$28

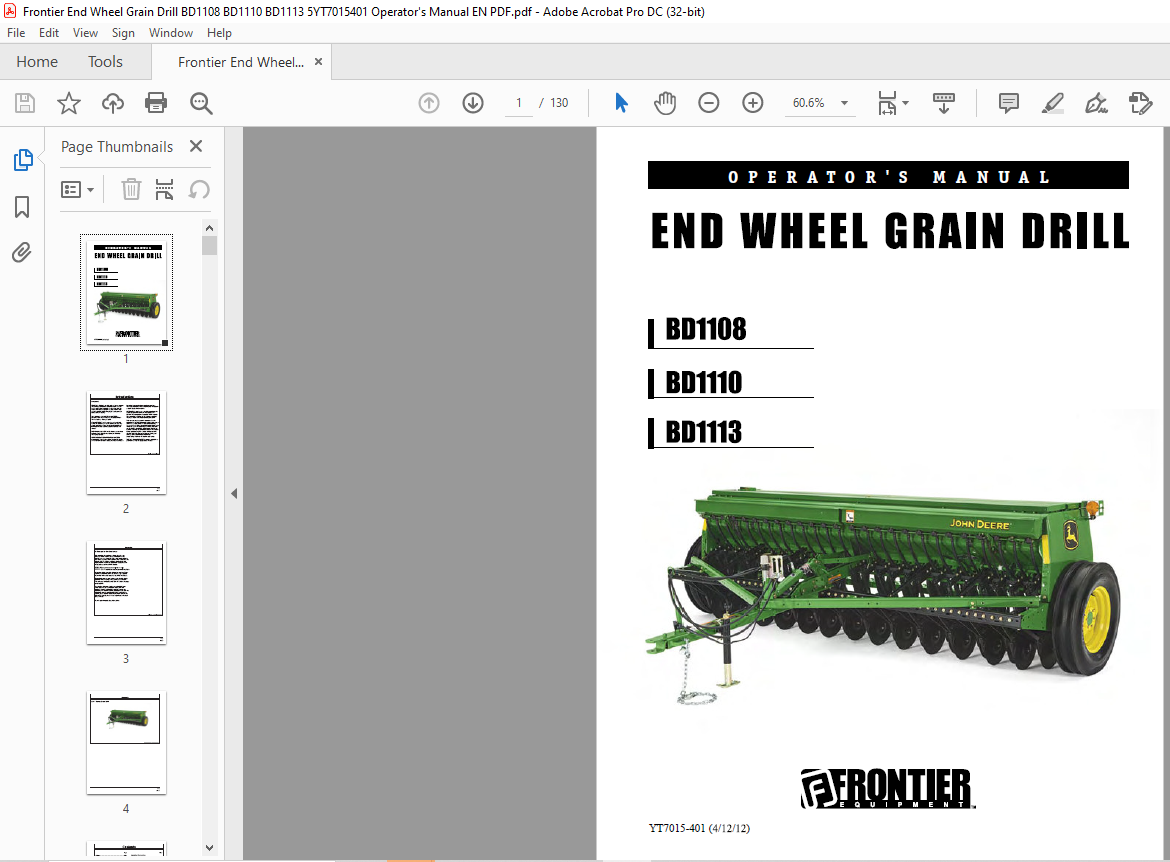

Frontier End Wheel Grain Drill BD1108 BD1110 BD1113 Operator’s Manual(5YT7015401) – PDF DOWNLOAD

Frontier End Wheel Grain Drill BD1108 BD1110 BD1113 Operator’s Manual(5YT7015401) – PDF DOWNLOAD

FILE DETAILS:

Frontier End Wheel Grain Drill BD1108 BD1110 BD1113 Operator’s Manual(5YT7015401) – PDF DOWNLOAD

Language : English

Pages :130

Downloadable : Yes

File Type : PDF

Size:5.32 MB

DESCRIPTION

Frontier End Wheel Grain Drill BD1108 BD1110 BD1113 Operator’s Manual(5YT7015401) – PDF DOWNLOAD

Introduction

Foreword

- READ THIS MANUAL carefully to learn how to operate and service your machine correctly. Failure to do so could result in personal injury or equipment damage. This manual and safety signs on your machine may also be available in other languages. (See your John Deere dealer to order.)

- THIS MANUAL SHOULD BE CONSIDERED a permanent part of your machine and should remain with the machine when you sell it. MEASUREMENTS in this manual are given in both metric and customary U.S. unit equivalents. Use only correct replacement parts and fasteners.

- Metric and inch fasteners may require a specific metric or inch wrench. RIGHT-HAND AND LEFT-HAND sides are determined by facing in the direction the implement will travel when going forward. WRITE PRODUCT IDENTIFICATION NUMBERS (P.I.N.) in the Specification section.

