$33

Gehl 503Z Compact Excavator Service Manual 918159 – PDF DOWNLOAD

Gehl 503Z Compact Excavator Service Manual 918159 – PDF DOWNLOAD

FILE DETAILS:

Gehl 503Z Compact Excavator Service Manual 918159 – PDF DOWNLOAD

Language : English

Pages : 206

Downloadable : Yes

File Type : PDF

Size: 23.6 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gehl 503Z Compact Excavator Service Manual 918159 – PDF DOWNLOAD

Serial Number AC02471 and up

Operation

General information

Your decision to purchase the Gehl compact excavator was a good one. We are sure that

your decision was carefully considered and that you are looking forward to many years of

reliable performance from the machine.

Gehl Company has invested much time and effort in developing its lines of equipment. The

equipment you have purchased is built with a great deal of pride, and designed to provide

long life, efficient operation, durability and dependability.

Modern machinery has become more sophisticated and, with that in mind, Gehl Company

asks that you read and COMPLETELY understand the contents of this manual and

become familiar with the new machine, BEFORE attempting to service it.

This manual was developed specifically for the machine you have purchased. The information

within is for your assistance in preparing, adjusting, maintaining and servicing the

machine. More important, this manual provides a service plan for safe and proper servicing

of the machine. Refer to the Table of Contents for an outline (by chapters) of this manual.

Use the Index, located at the back of this manual, for specific chapter and topic/page

number references.

If the machine is resold, Gehl Company recommends that this manual be given to the new

owner.

If the machine was purchased “used,” or if the owner’s address has changed, please provide

your Gehl dealer or Gehl Company with the owner’s name and current address, along

with the machine model and serial number. This will allow the registered owner information

to be updated, so that the owner can be notified directly in case of an important product

issue, such as a safety update program.

“Right” and “left” are determined from the position of sitting in the operator’s seat, facing

forward.

Gehl Company reserves the right to make changes or improvements in the design or construction

of any part without incurring the obligation to install such changes on any unit

previously delivered.

