$34

Gehl All Wheel Steer Loader 680 Service Manual 918123A – PDF DOWNLOAD

Gehl All Wheel Steer Loader 680 Service Manual 918123A – PDF DOWNLOAD

FILE DETAILS:

Gehl All Wheel Steer Loader 680 Service Manual 918123A – PDF DOWNLOAD

Language : English

Pages : 212

Downloadable : Yes

File Type : PDF

Size: 35.1 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gehl All Wheel Steer Loader 680 Service Manual 918123A – PDF DOWNLOAD

Beginning Serial Number: 343010001

Operation:

1. 1 Important information on this service manual:

Your decision to purchase this piece of Gehl equipment was a good one. We are sure that

your decision was carefully considered and that you are looking forward to many years of

reliable performance from this machine.

Gehl Company has invested much time and effort in developing its lines of equipment. The

equipment you have purchased is built with a great deal of pride, and designed to provide

long life, efficient operation, durability and dependability.

Modern machinery has become more sophisticated and, with that in mind, Gehl Company

asks that you read and COMPLETELY understand the contents of this manual and

become familiar with your new machine, BEFORE attempting to service it.

This manual was developed specifically for the machine you have purchased. The information

within is for your assistance in preparing, adjusting, maintaining and servicing your

machine. More importantly, this manual provides a service plan for safe and proper use of

your machine. Refer to the Table of Contents for an outline (by chapters) of this manual.

Use the Index, located at the back of this manual, for specific chapter and topic/page

number references.

If this machine is resold, Gehl Company recommends that this manual be given to the new

owner.

If this machine was purchased “used,” or if the owner’s address has changed, please provide

your Gehl dealer or Gehl Company with the owner’s name and current address, along

with the machine model and serial number. This will allow the registered owner information

to be updated, so that the owner can be notified directly in case of an important product

issue, such as a safety update program.

“Right” and “left” are determined from the position of sitting in the operator’s seat, facing

forward.

Gehl Company reserves the right to make changes or improvements in the design or construction

of any part without incurring the obligation to install such changes on any unit

previously delivered.

Throughout this manual information is provided that is introduced by the word NOTE or

IMPORTANT. Be sure to read carefully and comply with the message or directive given.

Following this information will improve your maintenance efficiency, help you to avoid

costly breakdowns or unnecessary damage and extend your machine’s life.

Operational safety and readiness of the machine depend partially on maintenance and

service of the machine. This is why regular maintenance and service work is absolutely

necessary. Extensive maintenance and repair work must always be carried out by a qualified

technician with appropriate training. Insist on using Gehl original service parts when

carrying out maintenance and repair work. This ensures operational safety and readiness

of your machine, and maintains its value.

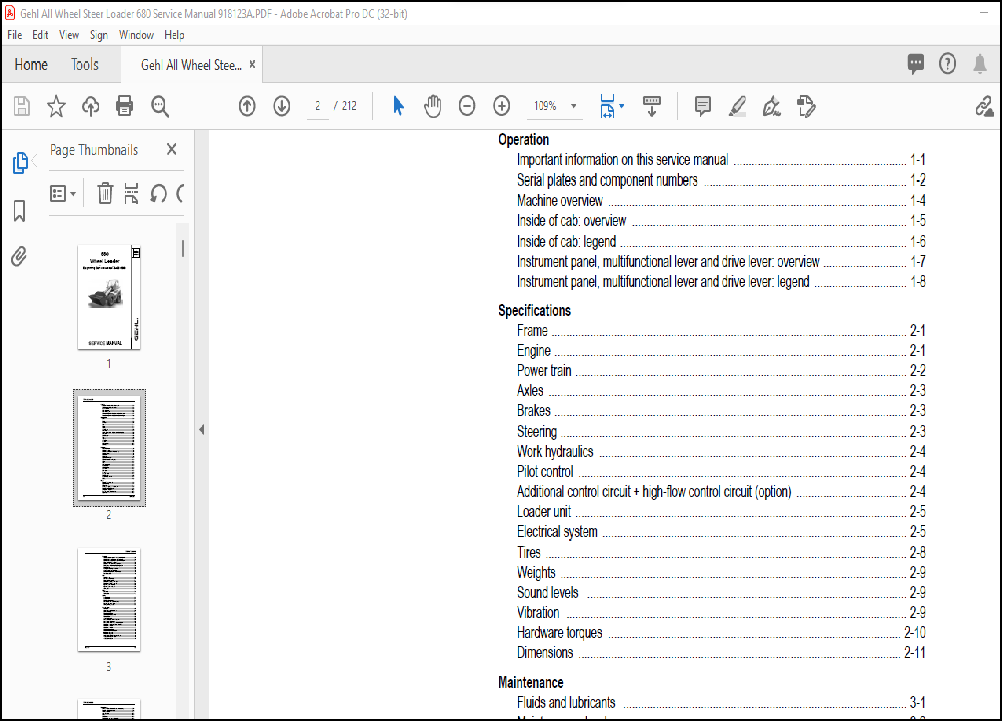

TABLE OF CONTENTS:

Gehl All Wheel Steer Loader 680 Service Manual 918123A – PDF DOWNLOAD

Operation

Important information on this service manual …………………………………………………. 1-1

Serial plates and component numbers ………………………………………………………….. 1-2

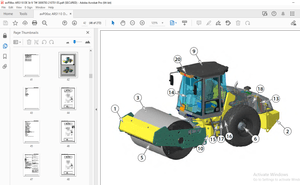

Machine overview ………………………………………………………………………………………. 1-4

Inside of cab: overview ……………………………………………………………………………….. 1-5

Inside of cab: legend …………………………………………………………………………………… 1-6

Instrument panel, multifunctional lever and drive lever: overview ………………………. 1-7

Instrument panel, multifunctional lever and drive lever: legend …………………………. 1-8

Specifications

Frame ……………………………………………………………………………………………………….. 2-1

Engine ………………………………………………………………………………………………………. 2-1

Power train ………………………………………………………………………………………………… 2-2

Axles ………………………………………………………………………………………………………… 2-3

Brakes ………………………………………………………………………………………………………. 2-3

Steering …………………………………………………………………………………………………….. 2-3

Work hydraulics …………………………………………………………………………………………. 2-4

Pilot control ……………………………………………………………………………………………….. 2-4

Additional control circuit + high-flow control circuit (option) ………………………………. 2-4