- Accurately record all the numbers to help in tracing the machine should it be stolen. Your dealer also needs these numbers when you order parts. File the identification numbers in a secure place off the machine. WARRANTY is provided as part of the manufacturer’s support program for customers who operate and maintain their equipment as described in this manual.

- The warranty is explained on the warranty certificate which you should have received from your dealer This warranty provides you the assurance that the manufacturer will back itsproducts where d efects appear within the warranty period. In some circumstances, lso rovides field mprovements, ften without charge to the customer, even if the product is out of warranty.

- Should the equipment be abused, or modified to change its performance beyond the original factory specifications, the warranty will become void and field improvements may be denied. Setting fuel delivery above specifications or otherwise overpowering machines will result in such action. THE TIRE MANUFACTURER’S warranty applicable to your machine may not apply outside the U.S.

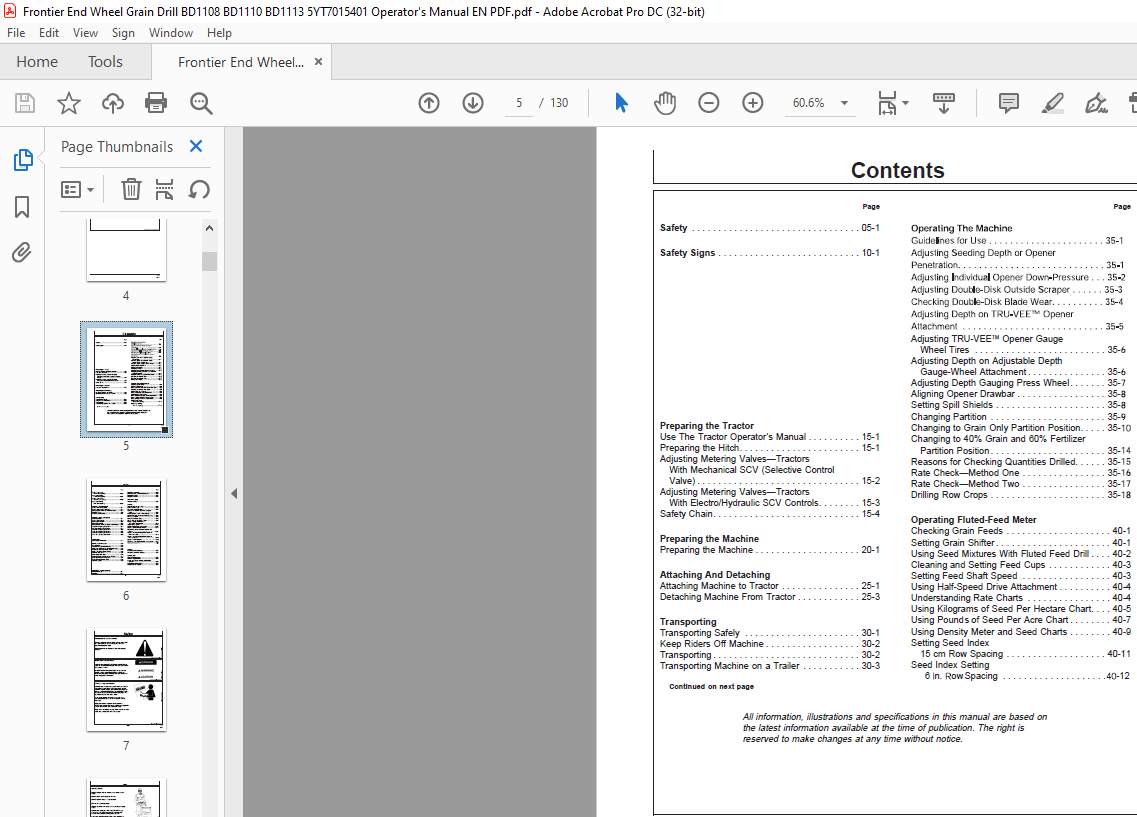

TABLE OF CONTENTS:

Frontier End Wheel Grain Drill BD1108 BD1110 BD1113 Operator’s Manual(5YT7015401) – PDF DOWNLOAD

