$34

Gehl Kirloskar Engine 4R1040 Service Manual 53112662B – PDF DOWNLOAD

Gehl Kirloskar Engine 4R1040 Service Manual 53112662B – PDF DOWNLOAD

FILE DETAILS:

Gehl Kirloskar Engine 4R1040 Service Manual 53112662B – PDF DOWNLOAD

Language : English

Pages : 128

Downloadable : Yes

File Type : PDF

Size: 6.35 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gehl Kirloskar Engine 4R1040 Service Manual 53112662B – PDF DOWNLOAD

INTRODUCTION:

“The perfect symphony of design and efficiency.

Manitou engines: Prime movers to the Indian nation.

- 1946 saw Manitou Oil Engines Limited (KOEL) taking shape. A powerhouse today, it easily stands out as India’s leading manufacturer of engines. Giving its customers a wide choice ranging from 3 hp to 300 hp, and 2400 hp to 8000 hp. Manufactured in both air-cooled and liquid-cooled versions, every detail in these engines is carefully perfected. A variety so large also makes these engines the backbone in many an industry.

- Including the role of prime movers for industrial, agricultural, construction, power generation and marine applications. On the other hand, engines ranging from 2400 hp to 8000 hp are also used for marine propulsion and auxiliary power on naval and coast guard ships. Such a wide acceptance has resulted in the manufacture of 187,000 engines in the year ending March 2001.

- Being a leader is also about being driven by technology. And that means constant technology up-gradation, using in-house research, investment in state-of-the-art manufacturing facilities with thoroughly perfected processes. All aimed at one goal: Deliver well thought-out quality products and services to the customers at competitive prices.

- Of special mention are critical components like crankcases, crankshafts, camshafts, gear casing, cylinder heads and connecting rods that are manufactured in-house. And for KOEL’s exclusive use, even special purpose machines to achieve critical degrees of precision that international specifications demand.

- This practice towards achieving efficiency and performance is a mantra at all KOEL plants, starting from the main engine manufacturing plant at Pune to all the other units at Nashik, Ahmednagar, Rajkot, Indore and Kolhapur. This rigorous internal quality pace easily makes sure that KOEL’s processes meet all the standards that global specifications demand.

- In 1992, ABS QE (USA) awarded KOEL the prestigious ISO 9001 certification for its Quality Management Systems. Similarly, the belief that industry and environment can co-exist, led to in-house development of the environmental-friendly engines produced using environmental-friendly manufacturing facilities.

- Recognition for this came as an ISO 14001 certification for Environment Management Systems. Product support: Assurance through adequate product support is derived out of clear thought processes. Coupled with the most extensive service network in the country. Around 90% of Manitou engines are with in 100 km of a Manitou Service Dealer. 176 Service Dealerships are operating efficiently to provide relentless service to the customers.

- The dealership locations and infrastructure is continuously assessed based on the Manitou engine population build up in each territory and the customer’s emerging service needs. Out of these, 41 Service Dealership locations provide 24-hour service as of August 2001, with the number growing steadily.

- Add on, Manitou Service Managers, Service Engineers and Technicians have been stationed at 21 Manitou Area Offices. A well spread out service network manned by about 1,500 Manitou trained engineers and technicians ensure prompt service and easy availability of genuine spare parts, making sure that there’s always the highest up-time for Manitou engines.

TABLE OF CONTENTS:

Gehl Kirloskar Engine 4R1040 Service Manual 53112662B – PDF DOWNLOAD

10 1 INTRODUCTION 4

10 2 GENERAL INSTRUCTIONS 6

10 3 ENGINE DESCRIPTION 7

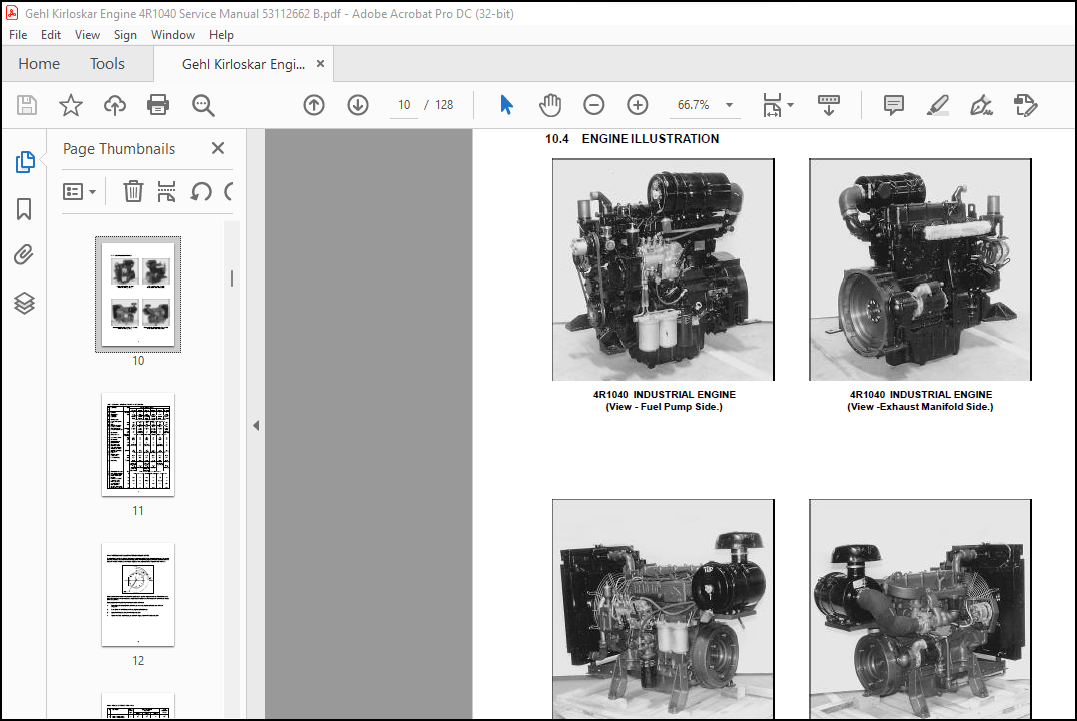

10 4 ENGINE ILLUSTRATIONS 8

10 5 GENERAL SPECIFICATIONS -R 1040 ENGINE 9

10 5 1 TIGHTENING HIGH TENSILE FASTNERS BY ANGULAR METHOD 10

10 5 2 TIGHTENING TORQUE TABLE – R1040 11

10 5 3 R1040 ENGINE RUNNING DIMENSIONS & CLEARANCES OF IMPORTANT COMPONENTS 12

10 5 4 LIST OF SPECIAL TOOLS 16

10 5 5 STANDARD WORKSHOP TOOLS 17

10 6 ENGINE PRESERVATION 18

10 6 1 Properties of Preservative Oils 18

10 6 2 Recommended Preservative 18

10 6 3 Preservation Procedure 19

10 6 4 DE-PRESERVATION – BEFORE RE-COMMISSIONING THE ENGINE 19

10 7 CONSUMABLES REQUIRED 20

10 8 TOP OVERHAULING 21

10 8 1 Dismantling 21

10 8 2 Cleaning & Inspection 28

10 8 3 Assembly 33

10 9 MAJOR OVERHAULING 38

10 9 1 ENGINE DISMANTLING 38

10 9 2 CLEANING INSPECTION & SERVICING OF SUB-ASSEMBLIES 45

10 9 3 ENGINE ASSEMBLY 46

10 10 INSPECTION AND SERVICING OF MAJOR SUB-ASSEMBLIES 50

10 10 1 Inspection & Servicing the Crank case 50

10 10 2 Inspection & Servicing the Crank shaft 51

10 10 3 Inspection & Servicing the Cylinder Liner 55

10 10 4 Inspection & Servicing the Connecting rod 55

10 10 5 Inspection & Servicing the Piston 56

10 10 6 Inspection & Servicing of Cylinder Head 57

10 10 7 Inspection & Servicing of Camshaft 59

10 10 8 Inspection & Servicing the Intermediate Gear 60

10 10 9 Inspection & Servicing the Lubricating oil pump 60

10 10 10 Inspection & Servicing of Water Pump 61

10 10 11 Inspection & Servicing of Turbocharger 62

10 10 12 Inspecting the cylinder head surface flatness 67

10 10 13 Inspecting the Valve recess in Cylnder Head 68

10 10 14 Replacing Valve Guide 69

10 10 15 Replacing Valve Seat Inserts 69

10 10 16 Assembly of the Piston & Con-rod 70

10 10 17 7Checking Piston Ring Butt clearance 70

10 10 18 Checking internal diameter of main and Con-rod bearing shells 71

10 10 19 Fitting of Piston Rings on Piston 71

10 10 20 Fitting Crank shaft in Crank Case 72

10 10 21 Checking the Crank shaft end play 72

2

10 10 22 Fitting the Piston and Con-rod Assembly in liner 73

10 10 23 Valve Lapping 73

10 10 24 Valve checking by the Pencil Erase Test 75

10 10 25 Valve checking by Fuel Leakage Test 75

10 10 26 Inspection & Servicing of Oil Spray Nozzles 76

10 10 27 Checking the Gear backLash 76

10 10 28 Setting the Fuel timing 78

10 10 29 Valve Tappet Setting 79

10 10 30 Servicing Spin -On type lubricating oil filter 81

10 10 31 Bleeding the Fuel System 81

10 10 32 Inspection & Servicing the oil cooler 81

10 10 33 Inspection & Servicing of THE Radiator 82

10 10 34 Inspection & Servicing of Auto Electricals 82

10 10 35 Fitment procedure for the F W E Oil Seal 83

10 10 36 Fitment Procedure for G E Oil Seal 84

10 10 37 Servicing Oil Bath Type Air Cleaner 84

10 11 SPECIAL TOOLS ILLUSTRATION 85

10 12 TROUBLE SHOOTING 88

10 13 FUEL SYSTEM SETTING 95