Loader unit ………………………………………………………………………………………………… 2-5

Electrical system ………………………………………………………………………………………… 2-5

Tires …………………………………………………………………………………………………………. 2-8

Weights …………………………………………………………………………………………………….. 2-9

Sound levels …………………………………………………………………………………………….. 2-9

Vibration …………………………………………………………………………………………………… 2-9

Hardware torques …………………………………………………………………………………….. 2-10

Dimensions ……………………………………………………………………………………………… 2-11

Maintenance

Fluids and lubricants ………………………………………………………………………………….. 3-1

Maintenance decal ……………………………………………………………………………………… 3-2

Maintenance schedule Model 680 (overview) …………………………………………………. 3-4

Maintenance items ……………………………………………………………………………………… 3-7

Introduction ……………………………………………………………………………………………….. 3-7

Fuel system ……………………………………………………………………………………………….. 3-8

Engine lubrication system ………………………………………………………………………….. 3-11

Engine and hydraulics cooling system …………………………………………………………. 3-14

Air filter ……………………………………………………………………………………………………. 3-15

V-belt ………………………………………………………………………………………………………. 3-17

Gearboxes and axles ………………………………………………………………………………… 3-18

Hydraulic system ………………………………………………………………………………………. 3-24

Lubrication points ……………………………………………………………………………………… 3-28

Attachments …………………………………………………………………………………………….. 3-29

Brake system …………………………………………………………………………………………… 3-30

Tire care ………………………………………………………………………………………………….. 3-31

Changing wheels …………………………………………………………………………………….. 3-32

Electrical system ………………………………………………………………………………………. 3-33

General maintenance work ………………………………………………………………………… 3-36

Heating ……………………………………………………………………………………………………. 3-39

Engine

Engine BF4M 2011: overview ………………………………………………………………………. 4-1

Engine oil cooling ……………………………………………………………………………………….. 4-2

Fuel system ……………………………………………………………………………………………….. 4-3

Checking and adjusting valve tip clearance ……………………………………………………. 4-4

Replacing the fuel injection pump …………………………………………………………………. 4-5

Setting charge air pressure ………………………………………………………………………… 4-10

Removing/mounting the cylinder head …………………………………………………………. 4-12

Engine trouble ………………………………………………………………………………………….. 4-16

Table of contents

918123/AP0605 I-2

Table of contents

Power train

Variable displacement pump 12 – 25 mph (20 – 40 km/h) ……………………………….. 5-1

Hydraulic motor – control element 12 mph (20 km/h) ………………………………………. 5-2

Hydraulic motor – hydraulic connections 12 mph (20 km/h) ……………………………… 5-3

Power train diagram 12 mph (20 km/h) …………………………………………………………. 5-4

ECO-Speed – hydraulic motor 25 mph (40 km/h) ……………………………………………. 5-5

ECO speed power train (25 mph [40 km/h]): diagram ……………………………………… 5-7

Test report model ……………………………………………………………………………………….. 5-8

Towing and transporting the machine ……………………………………………………………. 5-9

Check and adjustment instructions ……………………………………………………………… 5-10

Drive electronics operator’s manual (SUSMIC) …………………………………………….. 5-17

Procedures (sensor) …………………………………………………………………………………. 5-18

Axles

Serial plate – axle ………………………………………………………………………………………. 6-1

Front axle screw connections ………………………………………………………………………. 6-2

Rear axle screw connections ……………………………………………………………………….. 6-3

Drain, fill and check plug – front axle …………………………………………………………….. 6-4

Drain, fill and check plug – rear axle ……………………………………………………………… 6-5

Tightening torques – front axle …………………………………………………………………….. 6-6

Tightening torques – rear axle ……………………………………………………………………… 6-7

Sealing work ……………………………………………………………………………………………… 6-8

Brakes

Brake circuit ………………………………………………………………………………………………. 7-1

Service brake …………………………………………………………………………………………….. 7-3

Steering

Steering circuit …………………………………………………………………………………………… 8-1

Steering circuit …………………………………………………………………………………………… 8-2

Hydraulic ports on servostat ………………………………………………………………………… 8-3

Pressure relief valve – servostat: settings ……………………………………………………… 8-3

Front/rear axle steering cylinder …………………………………………………………………… 8-4

Setting the steering sensors ………………………………………………………………………… 8-5

Hydraulic system

Test report ………………………………………………………………………………………………… 9-1

Control valve connections: overview …………………………………………………………….. 9-2

Control valve: design ………………………………………………………………………………….. 9-3

Pilot control unit: design ………………………………………………………………………………. 9-4

Valve block connections: overview ……………………………………………………………….. 9-5

Pilot control circuit ………………………………………………………………………………………. 9-6

Work hydraulics circuit ………………………………………………………………………………… 9-7

Load stabilizer circuit with hose burst valve ……………………………………………………. 9-8

Load stabilizer: circuit diagram …………………………………………………………………….. 9-9

Load stabilizer with hose burst valve: circuit diagram …………………………………….. 9-10

Hose burst valve with load stabilizer: connections ………………………………………… 9-11

Hose burst valve circuit ……………………………………………………………………………… 9-12

Hose burst valve circuit ……………………………………………………………………………… 9-13

4th control circuit (front/rear) ………………………………………………………………………. 9-14

4th control circuit (front/rear) circuit …………………………………………………………….. 9-15

Lift cylinder: sealing work …………………………………………………………………………… 9-16

Tilt cylinder: sealing work …………………………………………………………………………… 9-17

Control cylinder (quickhitch frame): sealing work ………………………………………….. 9-18

Work hydraulics diagram: legend ……………………………………………………………….. 9-20

Work hydraulics diagram …………………………………………………………………………… 9-21

I-3 918123/AP0605

Table of contents

Electrical system

Ohm’s Law (current, voltage, resistance generates power) …………………………….. 10-1

Measuring equipment and methods …………………………………………………………….. 10-1

Terminal description ………………………………………………………………………………….. 10-3

Cable color-coding ………………………………………………………………………………….. 10-10

Relays …………………………………………………………………………………………………… 10-11

Electrical units ………………………………………………………………………………………… 10-12

Fuse box on left and right of steering column ……………………………………………… 10-12

Main fuse box with relays …………………………………………………………………………. 10-13

Relays …………………………………………………………………………………………………… 10-14

Steering electronics ………………………………………………………………………………… 10-15

Instrument panel, fuse box, relays: overview ………………………………………………. 10-16

Legend for wiring diagram ………………………………………………………………………. 10-17

Wiring diagram ………………………………………………………………………………………. 10-18

Legend for wiring harness 207749: engine – frame …………………………………….. 10-19

Wiring harness: 207749: engine – frame …………………………………………………… 10-20

Legend for wiring harness 207750: cab ……………………………………………………… 10-21

Wiring harness 207750: cab ……………………………………………………………………. 10-22

Wiring harness 208562: control lever base (option) …………………………………….. 10-23

Wiring harness 207968: control lever base (standard) ………………………………… 10-24

Wiring harness 207810: steering-column control lever ………………………………… 10-25

Wiring harness 208111: additional control circuit ……………………………………….. 10-26

Wiring harness 208609 (joystick) ………………………………………………………………. 10-27

Electronics between joystick and wiring harness 208609 ……………………………… 10-27

Wiring harness 207539: rotating beacon (option) ……………………………………….. 10-28

Wiring harness 207539: front working light (option) …………………………………….. 10-29

Wiring harness 208589: load stabilizer (option) ………………………………………….. 10-30

Wiring harness 208676: solenoid valve – load stabilizer (option) ………………….. 10-31

Wiring harness 209185: inching sensor …………………………………………………….. 10-32

Wiring harness 209185: crawler gear – potentiometer …………………………………. 10-33

Wiring harness 208563: numberplate light (option) …………………………………….. 10-34

Wiring harness 208113: air-suspension operator’s seat (option) …………………… 10-35

Wiring harness: air conditioning (option) ……………………………………………………. 10-36

Plug – SUSMIC ………………………………………………………………………………………. 10-37

Relay assignment …………………………………………………………………………………… 10-38

Plug and socket connection: steering electronics – steering-column control lever ……..

10-39

Plug and socket connection: fuse box and relay (left) ………………………………….. 10-40

Plug and socket connection: fuse box and relay (right) ………………………………… 10-41

Plug and socket connection: cab ………………………………………………………………. 10-42

Plug and socket connection: instrument panel ……………………………………………. 10-42

Plug and socket connections: load stabilizer, speedometer 25 mph (40 km/h), front

socket ……………………………………………………………………………………………………. 10-43