Safety 05-1

Adjusting TRU-VEE Opener Gauge

Wheel Tires 35-

Adjusting Depth on Adjustable Depth

Safety Signs 10-1

Gauge-Wheel Attachment 35-

Adjusting Depth Gauging Press Wheel 35-

Preparing the Tractor

Use The Tractor Operator’s Manual 15-1

Preparing the Hitch 15-1

Adjusting Metering Valves—Tractors

With Mechanical SCV (Selective Control

Valve) 15-2

Adjusting Metering Valves—Tractors

With Electro/Hydraulic SCV Controls 15-3

Safety Chain 15-4

Preparing the Machine

Preparing the Machine 20-1

Attaching And Detaching

Attaching Machine to Tractor 25-1

Detaching Machine From Tractor 25-3

Transporting

Transporting Safely 30-1

Keep Riders Off Machine 30-2

Transporting 30-2

Transporting Machine on a Trailer 30-3

Aligning Opener Drawbar 35-

Setting Spill Shields 35-

Changing Partition 35-

Changing to Grain Only Partition Position 35-

Changing to 40% Grain and 60% Fertilizer

Partition Position 35-

Reasons for Checking Quantities Drilled 35-

Rate Check—Method One 35-

Rate Check—Method Two 35-

Drilling Row Crops 35-

Operating Fluted-Feed Meter

Checking Grain Feeds 40-1

Setting Grain Shifter 40-1

Using Seed Mixtures With Fluted Feed Drill 40-2

Cleaning and Setting Feed Cups 40-3

Setting Feed Shaft Speed 40-3

Using Half-Speed Drive Attachment 40-4

Understanding Rate Charts 40-4

Using Kilograms of Seed Per Hectare Chart 40-5

Using Pounds of Seed Per Acre Chart 40-7

Using Density Meter and Seed Charts 40-9

Setting Seed Index

15 cm Row Spacing 40-11

Seed Index Setting

6 n ow Spacing -12

Continued on next page

All information, illustrations and specifications in this manual are based on

the latest information available at the time of publication The right is

reserved to make changes at any time without notice

i 042406

PN=1

Contents

Page Page

Setting Seed Index Lubrication Symbols 60-2

Alternative and 19 cm Row Spacing 40-13 Synthetic Lubricants 60-2

Seed Index Setting Lubricant Storage 60-3

75 in Row Spacing 40-14 Lubrication Points 60-4

Setting Seed Index

245 cm Row Spacing 40-15 Troubleshooting

Seed Index Setting Troubleshooting 65-1

10 in Row Spacing 40-16

Service

Operating Fertilizer Meter Avoid High-Pressure Fluids 70-1

Setting Feed Shaft Speed 45-1 Service Tires Safely 70-1

Setting Feed Shaft Gear Case 45-1 Preventing Contamination 70-2

Using Density Meter and Fertilizer Charts 45-2 Service and Operate Chemical Sprayers

Fertilizer Charts 45-3 Safely 70-3

Cleaning Fertilizer Box 45-4 Metric Bolt and Screw Torque Values 70-4

Unified Inch Bolt and Screw Torque Values 70-5

Operating Grass Seed Meter Check Acremeter 70-6

Checking Feeds 50-1 Reset Fluted-Feed Cups 70-6

Setting Feed Shifter 50-2 Check Feed Shaft Rolling Torque 70-8

Using Seed Mixtures 50-3 Replace Gauge Wheel Arm—

Using Rate Charts 50-4 TRU-VEE™ Attachment 70-9

Using Density Meter and Grass Seed Charts 50-5 Tighten Drive Chains 70-10

15 cm Row Spacing Rate Chart 50-7 Tighten Fluted-Feed Drive Chains 70-10

Replace Fertilizer Feed Wheels 70-11

DeterminingWhentoReplaceDouble-Disk

Blades 70-11

ReplaceandAdjustDouble-DiskBladeson

AluminumBoots 70-12

ReplaceandAdjustDouble-DiskBladeson

Cast-IronBoots 70-15

ReplaceInsideScrapers 70-16

Replacing Seed Tubes-Double-Disk Opener 70-

6 in Row Spacing Rate Chart 50-7

19 cm Row Spacing Rate Chart 50-8

75 in Row Spacing Rate Chart 50-8

25 cm Row Spacing Rate Chart 50-9

10 in Row Spacing Rate Chart 50-9

Attachments

Grass Seed Attachment 55-1

Drill-Shaft Turn Indicator 55-3

Cover Chains 55-3

TRU-VEE Opener Attachment 55-4

Adjustable Depth Gauge Wheel Attachment 55-4

Half-Speed Drive For Fluted-Feed 55-5 Storage

Grain Feed Stop—Fluted Feeds 55-5 Preparing Drill for Storage 75-1

Fertilizer Feed Stop 55-5 Removing Drill From Storage 75-3

Grass Seed Feed Stop 55-6

Adjusting Depth Gauging Press Wheel 55-7 Specifications

Depth Bands-Aluminum Boots 55-8 Tractor Requirements 80-1

Depth Bands-Cast Iron Boots 55-9 Machine Specifications 80-1

Fertilizer Spouts 55-9 Locate and Record Product Identification

Number 80-2

Keep Proof of Ownership 80-2

Keep Machines Secure 80-3

Lubrication and Maintenance

Multiluber Grease 60-1

Gear Oil 60-1

ii

IMAGES PREVIEW OF THE MANUAL: