$30

Gehl 4010 Series SL4510 Gasoline SL4610 Skid Loader Shop Manual 903931 – PDF DOWNLOAD

Gehl 4010 Series SL4510 Gasoline SL4610 Skid Loader Shop Manual 903931 – PDF DOWNLOAD

FILE DETAILS:

Gehl 4010 Series SL4510 Gasoline SL4610 Skid Loader Shop Manual 903931 – PDF DOWNLOAD

Language : English

Pages : 104

Downloadable : Yes

File Type : PDF

Size: 3.3 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gehl 4010 Series SL4510 Gasoline SL4610 Skid Loader Shop Manual 903931 – PDF DOWNLOAD

INTRODUCTION:

This manual has been written and illustrated to help you, the serviceman, in troubleshooting and servicing the SL4010 Series (SL4510, SL4610, SL4515* & SL4615*) Skid Loaders. The material in this manual is the latest in factory service information. It has been compiled by our factory Service Department and Engineering personnel to give you the best service information available. Follow all procedures carefully, to avoid unnecessary delays and/ or damage to the equipment.

- Where procedures are given in a step-by-step manner, follow them in the order given. Although we have outlined assembly and disassembly procedures for you to follow, there are probably alternate methods that could also work. The Hydraulic System and the Engine are the two most important parts of an SL4010 Series Skid Loader.

- When any service is performed on the Hydraulics System, always clean the hydraulic component and fittings, before disconnecting any hydraulic lines. Contamination is the greatest cause of failure in Hydraulics Systems. For any Engine repairs, consult your Ford or Perkins Engine Service Manual.

- The SL45 l O or SL45 l 5* model Loader uses the Ford 98 CID Gasoline Engine. The SL4610 or SL4615* model Loader uses the Perkins 4.108 Diesel Engine. The Model and Serial Numbers Plate, for the SL4010 Series Skid Loaders, is located inside the Right Chassis Riser, between the Lift Arm and Lift Cylinder Pivots.

- “Right” and “Left” are determined from a position sitting on the Seat and facing forward. From this position, the Traction (Propulsion) Control T-Bar is on the “left” and the Lift/Tilt Control T-Bar is on the “right”. The Ford 98 CID Engine has an identification decal affixed to the right side of the rocker cover.

- The decal contains the engine serial number, which differentiates that engine from any other. · Besides the serial number, there is the displacement (that determines the engine specifications), the model number and, the SO (Special Options) number (which determines the parts or components required on this unit). When requesting information or ordering replacement parts for this engine, BE SURE to provide all the numbers.

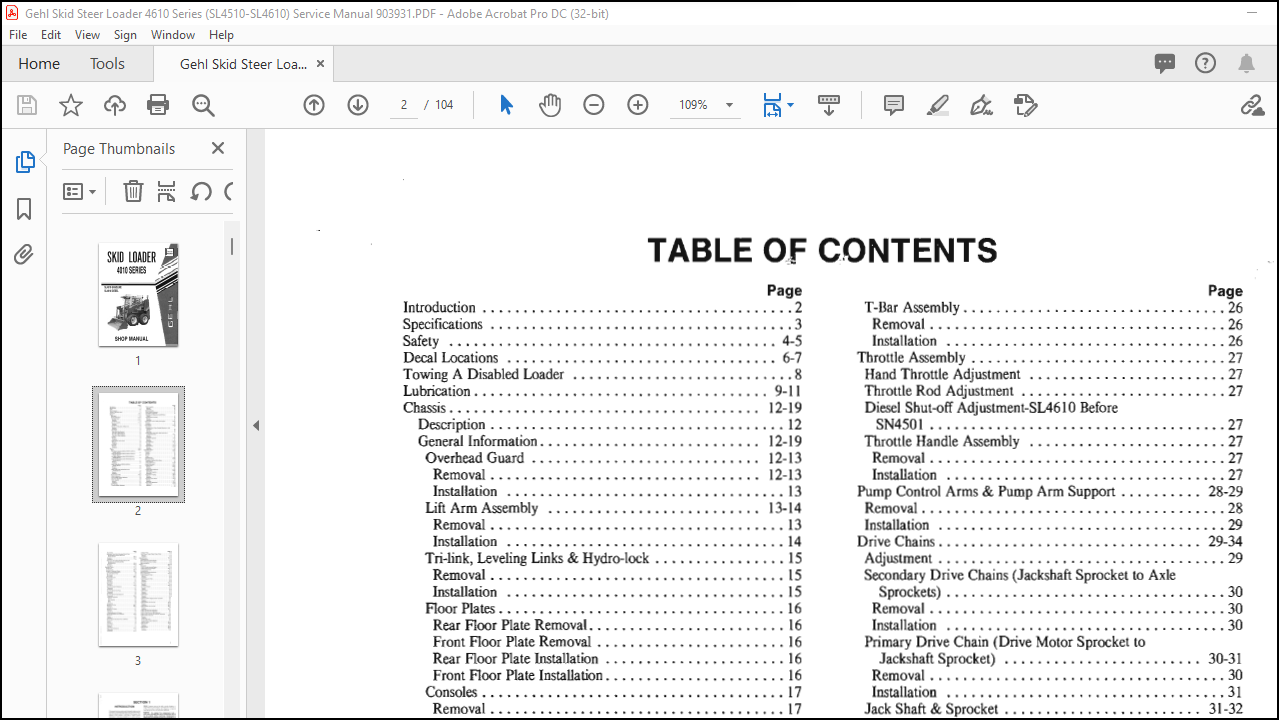

TABLE OF CONTENTS:

Gehl 4010 Series SL4510 Gasoline SL4610 Skid Loader Shop Manual 903931 – PDF DOWNLOAD

Introduction 2

Specifications 3

Safety 4-5

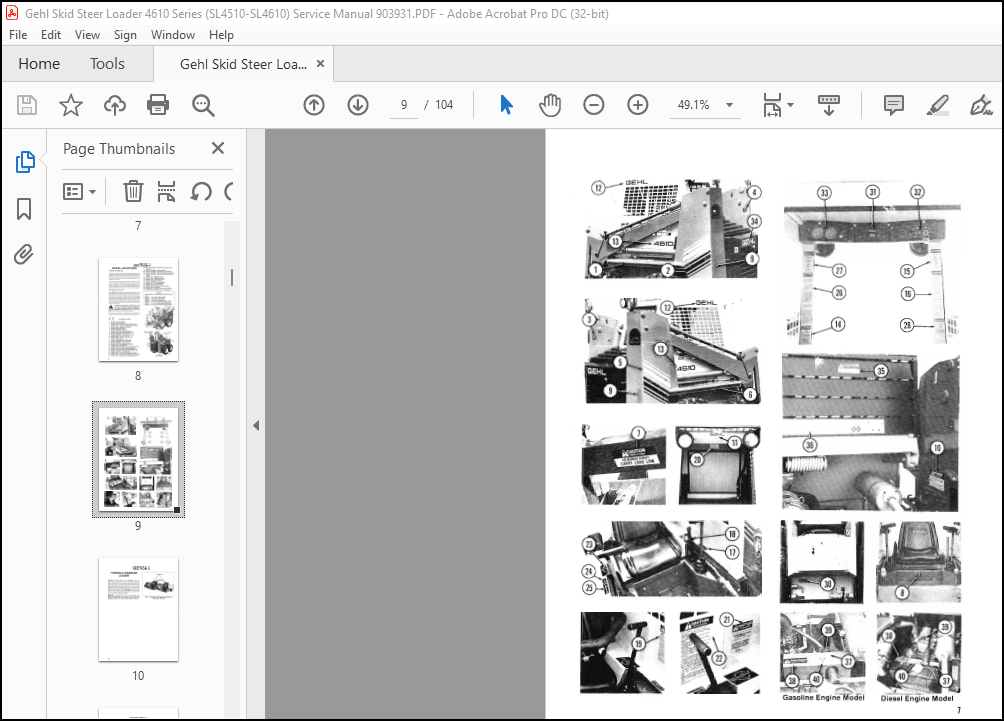

Decal Locations 6-7

Towing A Disabled Loader 8

Lubrication 9-11

Chassis 12-19

Description 12

General Information 12-19

Overhead Guard 12-13

Removal 12-13

Installation 13

Lift Arm Assembly 13-14

Removal 13

Installation 14

Tri-link, Leveling Links & Hydro-lock 15

Removal • 15

Installation I 5

Floor Plates 16

Rear Floor Plate Removal 16

Front Floor Plate Removal 16

Rear Floor Plate Installation 16

Front Floor Plate Installation 16

Consoles 17

Removal 17

Installation 17

Chain Case & Access Covers 18

Removal 18

Installation 18

Fuel Tank 19

Removal 19

Installation 19

Drive 20-34

Brakes 20-23

Disc Brakes Adjustment-Before SN3251-SL4510 &

SN3601-SL4610 20

Brake Pad Replacement-Before SN3251-SL4510 &

SN360I-SL4610 20

Disc Brake Adjustment-After SN3250-SL45!0 &

SN3600-SL4610 20

Brake Pad Replacement-After SN3250-SL4510 &

SN3600-SL46!0 21

Removal 21

Installation 21

Brake Cables-Before SN3251-SL45!0 &

SN3601-SL4610 22

Removal 22

Installation 22

Brake Cables-After SN3250-SL45!0 &

SN3600-SL4610 23

Removal 23

Installation 23

Traction Drive T-Bar 24-25

Detent Adjustment 24

Drive Linkage Neutral Adjustment 24

Stop Cam Adjustment 24

T-Bar Assembly 25

Removal 25

Installation 25

Lift/Tilt T-Bar 26

Control Linkage Adjustment 26

Page

T-Bar Assembly 26

Removal 26

Installation 26

Throttle Assembly 27

Hand Throttle Adjustment 27

Throttle Rod Adjustment 27

Diesel Shut-off Adjustment-SL46 I O Before

SN4501 27

Throttle Handle Assembly 27

Removal 27

Installation 27

Pump Control Arms & Pump Arm Support 28-29

Removal 28

Installation 29

Drive Chains 29-34

Adjustment 29

Secondary Drive Chains (Jackshaft Sprocket to Axle

Sprockets) 30

Removal 30

Installation 30

Primary Drive Chain (Drive Motor Sprocket to

Jackshaft Sprocket) 30-31

Removal 30

Installation 31

Jack Shaft & Sprocket 31-32

Removal 31

Installation 31-32

Axle & Sprocket 32-33

Removal 32

Installation 32-33

Wheel Bearings 33-34

Removal 33-34

Installation 34

Hydrostatic System 35-56

Introduction 35-38

Neutral 36

Forward 37

Reverse 38

Turns 38

Troubleshooting 39-42

Hydrostatic Testing 43-44

Propulsion Pump and Drive Motor 43

Charge Pressure 43

Charge Inlet Pressure • 43-44

General Information 44-56

Tandem Pump 44-45

Removal 44-45

Installation 45

Tandem Pump Breakdown 45-50

Disassembly 45-48

Parts Wear Inspection 49

Reassembly 49-50

Pump Drive Coupling 50-52

Removal 50-51

Installation 51-52

Hydrostatic Drive Motor 52-53

Removal 52

Installation 52-53

Drive Motors Breakdown 53-54

Disassembly 53-54

Inspection 54

Page

Reassembly 54

Hydrostatic Drive Motor Mounting Plate & Drive

Sprocket-Before SN3251-SL4510 &

SN3601-SL4610 54-55

Removal 54-55

Installation 55

Hydrostatic Drive Motor Mounting Plate & Drive

Sprocket-After SN3250-SL4510 &

SN3600-SL4610 55-56

Removal 55-56

Installation 56

Hydraulics System 57-75

Introduction 57

Toubleshooting 58-59

Hydraulic Component Testing 60-61

Control Valve Relief Pressure 60

Lift & Tilt System Pump 60

Tilt Cylinder 60

Lift Cylinder 60-61

General Information 61-75

Tilt Cylinders 61

Removal 61

Installation 6 I

Lift Cylinders 61-62

Removal 61

Installation 61-62

Lift & Tilt Cylinders Breakdown 63

Disassembly 63

Reassembly 63

Lift & Tilt System Gear Pump 64

Disassembly 64

Reassembly 64

Lift & Tilt System Pump Breakdown 65

Disassembly 65-66

Pump Parts Inspection 66

General 66

Gear Assembly 66

Body 66

Cover 66

Reassembly 66

Hydraulic Oil Filter 66-67

Removal 66-67

Installation 67

Hydraulic Oil Strainer 67

Removal 67

Installation 67

Cleaning Hydraulic Oil Strainer 67

Self-Leveling Relief Valve (1200 PSI) 67-68

Removal 67

Service 68

Installation 68

Self-Leveling By-Pass Relief Valve (1000 PSI) 70

Removal 70

Service 70

Installation 70

Control Valve 71

Removal :· 71

Installation 71

Control Valve Breakdown 73-74

Disassembly 73

Reassembly 73-74

Page

Auxiliary Valve 74

Back Pressure Poppet (Super Charge Valve) 75

Removal 75

Installation 7 5

Electrical System 76-79

Troubleshooting 76

SL4610 Electrical System Diagram 77

SL45 l O Electrical System Diagram 78

Light Mounting Kit 79

Engines 80-98

Introduction 80-81

SL4510 Gasoline-powered Engine 80

SL46 l O Diesel-powered Engine 80-81

Ordering Engine Parts 8 I

Troubleshooting 81-82

International Symbols Explanation 83

General Information 84-98

SL4610 Engine Oil Filter 84

Removal 84

Installation 84

SL45 l O Engine Oil Filter 84

Removal 84

Installation 84

Air Cleaner 84-85

Removal 84

Installation 84-85

Air Cleaner Element 85

Removal 85

Cleaning 85

SL4610 Starter 85

Removal 85

Installation 85

SL45 l O Starter 86

Removal 86

Installation 86

SL45 l O & SL46 l O Engine Exhaust Assemblies 87

Removal 87

Installation 87

SL4610 Radiator & Oil Cooler 87-89

Removal 87-88

Installation 88-89

SL4510 Radiator & Oil Cooler 89-91

Removal 89

Installation 89-91

SL4610 Alternator Belt Adjustment 91

SL45 l O Alternator Belt Adjustment 91

SL4510 (Only) Governor Belt Adjustment 91

SL4510 (Only) Governor & Carburetor Adjustment 92

SL4510 (Only) Carburetor 92-94

Removal 92

Installation 93

Dwell Angle Check 93

Dynamic Dwell Angle Adjustment 93

Ignition Timing 93-94

SL46 I O Engine 95-96

Removal 95

Installation 95-96

SL4510 Engine 96-98

Removal 96-98

Installation 98/