$33

Gehl AL 440 AL 540 Articulated Loader Service Manual 918275 – PDF DOWNLOAD

Gehl AL 440 AL 540 Articulated Loader Service Manual 918275 – PDF DOWNLOAD

FILE DETAILS:

Gehl AL 440 AL 540 Articulated Loader Service Manual 918275 – PDF DOWNLOAD

Language : English

Pages : 220

Downloadable : Yes

File Type : PDF

Size: 10.3 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gehl AL 440 AL 540 Articulated Loader Service Manual 918275 – PDF DOWNLOAD

Mandatory Safety Shutdown:

Procedure:

BEFORE cleaning, adjusting, lubricating, fueling or servicing the machine, or leaving it unattended:

1. Bring the machine to a complete stop on a level surface. Avoid parking on an incline or hillside, but if this is not possible, park across the slope and block the tires.2. Be sure all working equipment and/or attachments are stopped and the auxiliary valve is in neutral.3. Lower the lift arm and attachment completely.4. Place forward/reverse drive switch (on top of the joystick) into the neutral position.5. Apply the parking brake. 6. Move the throttle to low idle position and shut off the engine.7. Wait for all movement to stop. Turn the ignition key to the “I” or RUN position and move the multipurpose joystick in all directions to verify that the hydraulic system is de-pressurized.8. Turn off the ignition and remove the key.9. Unfasten the seat belt, remove the ignition key and take it with you. Exit the machine using the hand holds. ONLY when these precautions have been taken can you be sure it is safe to proceed. Failure to follow this procedure could result in death or serious injury.

Before Starting:

• Do not modify the Roll-Over Protective Structure (“ROPS”) unless instructed to do so in Gehl Company-approved installation instructions. Modifications, such as welding, drilling or cutting, can weaken the structure and reduce the protection it provides. A damaged ROPS cannot be repaired – it must be replaced.• To ensure safe operation, replace damaged or worn-out parts with genuine Gehl service parts.• Gehl loaders are designed and intended to be used only wi th Gehl a ttachments and approved attachments. To avoid possible personal injury, equipment damage and performance problems, use only attachments that are approved for use on and within the operating capacity of the machine. Contact the Gehl Company for information on attachment approval and compatibility with specific machine models. Gehl cannot be responsible if the machine is used with a non-approved attachment.• Remove all trash and debris from the machine every day, especially in the engine compartment, to minimize the risk of fire.• Always face the machine and use the hand holds and steps when entering and exiting the machine. Do not jump off the machine.• Do not use starting fluid (ether).• Walk around the machine and inspect it before using it. Look for damage, loose or missing parts, leaks, etc.• Warn all nearby personnel before starting the machine.

