$45

Flexicoil 340 Chisel Plow Service Repair Manual (87053715) – Flexicoil 340 Chisel Plow

Flexicoil 340 Chisel Plow Service Repair Manual (87053715) – Flexicoil 340 Chisel Plow

File Details:

Flexicoil 340 Chisel Plow Service Manual_87053715

Size: 14.8 MB

Language: English

Format: PDF

Number of Page: 172

Date Modified: 2/2005

Brand: Flexicoil

Model: Flexicoil 340 Chisel Plow

Type of document: Service Manual

Type of Machine: Flexicoil Chisel Plow

Part Number: 87053715

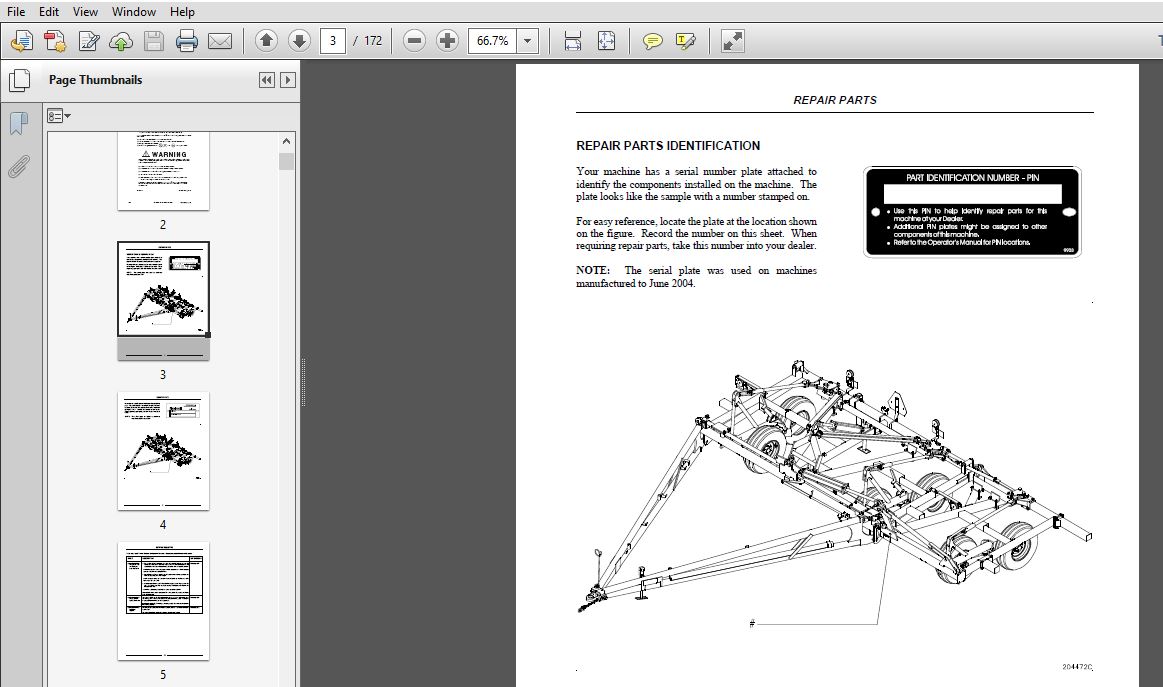

Image Preview:

Sample Page From The Manual:

Flexicoil 340 Chisel Plow Service Repair Manual (87053715) – Flexicoil 340 Chisel Plow

- Be alert for overhead electrical wires. Failure to stay clear of electrical wires will result in electrocution. Electrocution can occur without direct contact with overhead electrical wires.

- To prevent personal injury when assembling the implement, always block up the raised section. Be sure the section is stable before assembly and never rely on a jack or hydraulic device to support the raised implement.

- Always make sure that pressure is relieved from hydraulic circuits before servicing or disconnecting from the tractor. Failure to do so may result in hydraulic fluid being injected into the skin, that may result in gangrene.

Table Of Contents:

Flexicoil 340 Chisel Plow Service Repair Manual (87053715) – Flexicoil 340 Chisel Plow

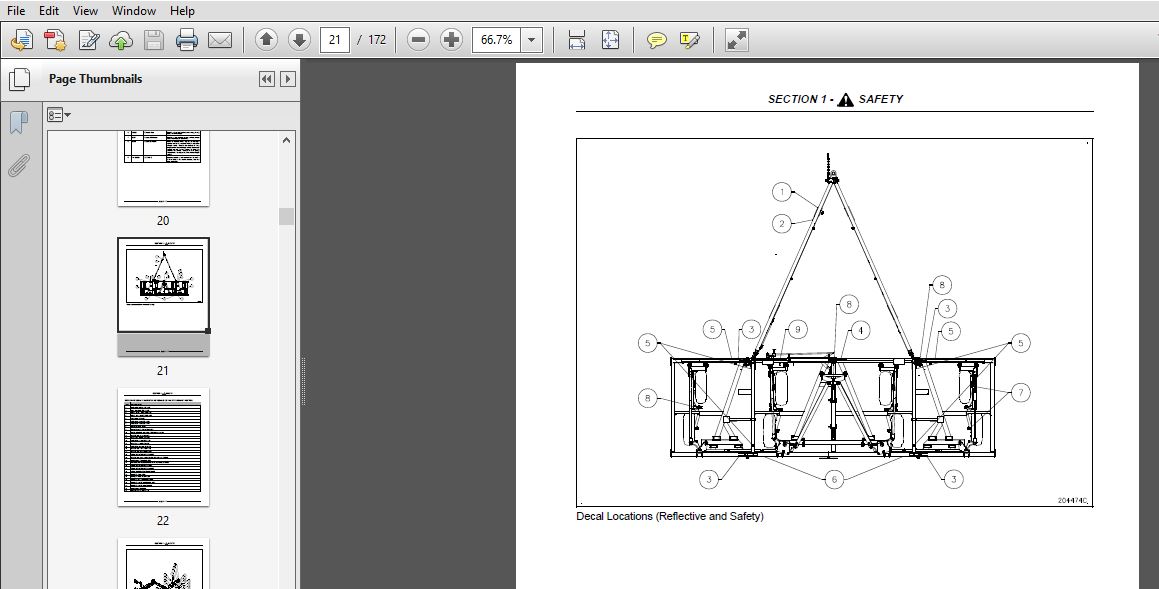

1 – SAFETY 1-1

Safety

Decal Locations

Reflector Decals, Slow Moving Vehicle Sign and

Transport Lighting

Transport Lighting Wiring Schematic

2 – ADJUSTMENTS 2-1

General Service Information

Initial Leveling

Initial Leveling Procedure

Final Leveling

Final Leveling Procedure

Trip Adjustment

Sweep Pitch Adjustment

3 – MECHANICAL SERVICE 3-1

Machine Specifications – Imperial Units

Machine Specifications – Metric Units

Troubleshooting Tables

Grease Locations

Daily Maintenance (Every 10 Hours)

Weekly Maintenance (Every 50 Hours)

Semi-Annual Maintenance (Every 200 Hours)

Yearly Maintenance

Welding Procedures

Frame Components

Wheel Bolt Torque

Tire Pressures and Hub and Spindle Details

Hub / Spindles / Wheels / Walking Beams

Removal and Replacement of Bushings on Bell Crank

Assembly

4 – HYDRAULICS 4-1

Hydraulics

Replace Seals in Cylinders

Hydraulic Cylinder Components

Hydraulic Schematics

Ram Mount Depth Stop Connection

5 – ELECTRICAL 5-1

Connector Service Kit

6 – TRIPS AND OPENERS 6-1

Trip Compressor Tool Kit

Tension Link Kit TP-133K – 550lb Trip

Adjustment of Trip Assemblies

Anti-Skewing Trip Shim Installation

Trip Shim Kit for 650lb Trip

7 – OPTIONS 7-1

Harrows

Mounted Harrow Assembly

Heavy Harrows

High Draft Assembly

Anhydrous Hitch

Front Hitch Weight Assembly

INDEX