$34

Gehl RT185 RT215 RT255 Compact Track Loader Operator’s Manual 50940610 – PDF DOWNLOAD

Gehl RT185 RT215 RT255 Compact Track Loader Operator’s Manual 50940610 – PDF DOWNLOAD

FILE DETAILS:

Gehl RT185 RT215 RT255 Compact Track Loader Operator’s Manual 50940610 – PDF DOWNLOAD

Language : English

Pages : 210

Downloadable : Yes

File Type : PDF

Size: 23.3 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gehl RT185 RT215 RT255 Compact Track Loader Operator’s Manual 50940610 – PDF DOWNLOAD

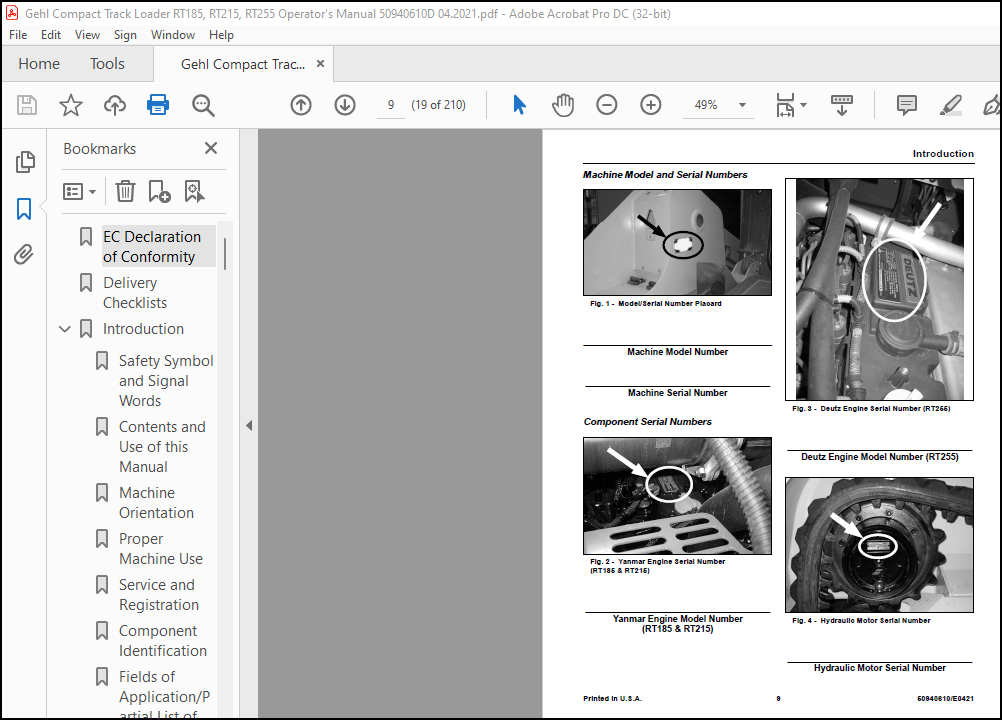

Introduction:Contents and Use of this Manual:

This Operator’s Manual provides information about the safe and proper operation and maintenance for the machine. Major points of safe operation and maintenance are detailed in the Safety chapter of this manual. This manual also includes general troubleshooting and specification information about the machine. Follow the instructions in the Operator’s Manual Safety, Operation and Maintenance chapters, concerning accident prevention regulations, safety and occupational regulations, and machine and traffic regulations. Manitou Americas is not liable for damage resulting from the failure to follow these regulations.

- It is the owner’s or employer’s responsibility to fully instruct each operator in the proper and safe operation and maintenance of the machine. A storage container is provided behind the operator’s seat for storing the Operator’s Manual. After using the manual, return it to the storage container.

- This manual is considered a permanent part of the machine and should be with the machine at all times. If the machine is resold, include this operator’s manual as part of the sale. Replace this manual promptly if it becomes damaged, lost or stolen.

- Some illustrations in this manual may show doors, guards and shields open or removed for illustrative purposes only. BE SURE all doors, guards and shields are in their proper operating positions BEFORE starting the engine to operate the machine. Because of ongoing product improvements, information included in this manual may not exactly match the machine. Manitou Americas reserves the right to modify and improve products at any time without notice or obligation.

TABLE OF CONTENTS:

Gehl RT185 RT215 RT255 Compact Track Loader Operator’s Manual 50940610 – PDF DOWNLOAD

EC Declaration of Conformity. . 5

Delivery Checklists. . 7

Introduction. . 6

Safety Symbol and Signal Words . 6

Contents and Use of this Manual. . 6

Machine Orientation . 7

Proper Machine Use. . 7

Service and Registration . 7

Component Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fields of Application/Partial List of Attachments. . 11

Vibration Information . 12

Fire Extinguisher. . 13

Manufacturer Information . 13

Indicator and Operation Symbols. . 14

Safety. . 17

Safety Symbol and Signal Words . 17

Mandatory Safety Shutdown Procedure. . 18

Before Starting . 18

During Operation. . 19

Applications with Load-Handling Devices . 23

Parking the Machine. . 23

Electrical Energy . 23

Maintenance and Service Safety Practices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Battery Hazards. . 26

Fire Hazards. . 26

Additional Safety Equipment . 27

Crystalline Silica Exposure. . 27

Transporting the Machine. . 27

Lifting the Machine with a Crane. . 28

Loading and Transporting the Machine. . 28

Decals. . 30

General Information. . 30

Decal Locations. . 30

Specifications. . 39

Fluids/Lubricants Types and Capacities. . 39

50940610/E0421 2 Printed in U.S.A.

Dimensions. . 40

Payloads/Capacities. . 41

Weights. . 42

Track Drive. . 43

Coolant Compound Table. . 43

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ………………………………………………………………..44

Hydraulic System. . 45

Electrical System. . 48

Sound Power/Pressure Levels. . 48

Standard and Optional Features. . 49

Common Materials and Densities. . 50

Indicators and Controls. . 54

Multi-Function Display. . 55

Control Button/Switches. . 61

Indicator Panel. . 62

Optional Light/Lockout Keypad Indicators/Buttons. . 64

Ignition Switch. . 65

Seat and Armrest/Joystick Console Adjustment. . 65

Control Joysticks. . 66

Parking Brake/Work Hydraulics Lock-out. . 68

Throttle Controls. . 68

Travel Controls. . 69

Lift Arm Float Button. . 69

Hydraglide™ Button. . 69

HVAC (Option). . 70

Work/Beacon/Road Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ………………………………………………….70

Window Wipers/Washers. . 71

Battery Disconnect Switch (Option). . 71

Rearview Camera (Option). . 72

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ………………………………………………………………..74

Operational Checks/Pre-start Inspection. . 74

Before Operation. . 76

Seat Belt. . 80

Starting the Engine. . 82

Warm Up. . 83

Run-In Period. . 84

Tier 4 Engine Operation. . 84

Stopping the Engine. . 84

Printed in U.S.A. 3 50940610/E0421

Engine Stalling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Travel Drive Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Rubber Track Use Cautions and Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Backup Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Lift Arm Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Lift Arm Float. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Hydraglide™ Ride Control System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Hydraulics Control Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Lift Arm Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Connecting/Disconnecting Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Hydraulically-Powered Attachments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

14-Pin Connector (Option). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Working with Buckets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Working with Pallet Forks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Diesel Particulate Filter (DPF) Regeneration Procedures (Model RT185 & RT215 withTier 4 Engines

Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

After Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Jump-Starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Lifting the Machine Using a Crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Transport on Public Roads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Loading and Transporting the Machine on a Transport Vehicle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Engine Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

DPF Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Fuel System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Hydraulic System Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

Hydraulic Hose Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Travel Motor Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Track Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

General Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Tilting ROPS/FOPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

Electrical System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Long-Term Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Air Conditioning Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Window Washer Reservoir. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .149

Window Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .149

Final Shutdown / Decommissioning. . 150

Maintenance Log. . 152

Troubleshooting. . 156

Engine Error Codes. . 163

Schematics. . 179

Hydraulic Schematics. . 179

Electrical Schematics – Power Distribution. . 180

Electrical Schematic – Chassis. . 181

Electrical Schematics – ROPS/FOPS. . 182

Electrical Schematics – Operator’s Seat. . 183

Electrical Schematic – Rear Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . …………………………………………….184

Electrical Schematic – Models RT185 & RT215 Yanmar Engine (Tier 4). . 185

Electrical Schematic – Models RT185 & RT215 Yanmar Engine (interim Tier 4). . . . . . . . . . . . . . . . ……………186

Electrical Schematic – Model RT255 Duetz Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Electrical Schematic – Road Lights. . 188

Electrical Schematic – 14-Pin Connector. . 189

Torque Specifications. . 192