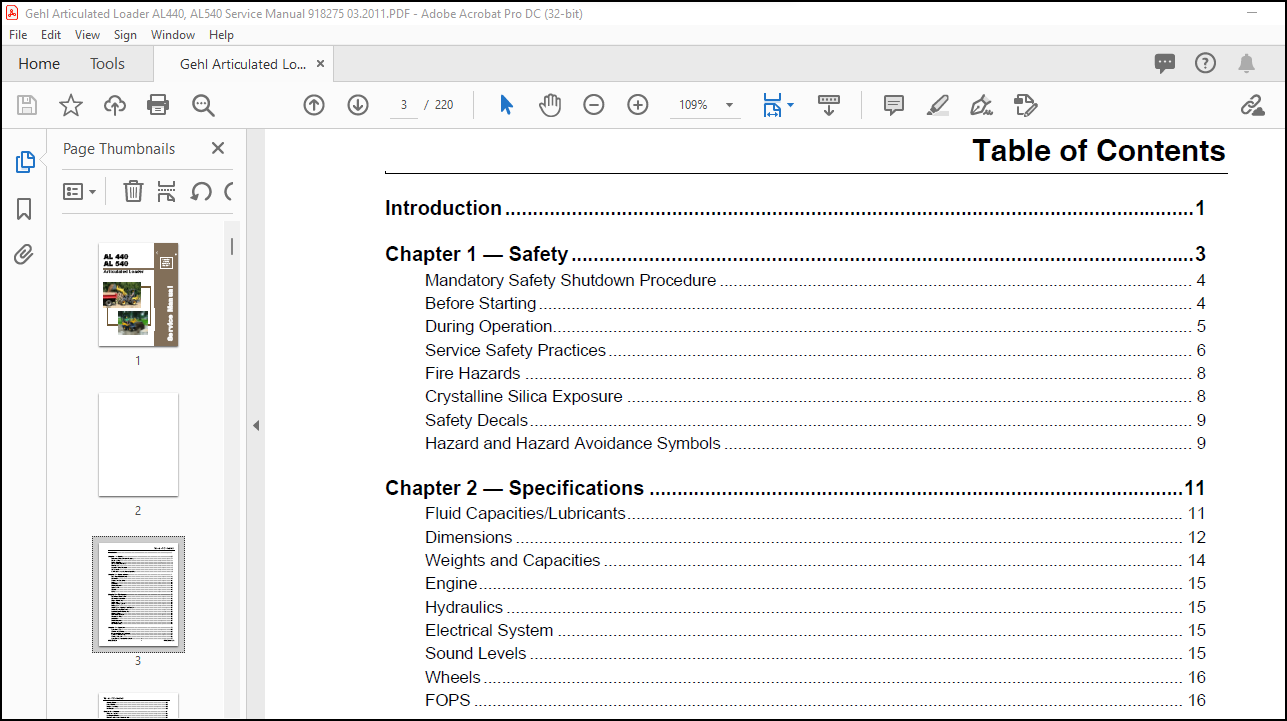

TABLE OF CONTENTS:

Gehl AL 440 AL 540 Articulated Loader Service Manual 918275 – PDF DOWNLOAD

Introduction…………………………………………………………………………………………………………….1

Chapter 1 — Safety………………………………………………………………………………………………….3

Mandatory Safety Shutdown Procedure ………………………………………………………………………………………… 4

Before Starting…………………………………………………………………………………………………………………………… 4

During Operation………………………………………………………………………………………………………………………… 5

Service Safety Practices ……………………………………………………………………………………………………………… 6

Fire Hazards ……………………………………………………………………………………………………………………………… 8

Crystalline Silica Exposure ………………………………………………………………………………………………………….. 8

Safety Decals…………………………………………………………………………………………………………………………….. 9

Hazard and Hazard Avoidance Symbols ……………………………………………………………………………………….. 9

Chapter 2 — Specifications ……………………………………………………………………………………11

Fluid Capacities/Lubricants………………………………………………………………………………………………………… 11

Dimensions ……………………………………………………………………………………………………………………………… 12

Weights and Capacities …………………………………………………………………………………………………………….. 14

Engine…………………………………………………………………………………………………………………………………….. 15

Hydraulics ……………………………………………………………………………………………………………………………….. 15

Electrical System ……………………………………………………………………………………………………………………… 15

Sound Levels …………………………………………………………………………………………………………………………… 15

Wheels ……………………………………………………………………………………………………………………………………. 16

FOPS ……………………………………………………………………………………………………………………………………… 16

Chapter 3 — Maintenance………………………………………………………………………………………17

Maintenance Introduction…………………………………………………………………………………………………………… 17

Maintenance Schedule ……………………………………………………………………………………………………………… 18

Engine Maintenance …………………………………………………………………………………………………………………. 20

Air Cleaner ………………………………………………………………………………………………………………………………. 22

Engine Cooling System……………………………………………………………………………………………………………… 23

Fuel System…………………………………………………………………………………………………………………………….. 25

Checking and Adjusting V-belt Tension……………………………………………………………………………………….. 27

Air Conditioning Maintenance …………………………………………………………………………………………………….. 28

Hydraulic System Maintenance ………………………………………………………………………………………………….. 29

Planetary Axles ………………………………………………………………………………………………………………………… 30

Brake Fluid Reservoir ……………………………………………………………………………………………………………….. 32

Wheels and Tires ……………………………………………………………………………………………………………………… 33

Lubrication ………………………………………………………………………………………………………………………………. 35

Electrical System ……………………………………………………………………………………………………………………… 37

Storing the Loader ……………………………………………………………………………………………………………………. 44

Maintenance Log ……………………………………………………………………………………………………………………… 45

Chapter 4 — Operation…………………………………………………………………………………………..49

Operation Safety ………………………………………………………………………………………………………………………. 49

Controls and Switches ………………………………………………………………………………………………………………. 50

Instrument Panel and Indicators …………………………………………………………………………………………………. 52

Cab Controls (Cab only) ……………………………………………………………………………………………………………. 54

Warning Indicators ……………………………………………………………………………………………………………………. 56

Operator’s Seat and Ignition Switch…………………………………………………………………………………………….. 57

Table of Contents

PRINTED IN U.S.A. ii 918275/BP0311

Steering Column ………………………………………………………………………………………………………………………..58

Hand Throttle …………………………………………………………………………………………………………………………….59

Lift Arm Down-Stop…………………………………………………………………………………………………………………….59

Lift/Tilt Lock……………………………………………………………………………………………………………………………….60

Chapter 5 — Chassis……………………………………………………………………………………………..61

Tilting the Platform……………………………………………………………………………………………………………………..61

Lowering the Platform…………………………………………………………………………………………………………………62

Repairing or Replacing Platform Switch ………………………………………………………………………………………..64

Hood Removal …………………………………………………………………………………………………………………………..65

Hood Installation ………………………………………………………………………………………………………………………..66

Center/Steering Bearing Removal ………………………………………………………………………………………………..67

Center/Steering Bearing Installation ……………………………………………………………………………………………..70

Lift Arm Removal ……………………………………………………………………………………………………………………….74

Lift Arm Installation …………………………………………………………………………………………………………………….75

Attachment Plate Hydraulics Removal…………………………………………………………………………………………..77

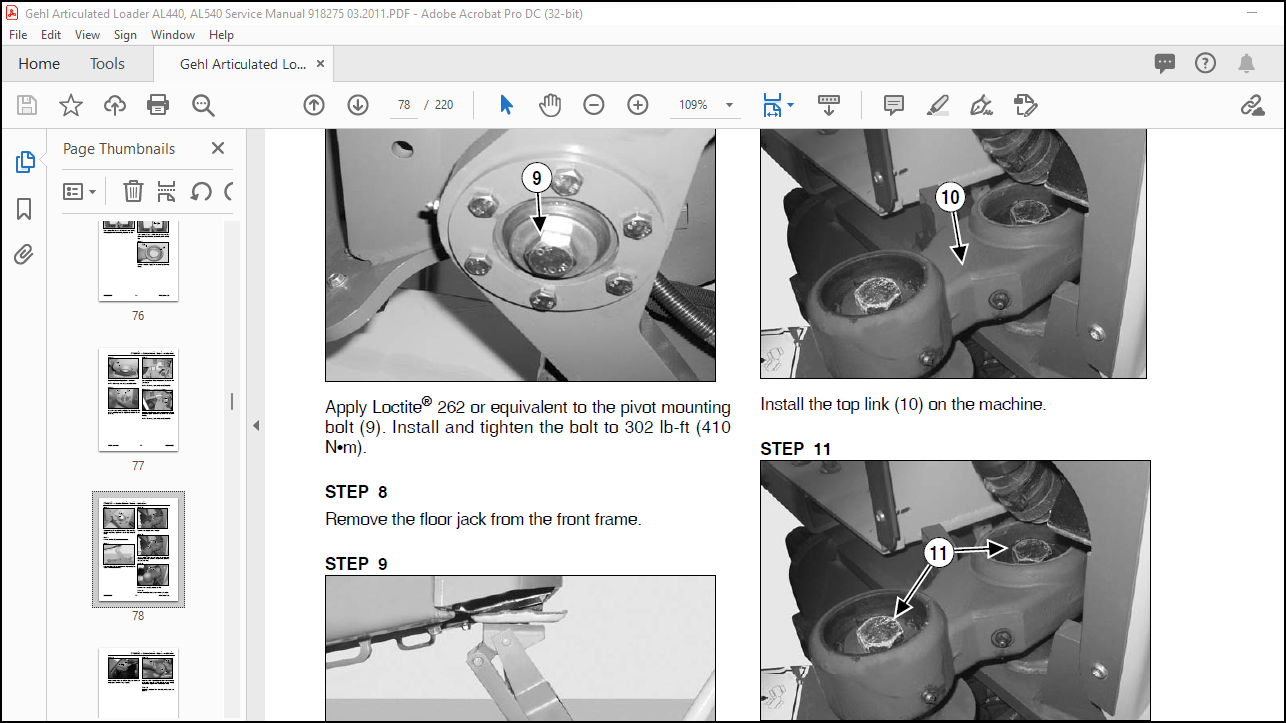

Attachment Plate Hydraulics Installation………………………………………………………………………………………..78

Chapter 6 — Engine……………………………………………………………………………………………….79

Engine Removal…………………………………………………………………………………………………………………………79

Engine Installation………………………………………………………………………………………………………………………83

Drive Coupling Removal ……………………………………………………………………………………………………………..87

Drive Coupling Installation …………………………………………………………………………………………………………..87

Starter Removal …………………………………………………………………………………………………………………………88

Starter Installation………………………………………………………………………………………………………………………88

Chapter 7 — Cooling System …………………………………………………………………………………89

Radiator/Oil Cooler Removal ……………………………………………………………………………………………………….89

Radiator/Oil Cooler Installation …………………………………………………………………………………………………….92

Chapter 8 — Axles…………………………………………………………………………………………………95

Front Axle Removal ……………………………………………………………………………………………………………………95

Front Axle Installation …………………………………………………………………………………………………………………98

Rear Axle Removal …………………………………………………………………………………………………………………..100

Rear Axle Installation………………………………………………………………………………………………………………..102

Chapter 9 — Hydraulics ……………………………………………………………………………………….103

Work Hydraulics Troubleshooting……………………………………………………………………………………………….103

Hydrostatic Drive System…………………………………………………………………………………………………………..106

Hydraulics Troubleshooting Diagnostic Flow Charts ……………………………………………………………………..107

Drive System Pressure Tests …………………………………………………………………………………………………….121

Work System Pressure Tests …………………………………………………………………………………………………….124

Steering Circuit Pressure Test ……………………………………………………………………………………………………125

2-Spool Control Valve Removal………………………………………………………………………………………………….126

3-Spool Control Valve Removal………………………………………………………………………………………………….128

2-Spool Control Valve Installation……………………………………………………………………………………………….131

3-Spool Control Valve Installation……………………………………………………………………………………………….133

Lift/Tilt Lock, Power-A-Tach® System and Auxiliary Hydraulics Valve Locations ………………………………135

Table of Contents

918275/BP0311 iii PRINTED IN U.S.A

Lift Cylinder Removal………………………………………………………………………………………………………………. 136

Lift Cylinder Installation……………………………………………………………………………………………………………. 137

Tilt Cylinder Removal………………………………………………………………………………………………………………. 138

Tilt Cylinder Installation……………………………………………………………………………………………………………. 138

Steering Cylinder Removal ………………………………………………………………………………………………………. 139

Steering Cylinder Installation ……………………………………………………………………………………………………. 139

Hydraulic Cylinder Disassembly/Assembly…………………………………………………………………………………. 141

Gear/Work Hydraulic Pump Removal ………………………………………………………………………………………… 149

Gear/Work Hydraulic Pump Installation ……………………………………………………………………………………… 149

Piston/Drive Hydraulic Pump Removal ………………………………………………………………………………………. 150

Piston/Drive Hydraulic Pump Installation……………………………………………………………………………………. 152

Hydrostatic Motor Removal………………………………………………………………………………………………………. 153

Hydrostatic Motor Installation……………………………………………………………………………………………………. 155

Steering Control Valve Removal……………………………………………………………………………………………….. 156

Steering Control Valve Removal……………………………………………………………………………………………….. 158

Steering Control Valve Installation…………………………………………………………………………………………….. 159

Steering Control Valve Installation…………………………………………………………………………………………….. 160

Raising Machine for Drive System Troubleshooting …………………………………………………………………….. 161

AL 400 Series Hydraulic Schematic – SN 41250 and Up……………………………………………………………… 163

AL 400 Series Hydraulic Schematic – SN 41249 and Before ………………………………………………………… 164

AL 500 Series Hydraulic Schematic – SN 51242 and Up……………………………………………………………… 165

AL 500 Series Hydraulic Schematic – SN 51241 and Before ………………………………………………………… 166

Chapter 10 — Machine/Drive Controllers ………………………………………………………………167

Machine and Drive Controllers………………………………………………………………………………………………….. 167

Machine Controller………………………………………………………………………………………………………………….. 168

Drive Controller (Plus+1 Module)………………………………………………………………………………………………. 172

Service Communication Kit and PLUS+1 GUIDE Service Tool Software………………………………………… 173

Plus+1 Service Tool Navigation/Overview………………………………………………………………………………….. 174

Software Log Monitoring Screen……………………………………………………………………………………………….. 175

Electrical Inputs/Outputs Monitoring Screen……………………………………………………………………………….. 176

Electrical Status Error Reporting Screen ……………………………………………………………………………………. 177

System Definition Error Count/Timestamp Reset Screen……………………………………………………………… 178

Drive Controller Pedal Calibration Parameters ……………………………………………………………………………. 179

Pump Profiling Screen/Drive “Creep” Adjustment………………………………………………………………………… 179

Pedal Calibration Procedure …………………………………………………………………………………………………….. 181

Chapter 11 — Electrical System……………………………………………………………………………183

Battery Removal …………………………………………………………………………………………………………………….. 183

Battery Installation ………………………………………………………………………………………………………………….. 184

AL 400 Series (Serial Numbers 41250 and up) Complete Electrical Schematic ………………………………. 185

AL 400 Series (Serial Numbers 41250 and up) Steering Column Electrical Schematic …………………….. 186

AL 400 Series (Serial Numbers 41250 and up) Chassis Electrical Schematic …………………………………. 187

AL 400 Series (Serial Numbers 41250 and up) Engine Electrical Schematic…………………………………… 188

AL 400 Series (Serial Numbers 41250 and up) FOPS, Power-A-Tach® and Tail Light

Electrical Schematic………………………………………………………………………………………………………………. 189

AL 500 Series (Serial Numbers 51242 and up) Complete Electrical Schematic (Includes Air

Conditioning Option) ……………………………………………………………………………………………………………… 190

Table of Contents

PRINTED IN U.S.A. iv 918275/BP0311

AL 500 Series (Serial Numbers 51242 and up) Steering Column Electrical Schematic (Includes Air

Conditioning Option) ……………………………………………………………………………………………………………….191

AL 500 Series (Serial Numbers 51242 and up) Chassis Electrical Schematic (Includes Air Conditioning

Option) ………………………………………………………………………………………………………………………………….192

AL 500 Series (Serial Numbers 51242 and up) Engine Electrical Schematic (Includes Air Conditioning

Option) ………………………………………………………………………………………………………………………………….193

AL 500 Series (Serial Numbers 51242 and up) FOPS, CAB, Power-A-Tach® and Tail Light Electrical

Schematic (Includes Air Conditioning Option) …………………………………………………………………………….194

AL 400 Series (Serial Numbers 41249 and below), AL 500 Series (Serial Numbers 51241 and below)

Complete Electrical Schematic …………………………………………………………………………………………………195

Chapter 12 — Troubleshooting …………………………………………………………………………….197

Engine…………………………………………………………………………………………………………………………………….197

Indicator Lamps / Seals and Hoses …………………………………………………………………………………………….199

Hydraulic System……………………………………………………………………………………………………………………..200

Hydrostatic Drive System…………………………………………………………………………………………………………..202