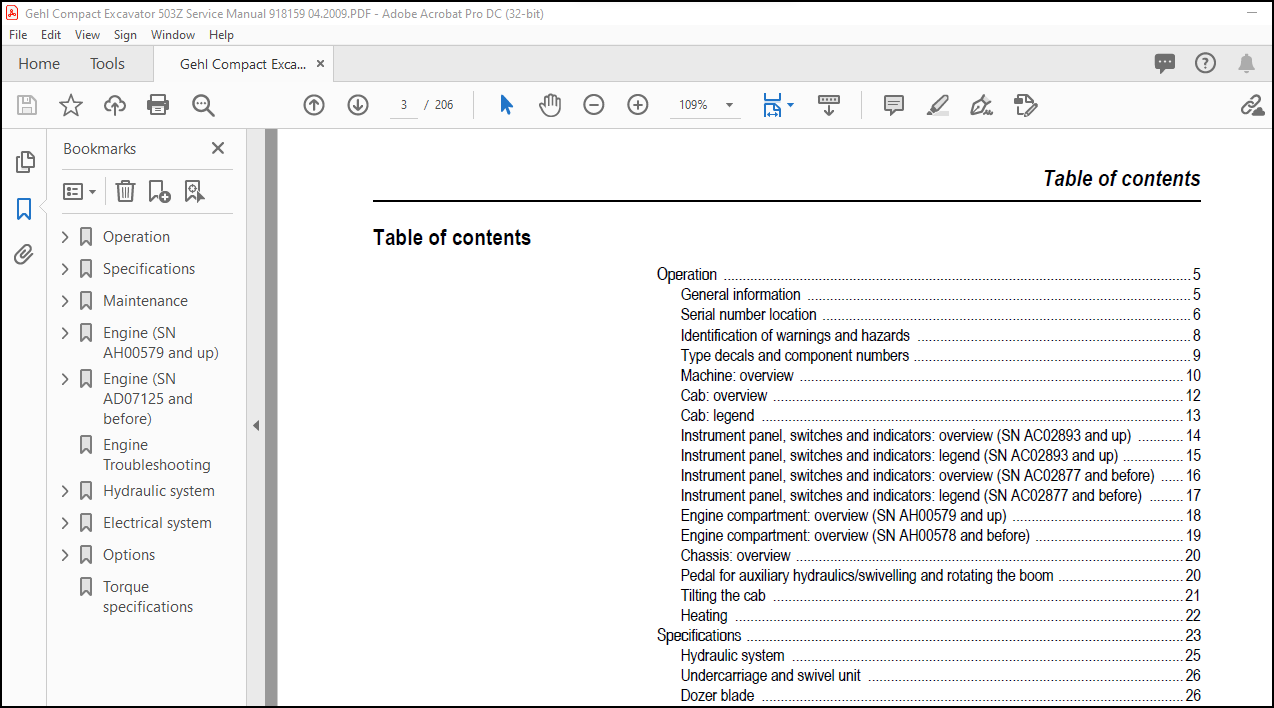

TABLE OF CONTENTS:

Gehl 503Z Compact Excavator Service Manual 918159 – PDF DOWNLOAD

Operation……………………………………………………………………………………….. 7

General information…………………………………………………………………………… 7

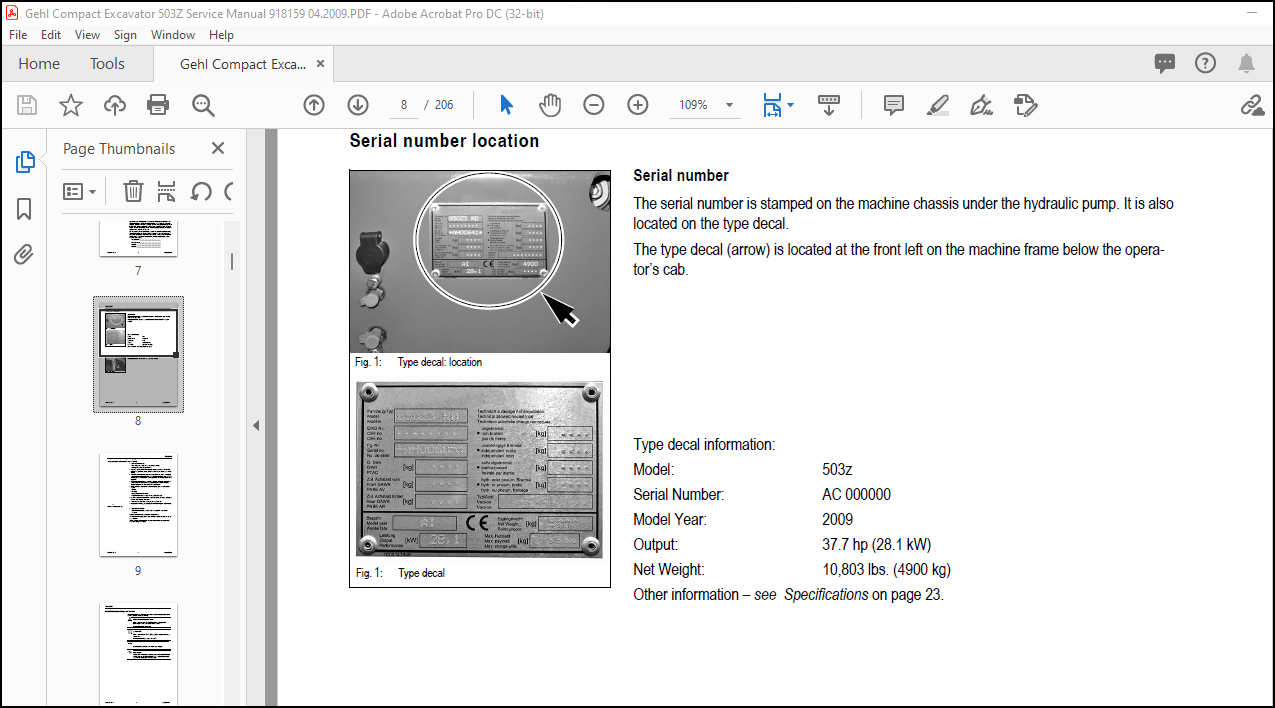

Serial number location………………………………………………………………………… 8

Identification of warnings and hazards………………………………………………………….. 10

Type decals and component numbers………………………………………………………………. 11

Machine: overview…………………………………………………………………………….. 12

Cab: overview………………………………………………………………………………… 14

Cab: legend………………………………………………………………………………….. 15

Instrument panel, switches and indicators: overview (SN AC02893 and up)…………………………….. 16

Instrument panel, switches and indicators: legend (SN AC02893 and up)………………………………. 17

Instrument panel, switches and indicators: overview (SN AC02877 and before)…………………………. 18

Instrument panel, switches and indicators: legend (SN AC02877 and before)…………………………… 19

Engine compartment: overview (SN AH00579 and up)…………………………………………………. 20

Engine compartment: overview (SN AH00578 and before)……………………………………………… 21

Chassis: overview…………………………………………………………………………….. 22

Pedal for auxiliary hydraulics/swivelling and rotating the boom……………………………………. 22

Tilting the cab………………………………………………………………………………. 23

Heating……………………………………………………………………………………… 24

Preheated fresh air……………………………………………………………………….. 24

Specifications…………………………………………………………………………………… 25

Frame……………………………………………………………………………………….. 25

Engine………………………………………………………………………………………. 25

Fuel injection pump…………………………………………………………………………… 26

Engine capacities…………………………………………………………………………….. 26

Engine tightening torques……………………………………………………………………… 26

Hydraulic system……………………………………………………………………………… 27

Auxiliary hydraulics oil flow………………………………………………………………. 28

Undercarriage and swivel unit………………………………………………………………….. 28

Dozer blade………………………………………………………………………………….. 28

Electrical system…………………………………………………………………………….. 29

Fuse box in instrument panel……………………………………………………………….. 29

Main fuse box with relays under the cab……………………………………………………… 29

Relays…………………………………………………………………………………… 30

Sound levels…………………………………………………………………………………. 30

Coolant compound table………………………………………………………………………… 30

Model-specific tightening torques………………………………………………………………. 31

General tightening torques…………………………………………………………………….. 31

Tightening torques for hydraulic screw connections (dry assembly)………………………………. 31

Tightening torques for high- resistance screw connections……………………………………… 33

503Z dimensions………………………………………………………………………………. 34

Lift capacity table with short dipper arm……………………………………………………….. 35

Lift capacity table with long dipper arm………………………………………………………… 36

Lift capacity table with short dipper arm and counterweight……………………………………….. 37

Lift capacity table with long dipper arm and counterweight………………………………………… 38

Bucket geometry………………………………………………………………………………. 39

Maintenance……………………………………………………………………………………… 41

Fluids and lubricants…………………………………………………………………………. 41

Additional oil change and filter replacement (hydraulics)……………………………………… 42

Maintenance decal…………………………………………………………………………….. 43

Explanation of symbols on the maintenance decal………………………………………………. 43

Maintenance schedule (overview)………………………………………………………………… 45

Introduction…………………………………………………………………………………. 49

Fuel system………………………………………………………………………………….. 50

Specific safety instructions……………………………………………………………….. 50

Refuelling……………………………………………………………………………….. 50

Stationary fuel pumps……………………………………………………………………… 51

Diesel fuel specification………………………………………………………………….. 51

Bleeding the fuel system…………………………………………………………………… 51

Emptying the fuel tank…………………………………………………………………….. 52

Fuel pre-filter with water separator………………………………………………………… 52

Replacing the fuel filter………………………………………………………………….. 53

Engine lubrication system……………………………………………………………………… 54

Checking the oil level…………………………………………………………………….. 54

Adding engine oil…………………………………………………………………………. 55

Changing engine oil……………………………………………………………………….. 55

Replacing the engine oil filter cartridge……………………………………………………. 56

Cooling system……………………………………………………………………………….. 57

Specific safety instructions……………………………………………………………….. 57

Checking/adding coolant……………………………………………………………………. 58

Draining coolant………………………………………………………………………….. 59

Air filter…………………………………………………………………………………… 60

Replacing the filter………………………………………………………………………. 61

Weekly functional check of the dust valve……………………………………………………. 62

V-belt………………………………………………………………………………………. 62

Checking V-belt tension……………………………………………………………………. 63

Tightening the V-belt……………………………………………………………………… 63

Checking the air conditioning V-belt………………………………………………………… 64

Tightening the air conditioning V-belt………………………………………………………. 65

Pressure check……………………………………………………………………………….. 66

General………………………………………………………………………………….. 66

Checking pilot control pressure…………………………………………………………….. 66

Pressure check of variable displacement pump P1………………………………………………. 67

Pressure check of variable displacement pump P2………………………………………………. 68

Pressure check of gear pump P3……………………………………………………………… 69

Secondary pressure limiting valve of the gear motor…………………………………………… 70

Measuring ports: overview………………………………………………………………….. 70

Primary pressure limiting valves……………………………………………………………. 71

Test report………………………………………………………………………………….. 73

Hydraulic system……………………………………………………………………………… 77

Specific safety instructions……………………………………………………………….. 77

Checking the hydraulic oil level……………………………………………………………. 78

Adding hydraulic oil………………………………………………………………………. 79

Changing hydraulic oil…………………………………………………………………….. 79

Monitoring the hydraulic oil return filter…………………………………………………… 80

Checking hydraulic pressure lines…………………………………………………………… 81

Travel drive…………………………………………………………………………………. 82

Checking the oil level and adding oil……………………………………………………….. 82

Draining oil……………………………………………………………………………… 82

Tracks………………………………………………………………………………………. 83

Checking track tension…………………………………………………………………….. 83

Setting the tracks………………………………………………………………………… 84

Lubrication work……………………………………………………………………………… 85

Dozer blade lubrication points……………………………………………………………… 85

Swivel console lubrication points…………………………………………………………… 86

Boom lubrication points……………………………………………………………………. 86

Dipper arm lubrication points………………………………………………………………. 87

Lubrication strip…………………………………………………………………………. 87

Maintenance of attachments…………………………………………………………………. 87

Electrical system…………………………………………………………………………….. 88

Safety instructions……………………………………………………………………….. 88

Service and maintenance work at regular intervals…………………………………………….. 89

Instructions concerning specific components………………………………………………….. 89

Alternator……………………………………………………………………………….. 89

Battery………………………………………………………………………………….. 90

Using a Booster Battery (Jump-Starting)……………………………………………………… 91

Cab…………………………………………………………………………………………. 92

Replacing the cab filter…………………………………………………………………… 92

General maintenance work………………………………………………………………………. 93

General instructions for all areas of the machine…………………………………………….. 93

Inside the cab……………………………………………………………………………. 93

The seat belt…………………………………………………………………………….. 94

Exterior of the machine……………………………………………………………………. 94

Engine compartment………………………………………………………………………… 94

Screw connections and attachments…………………………………………………………… 94

Pivots and hinges…………………………………………………………………………. 94

Long-term storage…………………………………………………………………………….. 95

Before storage……………………………………………………………………………. 95

During storage……………………………………………………………………………. 95

After storage…………………………………………………………………………….. 95

Engine (SN AH00579 and up)………………………………………………………………………… 97

Engine marked 4TNV88-BPNS (SN AH00579 and up): overview…………………………………………… 97

Fuel system………………………………………………………………………………….. 99

Preparing for cylinder head removal……………………………………………………………..100

Checking and adjusting valve tip clearance……………………………………………………….100

Removing/Tightening order for cylinder head bolts…………………………………………………101

Checking the injection nozzles………………………………………………………………….102

Pressure check…………………………………………………………………………….102

Checking the nozzle jet………………………………………………………………………..102

Injection timing………………………………………………………………………………103

Checking injection timing…………………………………………………………………..103

Adjusting injection timing………………………………………………………………….103

Replacement of fuel injection pump…………………………………………………………..104

Adjusting engine speeds………………………………………………………………………..106

Compression…………………………………………………………………………………..107

Checking the coolant thermostat…………………………………………………………………107

Checking the thermal switch…………………………………………………………………….108

Oil pressure switch……………………………………………………………………………108

Checking the coolant circuit……………………………………………………………………108

Engine (SN AD07125 and before)……………………………………………………………………..109

Engine marked 4TNV88-PNS (SN AD07125 and before): overview…………………………………………109

Fuel system…………………………………………………………………………………..111

Checking and adjusting valve tip clearance……………………………………………………….112

Removing/Tightening order for cylinder head bolts…………………………………………………112

Checking the injection nozzles………………………………………………………………….113

Pressure check…………………………………………………………………………….113

Checking the nozzle jet………………………………………………………………………..114

Injection timing………………………………………………………………………………114

Checking injection timing…………………………………………………………………..114

Adjusting injection timing………………………………………………………………….115

Replacement of fuel injection pump…………………………………………………………..115

Adjusting engine speeds………………………………………………………………………..118

Compression…………………………………………………………………………………..118

Checking the coolant thermostat…………………………………………………………………118

Checking the thermal switch…………………………………………………………………….119

Oil pressure switch……………………………………………………………………………119

Checking the coolant circuit……………………………………………………………………120

Engine Troubleshooting…………………………………………………………………………….121

Hydraulic system………………………………………………………………………………….123

Hydraulic pump: PVD-2B-41BP-16G5-4713F (SN AH00579 and up) PVD-2B-44BP-16G5-4713F (AD07125 and before)….123

Pump unit: exploded view……………………………………………………………………125

Pilot oil supply unit………………………………………………………………………126

Main valve block………………………………………………………………………………127

Ports…………………………………………………………………………………….127

Legend……………………………………………………………………………………127

Main valve block diagram……………………………………………………………………128

Pressure limiting valves……………………………………………………………………129

Auxiliary hydraulics pressure limiting valves…………………………………………………130

Pump assignment……………………………………………………………………………131

Drive counterbalancing system…………………………………………………………………..132

Pump assignment for drive counterbalancing……………………………………………………132

Drive counterbalancing system diagram………………………………………………………..133

Regeneration – dipper arm section……………………………………………………………….134

Bucket pre-tension…………………………………………………………………………….134

Flow rate adjustment for auxiliary hydraulics…………………………………………………….135

Pilot valves………………………………………………………………………………….136

Joystick………………………………………………………………………………….136

Pilot valve for auxiliary hydraulics…………………………………………………………140

Pilot valve for dozer blade…………………………………………………………………141

Valves……………………………………………………………………………………….142

7/2 directional valve (changeover valve)……………………………………………………..142

Shuttle valve block………………………………………………………………………..143

Changeover valve for SAE/ISO controls (option)………………………………………………..144

Travel drive………………………………………………………………………………….145

Function………………………………………………………………………………….146

2nd speed range function……………………………………………………………………146

Swivel unit…………………………………………………………………………………..148

Parking brake/multi-disc brake function………………………………………………………149

Swivel joint………………………………………………………………………………….152

Swivel joint servicing:…………………………………………………………………….153

Breather filter……………………………………………………………………………….153

Troubleshooting the hydraulic system…………………………………………………………….154

Hydraulics diagram (legend)…………………………………………………………………….155

Options diagram………………………………………………………………………………. 0

Main valve block diagram 503Z………………………………………………………………….. 0

Hydraulics diagram 503Z……………………………………………………………………….. 0

Electrical system…………………………………………………………………………………161

Ohm’s Law (defines current, voltage and resistance relationship)……………………………………161

Measuring equipment and methods…………………………………………………………………161

Cable color coding…………………………………………………………………………….162

Relays……………………………………………………………………………………….163

Use, mode of function………………………………………………………………………163

Electrical units………………………………………………………………………………163

Fuse box in instrument panel……………………………………………………………………163

Main fuse box with relays………………………………………………………………………164

Relays……………………………………………………………………………………….164

Socket……………………………………………………………………………………….165

Joystick switch buttons………………………………………………………………………..165

Joystick (left)……………………………………………………………………………165

Joystick (right)…………………………………………………………………………..165

Instrument panel: overview……………………………………………………………………..166

Switches overview (SN AC02893 and up)……………………………………………………………167

Switches overview (SN AC02877 and below)…………………………………………………………167

Alternator……………………………………………………………………………………168

Starter………………………………………………………………………………………168

Wiring harness overview………………………………………………………………………..168

Wiring diagram (SN AC02890 and up)……………………………………………………………… 0

Wiring diagram legend (SN AC02889 and before)……………………………………………………. 0

Wiring diagram (SN AC02889 and before)………………………………………………………….. 0

Engine – chassis wiring harness legend………………………………………………………….. 0

Engine – chassis wiring harness………………………………………………………………… 0

Wiring harness switches (SN AC02890 and up)……………………………………………………… 0

Wiring diagram legend (SN AC02890 and up)……………………………………………………….. 0

Wiring harness switches legend (SN AC02889 and before)……………………………………………. 0

Wiring harness switches (SN AC02889 and before)………………………………………………….. 0

Cab roof wiring harness……………………………………………………………………….. 0

Armrest wiring harness………………………………………………………………………… 0

Boom working light wiring harness………………………………………………………………. 0

Options………………………………………………………………………………………….183

Air conditioning………………………………………………………………………………183

Specific safety instructions………………………………………………………………..183

Specifications…………………………………………………………………………….183

Installation: overview……………………………………………………………………..184

Components………………………………………………………………………………..185

Adding refrigerating agent to the air conditioning system………………………………………187

Maintenance……………………………………………………………………………….188

Troubleshooting……………………………………………………………………………189

Air-suspension seat……………………………………………………………………………190

Connections……………………………………………………………………………….190

Counterweight…………………………………………………………………………………190

Specifications…………………………………………………………………………….190

Long dipper arm……………………………………………………………………………….191

Specifications…………………………………………………………………………….191

Auxiliary hydraulics connections………………………………………………………………..191

Quick-couplers…………………………………………………………………………….192

Attachments……………………………………………………………………………….192

Proportional controls………………………………………………………………………….193

Function………………………………………………………………………………….193

Two-speed variable auxiliary hydraulic mode selection………………………………………….193

Auxiliary hydraulics proportional joystick control…………………………………………….194

Auxiliary hydraulic hammer operation…………………………………………………………194

Ports…………………………………………………………………………………….195

Wiring harness…………………………………………………………………………….195

Control unit………………………………………………………………………………195

Control valve plug assignment……………………………………………………………….196

Safety features……………………………………………………………………………197

Measures to be taken in case of malfunctions………………………………………………….197

Diagnostic display…………………………………………………………………………198

Auto-idle feature (SN AH00579 and up)……………………………………………………………199

Function………………………………………………………………………………….199

Installation overview………………………………………………………………………200

Torque specifications……………………………………………………………………………..203