$36

Gehl Articulated Loader 650, 750, T750 Service Manual 50940441C – PDF DOWNLOAD

Gehl Articulated Loader 650, 750, T750 Service Manual 50940441C – PDF DOWNLOAD

FILE DETAILS:

Gehl Articulated Loader 650, 750, T750 Service Manual 50940441C – PDF DOWNLOAD

Language : English

Pages : 650

Downloadable : Yes

File Type : PDF

Size: 97.8 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gehl Articulated Loader 650, 750, T750 Service Manual 50940441C – PDF DOWNLOAD

Gehl 650

Gehl 750

Gehl T750

Mustang 608

Mustang 708

Mustang 708T

Manitou MLA-6

Manitou MLA-7

Manitou MLA-T 516

SAFETY:

Before operating the machine, first read and study the safety information in this manual. Be sure that anyone who operates or works on the machine is familiar with the safety precautions. This includes providing translations of the warnings and instructions for operators who are not fluent in reading English.

• It is essential that operators be thoroughly trained in the safe operation of the machine and load handling. Such training should be presented completely to all new operators and not condensed for those claiming previous experience.• Operators must not be physically or mentally impaired or under the influence of drugs or alcohol. Do not allow minors or unqualified personnel to operate the machine or to be near the machine unless they are properly supervised. It is recommended that the operator be capable of obtaining a valid motor vehicle operator’s license.• Do not use the machine for any application or purpose other than those described in this manual or in manuals supplied with any attachments used with the machine.• Use of the machine is subject to certain hazards that cannot be eliminated by mechanical means but only by exercising intelligence, care, and common sense. Examples of such hazards include but are not limited to: hillside operation, overloading, load instability, poor maintenance, operating too fast for conditions, and using the machine for a purpose for which it was not intended or designed.• Manitou Group always takes operator’s safety into consideration during the design process. Guards and shields are provided, which protect the operator and bystanders from moving parts and other hazards. Operators must be alert, however, because some areas cannot be guarded or shielded without preventing or interfering with proper operation.

TABLE OF CONTENTS:

Gehl Articulated Loader 650, 750, T750 Service Manual 50940441C – PDF DOWNLOAD

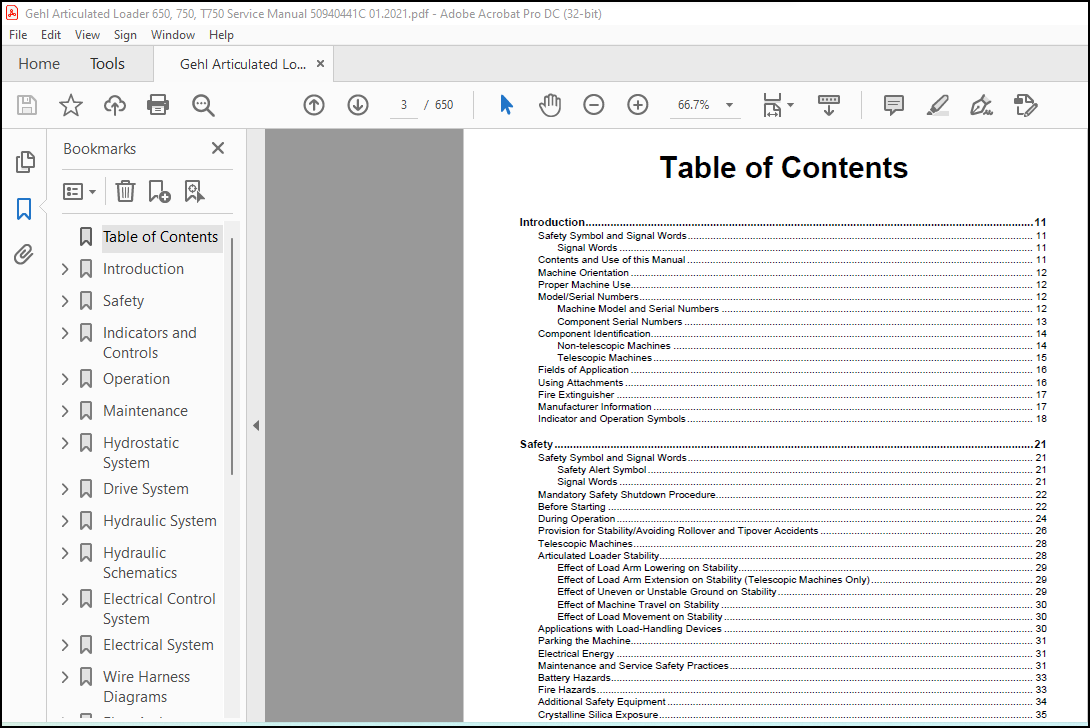

Table of Contents……………………………………………………………………………………………………………………………………… 3

Introduction………………………………………………………………………………………………………………………………………….. 13

Safety Symbol and Signal Words………………………………………………………………………………………………………………………. 13

Signal Words…………………………………………………………………………………………………………………………………… 13

Legal Notices……………………………………………………………………………………………………………………………………… 13

Software IP……………………………………………………………………………………………………………………………………. 13

Data Privacy…………………………………………………………………………………………………………………………………… 13

Contents and Use of this Manual……………………………………………………………………………………………………………………… 14

Machine Orientation………………………………………………………………………………………………………………………………… 14

Proper Machine Use…………………………………………………………………………………………………………………………………. 14

Model/Serial Numbers……………………………………………………………………………………………………………………………….. 16

Machine Model and Serial Numbers…………………………………………………………………………………………………………………. 16

Component Serial Numbers………………………………………………………………………………………………………………………… 16

Component Identification……………………………………………………………………………………………………………………………. 17

Non-telescopic Machines…………………………………………………………………………………………………………………………. 17

Telescopic Machines…………………………………………………………………………………………………………………………….. 18

Attachments……………………………………………………………………………………………………………………………………….. 19

Using Attachments………………………………………………………………………………………………………………………………….. 19

Fire Extinguisher………………………………………………………………………………………………………………………………….. 20

Manufacturer Information……………………………………………………………………………………………………………………………. 20

Indicator and Operation Symbols……………………………………………………………………………………………………………………… 21

Safety……………………………………………………………………………………………………………………………………………….. 23

Safety Symbol and Signal Words………………………………………………………………………………………………………………………. 23

Safety Alert Symbol…………………………………………………………………………………………………………………………….. 23

Signal Words…………………………………………………………………………………………………………………………………… 23

Mandatory Safety Shutdown Procedure………………………………………………………………………………………………………………….. 24

Before Starting……………………………………………………………………………………………………………………………………. 24

During Operation…………………………………………………………………………………………………………………………………… 26

Provision for Stability/Avoiding Rollover and Tipover Accidents…………………………………………………………………………………………. 28

Telescopic Machines………………………………………………………………………………………………………………………………… 30

Articulated Loader Stability………………………………………………………………………………………………………………………… 30

Effect of Load Arm Lowering on Stability………………………………………………………………………………………………………….. 31

Effect of Load Arm Extension on Stability (Telescopic Machines Only)…………………………………………………………………………………. 31

Effect of Uneven or Unstable Ground on Stability…………………………………………………………………………………………………… 31

Effect of Machine Travel on Stability…………………………………………………………………………………………………………….. 32

Effect of Load Movement on Stability……………………………………………………………………………………………………………… 32

Applications with Load-Handling Devices………………………………………………………………………………………………………………. 32

Parking the Machine………………………………………………………………………………………………………………………………… 33

Electrical Energy………………………………………………………………………………………………………………………………….. 33

Maintenance and Service Safety Practices……………………………………………………………………………………………………………… 33

Battery Hazards……………………………………………………………………………………………………………………………………. 35

Fire Hazards………………………………………………………………………………………………………………………………………. 35

Additional Safety Equipment…………………………………………………………………………………………………………………………. 36

Crystalline Silica Exposure…………………………………………………………………………………………………………………………. 37

Transporting the Machine……………………………………………………………………………………………………………………………. 37

Raising the Machine with a Crane…………………………………………………………………………………………………………………….. 37

Loading and Transporting the Machine…………………………………………………………………………………………………………………. 37

Safety Decals……………………………………………………………………………………………………………………………………… 38

New Decal Application…………………………………………………………………………………………………………………………… 38

Non-Telescopic Machines…………………………………………………………………………………………………………………………. 39

Telescopic Machines…………………………………………………………………………………………………………………………….. 40

ANSI-Style and Common Safety Decal Locations………………………………………………………………………………………………………….. 41

ISO-Style Safety Decal Locations…………………………………………………………………………………………………………………….. 46

Indicators and Controls………………………………………………………………………………………………………………………………… 51

Multi-Function Display……………………………………………………………………………………………………………………………… 53

Multi-Function Display Symbols…………………………………………………………………………………………………………………… 54

Multi-Function Display Screens…………………………………………………………………………………………………………………… 56

Control Keypad…………………………………………………………………………………………………………………………………….. 62

Switch Panel………………………………………………………………………………………………………………………………………. 63

Audible Alerts…………………………………………………………………………………………………………………………………. 64

Telescopic Machines Load/Level Indicators (Telescopic Machines)…………………………………………………………………………………………. 64

Load Arm Angle Indicator (Telescopic Machines)…………………………………………………………………………………………………….. 64

Load Arm Extension Indicator (Domestic Telescopic Machines Only)…………………………………………………………………………………….. 64

Longitudinal Load Moment Indicator (LLMI) (EU Telescopic Machines Only)………………………………………………………………………………. 65

Lateral Level Indicator (Telescopic Machines)……………………………………………………………………………………………………… 65

Ignition Switch……………………………………………………………………………………………………………………………………. 66

Operator’s Seat/Armrest…………………………………………………………………………………………………………………………….. 66

Multi-Function Joystick…………………………………………………………………………………………………………………………….. 67

Load Arm/Attachment Tilt Control…………………………………………………………………………………………………………………. 67

Telescopic Load Arm Extend/Retract Control Switch (Telescopic Machines)………………………………………………………………………………. 67

Non-Telescopic Machines Float Controls……………………………………………………………………………………………………………. 68

Non-Telescopic Machines Load Arm Float Detent Lock Disable (if equipped)………………………………………………………………………….. 68

Telescopic Machines Raise Float Controls………………………………………………………………………………………………………….. 69

Travel Direction Switch…………………………………………………………………………………………………………………………. 69

Travel Speed Range Selection Button………………………………………………………………………………………………………………. 70

Differential Lock Button………………………………………………………………………………………………………………………… 70

Auxiliary Hydraulics Control Switch………………………………………………………………………………………………………………. 71

Parking Brake……………………………………………………………………………………………………………………………………… 71

Parking Brake Adjustment/Service…………………………………………………………………………………………………………………. 71

Control Lever (Option)……………………………………………………………………………………………………………………………… 72

Throttle Controls………………………………………………………………………………………………………………………………….. 72

Travel Controls……………………………………………………………………………………………………………………………………. 73

Travel Direction Switch…………………………………………………………………………………………………………………………. 73

Travel Pedal…………………………………………………………………………………………………………………………………… 73

Brake/Inching Pedal…………………………………………………………………………………………………………………………….. 74

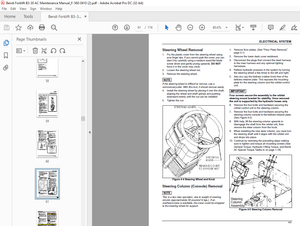

Steering Wheel…………………………………………………………………………………………………………………………………. 74

Steering Column Adjustment…………………………………………………………………………………………………………………… 74

High/Low Travel Speed Selection……………………………………………………………………………………………………………………… 75

Constant Speed (Option)…………………………………………………………………………………………………………………………….. 75

Differential Lock………………………………………………………………………………………………………………………………….. 76

Engine Off Load Arm Lower…………………………………………………………………………………………………………………………… 76

Non-Telescopic Machines…………………………………………………………………………………………………………………………. 76

Telescopic Machines…………………………………………………………………………………………………………………………….. 76

Hydraulics Transport Lock-out……………………………………………………………………………………………………………………….. 76

Attachment Mounting………………………………………………………………………………………………………………………………… 77

Quick Attachment Hitch………………………………………………………………………………………………………………………….. 77

Auxiliary Hydraulic System………………………………………………………………………………………………………………………….. 77

Auxiliary Circuit Pressure Relief………………………………………………………………………………………………………………… 77

Auxiliary Hydraulic Control……………………………………………………………………………………………………………………… 78

Standard-Flow Auxiliary Hydraulics Control…………………………………………………………………………………………………….. 78

2nd Auxiliary Hydraulics Circuit (Option)……………………………………………………………………………………………………… 78

High-Flow Auxiliary Hydraulics Control (Option)………………………………………………………………………………………………… 79

Hydraglide™ Button (Option)…………………………………………………………………………………………………………………………. 79

Cooling Fan Rotation Reversing Button………………………………………………………………………………………………………………… 79

Cab Heat and Air Conditioning (HVAC)…………………………………………………………………………………………………………………. 80

Work Lights Button…………………………………………………………………………………………………………………………………. 80

Load Arm Lights Button (Telescopic Machines Only)……………………………………………………………………………………………………… 81

Beacon (Option)……………………………………………………………………………………………………………………………………. 81

Windshield Wiper/Washer and Defrost………………………………………………………………………………………………………………….. 82

Windshield Wiper Button…………………………………………………………………………………………………………………………. 82

Windshield Washer Button………………………………………………………………………………………………………………………… 82

Washer Fluid Reservoir………………………………………………………………………………………………………………………….. 82

Rear Window/Washer Switch……………………………………………………………………………………………………………………….. 82

Rear Window Defrost Switch………………………………………………………………………………………………………………………. 82

12V Accessory Power Outlet………………………………………………………………………………………………………………………….. 83

External 12V Attachment Power Connections (Option)…………………………………………………………………………………………………….. 83

12V Attachment Power Controls……………………………………………………………………………………………………………………. 83

Front Installation………………………………………………………………………………………………………………………….. 83

Rear Installation…………………………………………………………………………………………………………………………… 83

External 12V Attachment Power Extension Harness……………………………………………………………………………………………………. 84

Battery Disconnect Switch…………………………………………………………………………………………………………………………… 84

Operation…………………………………………………………………………………………………………………………………………….. 85

Operational Checks…………………………………………………………………………………………………………………………………. 85

Pre-Start Checks……………………………………………………………………………………………………………………………….. 85

Checks During Operation…………………………………………………………………………………………………………………………. 86

Parking Checks…………………………………………………………………………………………………………………………………. 86

Before Operation…………………………………………………………………………………………………………………………………… 87

Cab Entry and Exit……………………………………………………………………………………………………………………………… 87

Cab Door (Option)………………………………………………………………………………………………………………………………. 87

Door Prop………………………………………………………………………………………………………………………………….. 88

Cab Window Latches……………………………………………………………………………………………………………………………… 88

Emergency Exit…………………………………………………………………………………………………………………………………. 88

Right Window Stop………………………………………………………………………………………………………………………………. 89

Operator’s Seat Adjustment………………………………………………………………………………………………………………………. 89

Seat/Armrest Forward and Back Horizontal Adjustment…………………………………………………………………………………………….. 89

Seat Back Tilt Adjustment……………………………………………………………………………………………………………………. 90

Optional Deluxe Seat Back Adjustment………………………………………………………………………………………………………….. 90

Armrest Height Adjustment……………………………………………………………………………………………………………………….. 90

Optional Deluxe Seat Left Armrest Adjustment…………………………………………………………………………………………………… 90

Seat Belt…………………………………………………………………………………………………………………………………………. 91

Fastening/Unfastening the Seat Belt………………………………………………………………………………………………………………. 91

Dome Light………………………………………………………………………………………………………………………………………… 91

Starting the Engine………………………………………………………………………………………………………………………………… 92

Cold-Starting………………………………………………………………………………………………………………………………….. 94

After Starting…………………………………………………………………………………………………………………………………. 94

Engine Warm Up…………………………………………………………………………………………………………………………………….. 94

Run-In Period……………………………………………………………………………………………………………………………………… 95

Stopping the Engine………………………………………………………………………………………………………………………………… 95

Engine Stalling……………………………………………………………………………………………………………………………………. 95

Safety Interlock System (Hydraloc™)………………………………………………………………………………………………………………….. 95

Safety Interlock System Test…………………………………………………………………………………………………………………….. 95

Travel Drive Operation……………………………………………………………………………………………………………………………… 96

High/Low and Optional 3-Speed Travel Speed Modes…………………………………………………………………………………………………… 99

High/Low Drive Speed Button………………………………………………………………………………………………………………….. 99

3-Speed Option……………………………………………………………………………………………………………………………… 99

Differential Lock Operation……………………………………………………………………………………………………………………… 99

Constant Speed Operation (Option)…………………………………………………………………………………………………………………….100

Travel Drive Error Condition Operation (Limited and Safe Modes)………………………………………………………………………………………101

Backup Alarm (Option)……………………………………………………………………………………………………………………………101

Special Considerations for Telescopic Machines…………………………………………………………………………………………………………102

Telescopic Load Arm Operation…………………………………………………………………………………………………………………….102

Longitudinal Load Moment Indicator (LLMI) – EU Telescopic Machines Only……………………………………………………………………………….103

Load Arm Operation………………………………………………………………………………………………………………………………….104

Load Arm Travel Position…………………………………………………………………………………………………………………………104

Load Arm/Attachment Tilt Operation………………………………………………………………………………………………………………..105

Engine Off Load Arm Lower (Non-Telescopic Machines)…………………………………………………………………………………………………105

Non-Telescopic Machines Float Operation (Raise and Tilt)…………………………………………………………………………………………….106

Non-Telescopic Machines Load Arm Float Detent Lock Disable Operation (if so equipped)……………………………………………………………….107

Telescopic Machines Raise Float Operation………………………………………………………………………………………………………….107

Load Arm Extend/Retract (Telescopic Machines Only)………………………………………………………………………………………………….108

Load Arm Raise/Tilt Support (Non-Telescopic Machines Only)………………………………………………………………………………………………110

Engage Load Arm Support………………………………………………………………………………………………………………………….110

Disengage Load Arm Support……………………………………………………………………………………………………………………….111

Engage Tilt Support……………………………………………………………………………………………………………………………..112

Disengage Tilt Support…………………………………………………………………………………………………………………………..113

Self-Leveling and Return-To Dig………………………………………………………………………………………………………………………114

Self-Leveling (Load Arm Raise)……………………………………………………………………………………………………………………114

Return to Dig (Load Arm Lower)……………………………………………………………………………………………………………………114

Hydraglide™ Ride Control System (Option)………………………………………………………………………………………………………………114

Hydraulics Transport Lock-Out Operation……………………………………………………………………………………………………………….115

Connecting/Disconnecting Attachments………………………………………………………………………………………………………………….116

Power-A-Tach® System Hitch Operation………………………………………………………………………………………………………………116

Connecting Attachments Using Power-A-Tach® System Hitch………………………………………………………………………………………….116

Disconnecting Attachments Using Power-A- Tach® System Hitch………………………………………………………………………………………117

Euro-Style and 4-Point Hitch Operation…………………………………………………………………………………………………………….118

Connecting Attachments Using Euro-Style and 4-Point Hitches………………………………………………………………………………………118

Disconnecting Attachments Using Euro-Style and 4-Point Hitches……………………………………………………………………………………121

Powering Attachments with Hydraulic Function…………………………………………………………………………………………………………..122

Connecting Hydraulic Attachments to the Auxiliary Hydraulic Circuits………………………………………………………………………………….122

Disconnecting Hydraulic Attachments from the Auxiliary Hydraulics Circuit……………………………………………………………………………..124

Auxiliary Hydraulics Operation……………………………………………………………………………………………………………………124

Standard-Flow Auxiliary Hydraulics Operation……………………………………………………………………………………………………124

2nd Auxiliary Hydraulics Circuit (Option – Non- Telescopic Machines Only)………………………………………………………………………….125

High-Flow Auxiliary Hydraulics Operation……………………………………………………………………………………………………….125

14-Pin Connector (Option)……………………………………………………………………………………………………………………………126

Switch / Pin Assignments…………………………………………………………………………………………………………………………126

Working with Buckets………………………………………………………………………………………………………………………………..127

Digging Tips……………………………………………………………………………………………………………………………………127

Safety Instructions When Working with Buckets………………………………………………………………………………………………………127

Working with Buckets…………………………………………………………………………………………………………………………….128

Scooping……………………………………………………………………………………………………………………………………128

Loading…………………………………………………………………………………………………………………………………….128

Digging…………………………………………………………………………………………………………………………………….128

Grading…………………………………………………………………………………………………………………………………….129

Using Attachment Tilt Float…………………………………………………………………………………………………………………..129

Backfilling…………………………………………………………………………………………………………………………………130

Operating on Hard Surfaces……………………………………………………………………………………………………………………130

Working with Pallet Forks……………………………………………………………………………………………………………………………130

Safety Instructions When Working with Pallet Forks………………………………………………………………………………………………….130

Moving Loads Using Pallet Forks…………………………………………………………………………………………………………………..132

Loading Pallet Forks…………………………………………………………………………………………………………………………132

Raising Loads Using Pallet Forks………………………………………………………………………………………………………………132

Moving Loads Using Pallet Forks……………………………………………………………………………………………………………….133

Setting Down Loads Using Pallet Forks………………………………………………………………………………………………………….133

Diesel Particulate Filter (DPF) Regeneration Procedures…………………………………………………………………………………………………134

Reset Regeneration………………………………………………………………………………………………………………………………134

Reset Regeneration Inhibit……………………………………………………………………………………………………………………134

Stationary Regeneration………………………………………………………………………………………………………………………….135

Forcing Stationary Regeneration……………………………………………………………………………………………………………….136

DPF Maintenance…………………………………………………………………………………………………………………………………137

After Operation…………………………………………………………………………………………………………………………………….137

Jump-Starting………………………………………………………………………………………………………………………………………138

Raising the Machine using a Crane…………………………………………………………………………………………………………………….139

Crane Lifting Preparation………………………………………………………………………………………………………………………..140

Towing…………………………………………………………………………………………………………………………………………….141

Precautions…………………………………………………………………………………………………………………………………….141

Preparation…………………………………………………………………………………………………………………………………….141

Towing Procedure………………………………………………………………………………………………………………………………..142

After Towing……………………………………………………………………………………………………………………………………142

Loading and Transporting the Machine on a Transport Vehicle……………………………………………………………………………………………..143

Loading and Securing the Machine………………………………………………………………………………………………………………….143

Maintenance……………………………………………………………………………………………………………………………………………147

Maintenance Schedule………………………………………………………………………………………………………………………………..149

Checks, Cleaning and Inspection…………………………………………………………………………………………………………………..149

Leakage Check…………………………………………………………………………………………………………………………………..150

Lubrication and Filter Changes……………………………………………………………………………………………………………………151

Functional Check………………………………………………………………………………………………………………………………..151

Maintenance Interval………………………………………………………………………………………………………………………………..152

General Lubrication…………………………………………………………………………………………………………………………………153

Non-Telescopic Machines………………………………………………………………………………………………………………………….153

Telescopic Machines……………………………………………………………………………………………………………………………..154

General Lubrication Detail……………………………………………………………………………………………………………………….155

Telescopic Load Arm Maintenance (Telescopic Machines Only)………………………………………………………………………………………………159

Telescopic Load Arm Section Lubrication……………………………………………………………………………………………………………159

Telescopic Load Arm Wear Pad Replacement…………………………………………………………………………………………………………..160

LLMI Calibration (EU Telescopic Machines Only)…………………………………………………………………………………………………………160

Engine Maintenance………………………………………………………………………………………………………………………………….162

Engine Oil……………………………………………………………………………………………………………………………………..162

Checking Engine Oil Level…………………………………………………………………………………………………………………….162

Changing Engine Oil and Filter………………………………………………………………………………………………………………..163

Engine Air Filters………………………………………………………………………………………………………………………………165

Changing Air Filter Elements……………………………………………………………………………………………………………………..165

Engine Cooling System……………………………………………………………………………………………………………………………166

Checking Coolant Level……………………………………………………………………………………………………………………….166

Cleaning Radiator Fins……………………………………………………………………………………………………………………….167

Draining/Refilling Cooling System……………………………………………………………………………………………………………..167

Belt Maintenance………………………………………………………………………………………………………………………………..169

Checking and Adjusting Belt Tension……………………………………………………………………………………………………………169

DPF Service………………………………………………………………………………………………………………………………………..171

Fuel System Maintenance……………………………………………………………………………………………………………………………..171

Adding Fuel…………………………………………………………………………………………………………………………………….172

Water Separator Inspection/Maintenance…………………………………………………………………………………………………………….172

Changing Fuel Filter…………………………………………………………………………………………………………………………….174

Hydraulic System Maintenance…………………………………………………………………………………………………………………………175

Checking Hydraulic Oil Level……………………………………………………………………………………………………………………..175

Changing Hydraulic Oil…………………………………………………………………………………………………………………………..176

Changing Hydraulic Filter………………………………………………………………………………………………………………………..177

Hydraulic Hose Maintenance…………………………………………………………………………………………………………………………..179

Planetary Axles…………………………………………………………………………………………………………………………………….180

Changing Axle Wheel Hub Oil………………………………………………………………………………………………………………………180

Changing Axle Center Oil…………………………………………………………………………………………………………………………180

Brake Fluid Reservoir……………………………………………………………………………………………………………………………….181

Checking/Replenishing Brake Fluid Reservoir Level…………………………………………………………………………………………………..181

Parking Brake Adjustment/Service……………………………………………………………………………………………………………………..182

Parking Brake Cable Adjustment……………………………………………………………………………………………………………………182

Parking Brake Actuator Bracket Adjustment………………………………………………………………………………………………………….183

Wheels and Tires……………………………………………………………………………………………………………………………………184

Wheel Fasteners…………………………………………………………………………………………………………………………………184

Tires………………………………………………………………………………………………………………………………………….184

Tire Rotation……………………………………………………………………………………………………………………………….184

Checking Tire Pressure……………………………………………………………………………………………………………………….184

Travel Motor Lubrication…………………………………………………………………………………………………………………………….184

Electrical System…………………………………………………………………………………………………………………………………..185

Battery………………………………………………………………………………………………………………………………………..185

Using a Booster Battery (Jump-Starting)……………………………………………………………………………………………………………186

Fuses and Relays………………………………………………………………………………………………………………………………..187

Fuse Box Fuses………………………………………………………………………………………………………………………………187

Fuse Box Relays/Diodes……………………………………………………………………………………………………………………….188

Cooling Fan Control Diode…………………………………………………………………………………………………………………….188

Front Wiper Relay……………………………………………………………………………………………………………………………188

Engine Compartment Relays…………………………………………………………………………………………………………………….189

CAN Resistor……………………………………………………………………………………………………………………………………189

Chassis Grounds…………………………………………………………………………………………………………………………………189

Light Bulb Replacement…………………………………………………………………………………………………………………………..190

Work/Telescopic Load Arm Light Bulb Replacement…………………………………………………………………………………………………190

Tail Light Bulb Replacements………………………………………………………………………………………………………………….190

Headlight Bulb Replacements…………………………………………………………………………………………………………………..191

Dome Light Bulb Replacement…………………………………………………………………………………………………………………..194

14-Pin Connector Fuses, Diodes and Relays (Option)………………………………………………………………………………………………….194

HVAC/Air Conditioning Maintenance…………………………………………………………………………………………………………………….196

HVAC Filters……………………………………………………………………………………………………………………………………196

Cab Air Filters Replacement…………………………………………………………………………………………………………………..196

Air Conditioning Compressor Belt………………………………………………………………………………………………………………….197

Windshield Washer Reservoir………………………………………………………………………………………………………………………….197

Long-Term Storage…………………………………………………………………………………………………………………………………..198

Before Storage………………………………………………………………………………………………………………………………….198

After Storage…………………………………………………………………………………………………………………………………..198

Final Shutdown / Decommissioning……………………………………………………………………………………………………………………..199

Before Disposal…………………………………………………………………………………………………………………………………199

Machine Disposal………………………………………………………………………………………………………………………………..199

Hydrostatic System……………………………………………………………………………………………………………………………………..201

Hydrostatic System General Information………………………………………………………………………………………………………………..201

Charge Pressure Test and Adjustment…………………………………………………………………………………………………………………..204

Preparation…………………………………………………………………………………………………………………………………….204

Test Procedure………………………………………………………………………………………………………………………………….204

Hydrostatic Pump Pressure Relief Valves……………………………………………………………………………………………………………….205

600 Series / MLA-6 Hydrostatic Pump Removal……………………………………………………………………………………………………………206

Splined Coupler Removal/Installation………………………………………………………………………………………………………………….209

600 Series / MLA-6 Hydrostatic Pump Installation……………………………………………………………………………………………………….209

700 Series / MLA-7 / MLA-T Hydrostatic Pump Removal…………………………………………………………………………………………………….213

Splined Coupler Removal/Installation………………………………………………………………………………………………………………….217

700 Series / MLA-7 / MLA-T Hydrostatic Pump Installation………………………………………………………………………………………………..217

Hydrostatic Pump Drive Coupling Removal and Installation………………………………………………………………………………………………..221

Installation……………………………………………………………………………………………………………………………………222

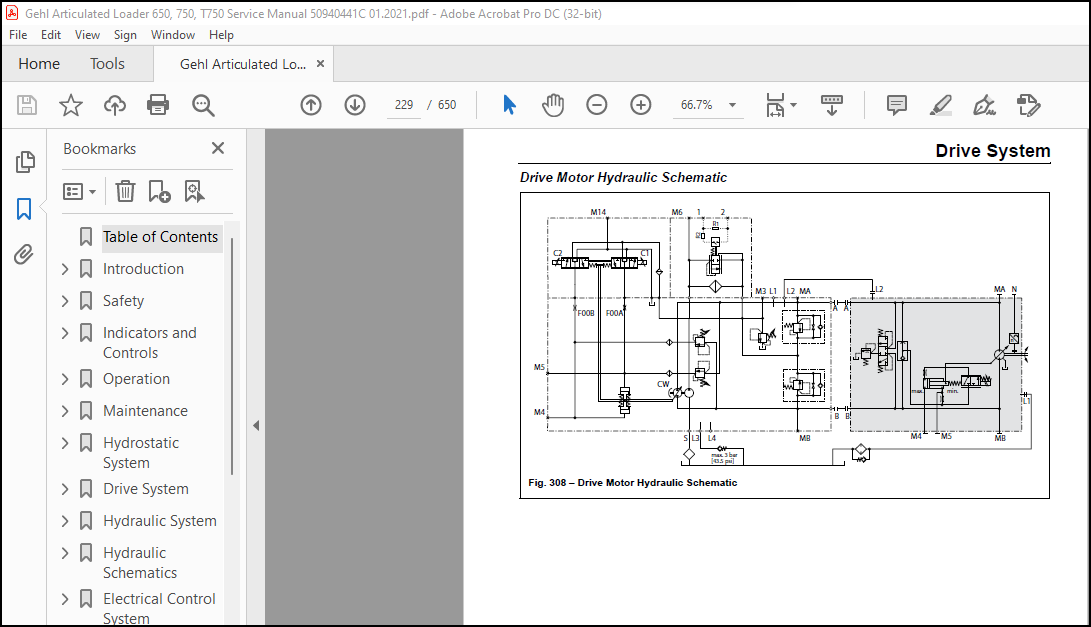

Drive System…………………………………………………………………………………………………………………………………………..225

Drive System General Information……………………………………………………………………………………………………………………..225

Pump and Drive Motor Error Codes……………………………………………………………………………………………………………………..225

Hydraulic Drive Motor……………………………………………………………………………………………………………………………….228

600 Series / MLA-6 Hydraulic Motor Removal…………………………………………………………………………………………………………….230

600 Series / MLA-6 Hydraulic Motor Installation………………………………………………………………………………………………………..232

700 Series / MLA-7 / MLA-T Hydraulic Motor Removal……………………………………………………………………………………………………..235

700 Series / MLA-7 / MLA-T Hydraulic Motor Installation…………………………………………………………………………………………………239

Brake/Inching Pedal Calibration………………………………………………………………………………………………………………………243

Bleeding the Brake System……………………………………………………………………………………………………………………………245

Brake/Inching Pedal Electrical……………………………………………………………………………………………………………………….246

Throttle Pedal Electrical……………………………………………………………………………………………………………………………246

Hand Throttle Electrical…………………………………………………………………………………………………………………………….247

Transmission Control Unit (TCU)/ Drive Controller………………………………………………………………………………………………………247

Travel Drive Control Module Error Codes……………………………………………………………………………………………………………247

Hydrostatic Pump and Drive Motor Error Codes……………………………………………………………………………………………………….249

Hydraulic System……………………………………………………………………………………………………………………………………….251

Hydraulic System General Information………………………………………………………………………………………………………………….251

General Hydraulic Service Notes………………………………………………………………………………………………………………………251

Hydraulic System Diagrams……………………………………………………………………………………………………………………………251

Hydraulic Hoses/Tubes……………………………………………………………………………………………………………………………263

Seals………………………………………………………………………………………………………………………………………….263

Main Pressure Test and Adjustment…………………………………………………………………………………………………………………….264

Control Valve………………………………………………………………………………………………………………………………………266

Main Control Valve Removal……………………………………………………………………………………………………………………….267

Main Control Valve Installation…………………………………………………………………………………………………………………..267

Control Valve Disassembly/Assembly………………………………………………………………………………………………………………..268

Disassembly…………………………………………………………………………………………………………………………………268

Control Valve Assembly……………………………………………………………………………………………………………………….269

Control Valve Solenoid Removal/Installation………………………………………………………………………………………………………..269

Removal…………………………………………………………………………………………………………………………………….269

Installation………………………………………………………………………………………………………………………………..270

Relief Valves Removal and Installation…………………………………………………………………………………………………………….270

Removal…………………………………………………………………………………………………………………………………….270

Installation………………………………………………………………………………………………………………………………..271

Non-Telescopic Machines Tilt/ Lift Cylinder Tests………………………………………………………………………………………………………271

Non-Telescopic Machines Tilt Cylinder Drift Test……………………………………………………………………………………………………271

Non-Telescopic Machines Tilt Cylinder Internal Leakage Test………………………………………………………………………………………….271

Non-Telescopic Machines Lift Cylinder Drift Test……………………………………………………………………………………………………272

Non-Telescopic Machines Lift Cylinder Internal Leakage Test………………………………………………………………………………………….273

Telescopic Machines Lift/Tilt Functional Description……………………………………………………………………………………………………274

Telescopic Load Arm Lift/Tilt Hydraulic Circuit Operation Overview……………………………………………………………………………………274

Telescopic Load Arm Raise Function Overview………………………………………………………………………………………………………..275

Telescopic Load Arm Lower Function Overview………………………………………………………………………………………………………..276

Telescopic Load Arm Hydraglide (Ride Control) Function Overview………………………………………………………………………………………277

Telescopic Load Arm Tilt Self-Level Over-ride………………………………………………………………………………………………………278

Telescopic Machines Tilt/Lift/ Extension Cylinder Tests…………………………………………………………………………………………………279

Telescopic Machines Tilt Cylinder Drift Test……………………………………………………………………………………………………….279

Telescopic Machines Tilt Cylinder Internal Leakage Test……………………………………………………………………………………………..279

Telescopic Machines Lift Cylinder Drift Test……………………………………………………………………………………………………….280

Telescopic Machines Lift Cylinder Internal Leakage Test……………………………………………………………………………………………..280

Telescopic Machines Extension Cylinder Drift Test…………………………………………………………………………………………………..281

Telescopic Machines Extension Cylinder Internal Leakage Test…………………………………………………………………………………………281

Hydraulic Cylinder Disassembly/ Assembly………………………………………………………………………………………………………………282

Cylinder Disassembly…………………………………………………………………………………………………………………………….282

Cylinder Assembly……………………………………………………………………………………………………………………………….282

Bleeding Air After Cylinder Installation…………………………………………………………………………………………………………..282

Hydraulic Solenoid Valves and Tests…………………………………………………………………………………………………………………..283

Cylinder Lower Valve and Test (Non- Telescopic Machines)…………………………………………………………………………………………….283

Isolation Valve (Telescopic Machines)……………………………………………………………………………………………………………..284

Standard Auxiliary Hydraulics Pressure Release Valve and Test………………………………………………………………………………………..284

Machines equipped with standard auxiliary hydraulics only:……………………………………………………………………………………….284

Secondary Auxiliary Hydraulics Pressure Release Valve and Test……………………………………………………………………………………….286

Machines equipped with secondary auxiliary hydraulics only:………………………………………………………………………………………286

High-Flow Auxiliary Hydraulics Valve and Test (Non-Telescopic Machines)……………………………………………………………………………….287

Standard Auxiliary Hydraulics Priority Valve and Test (Telescopic Machines)……………………………………………………………………………289

High-Flow Valve and Test (Telescopic Machines)……………………………………………………………………………………………………..293

Lift/Tilt Lockout Valve and Test………………………………………………………………………………………………………………….294

Fan/Power-A-Tach/Differential Lock Valve Tests……………………………………………………………………………………………………..296

Power-A-Tach/Quick Attachment Lock Solenoids Test……………………………………………………………………………………………….297

Hydraulic Fan Solenoids………………………………………………………………………………………………………………………298

Differential Lock Solenoid Test……………………………………………………………………………………………………………….298

Hydraglide…………………………………………………………………………………………………………………………………………300

Hydraglide™ Ride Control Solenoid Test…………………………………………………………………………………………………………….302

Solenoid Valve Disassembly/ Reassembly………………………………………………………………………………………………………………..303

Steering…………………………………………………………………………………………………………………………………………..304

Steering Priority Valve Test……………………………………………………………………………………………………………………..304

Hydraulic System Troubleshooting……………………………………………………………………………………………………………………..306

Hydraulic Schematics……………………………………………………………………………………………………………………………………309

Hydraulic Schematic — Standard (Non-Telescopic Machines)………………………………………………………………………………………………..309

Hydraulic Schematic — with High-Flow/2nd Auxiliary Hydraulics and Hydraglide (Non-Telescopic Machines)……………………………………………………….310

Hydraulic Schematic — Standard Auxiliary Hydraulics (Telescopic Machines)…………………………………………………………………………………311

Hydraulic Schematic – Standard Hydraulics with Options (Telescopic Machines)………………………………………………………………………………312

Hydraulic Schematic – High-Flow Auxiliary Hydraulics (Telescopic Machines)………………………………………………………………………………..313

Hydraulic Schematic – High-Flow Auxiliary Hydraulics with Options (Telescopic Machines)…………………………………………………………………….314

Electrical Control System……………………………………………………………………………………………………………………………….315

Electrical Control System General Information………………………………………………………………………………………………………….315

CAN System General Information……………………………………………………………………………………………………………………315

Control Modules…………………………………………………………………………………………………………………………………….316

Machine Control Unit (MCU)……………………………………………………………………………………………………………………….316

Transmission Control Unit (TCU)…………………………………………………………………………………………………………………..316

Engine Control Unit (ECU)………………………………………………………………………………………………………………………..316

Display/Indicators/Controls………………………………………………………………………………………………………………………317

Multi-Function Display……………………………………………………………………………………………………………………….317

Keypad……………………………………………………………………………………………………………………………………..317

Switch Panel………………………………………………………………………………………………………………………………..317

Multi-Function Joystick………………………………………………………………………………………………………………………317

Control Lever (Option)……………………………………………………………………………………………………………………….318

CAN System Service/Computer Connection………………………………………………………………………………………………………………..319

J1939 Data Connector…………………………………………………………………………………………………………………………….319

CAN/Computer Connection Harnesses…………………………………………………………………………………………………………………319

Service Adapter Harness………………………………………………………………………………………………………………………319

Yanmar Engine Connection Harness………………………………………………………………………………………………………………319

MCU/TCU Data Connection Harness……………………………………………………………………………………………………………….319

Multi-Function Display Data Connection Harness………………………………………………………………………………………………….320

Deutz Engine CAN/Computer Connection Harness (SerDia)……………………………………………………………………………………………….320

Danfoss Service Tool (Plus+1) Software…………………………………………………………………………………………………………….321

Multi-Function Display Service Software Update/Pass Code Reset……………………………………………………………………………………….321

Operation/Controller Area Network (CAN) Functional Organization………………………………………………………………………………………….322

Operation/CAN Function Organization Overview……………………………………………………………………………………………………….322

Keypad Input/Output Detail……………………………………………………………………………………………………………………….323

Display Output Detail……………………………………………………………………………………………………………………………324

Machine Control Unit (MCU) Input/Output Detail……………………………………………………………………………………………………..325

Travel Control Unit (TCU) Input/Output Detail………………………………………………………………………………………………………327

HydralocTM (Safety Interlock) Functional Detail…………………………………………………………………………………………………….328

Ignition/Starting Functional Detail……………………………………………………………………………………………………………….329

Operation Functional Detail………………………………………………………………………………………………………………………331

Load Arm Functional Detail……………………………………………………………………………………………………………………….332

Drive System Functional Detail……………………………………………………………………………………………………………………333

Auxiliary Hydraulics Functional Detail…………………………………………………………………………………………………………….337

Cooling Fan Functional Detail…………………………………………………………………………………………………………………….339

Warning Indicators Functional Detail………………………………………………………………………………………………………………340

Lighting Functional Detail……………………………………………………………………………………………………………………….342

Accessories and Options Functional Detail……………………………………………………………………………………………………………..344

CAN/Control System Troubleshooting……………………………………………………………………………………………………………………346

Inputs/Outputs Detail……………………………………………………………………………………………………………………………346

Error Codes…………………………………………………………………………………………………………………………………….372

MCU and Keypad CAN Error Codes……………………………………………………………………………………………………………………372

Electrical System………………………………………………………………………………………………………………………………………375

Power Distribution………………………………………………………………………………………………………………………………….383

Fuses/Relays……………………………………………………………………………………………………………………………………383

Power Distribution Module Fuse Socket Test…………………………………………………………………………………………………………383

Main Power Relay………………………………………………………………………………………………………………………………..383

Front Wiper Relay……………………………………………………………………………………………………………………………….383

Relay Testing…………………………………………………………………………………………………………………………………..384

Machine Test………………………………………………………………………………………………………………………………..384

Bench Test………………………………………………………………………………………………………………………………….384

Start/Glow Relay Solenoid Test……………………………………………………………………………………………………………………….385

Control Modules…………………………………………………………………………………………………………………………………….385

J1939 Data Connector………………………………………………………………………………………………………………………………..386

Easy Manager……………………………………………………………………………………………………………………………………….386

Easy Manager Fuse……………………………………………………………………………………………………………………………….386

Easy Manager Relay………………………………………………………………………………………………………………………………387

Wire Harness Diagrams…………………………………………………………………………………………………………………………………..389

Wire Harness Diagram — Front Chassis…………………………………………………………………………………………………………………389

Wire Harness Diagram — Rear Chassis — AL750 (SN J00070227 and Down), AL708 (SN A00075299 and Down), AL650 (SN C00060321 and Down), AL608 (SN C00065301 and Down)….390

Wire Harness Diagram — Telescopic Load Arm……………………………………………………………………………………………………………392

Wire Harness Diagram — Cab/Canopy……………………………………………………………………………………………………………………393

Wire Harness Diagram — Engine — AL650 (SN C00060322 and Up), AL608 (SN C00065302 and Up), MLA-6……………………………………………………………394

Wire Harness Diagram — Engine — AL650 (SN C00060321 and Down), AL608 (SN C00065301 and Down)………………………………………………………………395

Wire Harness Diagram — 700 Series / MLA-7 / MLA-T Engine……………………………………………………………………………………………….396

Electrical Schematics…………………………………………………………………………………………………………………………………..397

Electrical Schematic – Chassis (1 of 3)……………………………………………………………………………………………………………….397

Electrical Schematic – Chassis (2 of 3)……………………………………………………………………………………………………………….398

Electrical Schematic – Chassis – Switch Panel Splices (3 of 3)…………………………………………………………………………………………..399

Electrical Schematic – Chassis – Rear Frame (1 of 2)……………………………………………………………………………………………………400

Electrical Schematic – Chassis – Rear Frame (2 of 2)……………………………………………………………………………………………………401

Electrical Schematic – Chassis – Front Frame/Headlights (Non-Telescopic Machines)………………………………………………………………………….402

Electrical Schematic – Chassis – Front Frame/Headlights (Telescopic Machines) (1 of 2)……………………………………………………………………..403

Electrical Schematic – Chassis – Front Frame/Headlights (Telescopic Machines) (2 of 2)……………………………………………………………………..404

Electrical Schematic – Enclosed ROPS/FOPS……………………………………………………………………………………………………………..405

Electrical Schematic – HVAC………………………………………………………………………………………………………………………….406

Electrical Schematic – Open ROPS/FOPS…………………………………………………………………………………………………………………407

Electrical Schematic – 600 Series Engine (Yanmar 4TNV98CT-PGWLT)…………………………………………………………………………………………408

Electrical Schematic — 700 Series Engine (Deutz TD3.6L4) (1 of 2)………………………………………………………………………………………..409

Electrical Schematic — 700 Series Engine (Deutz TD3.6L4) (2 of 2)……………………………………………………………………………………….410

Electrical Schematic — Electrical Auxiliary Circuits……………………………………………………………………………………………………411

Electrical Schematic — Rear Lights Connection…………………………………………………………………………………………………………412

Electrical Schematic — 14-Pin Auxiliary Circuit………………………………………………………………………………………………………..413

Electrical Schematic — Turn Signal/Radio Jumpers………………………………………………………………………………………………………414

Chassis……………………………………………………………………………………………………………………………………………….415

Chassis General Information………………………………………………………………………………………………………………………….415

Cab/Canopy Removal………………………………………………………………………………………………………………………………….415

Cab/Canopy Installation……………………………………………………………………………………………………………………………..421

Engine Cover Removal/Replacement……………………………………………………………………………………………………………………..427

Engine Cover Removal…………………………………………………………………………………………………………………………….427

Engine Cover Replacement…………………………………………………………………………………………………………………………428

Articulation Joint………………………………………………………………………………………………………………………………….429

Articulation Joint Disassembly (Telescopic Machines)………………………………………………………………………………………………..430

Articulation Joint Assembly (Telescopic Machines)…………………………………………………………………………………………………..440

Articulation Joint Disassembly (Non- Telescopic Machines)……………………………………………………………………………………………456

Articulation Joint Assembly (Non-Telescopic Machines)……………………………………………………………………………………………….465

Telescopic Load Arm…………………………………………………………………………………………………………………………………….475

Telescopic Load Arm Component Identification…………………………………………………………………………………………………………..475

Load Arm Extend, Lift, and Slave Cylinders…………………………………………………………………………………………………………476

Outer Load Arm and Hose Support…………………………………………………………………………………………………………………..477

Inner Load Arm and Tilt Cylinder………………………………………………………………………………………………………………….478

Pivot Link……………………………………………………………………………………………………………………………………..479

Load Arm Hydraulics (1 of 3)……………………………………………………………………………………………………………………..480

Load Arm Hydraulics (2 of 3)……………………………………………………………………………………………………………………..481

Load Arm Hydraulics (3 of 3)……………………………………………………………………………………………………………………..482

Tilt Cylinder Removal/Installation……………………………………………………………………………………………………………………483

Tilt Cylinder Removal……………………………………………………………………………………………………………………………483

Tilt Cylinder Installation……………………………………………………………………………………………………………………….488

Inner Load Arm Hydraulic Tube and Hose Removal/Installation……………………………………………………………………………………………..492

Load Arm Hydraulic Tube and Hose Removal…………………………………………………………………………………………………………..492

Inner Load Arm Hydraulic Tube and Hose Installation…………………………………………………………………………………………………499

Load Arm Slide Pad Service…………………………………………………………………………………………………………………………..504

Load Arm Slide Pad Inspection/Shims……………………………………………………………………………………………………………….505

Front Slide Pad Inspection……………………………………………………………………………………………………………………505

Rear Slide Pad Inspection…………………………………………………………………………………………………………………….506

Front Slide Pad Replacement………………………………………………………………………………………………………………………507

Front Side Slide Pad Replacement………………………………………………………………………………………………………………507

Front Top/Bottom Slide Pad Replacement…………………………………………………………………………………………………………508

Rear Slide Pad Replacement……………………………………………………………………………………………………………………….508

Rear Side Slide Pad Replacement……………………………………………………………………………………………………………….509

Rear Top/Bottom Slide Pad Replacement………………………………………………………………………………………………………….509

Rear Slide Pad Replacement Completion………………………………………………………………………………………………………….510

Hose Support Removal………………………………………………………………………………………………………………………………..510

Hose Support Installation……………………………………………………………………………………………………………………………513

Extension Indicator Potentiometer (Domestic Telescopic Machines)…………………………………………………………………………………………517

Extension Indicator Potentiometer Description………………………………………………………………………………………………………518

Extension Potentiometer Removal…………………………………………………………………………………………………………………..518

Extension Potentiometer Installation………………………………………………………………………………………………………………519

Extension Indicator Potentiometer Calibration (Domestic Telescopic Machines Only)………………………………………………………………………520

HVAC System……………………………………………………………………………………………………………………………………………523

Air Conditioning Refrigerant Recovery…………………………………………………………………………………………………………………528

Air Conditioning System Port Access……………………………………………………………………………………………………………….528

Air Conditioning System Charging……………………………………………………………………………………………………………………..528

700 Series / MLA-7 / MLA-T Air Conditioning Compressor Removal…………………………………………………………………………………………..529

700 Series / MLA-7 / MLA-T Air Conditioning Compressor Installation………………………………………………………………………………………530

600 Series / MLA-6 Engine……………………………………………………………………………………………………………………………….533

600 Series / MLA-6 Engine Removal…………………………………………………………………………………………………………………….533

600 Series / MLA-6 Engine Installation………………………………………………………………………………………………………………..542

700 Series / MLA-7 / MLA-T Engine………………………………………………………………………………………………………………………..551

700 Series / MLA-7 / MLA-T Engine Removal……………………………………………………………………………………………………………..551

700 Series / MLA-7 / MLA-T Engine Installation…………………………………………………………………………………………………………561

Engine Cooling System…………………………………………………………………………………………………………………………………..571

Engine Cooling System General Information……………………………………………………………………………………………………………..571

Cooling Fan Operation……………………………………………………………………………………………………………………………571

Cooling Fan Reversal…………………………………………………………………………………………………………………………572

600 Series / MLA-6 Radiator Removal…………………………………………………………………………………………………………………..575

600 Series / MLA-6 Radiator Installation………………………………………………………………………………………………………………579

700 Series / MLA-7 / MLA-T Radiator Removal……………………………………………………………………………………………………………583

700 Series / MLA-7 / MLA-T Radiator Installation……………………………………………………………………………………………………….588

Troubleshooting………………………………………………………………………………………………………………………………………..593

Engine Troubleshooting………………………………………………………………………………………………………………………………593

Indicator Lamp Troubleshooting……………………………………………………………………………………………………………………….594

Seal and Hose Troubleshooting………………………………………………………………………………………………………………………..595

Hydraulic System Troubleshooting……………………………………………………………………………………………………………………..596

Hydrostatic Travel Drive System Troubleshooting………………………………………………………………………………………………………..596

Electrical Troubleshooting…………………………………………………………………………………………………………………………..596

Electrical Inputs/Outputs………………………………………………………………………………………………………………………..597

Error Codes………………………………………………………………………………………………………………………………………..597

MCU and Keypad CAN Error Codes……………………………………………………………………………………………………………………597

Yanmar Engine Diagnostic Trouble Codes (DTC)……………………………………………………………………………………………………….599

Deutz Engine Diagnostic Trouble Codes (DTC)………………………………………………………………………………………………………..606

Specifications…………………………………………………………………………………………………………………………………………625

Fluids/Lubricants Types and Capacities………………………………………………………………………………………………………………..625

Payloads/Capacities…………………………………………………………………………………………………………………………………627

Non-Telescopic Machines………………………………………………………………………………………………………………………….627

Telescopic Machines……………………………………………………………………………………………………………………………..628

Pallet Fork Capacities Load Chart – Domestic (Telescopic Machines)………………………………………………………………………………..629

Pallet Fork Capacities Load Chart – EU (Telescopic Machines)……………………………………………………………………………………..630

Dimensions…………………………………………………………………………………………………………………………………………631

Non-Telescopic Machines………………………………………………………………………………………………………………………….631

Telescopic Machines……………………………………………………………………………………………………………………………..633

Weights……………………………………………………………………………………………………………………………………………635

Coolant Compound Table………………………………………………………………………………………………………………………………635

Wheels/Tires……………………………………………………………………………………………………………………………………….636

Engine…………………………………………………………………………………………………………………………………………….636

Hydraulic System……………………………………………………………………………………………………………………………………637

Drive Hydraulics………………………………………………………………………………………………………………………………..637

Work Hydraulics…………………………………………………………………………………………………………………………………637

Sound Power/Pressure Levels (Non-Telescopic Machines)…………………………………………………………………………………………………..637

Sound Power/Pressure Levels (Telescopic Machines)………………………………………………………………………………………………………637

Vibration Levels……………………………………………………………………………………………………………………………………638

Common Materials and Densities……………………………………………………………………………………………………………………….639

Index…………………………………………………………………………………………………………………………………………………641

Torque Specifications…………………………………………………………………………………………………………………………………..647