$33

Gehl 650 750 T750 Articulated Loader Operator’s Manual 50940508 – PDF DOWNLOAD

Gehl 650 750 T750 Articulated Loader Operator’s Manual 50940508 – PDF DOWNLOAD

FILE DETAILS:

Gehl 650 750 T750 Articulated Loader Operator’s Manual 50940508 – PDF DOWNLOAD

Language : English

Pages : 294

Downloadable : Yes

File Type : PDF

Size: 32.8 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gehl 650 750 T750 Articulated Loader Operator’s Manual 50940508 – PDF DOWNLOAD

Introduction:Contents and Use of this Manual:

This Operator’s Manual provides information about the safe and proper operation and maintenance for the machine. Major points of safe operation and maintenance are detailed in the Safety chapter of this manual. This manual also includes general troubleshooting and specification information about the machine. Follow the instructions in the Operator’s Manual Safety, Operation and Maintenance chapters, concerning accident prevention regulations, safety and occupational regulations, and machine and traffic regulations. Manitou Americas is not liable for damage resulting from the failure to follow these regulations.

- It is the owner’s or employer’s responsibility to fully instruct each operator in the proper and safe operation and maintenance of the machine. A storage container is provided behind the operator’s seat for storing the Operator’s Manual. After using the manual, return it to the storage container.

- This manual is considered a permanent part of the machine and should be with the machine at all times. If the machine is resold, include this operator’s manual as part of the sale. Replace this manual promptly if it becomes damaged, lost or stolen.

- Some illustrations in this manual may show doors, guards and shields open or removed for illustrative purposes only. BE SURE all doors, guards and shields are in their proper operating positions BEFORE starting the engine to operate the machine. Because of ongoing product improvements, information included in this manual may not exactly match the machine. Manitou Americas reserves the right to modify and improve products at any time without notice or obligation.

TABLE OF CONTENTS:

Gehl 650 750 T750 Articulated Loader Operator’s Manual 50940508 – PDF DOWNLOAD

Delivery Checklists………………………………………………………………………………………………………………………i

Introduction………………………………………………………………………………………………………………………………..7

Safety Symbol ……………………………………………………………………………………………………………………………………… 7

Contents and Use of this Manual ……………………………………………………………………………………………………………. 7

Safety Symbol and Signal Words……………………………………………………………………………………………………………. 8

Safety Alert Symbol ………………………………………………………………………………………………………………………… 8

Signal Words …………………………………………………………………………………………………………………………………. 8

Machine Orientation ……………………………………………………………………………………………………………………………… 8

Proper Machine Use……………………………………………………………………………………………………………………………… 8

Service and Registration ……………………………………………………………………………………………………………………….. 9

Machine Model and Serial Numbers …………………………………………………………………………………………………. 9

Component Serial Numbers …………………………………………………………………………………………………………….. 9

Component Identification……………………………………………………………………………………………………………………… 10

Non-telescopic Machines ………………………………………………………………………………………………………………. 10

Telescopic Machines …………………………………………………………………………………………………………………….. 11

Attachments ………………………………………………………………………………………………………………………………………. 12

Using Attachments ……………………………………………………………………………………………………………………………… 12

Vibration Information …………………………………………………………………………………………………………………………… 13

Vibration Measurement and Actions………………………………………………………………………………………………… 13

Vibration Levels ……………………………………………………………………………………………………………………………. 14

Fire Extinguisher ………………………………………………………………………………………………………………………………… 14

Manufacturer Information …………………………………………………………………………………………………………………….. 14

Indicator and Operation Symbols………………………………………………………………………………………………………….. 15

Safety……………………………………………………………………………………………………………………………………….17

Safety Symbol and Signal Words………………………………………………………………………………………………………….. 17

Safety Alert Symbol ………………………………………………………………………………………………………………………. 17

Signal Words ……………………………………………………………………………………………………………………………….. 17

Mandatory Safety Shutdown Procedure…………………………………………………………………………………………………. 18

Before Starting …………………………………………………………………………………………………………………………………… 18

During Operation ………………………………………………………………………………………………………………………………… 20

Provision for Stability/Avoiding Rollover and Tipover Accidents ………………………………………………………………… 22

Telescopic Machines…………………………………………………………………………………………………………………………… 24

Articulated Loader Stability…………………………………………………………………………………………………………………… 24

Effect of Load Arm Lowering on Stability………………………………………………………………………………………….. 25

Effect of Load Arm Extension on Stability (Telescopic Machines Only) ………………………………………………… 25

Effect of Uneven or Unstable Ground on Stability ……………………………………………………………………………… 25

Effect of Machine Travel on Stability ……………………………………………………………………………………………….. 26

Effect of Load Movement on Stability ………………………………………………………………………………………………. 26

Applications with Load-Handling Devices ………………………………………………………………………………………………. 26

Parking the Machine……………………………………………………………………………………………………………………………. 27

Electrical Energy ………………………………………………………………………………………………………………………………… 27

Maintenance and Service Safety Practices…………………………………………………………………………………………….. 27

Battery Hazards………………………………………………………………………………………………………………………………….. 29

Fire Hazards………………………………………………………………………………………………………………………………………. 29

Additional Safety Equipment ………………………………………………………………………………………………………………… 30

Crystalline Silica Exposure…………………………………………………………………………………………………………………… 31

Transporting the Machine…………………………………………………………………………………………………………………….. 31

Raising the Machine with a Crane…………………………………………………………………………………………………………. 31

Loading and Transporting the Machine………………………………………………………………………………………………….. 31

Safety Decals …………………………………………………………………………………………………………………………………….. 31

New Decal Application…………………………………………………………………………………………………………………… 32

Non-Telescopic Machines ……………………………………………………………………………………………………………… 33

Table of Contents

Table of Contents

50940508/E0121 2 Printed in U.S.A.

Telescopic Machines ……………………………………………………………………………………………………………………..34

ANSI-Style and Common Safety Decal Locations…………………………………………………………………………………….35

ISO-Style Safety Decal Locations…………………………………………………………………………………………………………..40

Specifications …………………………………………………………………………………………………………………………..45

Fluids/Lubricants Types and Capacities ………………………………………………………………………………………………….45

Payloads/Capacities …………………………………………………………………………………………………………………………….47

Non-Telescopic Machines……………………………………………………………………………………………………………….47

Telescopic Machines ……………………………………………………………………………………………………………………..48

Dimensions …………………………………………………………………………………………………………………………………………51

Non-Telescopic Machines……………………………………………………………………………………………………………….51

Telescopic Machines ……………………………………………………………………………………………………………………..53

Weights………………………………………………………………………………………………………………………………………………55

Coolant Compound Table……………………………………………………………………………………………………………………..55

Wheels/Tires……………………………………………………………………………………………………………………………………….56

Engine………………………………………………………………………………………………………………………………………………..56

Hydraulic System…………………………………………………………………………………………………………………………………57

Drive Hydraulics…………………………………………………………………………………………………………………………….57

Work Hydraulics…………………………………………………………………………………………………………………………….57

Sound Power/Pressure Levels (Non-Telescopic Machines)……………………………………………………………………….57

Sound Power/Pressure Levels (Telescopic Machines) ……………………………………………………………………………..57

Vibration Levels …………………………………………………………………………………………………………………………………..58

Common Materials and Densities…………………………………………………………………………………………………………..59

Indicators and Controls …………………………………………………………………………………………………………….61

Multi-Function Display ………………………………………………………………………………………………………………………….63

Multi-Function Display Symbols……………………………………………………………………………………………………….64

Multi-Function Display Screens ……………………………………………………………………………………………………….66

Control Keypad ……………………………………………………………………………………………………………………………………72

Switch Panel ……………………………………………………………………………………………………………………………………….73

Audible Alerts………………………………………………………………………………………………………………………………..74

Telescopic Machines Load/Level Indicators (Telescopic Machines) ……………………………………………………………74

Load Arm Angle Indicator (Telescopic Machines) ………………………………………………………………………………74

Load Arm Extension Indicator (Domestic Telescopic Machines Only)……………………………………………………74

Longitudinal Load Moment Indicator (LLMI) (EU Telescopic Machines Only) …………………………………………75

Lateral Level Indicator (Telescopic Machines)……………………………………………………………………………………75

Ignition Switch……………………………………………………………………………………………………………………………………..76

Operator’s Seat/Armrest ……………………………………………………………………………………………………………………….76

Multi-Function Joystick …………………………………………………………………………………………………………………………77

Load Arm/Attachment Tilt Control…………………………………………………………………………………………………….77

Telescopic Load Arm Extend/Retract Control Switch (Telescopic Machines) …………………………………………77

Non-Telescopic Machines Float Controls ………………………………………………………………………………………….78

Telescopic Machines Raise Float Controls………………………………………………………………………………………..79

Travel Direction Switch …………………………………………………………………………………………………………………..79

Travel Speed Range Selection Button………………………………………………………………………………………………80

Differential Lock Button…………………………………………………………………………………………………………………..80

Auxiliary Hydraulics Control Switch ………………………………………………………………………………………………….81

Parking Brake ……………………………………………………………………………………………………………………………………..81

Parking Brake Adjustment/Service …………………………………………………………………………………………………..81

Control Lever (Option) ………………………………………………………………………………………………………………………….82

Throttle Controls ………………………………………………………………………………………………………………………………….82

Travel Controls ……………………………………………………………………………………………………………………………………83

Travel Direction Switch …………………………………………………………………………………………………………………..83

Travel Pedal………………………………………………………………………………………………………………………………….83

Brake/Inching Pedal……………………………………………………………………………………………………………………….84

Steering Wheel ……………………………………………………………………………………………………………………………..84

High/Low Travel Speed Selection…………………………………………………………………………………………………………..85

Table of Contents

Printed in U.S.A. 3 50940508/E0121

Constant Speed (Option)……………………………………………………………………………………………………………………… 85

Differential Lock………………………………………………………………………………………………………………………………….. 86

Engine Off Load Arm Lower …………………………………………………………………………………………………………………. 86

Non-Telescopic Machines ……………………………………………………………………………………………………………… 86

Telescopic Machines …………………………………………………………………………………………………………………….. 86

Hydraulics Transport Lock-out ……………………………………………………………………………………………………………… 86

Attachment Mounting ………………………………………………………………………………………………………………………….. 87

Quick Attachment Hitch …………………………………………………………………………………………………………………. 87

Auxiliary Hydraulic System…………………………………………………………………………………………………………………… 87

Auxiliary Circuit Pressure Relief ……………………………………………………………………………………………………… 87

Auxiliary Hydraulic Control …………………………………………………………………………………………………………….. 88

Hydraglide™ Button (Option) ……………………………………………………………………………………………………………….. 89

Cooling Fan Rotation Reversing Button…………………………………………………………………………………………………. 89

Cab Heat and Air Conditioning (HVAC) …………………………………………………………………………………………………. 90

Work Lights Button ……………………………………………………………………………………………………………………………… 90

Load Arm Lights Button (Telescopic Machines Only) ………………………………………………………………………………. 91

Beacon (Option) …………………………………………………………………………………………………………………………………. 91

Windshield Wiper/Washer and Defrost ………………………………………………………………………………………………….. 92

Windshield Wiper Button ……………………………………………………………………………………………………………….. 92

Windshield Washer Button …………………………………………………………………………………………………………….. 92

Washer Fluid Reservoir …………………………………………………………………………………………………………………. 92

Rear Window/Washer Switch …………………………………………………………………………………………………………. 92

Rear Window Defrost Switch………………………………………………………………………………………………………….. 92

12V Accessory Power Outlet………………………………………………………………………………………………………………… 93

External 12V Attachment Power Connections (Option) ……………………………………………………………………………. 93

12V Attachment Power Controls …………………………………………………………………………………………………….. 93

External 12V Attachment Power Extension Harness …………………………………………………………………………. 94

Battery Disconnect Switch……………………………………………………………………………………………………………………. 94

Operation………………………………………………………………………………………………………………………………….95

Operational Checks…………………………………………………………………………………………………………………………….. 95

Pre-Start Checks ………………………………………………………………………………………………………………………….. 95

Checks During Operation ………………………………………………………………………………………………………………. 96

Parking Checks ……………………………………………………………………………………………………………………………. 96

Before Operation ………………………………………………………………………………………………………………………………… 97

Cab Entry and Exit………………………………………………………………………………………………………………………… 97

Cab Door (Option) ………………………………………………………………………………………………………………………… 97

Cab Window Latches…………………………………………………………………………………………………………………….. 98

Emergency Exit ……………………………………………………………………………………………………………………………. 98

Right Window Stop ……………………………………………………………………………………………………………………….. 99

Operator’s Seat Adjustment …………………………………………………………………………………………………………… 99

Armrest Height Adjustment…………………………………………………………………………………………………………… 100

Seat Belt………………………………………………………………………………………………………………………………………….. 101

Fastening/Unfastening the Seat Belt ……………………………………………………………………………………………… 101

Dome Light ………………………………………………………………………………………………………………………………………. 101

Starting the Engine……………………………………………………………………………………………………………………………. 102

Cold-Starting………………………………………………………………………………………………………………………………. 104

After Starting………………………………………………………………………………………………………………………………. 104

Engine Warm Up………………………………………………………………………………………………………………………………. 104

Run-In Period …………………………………………………………………………………………………………………………………… 105

Stopping the Engine ………………………………………………………………………………………………………………………….. 105

Engine Stalling …………………………………………………………………………………………………………………………………. 105

Safety Interlock System (Hydraloc™) ………………………………………………………………………………………………….. 105

Safety Interlock System Test………………………………………………………………………………………………………… 105

Travel Drive Operation ………………………………………………………………………………………………………………………. 106

High/Low and Optional 3-Speed Travel Speed Modes …………………………………………………………………….. 109

Differential Lock Operation …………………………………………………………………………………………………………… 109

Table of Contents

50940508/E0121 4 Printed in U.S.A.

Constant Speed Operation (Option) ……………………………………………………………………………………………………..110

Travel Drive Error Condition Operation (Limited and Safe Modes)………………………………………………………111

Backup Alarm (Option)………………………………………………………………………………………………………………….111

Special Considerations for Telescopic Machines ……………………………………………………………………………………112

Telescopic Load Arm Operation …………………………………………………………………………………………………….112

Longitudinal Load Moment Indicator (LLMI) – EU Telescopic Machines Only……………………………………….113

Load Arm Operation …………………………………………………………………………………………………………………………..114

Load Arm Travel Position………………………………………………………………………………………………………………114

Load Arm/Attachment Tilt Operation……………………………………………………………………………………………….115

Engine Off Load Arm Lower (Non-Telescopic Machines)…………………………………………………………………..115

Non-Telescopic Machines Float Operation (Raise and Tilt) ……………………………………………………………….116

Telescopic Machines Raise Float Operation ……………………………………………………………………………………117

Load Arm Extend/Retract (Telescopic Machines Only) ……………………………………………………………………..118

Load Arm Raise/Tilt Support (Non-Telescopic Machines Only) ………………………………………………………………..120

Engage Load Arm Support ……………………………………………………………………………………………………………120

Disengage Load Arm Support………………………………………………………………………………………………………..121

Engage Tilt Support ……………………………………………………………………………………………………………………..122

Disengage Tilt Support …………………………………………………………………………………………………………………123

Self-Leveling and Return-To Dig ………………………………………………………………………………………………………….124

Self-Leveling (Load Arm Raise) ……………………………………………………………………………………………………..124

Return to Dig (Load Arm Lower) …………………………………………………………………………………………………….124

Hydraglide™ Ride Control System (Option) …………………………………………………………………………………………..124

Hydraulics Transport Lock-Out Operation ……………………………………………………………………………………………..125

Connecting/Disconnecting Attachments ………………………………………………………………………………………………..126

Power-A-Tach® System Hitch Operation ………………………………………………………………………………………..126

Euro-Style and 4-Point Hitch Operation…………………………………………………………………………………………..128

Powering Attachments with Hydraulic Function………………………………………………………………………………………132

Connecting Hydraulic Attachments to the Auxiliary Hydraulic Circuits …………………………………………………132

Disconnecting Hydraulic Attachments from the Auxiliary Hydraulics Circuit………………………………………….134

Auxiliary Hydraulics Operation……………………………………………………………………………………………………….134

14-Pin Connector (Option)…………………………………………………………………………………………………………………..136

Switch / Pin Assignments………………………………………………………………………………………………………………136

Working with Buckets …………………………………………………………………………………………………………………………137

Digging Tips ………………………………………………………………………………………………………………………………..137

Safety Instructions When Working with Buckets……………………………………………………………………………….137

Working with Buckets……………………………………………………………………………………………………………………138

Working with Pallet Forks ……………………………………………………………………………………………………………………140

Safety Instructions When Working with Pallet Forks …………………………………………………………………………140

Moving Loads Using Pallet Forks …………………………………………………………………………………………………..142

Diesel Particulate Filter (DPF) Regeneration Procedures ………………………………………………………………………..144

Reset Regeneration ……………………………………………………………………………………………………………………..144

Stationary Regeneration ……………………………………………………………………………………………………………….145

DPF Maintenance ………………………………………………………………………………………………………………………..147

After Operation ………………………………………………………………………………………………………………………………….147

Jump-Starting ……………………………………………………………………………………………………………………………………148

Raising the Machine using a Crane………………………………………………………………………………………………………149

Crane Lifting Preparation ………………………………………………………………………………………………………………150

Towing ……………………………………………………………………………………………………………………………………………..151

Precautions …………………………………………………………………………………………………………………………………151

Preparation …………………………………………………………………………………………………………………………………151

Towing Procedure………………………………………………………………………………………………………………………..152

After Towing………………………………………………………………………………………………………………………………..152

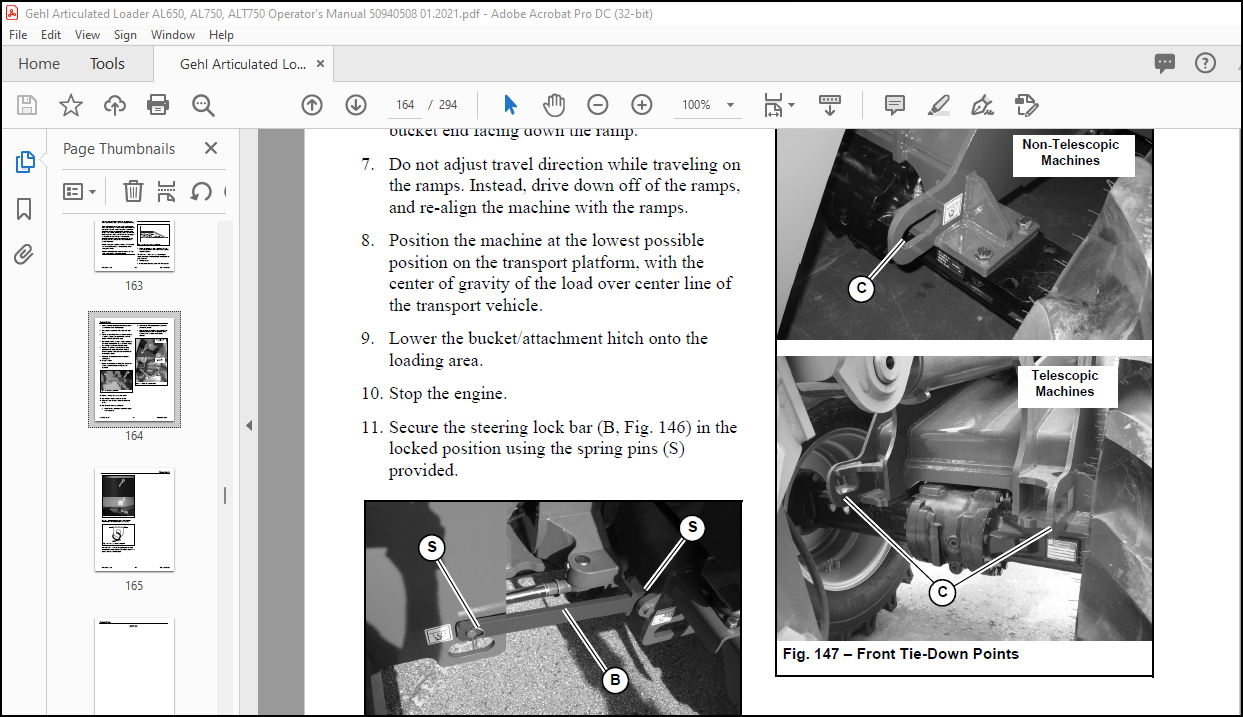

Loading and Transporting the Machine on a Transport Vehicle ………………………………………………………………..153

Loading and Securing the Machine ………………………………………………………………………………………………..153

Maintenance……………………………………………………………………………………………………………………………157

Maintenance Schedule ……………………………………………………………………………………………………………………….159

Checks, Cleaning and Inspection …………………………………………………………………………………………………..159

Table of Contents

Printed in U.S.A. 5 50940508/E0121

Leakage Check…………………………………………………………………………………………………………………………… 160

Lubrication and Filter Changes……………………………………………………………………………………………………… 161

Functional Check………………………………………………………………………………………………………………………… 161

Maintenance Interval …………………………………………………………………………………………………………………………. 162

General Lubrication …………………………………………………………………………………………………………………………… 163

Non-Telescopic Machines ……………………………………………………………………………………………………………. 163

Telescopic Machines …………………………………………………………………………………………………………………… 164

General Lubrication Detail ……………………………………………………………………………………………………………. 165

Telescopic Load Arm Maintenance (Telescopic Machines Only)……………………………………………………………… 169

Telescopic Load Arm Section Lubrication ………………………………………………………………………………………. 169

Telescopic Load Arm Wear Pad Replacement………………………………………………………………………………… 170

LLMI Calibration (EU Telescopic Machines Only)………………………………………………………………………………….. 170

Engine Maintenance………………………………………………………………………………………………………………………….. 172

Engine Oil ………………………………………………………………………………………………………………………………….. 172

Engine Air Filters ………………………………………………………………………………………………………………………… 175

Changing Air Filter Elements………………………………………………………………………………………………………… 175

Engine Cooling System ……………………………………………………………………………………………………………….. 176

Belt Maintenance………………………………………………………………………………………………………………………… 179

DPF Service …………………………………………………………………………………………………………………………………….. 181

Fuel System Maintenance………………………………………………………………………………………………………………….. 181

Adding Fuel ……………………………………………………………………………………………………………………………….. 182

Water Separator Inspection/Maintenance ………………………………………………………………………………………. 182

Changing Fuel Filter ……………………………………………………………………………………………………………………. 184

Hydraulic System Maintenance…………………………………………………………………………………………………………… 185

Checking Hydraulic Oil Level………………………………………………………………………………………………………… 185

Changing Hydraulic Oil………………………………………………………………………………………………………………… 186

Changing Hydraulic Filter …………………………………………………………………………………………………………….. 187

Hydraulic Hose Maintenance ……………………………………………………………………………………………………………… 189

Planetary Axles ………………………………………………………………………………………………………………………………… 190

Changing Axle Wheel Hub Oil ………………………………………………………………………………………………………. 190

Changing Axle Center Oil …………………………………………………………………………………………………………….. 191

Brake Fluid Reservoir………………………………………………………………………………………………………………………… 191

Checking/Replenishing Brake Fluid Reservoir Level………………………………………………………………………… 191

Parking Brake Adjustment/Service………………………………………………………………………………………………………. 192

Parking Brake Cable Adjustment…………………………………………………………………………………………………… 192

Parking Brake Actuator Bracket Adjustment …………………………………………………………………………………… 193

Wheels and Tires ……………………………………………………………………………………………………………………………… 194

Wheel Fasteners ………………………………………………………………………………………………………………………… 194

Tires………………………………………………………………………………………………………………………………………….. 194

Travel Motor Lubrication…………………………………………………………………………………………………………………….. 194

Electrical System………………………………………………………………………………………………………………………………. 195

Battery ………………………………………………………………………………………………………………………………………. 195

Using a Booster Battery (Jump-Starting)………………………………………………………………………………………… 196

Fuses and Relays……………………………………………………………………………………………………………………….. 197

CAN Resistor……………………………………………………………………………………………………………………………… 199

Chassis Grounds ………………………………………………………………………………………………………………………… 199

Light Bulb Replacement ………………………………………………………………………………………………………………. 200

14-Pin Connector Fuses, Diodes and Relays (Option)……………………………………………………………………… 204

HVAC/Air Conditioning Maintenance …………………………………………………………………………………………………… 206

HVAC Filters………………………………………………………………………………………………………………………………. 206

Air Conditioning Compressor Belt …………………………………………………………………………………………………. 207

Windshield Washer Reservoir …………………………………………………………………………………………………………….. 207

Long-Term Storage …………………………………………………………………………………………………………………………… 208

Before Storage …………………………………………………………………………………………………………………………… 208

After Storage ……………………………………………………………………………………………………………………………… 208

Final Shutdown / Decommissioning …………………………………………………………………………………………………….. 209

Before Disposal ………………………………………………………………………………………………………………………….. 209

Machine Disposal ……………………………………………………………………………………………………………………….. 209

Table of Contents

50940508/E0121 6 Printed in U.S.A.

Maintenance Log ……………………………………………………………………………………………………………………………….210

Troubleshooting ……………………………………………………………………………………………………………………..213

Engine Troubleshooting………………………………………………………………………………………………………………………213

Indicator Lamp Troubleshooting …………………………………………………………………………………………………………..214

Seal and Hose Troubleshooting …………………………………………………………………………………………………………..215

Hydraulic System Troubleshooting ……………………………………………………………………………………………………….216

Hydrostatic Travel Drive System Troubleshooting…………………………………………………………………………………..218

Electrical Troubleshooting …………………………………………………………………………………………………………………..219

Electrical Inputs/Outputs ……………………………………………………………………………………………………………….220

Error Codes ………………………………………………………………………………………………………………………………………220

MCU and Keypad CAN Error Codes……………………………………………………………………………………………….220

Yanmar Engine Diagnostic Trouble Codes (DTC) …………………………………………………………………………….222

Deutz Engine Diagnostic Trouble Codes (DTC) ……………………………………………………………………………….229

Travel Drive Control Module Error Codes………………………………………………………………………………………..246

Pump and Drive Motor Error Codes………………………………………………………………………………………………..248

Schematics …………………………………………………………………………………………………………………………….249

Hydraulic Schematic — Standard (Non-Telescopic Machines) …………………………………………………………………249

Hydraulic Schematic — with High-Flow/2nd Auxiliary Hydraulics and Hydraglide (Non-Telescopic Machines) .250

Hydraulic Schematic — Standard Auxiliary Hydraulics (Telescopic Machines) …………………………………………..251

Hydraulic Schematic — Standard Auxiliary Hydraulics with Options (Telescopic Machines)…………………………252

Hydraulic Schematic — High-Flow Auxiliary Hydraulics (Telescopic Machines)………………………………………….253

Hydraulic Schematic — High-Flow Auxiliary Hydraulics with Options (Telescopic Machines) ……………………….254

Electrical Schematic – Chassis (1 of 3) …………………………………………………………………………………………………255

Electrical Schematic – Chassis (2 of 3) …………………………………………………………………………………………………256

Electrical Schematic – Chassis – Switch Panel Splices (3 of 3)………………………………………………………………..257

Electrical Schematic – Chassis – Rear Frame (1 of 2) …………………………………………………………………………….258

Electrical Schematic – Chassis – Rear Frame (2 of 2) …………………………………………………………………………….259

Electrical Schematic – Chassis – Front Frame/Headlights (Non-Telescopic Machines) ……………………………….260

Electrical Schematic – Chassis – Front Frame/Headlights (Telescopic Machines) (1 of 2) …………………………..261

Electrical Schematic – Chassis – Front Frame/Headlights (Telescopic Machines) (2 of 2) …………………………..262

Electrical Schematic – Enclosed ROPS/FOPS……………………………………………………………………………………….263

Electrical Schematic – HVAC ………………………………………………………………………………………………………………264

Electrical Schematic – Open ROPS/FOPS…………………………………………………………………………………………….265

Electrical Schematic – 600 Series Engine (Yanmar 4TNV98CT-PGWLT) ………………………………………………….266

Electrical Schematic — 700 Series Engine (Deutz TD3.6L4) (1 of 2) ………………………………………………………..267

Electrical Schematic — 700 Series Engine (Deutz TD3.6L4) (2 of 2)………………………………………………………….268

Electrical Schematic — Electrical Auxiliary Circuits…………………………………………………………………………………269

Electrical Schematic — Rear Lights Connection ……………………………………………………………………………………..270

Electrical Schematic — 14-Pin Auxiliary Circuit………………………………………………………………………………………271

Electrical Schematic — Turn Signal/Radio Jumpers ………………………………………………………………………………..272

EC Declaration of Conformity ………………………………………………………………………………………………….273

Index ………………………………………………………………………………………………………………………………………275

Torque Specifications……………………………………………………………………………………………………………..279

SAE Torque Values ……………………………………………………………………………………………………………………..281