$36

Gehl AL550 Mustang AL508 Manitou MLA 5-60 Articulated Loader Service Manual 50940658 – PDF DOWNLOAD

Gehl AL550 Mustang AL508 Manitou MLA 5-60 Articulated Loader Service Manual 50940658 – PDF DOWNLOAD

FILE DETAILS:

Gehl AL550 Mustang AL508 Manitou MLA 5-60 Articulated Loader Service Manual 50940658 – PDF DOWNLOAD

Language : English

Pages : 310

Downloadable : Yes

File Type : PDF

Size: 35 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gehl AL550 Mustang AL508 Manitou MLA 5-60 Articulated Loader Service Manual 50940658 – PDF DOWNLOAD

General:

Manual Purpose/Foreword:

- This manual provides information about the safe service procedures for the machine. Major points of safety are detailed in the Safety section of this manual. This manual also includes troubleshooting and specification information about the machine.

- Follow the instructions in this manual concerning accident prevention regulations, safety and occupational regulations, and machine and traffic regulations. Manitou Americas is not liable for damage resulting from the failure to follow these regulations.

- The machine is designed only for digging, picking up, raising, transporting and unloading materials. Approved attachment use is also allowed. Using the machine in any other way is considered contrary to the intended use. Compliance with, and strict adherence to, the conditions of operation, service and repair as specified in this manual and by the manufacturer, also constitute essential elements of the intended use.

- The machine was designed and built according to the best available technology and approved safety regulations in the countries where it is sold. However, it is impossible to completely safeguard against abusive, improper use. Always consider potential safety risks and hazards during operation, maintenance and service.

- Accident prevention regulations, all road traffic regulations, and all other generally recognized safety and occupational medicine regulations must be observed at all times. The machine must be maintained in proper operating condition. Any damaged or malfunctioning parts must be repaired or replaced immediately.

TABLE OF CONTENTS:

Gehl AL550 Mustang AL508 Manitou MLA 5-60 Articulated Loader Service Manual 50940658 – PDF DOWNLOAD

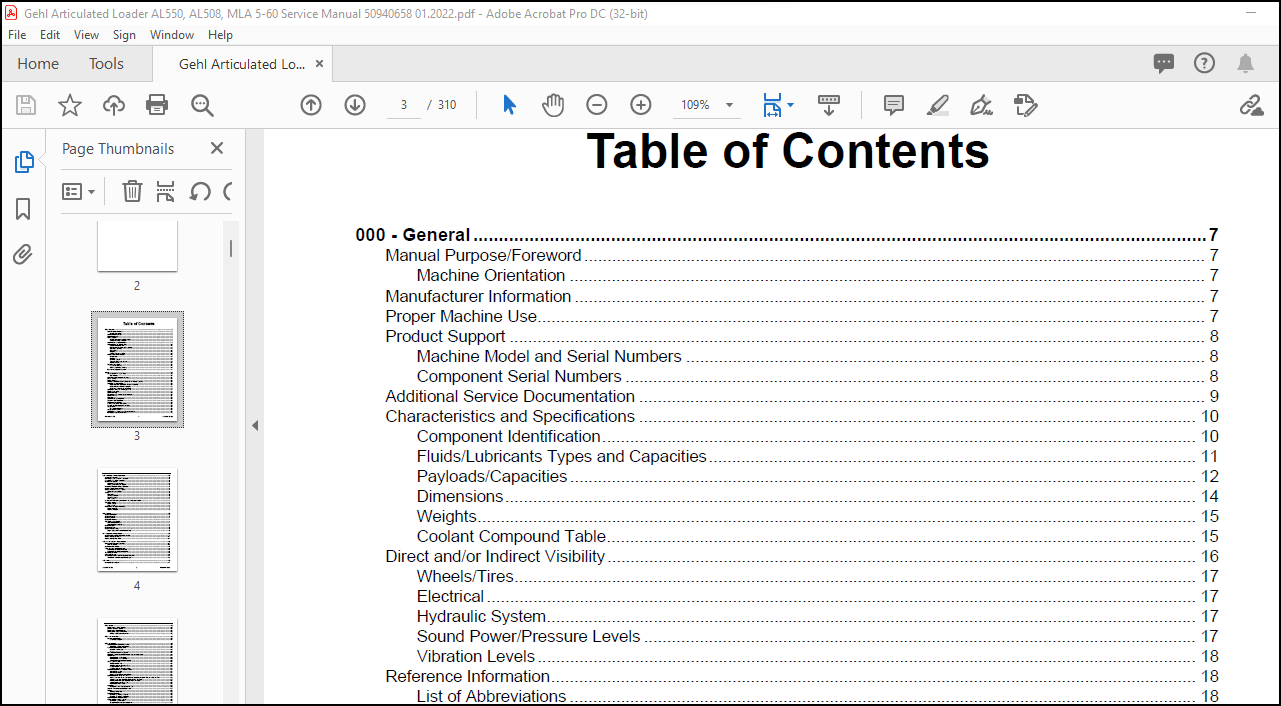

Table of Contents……………………………………………………………………………………… 3

000 – General…………………………………………………………………………………………. 9

Manual Purpose/Foreword…………………………………………………………………………….. 9

Machine Orientation…………………………………………………………………………….. 9

Manufacturer Information……………………………………………………………………………. 9

Proper Machine Use…………………………………………………………………………………. 9

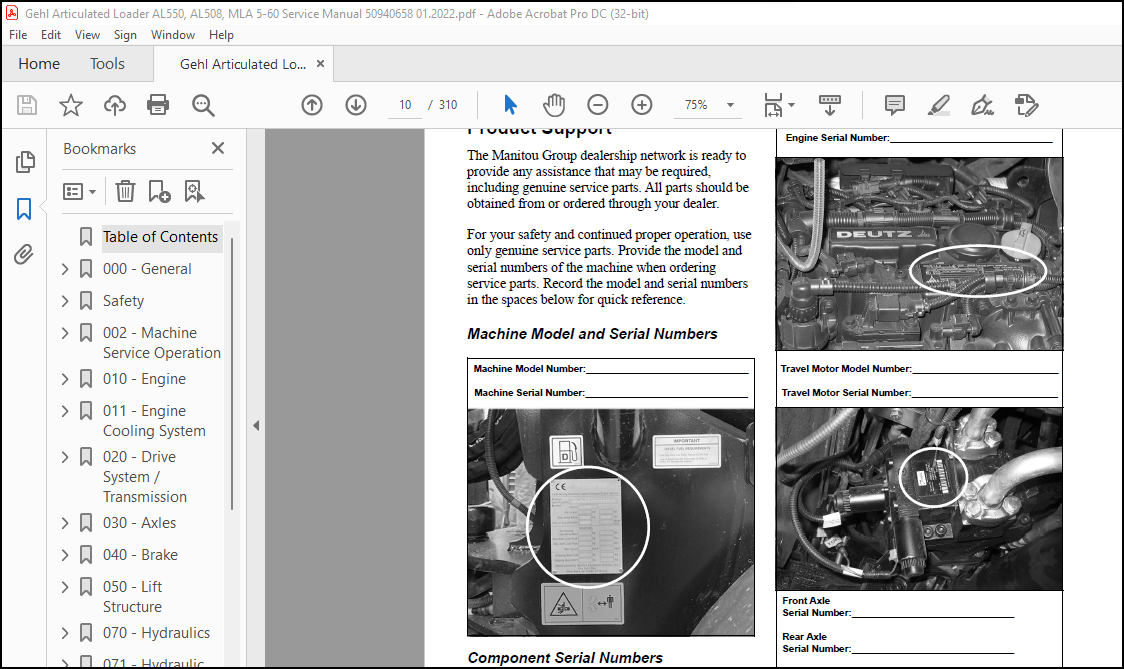

Product Support……………………………………………………………………………………. 10

Machine Model and Serial Numbers…………………………………………………………………. 10

Component Serial Numbers………………………………………………………………………… 10

Additional Service Documentation…………………………………………………………………….. 11

Characteristics and Specifications…………………………………………………………………… 12

Component Identification………………………………………………………………………… 12

Fluids/Lubricants Types and Capacities……………………………………………………………. 13

Payloads/Capacities…………………………………………………………………………….. 14

Dimensions…………………………………………………………………………………….. 16

Weights……………………………………………………………………………………….. 17

Coolant Compound Table………………………………………………………………………….. 17

Direct and/or Indirect Visibility……………………………………………………………………. 18

Wheels/Tires…………………………………………………………………………………… 19

Electrical…………………………………………………………………………………….. 19

Hydraulic System……………………………………………………………………………….. 19

Drive Hydraulics……………………………………………………………………………. 19

Work Hydraulics…………………………………………………………………………….. 19

Sound Power/Pressure Levels……………………………………………………………………… 19

Vibration Levels……………………………………………………………………………….. 20

Reference Information………………………………………………………………………………. 20

List of Abbreviations…………………………………………………………………………… 20

Standard Tightening Torques……………………………………………………………………… 21

Indicator and Operation Symbols……………………………………………………………………… 23

Safety……………………………………………………………………………………………….. 25

Safety Symbol and Signal Words………………………………………………………………………. 25

Signal Words…………………………………………………………………………………… 25

Mandatory Safety Shutdown Procedure………………………………………………………………….. 26

Before Starting……………………………………………………………………………………. 26

During Operation…………………………………………………………………………………… 28

Provision for Stability/Avoiding Rollover and Tipover Accidents…………………………………………. 30

Articulated Loader Stability………………………………………………………………………… 32

Effect of Uneven or Unstable Ground on Stability…………………………………………………… 32

Effect of Machine Travel on Stability…………………………………………………………….. 33

Effect of Load Movement on Stability……………………………………………………………… 33

Applications with Load-Handling Devices………………………………………………………………. 33

Parking the Machine………………………………………………………………………………… 33

Electrical Energy………………………………………………………………………………….. 34

Maintenance and Service Safety Practices……………………………………………………………… 34

Battery Hazards……………………………………………………………………………………. 36

Fire Hazards………………………………………………………………………………………. 36

Additional Safety Equipment…………………………………………………………………………. 37

Crystalline Silica Exposure…………………………………………………………………………. 37

Transporting the Machine……………………………………………………………………………. 37

Raising the Machine with a Crane…………………………………………………………………….. 37

Loading and Transporting the Machine…………………………………………………………………. 38

Safety Decals……………………………………………………………………………………… 38

New Decal Application…………………………………………………………………………… 38

Safety Decal Locations……………………………………………………………………………… 39

ANSI-Style and Common Safety Decal Locations………………………………………………………….. 40

ISO-Style Safety Decal Locations…………………………………………………………………….. 44

002 – Machine Service Operation…………………………………………………………………………. 47

Additional Information……………………………………………………………………………… 47

Mandatory Safety Shutdown Procedure………………………………………………………………….. 47

Preparation and Safety Instruction…………………………………………………………………… 47

Lift Structure Support……………………………………………………………………………… 47

Supporting the Lift Structure……………………………………………………………………. 47

Disengage Lift Structure Support…………………………………………………………………. 48

Hydraulics Transport Lock-Out Operation………………………………………………………………. 49

Auxiliary Circuit Pressure Relief……………………………………………………………………. 49

Raising the Machine using a Crane……………………………………………………………………. 50

Crane Lifting Preparation……………………………………………………………………….. 50

Towing……………………………………………………………………………………………. 51

Precautions……………………………………………………………………………………. 51

Towing Preparation……………………………………………………………………………… 51

Towing Procedure……………………………………………………………………………….. 52

After Towing…………………………………………………………………………………… 53

Loading and Transporting the Machine on a Transport Vehicle…………………………………………….. 53

Long-Term Storage………………………………………………………………………………….. 54

Before Storage…………………………………………………………………………………. 54

After Storage………………………………………………………………………………….. 54

Final Shutdown / Decommissioning…………………………………………………………………….. 54

Before Disposal………………………………………………………………………………… 54

Machine Disposal……………………………………………………………………………….. 55

010 – Engine………………………………………………………………………………………….. 57

Engine Specifications………………………………………………………………………………. 57

Engine Assembly……………………………………………………………………………………. 58

Engine Operation…………………………………………………………………………………… 63

Engine Maintenance…………………………………………………………………………………. 63

Belt Maintenance / Service………………………………………………………………………….. 63

Alternator Belt Removal…………………………………………………………………………. 63

Alternator Belt Installation…………………………………………………………………….. 64

Engine Removal…………………………………………………………………………………….. 65

Engine Installation………………………………………………………………………………… 72

Engine Troubleshooting……………………………………………………………………………… 79

Engine Diagnostic Trouble Codes (DTC)…………………………………………………………….. 80

011 – Engine Cooling System…………………………………………………………………………….. 99

Engine Cooling System General Information…………………………………………………………….. 99

Cooling Package Removal……………………………………………………………………………..103

Cooling Package Installation…………………………………………………………………………106

020 – Drive System / Transmission………………………………………………………………………..109

Drive System General Information……………………………………………………………………..109

Drive Hydraulics………………………………………………………………………………..110

Hydrostatic Travel Motor…………………………………………………………………………….113

Pump and Drive Motor Error Codes……………………………………………………………………..114

Hydrostatic Travel Motor Removal………………………………………………………………….115

Hydrostatic Travel Motor Installation……………………………………………………………..117

Travel Motor Service………………………………………………………………………………..121

Hand/Foot Throttle………………………………………………………………………………….122

Transmission Control Unit (TCU) / Drive Controller……………………………………………………..122

Travel Drive Control Module Error Codes……………………………………………………………122

030 – Axles……………………………………………………………………………………………125

Hydrostatic Drive Motor……………………………………………………………………………..126

040 – Brake……………………………………………………………………………………………127

Brake/Inching Pedal Calibration………………………………………………………………………127

Bleeding the Brake System……………………………………………………………………………129

Brake/Inching Pedal Electrical……………………………………………………………………….130

Parking Brake Adjustment/Service……………………………………………………………………..130

Parking Brake Cable Adjustment……………………………………………………………………130

050 – Lift Structure……………………………………………………………………………………131

Lift Structure Hydraulics……………………………………………………………………………139

Lift Structure Support…………………………………………………………………………..139

070 – Hydraulics……………………………………………………………………………………….141

Hydraulic System General Information………………………………………………………………….141

Open-Type / Hydrostatic Systems…………………………………………………………………..141

Open-Type…………………………………………………………………………………..141

Hydrostatic-Type…………………………………………………………………………….141

General Hydraulic Service Notes………………………………………………………………………142

Hydraulic Hoses/Tubes……………………………………………………………………………142

Seals………………………………………………………………………………………….142

Main Pressure Test and Adjustment…………………………………………………………………….146

High-Flow Auxiliary Hydraulics Pressure Test and Adjustment……………………………………………..147

Control Valve………………………………………………………………………………………149

Main Control Valve Removal……………………………………………………………………….151

Main Control Valve Installation…………………………………………………………………..151

Control Valve Disassembly/Assembly………………………………………………………………..152

Disassembly…………………………………………………………………………………152

Control Valve Assembly……………………………………………………………………….153

Tilt/Lift Cylinder Tests…………………………………………………………………………….153

Tilt Cylinder Drift Test…………………………………………………………………………153

Tilt Cylinder Internal Leakage Test……………………………………………………………….153

Lift Cylinder Drift Test…………………………………………………………………………154

Lift Cylinder Internal Leakage Test……………………………………………………………….155

Hydraulic Cylinder Disassembly/ Assembly………………………………………………………………156

Cylinder Disassembly…………………………………………………………………………….156

Cylinder Assembly……………………………………………………………………………….156

Bleeding Air After Cylinder Installation…………………………………………………………..156

Hydraulic Solenoid Valves and Tests…………………………………………………………………..157

Standard Auxiliary (Front Standard Only) Hydraulics Pressure Release Valve and Test…………………….157

Secondary Auxiliary Hydraulics Diverter Valve and Test………………………………………………159

Machines equipped with secondary auxiliary (2nd front auxiliary and rear auxiliary) hydraulics only:….159

Front High-Flow Auxiliary Hydraulics Valve and Test…………………………………………………160

Lift/Tilt Lockout Valves and Test…………………………………………………………………162

Multi-Purpose Valve Tests………………………………………………………………………..163

Power-A-Tach/Quick Attachment Lock Solenoids Test……………………………………………….164

Differential Lock Solenoid Test……………………………………………………………….164

Standard Auxiliary Hydraulics Forward/Reverse Solenoid Test………………………………………166

Hydraglide…………………………………………………………………………………………167

Hydraglide™ Ride Control Solenoid Test…………………………………………………………….168

Solenoid Valve Disassembly/ Reassembly………………………………………………………………..169

Steering…………………………………………………………………………………………..170

Steering Priority Test…………………………………………………………………………..171

Hydraulic Gear Pump…………………………………………………………………………………172

Hydraulic Gear Pump Removal………………………………………………………………………172

Hydraulic Gear Pump Installation………………………………………………………………….174

Hydraulic System Troubleshooting……………………………………………………………………..176

Hydrostatic Travel Drive System………………………………………………………………………178

Hydrostatic System Basics………………………………………………………………………..178

Hydrostatic System Overview…………………………………………………………………..178

System Control………………………………………………………………………………179

Over-pressure/Over-heating Conditions………………………………………………………….180

Charge Pressure Test and Adjustment……………………………………………………………….183

High-Pressure (Drive) Test……………………………………………………………………….184

Hydrostatic Pump Pressure Relief Valves……………………………………………………………184

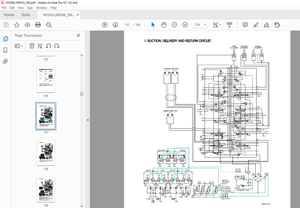

071 – Hydraulic Schematics………………………………………………………………………………187

Hydraulics Schematic – Standard-Flow Auxiliary…………………………………………………………187

Hydraulics Schematic – High-Flow Auxiliary…………………………………………………………….188

Hydraulics Schematic – Standard-Flow Auxiliary with Options……………………………………………..189

Hydraulics Schematic – High-Flow Auxiliary with Options…………………………………………………190

080 – Electrical System…………………………………………………………………………………191

Battery……………………………………………………………………………………………197

Battery Compartment Prop…………………………………………………………………………197

Power Distribution………………………………………………………………………………….198

Power Distribution Module Fuse Socket Test…………………………………………………………198

Fuses and Relays………………………………………………………………………………..199

Cab/Canopy Fuse Box………………………………………………………………………….199

HVAC Fuse Box……………………………………………………………………………….200

Engine Compartment Fuse Box…………………………………………………………………..201

Battery Compartment Fuses…………………………………………………………………….202

Engine Compartment Relays…………………………………………………………………….202

Front Electrical Auxiliary Relays……………………………………………………………..202

Rear Window Defrost Timer Relay/Diode (Machine Equipped with Heat/Air Conditioning)…………………203

Chassis Grounds…………………………………………………………………………………203

Relay Testing…………………………………………………………………………………..203

Machine Test………………………………………………………………………………..203

Bench Test………………………………………………………………………………….204

Control Modules…………………………………………………………………………………….204

J1939 Data Connector………………………………………………………………………………..204

Easy Manager……………………………………………………………………………………….204

Easy Manager Fuse……………………………………………………………………………….205

Easy Manager Relay………………………………………………………………………………205

Throttle Pedal Electrical/CAN………………………………………………………………………..205

Hand Throttle Electrical…………………………………………………………………………….207

Brake/Inching Pedal Electrical……………………………………………………………………….208

Wire Harness Diagrams…………………………………………………………………………………..209

Wire Harness Diagram — Front Chassis…………………………………………………………………209

Wire Harness Diagram — Rear Chassis………………………………………………………………….210

Wire Harness Diagram — Lower ROPS/FOPS (1 of 2)……………………………………………………….211

Wire Harness Diagram — Lower ROPS/FOPS (2 of 2)……………………………………………………….212

Wire Harness Diagram — Upper ROPS/FOPS……………………………………………………………….213

Wire Harness Diagram — Steering Column……………………………………………………………….214

Wire Harness Diagram — HVAC…………………………………………………………………………215

Wire Harness Diagram — Rear Electrical Auxiliary………………………………………………………216

Wire Harness Diagram — Front Electrical Auxiliary……………………………………………………..217

Electrical Schematics…………………………………………………………………………………..218

Electrical Schematic – Rear Chassis…………………………………………………………………..218

Electrical Schematic – Front Chassis………………………………………………………………….219

Electrical Schematic – Power Distribution……………………………………………………………..220

Electrical Schematic – Grounds……………………………………………………………………….221

Electrical Schematic – Lower ROPS/FOPS………………………………………………………………..222

Electrical Schematic – Upper ROPS/FOPS………………………………………………………………..223

Electrical Schematic – Steering Column………………………………………………………………..224

Electrical Schematic – HVAC………………………………………………………………………….225

Electrical Schematic – CAN Network……………………………………………………………………226

Electrical Schematic – Lights………………………………………………………………………..227

Electrical Schematic – Engine (Deutz TD 2.2 L3)………………………………………………………..228

Electrical Schematic — Electrical Auxiliary Circuits……………………………………………………229

Electrical Schematic — Hydraulics Electrical…………………………………………………………..230

085 – Operation Station…………………………………………………………………………………231

HVAC System………………………………………………………………………………………..231

Air Conditioning Service…………………………………………………………………………236

Air Conditioning System Port Access……………………………………………………………236

Air Conditioning Refrigerant Recovery………………………………………………………….236

Air Conditioning System Charging………………………………………………………………236

Air Conditioning Compressor………………………………………………………………………237

Air Conditioning Belt Maintenance / Service………………………………………………………..238

Air Conditioning Belt Removal…………………………………………………………………238

Air Conditioning Belt Installation…………………………………………………………….238

090 – Chassis………………………………………………………………………………………….239

Chassis General Information………………………………………………………………………….239

Side Panel Removal/Replacement……………………………………………………………………….239

Rear Cover Removal/Replacement……………………………………………………………………….241

Service Cover Removal/Replacement…………………………………………………………………….241

ROPS/FOPS………………………………………………………………………………………….242

ROPS/FOPS Removal……………………………………………………………………………….243

ROPS/FOPS Installation…………………………………………………………………………..249

Engine Cover Removal/Replacement……………………………………………………………………..256

Engine Cover Removal…………………………………………………………………………….256

Engine Cover Replacement…………………………………………………………………………257

Articulation Joint………………………………………………………………………………….258

Electrical Control System……………………………………………………………………………….259

Electrical Control System General Information………………………………………………………….259

CAN System General Information……………………………………………………………………259

Control Modules…………………………………………………………………………………….260

Machine Control Unit (MCU)……………………………………………………………………….260

Transmission Control Unit (TCU)…………………………………………………………………..264

Engine Control Unit (ECU)………………………………………………………………………..264

Display/Indicators/Controls………………………………………………………………………264

Display…………………………………………………………………………………….264

Switches……………………………………………………………………………………264

Joystick……………………………………………………………………………………265

Control Lever (Option)……………………………………………………………………….265

CAN System Service/Computer Connection………………………………………………………………..266

J1939 Data Connector…………………………………………………………………………….266

CAN/Computer Connection Harnesses…………………………………………………………………266

Service Adapter Harness………………………………………………………………………266

MCU/TCU Data Connection Harness……………………………………………………………….266

Display Data Connection Harness……………………………………………………………….267

Deutz Engine CAN/Computer Connection Harness (SerDia)……………………………………………….267

Danfoss Service Tool (Plus+1) Software…………………………………………………………….268

Display Service Software Update/Pass Code Reset…………………………………………………….268

Operation/Controller Area Network (CAN) Functional Organization………………………………………….269

Operation/CAN Function Organization Overview……………………………………………………….269

HydralocTM (Safety Interlock) Electrical Functional Detail…………………………………………..270

Ignition/Starting Electrical Functional Detail……………………………………………………..271

Engine Operation Electrical Functional Detail………………………………………………………273

Lift Structure Electrical Functional Detail………………………………………………………..273

Drive System Electrical Functional Detail………………………………………………………….274

Auxiliary Hydraulics Electrical Functional Detail…………………………………………………..278

Lighting Electrical Functional Detail……………………………………………………………..280

Accessories and Options Electrical Functional Detail……………………………………………………282

CAN/Control System Troubleshooting……………………………………………………………………284

Inputs/Outputs Detail……………………………………………………………………………284

Error Codes…………………………………………………………………………………….300

MCU CAN Error Codes……………………………………………………………………………..300

Index…………………………………………………………………………………………………303

Torque Specifications…………………………………………………………………………………..307