schematics

TABLE OF CONTENTS:

Epson Stylus Color 980 Service Manual - PDF DOWNLOAD

SC980 1

Product Description 8

11 Features 9

12 Specifications 10

121 Printing Specifications 10

122 Options and Consumable Products 13

123 Paper Specifications 15

1231 Cut Sheet 15

1232 Transparency, Glossy Film 15

1233 Envelope 15

1234 Index Card 15

1235 Self Adhesive Sheets 15

1236 Photo Paper 16

1237 Photo Stickers 16

124 Printable Area 17

125 Ink Cartridge Specifications 19

1251 Black Ink Cartridge 19

1252 Color Ink Cartridge 20

126 Electrical Specifications 21

127 Environmental Condition 21

128 Reliability 22

129 Safety Approvals 22

1210 Acoustic Noise 22

1211 CE Marking (220 ~ 240 V version) 22

1212 Physical Specifications 22

13 Interface 23

131 Parallel Interface (Forward Channel) 23

132 Parallel Interface (Reverse Channel) 26

133 USB Interface 28

134 Optional interface 28

135 Printer Language and Emulation 31

136 Prevention Hosts from Data Transfer time-out 31

137 Auto Interface Selection 31

1371 IEEE 12844 Protocol 32

14 Control Panel Operation 33

141 Indicators (LEDs) 33

142 Panel Functions 34

1421 Printer Setting Mode 34

1422 Special Setting Mode 36

143 Printer Condition and Panel Status 37

15 Error Status 38

151 Ink Out 38

152 Paper Out 38

153 Paper Jam 38

154 No Ink Cartridge 38

155 Maintenance Request 38

156 Fatal Errors 38

157 Double Feed Errors 38

16 Printer Initialization 39

17 Component Layout 40

171 Printer Mechanism 40

172 C380 Main Board 41

173 C265 PSB/PSE Board 43

174 C265 PNL Board 44

175 C265 Relay Board 44

Operating Principles 45

21 Overview 46

22 Printer Mechanism Operating Principles 46

221 Carriage Mechanism 48

222 Printing Mechanism 50

223 Paper Load Mechanism 51

224 Paper Feed Mechanism 53

225 Pump/ASF Switch Mechanism 54

226 Pump / Carriage Lock / Head Cleaner Mechanism 56

23 Electrical Circuit Operation Principles 58

231 C265 PSB/PSE Power Supply Board 58

232 C380Main Board 61

233 CR Motor Driver Circuit 69

234 PF Motor Driver Circuit 71

235 Pump/ASF Motor Driver Circuit 73

236 Printhead Driver Circuit 74

237 Cooling Fan Driver Circuit 76

238 ASF Solenoid Driver Circuit 78

239 EEPROM Control Driver Circuit 79

Troubleshooting 80

31 Overview 81

311 Troubleshooting with LED Error Indications 82

3111 Remedies for Paper Out Error 83

3112 Remedies for the Paper Jam Error 85

3113 Remedies for No I/C and Ink Out Errors 87

3114 Remedies for the Maintenance Error 89

3115 Remedies for Fatal Error 90

312 Isolating the Faulty Part on the Power Supply Board 92

313 Isolating the Faulty Part according to the Phenomenon 94

Disassembly and Assembly103

41 Overview104

411 Precautions for Disassembling the Printer104

42 Disassembly Procedures106

421 Upper Case and Control Panel Removal108

422 Printer Mechanism Removal109

423 C380 Main Board Unit Removal110

424 Relay Board and Cooling Fan Removal111

425 Shield Plate on the C380 Main Board Removal112

426 C265 PSB/PSE Board Removal113

427 Printer Mechanism Disassembly115

4271 Printhead Removal115

4272 CR Motor Removal117

4273 PF Motor Removal118

4274 Pump/ASF Motor and Solenoid Removal119

4275 ASF Unit Removal119

42751 ASF Disassembly120

4276 ASF Sensor Removal124

4277 CRHP Sensor Removal125

4278 PE Sensor Removal125

4279 Encoder Belt Sensor Removal126

42710 Carriage Unit Removal127

42711 Pump Unit Removal128

42712 Paper Eject Frame Removal129

42713 Paper Eject Roller Removal129

42714 Platen Removal130

42715 PF Roller Removal131

Adjustment133

51 Overview134

511 Conditions for Each Adjustment134

52 Adjustments137

521 Preliminary Operation137

522 Head Actuator Voltage Input139

523 Head ID Retrieval140

524 Head Angular Adjustment140

525 Bi-Directional Adjustment141

526 USB ID Input144

527 USB ID Retrieval145

528 Printhead Cleaning Using the Program146

529 Initial Ink Charge147

5210 Refurbishment for DOA147

5211 Indication of the Counter Value for the Waste Ink Pad148

5212 Fan Check150

5213 Paper Gap Adjustment151

Maintenance154

61 Overview155

611 Maintenance155

6111 Cleaning the Printhead156

6112 Maintenance Request Error157

62 Lubrication and Adhesion158

621 Lubricating the Carriage Guide Shaft159

Appendix164

71 Connector Summary165

72 EEPROM ADDRESS MAP169

73 Component Layout173

74 Parts List177

75 Exploded Diagrams180

76 Circuit Diagrams188

S.M 26/2/2025