$38

Fassi Crane Installation Instructions Manual – PDF DOWNLOAD

Fassi Crane Installation Instructions Manual – PDF DOWNLOAD

FILE DETAILS:

Fassi Crane Installation Instructions Manual – PDF DOWNLOAD

Language : English

Pages :242

Downloadable : Yes

File Type : PDF

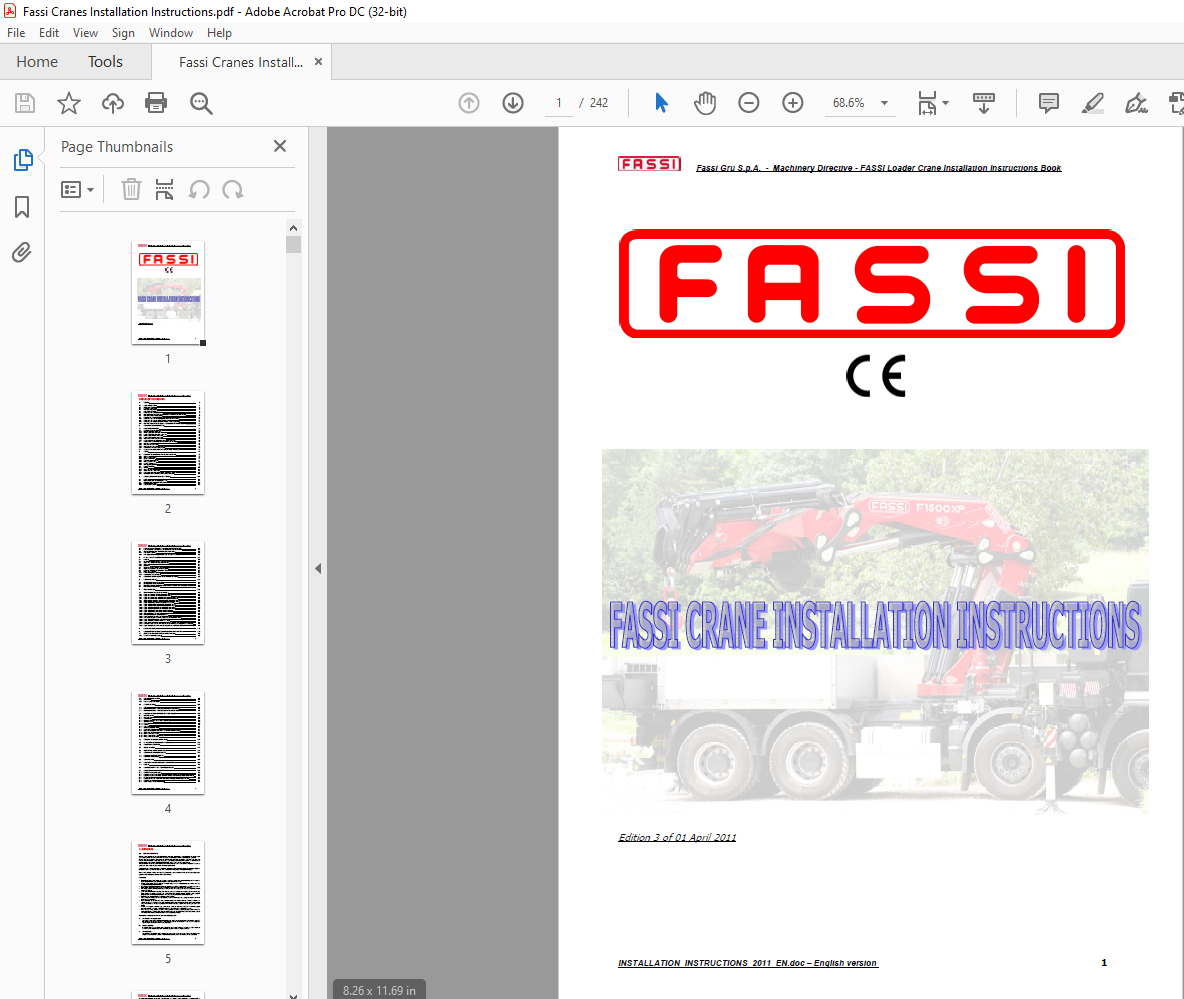

TABLE OF CONTENTS:

Fassi Crane Installation Instructions Manual – PDF DOWNLOAD

1. GENERAL 5

1.1 GENERAL INDICATIONS 5

1.2 APPLICABILITY 6

1.3 MACHINERY DIRECTIVE 6

1.4 REFERENCE DIRECTIVE 7

1.5 SAFETY REQUIREMENTS 8

1.6 DEFINITION OF RESPONSIBILITIES 8

1.7 PRECAUTIONS ABOUT THE RISKS DURING THE INSTALLATION OPERATIONS 9

1.8 REFERENCES FOR THE INSTALLER 1 0

1.9 CRANE MODEL IDENTIFICATION CODES 20

1.10 DEFINITION OF MAIN CRANE AND INSTALLATION COMPONENTS 2 2

1.11 DEFINITION OF MAIN CRANE ACCESSORIES 23

1.12 DEFINITION OF THE MAIN COMPONENTS OF THE INSTALLATION 2 4

1.13 IDENTIFICATION OF THE CRANE AND ACCESSORIES SERIAL NUMBER _ _____________ _ 24

2. CRANE-VEHICLE COMBINATIONS 27

2.1 COMBINATION PRINCIPLES 2 7

2.2 DETERMINATION OF AXLE LOADS 2 7

2.2.1 Where to find the technical data 2 8

2.2.2 2-axle vehicle / crane mounted behind cab 3 1

2.2.3 3-axle vehicle / crane mounted behind cab 3 4

2.2.4 2-axle vehicle / rear mounted crane 3 9

2.2.5 3-axle vehicle / rear mounted crane 4 2

2.2.6 Tractor truck / crane mounted behind cab 4 7

2.2.7 Example of axle loads distribution using Fassi FIP program 5 0

2.3 THEORETICAL STABILITY ANALYSIS – ANALYTICAL METHOD 5 1

2.3.1 Crane behind cab 5 1

2.3.2 Crane mounted on the rear 5 9

2.3.3 Crane mounted on three axle vehicles 6 7

2.3.4 Theoretical stability check using a graph 6 8

2.4 Example of theoretical stability check using the Fassi “FIP” program 6 9

3. SIZING 7 0

3.1 CHECKING THE VEHICLE CHASSIS AND CRANE SUB FRAME 7 0

3.1.1 Sub frame material 7 7

3.1.2 Sub frame end tapering 77

3.1.3 Length of sub frame 7 9

3.1.4 Connecting cross members 8 1

3.1.5 Sub frame construction 8 4

3.1.6 Securing the sub frame 8 6

3.1.7 Self supporting sub frame 9 0

3.2 CRANE ANCHORING 9 9

3.2.1 Tie rods 1 0 2

3.2.2 Blocks and plates 1 0 4

3.2.3 Tie rod nuts and counter nuts 1 0 4

3.2.4 Devices preventing the vehicle chassis from getting crushed 1 0 4

3.2.5 Identification and modification of the rotation dead point 1 0 5

4. SUPPLEMENTARY OUTRIGGERS MOUNTING 1 0 7

4.1 GENERAL 1 0 7

4.2 FREE SPACE UNDER THE OUTRIGGER RAM 1 0 7

4.3 SUPPLEMENTARY OUTRIGGERS INSTALLATION 1 0 8

4.3.1 Above-chassis mounting 1 0 8

4.3.2 Under-chassis mounting 1 09

Fassi Gru S.p.A. – Machinery Directive – FASSI Loader Crane Installation Instructions Book

INSTALLATION_INSTRUCTIONS_2011_EN.doc – English version 3

4.4 HYDRAULIC CONNECTIONS FOR THE SUPPLEMENTARY OUTRIGGERS 109

4.5 CALCULATION OF BOLTS Q.TY TO FIX SUPPLEMENTARY OUTRIGGERS 1 0 9

4.6 SPECIAL SUPPLEMENTARY OUTRIGGERS INSTALLATIONS 1 1 0

4.6.1 Under cabin mounting 1 1 0

4.6.2 Extra supplementary outriggers mounted on the rear of the vehicle 112

5. POWER TAKE-OFF AND PUMP 1 17

5.1 GENERAL 1 17

5.2 SELECTING THE POWER TAKE-OFF AND PUMP 1 17

5.3 INSTALLING POWER TAKE-OFF ON GEAR BOX 1 21

5.3.1 Limitations 1 21

5.3.2 Final check 121

5.4 POWER TAKE OFF – SPECIAL CASES 122

5.5 PNEUMATIC COUPLING OF POWER TAKE-OFF 123

5.6 MECHANICAL COUPLING OF POWER TAKE-OFF 123

5.7 INSTALLING THE PUMP 124

5.7.1 How to start up piston pumps 126

5.7.2 Adjustment of the engine speed 1 2 6

5.8 CRANE OPERATED THROUGH AN ALTERNATIVE POWER GROUP 126

6. HYDRAULIC SYSTEM 1 28

6.1 DIMENSION OF THE SUCTION LINE 1 2 8

6.2 DIMENSION OF THE PRESSURE LINE 1 2 9

6.3 PIPES FOR THE HYDRAULIC CONNECTION OF THE SUPPLEMENTARY OUTRIGGERS 1 3 1

6.4 FILLING-UP OF THE OIL TANK 1 3 1

7. ELECTRIC SYSTEM 132

7.1 SUPPLY LINE CONNECTION TO THE VEHICLE 1 3 3

7.1.1 Supply line for cranes with FX800 electronic system 134

7.1.2 Supply line for cranes with FX500 electronic system 1 3 5

7.1.3 Supply line for the FX804 slave unit for FX800 electronic system 1 3 5

7.1.4 Supply line for the FX504 slave unit for FX500 electronic system 1 3 6

7.1.5 Cable for radio remote control options for FX800 electronic system 1 3 6

7.1.6 Cable for radio remote control options for FX500 electronic system 1 3 7

7.1.7 Supply cable for user panels for FX800 electronic system 1 3 8

7.1.8 Supply cable for working lights for FX800 electronic system 1 3 9

7.1.9 Supply cable for working lights for FX500 electronic system 1 3 9

7.1.10 Supply cable for height sensor for FX800 electronic system 1 4 0

7.1.11 Supply cable for height sensor for FX500 electronic system 1 4 0

7.1.12 Supply cable for oil cooler for FX800 electronic system 1 4 1

7.1.13 Supply cable for oil cooler for FX500 electronic system 141

7.1.14 Signal cable from M.O.L. system 1 4 2

7.1.15 PLE signal cable for FX500 electronic system 1 4 3

7.1.16 Supply cable for DCS option for FX800 electronic system 1 4 3

7.1.17 Extra wires for eventual customer options for FX800 electronic system 1 4 4

7.1.18 Supply cable for FSC system – main unit 1 4 4

7.1.19 Supply cable for Can bus lines shunt box – IE696 1 4 5

7.1.20 Supply wire for outriggers selector to indicate the operator position 1 4 5

7.1.21 Connection cables between main FSC unit and SD2 shunt box for supplementary outriggers 1 4 6

7.1.22 Supply cable for M.O.L. system (version integrated in the FSC system) 1 4 7

8. PNEUMATIC SYSTEM 1 47

9. CRANE COMPONENTS ASSEMBLY IF NOT FITTED AT THE ORIGIN 1 4 8

9.1 APPLICATION OF THE OUTRIGGER RAMS FOR THE CRANE 1 4 8

9.1.1 Use of monocast outrigger plates 1 4 8

Fassi Gru S.p.A. – Machinery Directive – FASSI Loader Crane Installation Instructions Book

INSTALLATION_INSTRUCTIONS_2011_EN.doc – English version 4

9.2 ACCESSORIES INSTALLATION 1 4 9

9.2.1 Jib installation 1 4 9

9.2.2 Manual extensions installation 1 5 1

10. CONTROL STATION 1 5 2

10.1 ACCESS 152

10.2 PROTECTION AGAINST THE RISK OF INHALING EXHAUST FUMES 155

10.3 PROTECTION AGAINST THE RISK OF CRUSHING AND SHEARING 1 5 5

11. PRACTICAL TESTS CARRIED OUT BY THE INSTALLER 157

11.1 FUNCTIONAL TEST 157

11.2 STATIC TEST 157

11.3 DYNAMIC TEST 158

11.3.1 Sink rate of the boom system under nominal load 158

11.4 STABILITY TESTS 158

11.4.1 General 1 58

11.4.2 Test load 158

11.4.3 Test conditions 159

11.5 Stability test approval criteria 161

11.6 TEST REPORTS 163

11.7 VERIFICATION AND MEASUREMENT OF THE ACOUSTIC EMISSIONS 163

11.8 FSC SYSTEM SETTING 164

11.8.1 Setting of the FSC/L system 1 6 4

11.8.2 Setting of the FSC/M1 – FSC/M2 systems 1 6 4

11.8.3 Setting of the FSC/S system 1 6 6

12. CHECKING MAXIMUM MASS ON AXLES 174

13. RE-ADJUSTMENT AND SEALING OF THE CRANE 175

14. CRANE TRANSFORMATION 1 76

15. LIST OF HAZARDS 1 77

16. INSTRUCTION PLATES AND STICKERS 1 77

17. SPECIAL CASES AND INSTALLATION 1 77

17.1 CRANE INSTALLED ON FIX PEDESTAL 179

17.2 CRANE INSTALLED ON BOAT 1 7 9

18. TECHNICAL FILE 1 80

19. CE MARKING AND DECLARATION OF CONFORMITY 184

19.1 GENERAL 1 84

20. CRANE DELIVERY TO THE CUSTOMER/END USER 1 85

21. ENCLOSED 1 86

21.1 CHART WITH CRANE FEATURES 1 87

21.2 CHART WITH THE FEATURES OF THE SUPPLEMENTARY OUTRIGGERS 1 88

21.3 CHART WITH THE FEATURES OF THE HYDRAULIC CIRCUIT (working pressures and oil flow) 1 8 9

21.4 LIST OF HAZARDS 1 90

21.5 CE DECLARATION OF CONFORMITY ISSUED BY THE CRANE PRODUCER (fac-simile) 1 9 3

21.6 CHECK LIST (fac-simile) 1 95

21.7 LOADER CRANE LOGBOOK (fac-simile) 1 9 6

IMAGES PREVIEW OF THE MANUAL: