$29

Frontier Inline Bale Wrapper LW1166 Operator’s Manual(5TB109100337) – PDF DOWNLOAD

Frontier Inline Bale Wrapper LW1166 Operator’s Manual(5TB109100337) – PDF DOWNLOAD

FILE DETAILS:

Frontier Inline Bale Wrapper LW1166 Operator’s Manual(5TB109100337) – PDF DOWNLOAD

Language : English

Pages :155

Downloadable : Yes

File Type : PDF

Size: 15.2 MB

DESCRIPTION

Frontier Inline Bale Wrapper LW1166 Operator’s Manual(5TB109100337) – PDF DOWNLOAD

Safety Guidelines

- Safety of the operator is one of our main concerns, however we do hear of some accidents that could

have been avoided if some precautions had been taken. To avoid personal injury study the following - precautions and insist those working with you or for you, follow them.

- In most cases the pictures will have the shielding in place, in some they may be removed, only to

show a view behind the shield. Keep all the shields, safety doors in place. If they become faulty and

fail to work replace them. They are for your safety, do not operate the equipment with them removed. - Replace any decals that may be missing or that are not readable. Location of the decals is indicated

in this manual. - Do not operate this machine while under the influence of drugs or alcohol.

Review the safety instructions with all users annually. - This equipment should not be operated by children, or with those unfamiliar with the operation of the

machine. Do not allow persons to operate this machine until they have read this manual and/or were

instructed by a qualified person. - Do not paint over, remove or deface any safety signs or warning decals on your equipment. Observe

all safety signs and practice the instructions on them.

Before Operation

- Carefully study and understand the manual or be trained by an experienced operator.

Do not wear loose clothing that may get caught in moving parts. - Visually inspect the machine to make sure no parts are loose or missing.

- Be sure that no tools are left on the machine.

- Make sure no hay is lying on the engine and that the cooling fins are not clogged with dust and

hay (this could cause a fire). - Do not hurry the learning process. Be familiar with one part before trying the next part.

- Practice by running the machine through its paces, first in manual mode with no bales in the

machine until you are comfortable and familiar with the operation. - After you become familiar with the operation, switch the machine to Auto mode. Use a stick and

push the table switch down to start the cycle. - Do not reach in and push the switch paddle down by hand.

TABLE OF CONTENTS:

Frontier Inline Bale Wrapper LW1166 Operator’s Manual(5TB109100337) – PDF DOWNLOAD

Table of Contents

Frontier LW1166 Operator’s Manual

Warranty

Serial Number Decal.

Serial Number..

Section 1 – Safety

Safety Signal Words / Safety Messages

Safety Guidelines

Use a Safety Chain Lighting & Marking. Before Operation. Safety Sign Locations

Serial Plate Location

Safety Decals

Model and Brand Decals.

Section 2 – Operating the Model LW1166

Big Bale Silage

Bales..

Moisture.

Wrapping Site

Installation of Plastic

Bale Size…

Recommended Operating Procedure

Tire Pressure.

Trouble Shooting Plastic Installation Control Panel Functions

To Wrap Bales with Model LW1166. Steering..

Optional – Remote Control.

Slider Switch

Brake..

Ending a Bale Row

Folding Pushoff Arm Operation

Observe Maximum Transport Speed.

Build-up on Stretchers..

Wrapping Straw.

After Wrapping..

Feeding Out.

Disposal of Plastic.

Electric Hydraulic Sequence of Operation..

Section 3: Maintenance

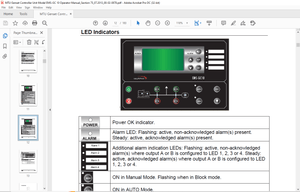

Diagnostics

Grease Points.

Greasing Specifications.

Oil Points.

Section 4 – Parts Breakdowns & Lists

Hoop Assembly..

Plastic Wrap Carrier

Hoop Brace

Hoop Brace – Current

Safety Guard..

Safety Guard – First Change

Safety Guard – Current Cylinder Support. Hoop Drive.

Axle-Spindle-Hub.

Front Steering

Rear Axle & Roller Bed

Rear Axle & Roller Bed – Current.

Ram…

Ram – Current.

Front Pushoff..

Front Pushoff with Ram Latch – Current

Front Corners

Rear Corners..

Gas Tank – Fenders – Original.

Gas Tank – Fenders.

Battery…

Hydraulic Oil Tank

Hydraulic Oil Tank – Current 13 HP Engine (5TB13HP). 20 HP Engine (5TB20HP). Throttle Linkages.. Hystar Hydraulic Valve Control Panel.

Limit Switch.

Table Trigger

Film Sensor.

Film Sensor Installation.

Film Sensor Wire Adjustment

Film Snap

Running Lights.

Hydraulic Schematic

Hydraulic Layout – Front Circuits. Hydraulic Layout – Rear Circuit. Hydraulic Manifold Connections Electric Schematic…

Wiring Diagram – Initial

Wiring Diagram – First Change Wiring Diagram – Current.

Section 5 – Options

Option – Single Power Drive – 5TBHPD5000 & 5TBHPD50001 Option – Single Power Drive – 5TB50002

Option – Single Power Drive – Current.

Option – Dual Power Drive – 5TBHPDD5000 & 5TBHPDD50001

Option – Dual Power Drive – 5TBHPDD50002..

Dual Power Drive – Current..

Option

– Light Kits.. Option – Remote Control..

Remote Control Installation.. Remote Control Functions… Option – Remote Start Add-on* Remote Start-Add Installation.. Option – Guide Roller..

Option – Twin Wrap Kit.

Folding Pushoff Arm – 5TBMP05000 Guidance System (Laser) – 5TBGS. Guidance System (Laser) – Installation Guidance System (Laser) – Adjustment.

Main Menu Screen ..

Laser L Screen …

Guidance System (Laser) – Control Screen Functions.. Main Menu: Count Bales….

Guidance System (Laser) – Wiring

Section 6 – Dealer Installation

Torque Values – Imperial

Torque Values – Metric

IMAGES PREVIEW OF THE MANUAL: