$34

Fantuzzi Reggiane KESSLER ACHSEN 81 NLB SERVICE MANUAL – PDF DOWNLOAD

Fantuzzi Reggiane KESSLER ACHSEN 81 NLB SERVICE MANUAL – PDF DOWNLOAD

FILE DETAILS:

Fantuzzi Reggiane KESSLER ACHSEN 81 NLB SERVICE MANUAL – PDF DOWNLOAD

Language : English

Pages :148

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Fantuzzi Reggiane KESSLER ACHSEN 81 NLB SERVICE MANUAL – PDF DOWNLOAD

Kessler D81 – Service Manual 1

Table of contents 3

Chapter 1 – Important remarks 4

11 – Important remarks 5

12 – Operation of creep gear, axle disconnection, inter axle diff-lock and cross diff-lock 7

13 – Instructions for ordering spare parts 9

Chapter 2 – Lubrication intervals and maintenance instructions 11

21 – General lubrication instructions 12

221 – Lubrication points 14

222 – Lubrication points 15

23 – Lubricants and lubrication intervals 16

231 – Recomendable hypoid gear oils corresp 18

24 – General maintenance instructions 19

Chapter 3 – General instructions for correct assembly and disassembly – Service tools 21

31 – General instructions for corrrect assembly and disassembly 22

321 – Using of Loctite and operating supplies 24

321 – Remarks for working up Loctite and operating supplies 24

322 – Utilization of Loctite and operating supplies 26

323 – Utilization of Loctite and operating supplies 27

33 – Tightening torques 28

34 – Tightening torques of wheel nuts 29

35 – Tightening torques for castle nuts on ball joints for track rods and ram cylinders 30

35 – Tightening torque of the adjusting nut resp slotted nut at flanges resp gearwheels ect 30

361 – Service tools 31

362 – Service tools 32

366 – Service tools 33

Chapter 4 – Assembly drive assembly 34

401 – Adjustment of gear meshing of Gleason gearrs 35

402 – Securing of the striking nut 37

41 – Drive assembly D51 39

411 – Adjustment of gear meshing 40

412 – Assembly of drive pinion bearing 42

413 – Assembly of the differential 44

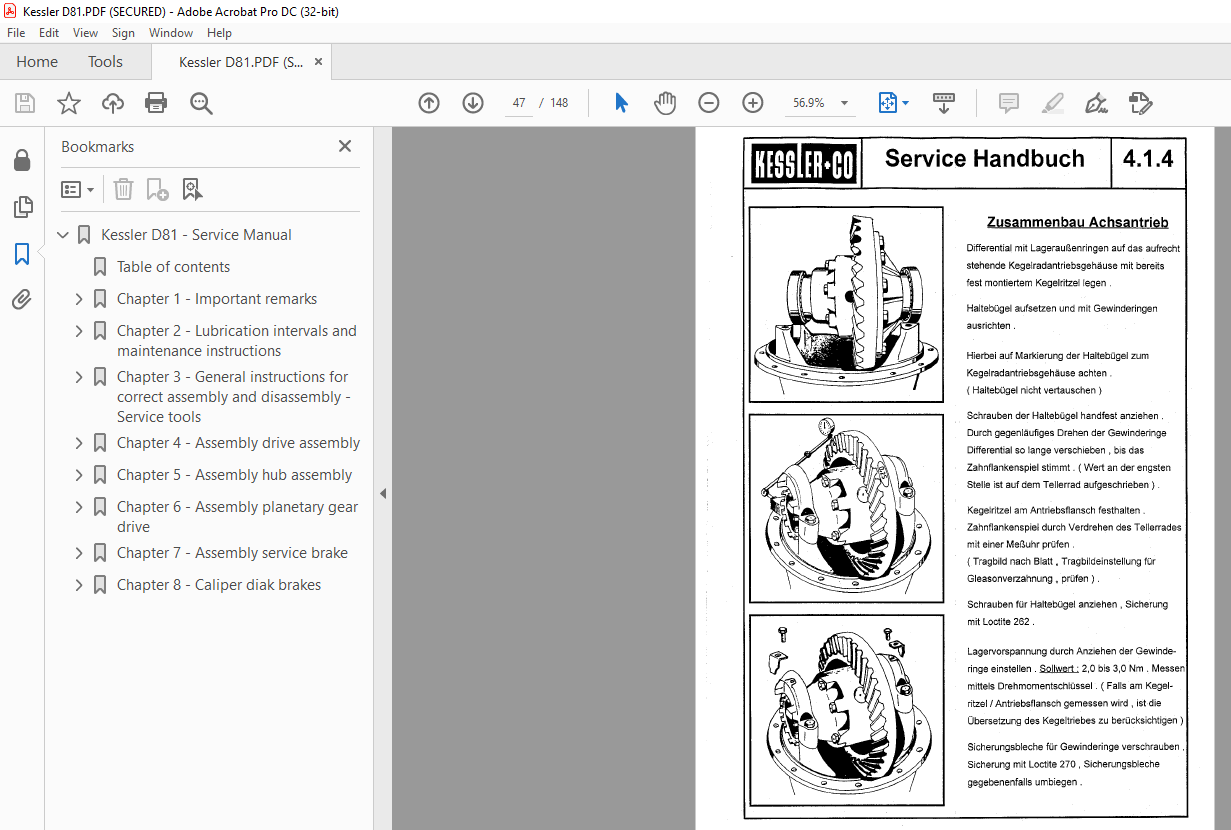

414 – Assembly of drive assembly 46

416 – Assembly of the cross differential lock D51/D108/D71 through drive 48

43 – Drive assembly D71 50

431 – Assembly of the drive pinion bearing 51

432 – Assembly of the drive pinion bearing 53

433 – Adjustment of gear meshing 55

413 – Assembly of the differential 57

414 – Assembly of drive assembly 59

Chapter 5 – Assembly hub assembly 61

516 – Assembly of the spacer ring 62

53 – Hub assembly drive axle 63

531 – Assembly of the drive assembly onto the axle housing 64

532 – Assembly hub assembly 66

552 – Prepare wheel hub 67

552 – Mount wheel hub 67

571 – Adjustment of wheel bearings 69

572 – Wheel safety nut 70

581 – Assembly of the face seal 71

582 – Assembly of the face seal 73

583 – Assembly of the face seal 75

584 – Assembly of the face seal 77

Chapter 6 – Assembly planetary gear drive 79

62 – Planetary gear drive 80

611 – Prepare the ring gear and the ring gear carrier 81

611 – Assembly of the ring gear carrier 81

611 – Assembly of the thrust ring 81

611 – Assembly of the sun gear 81

612 – Assembly of planetary gear 83

621 – Assembly of planetary housing 85

621 – Adjustments of the axial clearance 85

614 – Disassembly of planetary gear 87

66 – Planetary gear drive 89

651 – Prepare the ring gear and the ring gear carrier 90

651 – Assembly of the ring gear carrier 90

651 – Assembly of the thrust ring 90

651 – Assembly of the sun gear 90

612 – Assembly of planetary gear 92

661 – Adjustment if the axial clearance 94

661 – Assembly of the planetary housing 94

614 – Disassembly of the planetary gear 96

Chapter 7 – Assembly service brake 98

701 – Instruction for the servicing and repair of hydraulic and mechanically actuated drum and disk brakes 99

711 – Assembly of the wet disk brake101

712 – Assembly of the piston seals102

712 – Assembly of o-ring and supporting ring102

712 – Assembly of the Omegat seal kit102

713 – Assembly of the piston104

714 – Prepare housing and chack the air gap106

715 – Air gap and wear dimension108

716 – Finish assembly109

717 – Tightness checking instruction for brake hydraulic system and cooling oil room111

718 – Remarks to the Wet Disk Brake113

719 – Remarks to the Wet Disk Brake115

737 – Brake disk117

Chapter 8 – Caliper diak brakes118

811 – Torque capability based on disk diameter and clamping stroke s119

812 – Contents120

813 – Description of the spring applied hydraulically released floating caliper disk brake122

814 – Description of the spring applied hydraulically released floating caliper disk brake124

815 – Picture 1: Cutaway view126

816 – Assembly instruction for the disk brake127

817 – Picture 5 – Picture 6129

818 – Picture 7 – Picture 8131

819 – Picture 9 – 91 – 92133

8110 – Picture 10 – Picture 11135

8111 – Picture 12 – Picture 13137

8112 – Picture 14 – Picture 15139

8113 – Picture 16 – Picture 17142

8114 – Picture 18 – Picture 19143

8115 – Service and maintenance145

8116 – Service and maintenance147

IMAGES PREVIEW OF THE MANUAL: