Starting from:

$45

Home

Fiatallis HD 11 HD 11-B Crawler Tractors Service Manual - PDF DOWNLOAD

Fiatallis HD 11 HD 11-B Crawler Tractors Service Manual - PDF DOWNLOAD

Fiatallis HD 11 HD 11-B Crawler Tractors Service Manual - PDF DOWNLOAD

FILE DETAILS:

Fiatallis HD 11 HD 11-B Crawler Tractors Service Manual - PDF DOWNLOAD

FN 70682019

Language : English

Pages : 40

Downloadable : Yes

File Type : PDF

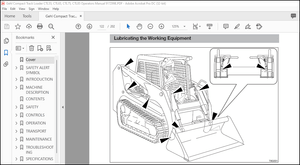

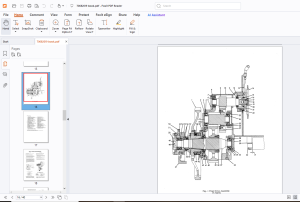

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Fiatallis HD 11 HD 11-B Crawler Tractors Service Manual - PDF DOWNLOAD

FN 70682019

1. General Description

Page 32. Troubleshooting

Page 33. Final Drive Disassembly

Page 8

- A. Track Sprocket and Shaft Removal

- B. Intermediate Shaft Removal

- C. Pinion Shaft Removal

6. Final Drive Assembly

Page 9

- A. Cleaning and Inspection

- B. Intermediate Pinion and Gear Installation

- C. Pinion (Top Shaft) Installation

- D. Sprocket Shaft Bearings Adjustment

- E. Sprocket Shaft Seal Assembly

- F. Sprocket Shaft and Gear Installation

- G. Track Sprocket Installation

- H. Sprocket Shaft Outboard Bearing Installation

- I. Truck Frame and Track Installation

7. Fits and Tolerances

Page 13

- A. Pinion Shaft Components

- B. Intermediate Shaft and Components

- C. Sprocket Shaft and Components

8. Service Tools

Page 169. Conversion Tables

Page 19

DESCRIPTION:

Fiatallis HD 11 HD 11-B Crawler Tractors Service Manual - PDF DOWNLOAD

FN 70682019

GENERAL:

- Study the Operation and Maintenance Instruction Manual be- fore starting, operating, maintaining, fueling, or servicing machine. Read and heed all machine-mounted safety signs before starting, operating, maintaining, fueling or servicing machine.

- Machine-mounted safety signs have been color coded yellow with black border and lettering for WARNING and red with white border and lettering for DANGER points. Never attempt to operate the machine or its tools from any position other than seated in the operator's seat.

- Keep head, body, limbs, hands and feet inside operator's compartment at all times to reduce exposure to hazards outside the operator's compartment. Do not allow unauthorized personnel to operate service or maintain this machine. Always check work area for dangerous features.

- The following are examples of dangerous work areas: slopes, over hangs, timber, demolitions, fire, high walls, drop off, back fills, rough terrain, ditches, ridges, excavations, heavy traffic, crowded parking, crowded maintenance and closed areas. Use extreme care when in areas such as these.

- An operator must know the machine's capabilities. When working on slopes or near drop offs be alert to avoid loose or soft conditions that could cause sudden tipping or loss of control. Do not jump on or off machine. Keep two hands and one foot, or two feet and one hand, in contact with stops grab rails and handles at all times.

- Do not use controls or hoses as hand holds when climbing on or off machine. Hoses and controls are movable and do not provide a solid support. Controls also may be inadvertently moved causing accidental machine or equipment movement.

- Keep operator's compartment, stepping points, grab-rails and handles clear of foreign objects, oil, grease, mud or snow accumulation to minimize the danger of slipping or stumbling. Clean mud or grease from shoes before attempting to mount or operate the machine. Be careful of slippery conditions on stepping points, hand rails, and on the ground.

- Wear safety boots or shoes that have a high slip resistant sole material. For your personal protection. Do not attempt to climb on or off machine while machine is in motion. Never leave the machine unattended with the engine running. Always lock up machine when leaving it unattended.

- Return keys to authorized security. Heed all shut down procedures of the Operation and Maintenance Instruction Manual. Always set the parking brake when leaving the machine for any reason.

G.B 26/03/25

1 file (3.9MB)