$34

Gehl VT320 Mustang Manitou 3200VT Track Loader Service Manual 50940548 – PDF DOWNLOAD

Gehl VT320 Mustang Manitou 3200VT Track Loader Service Manual 50940548 – PDF DOWNLOAD

FILE DETAILS:

Gehl VT320 Mustang Manitou 3200VT Track Loader Service Manual 50940548 – PDF DOWNLOAD

Language : English

Pages : 368

Downloadable : Yes

File Type : PDF

Size: 49.7 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gehl VT320 Mustang Manitou 3200VT Track Loader Service Manual 50940548 – PDF DOWNLOAD

SAFETY:

• Before operating the machine, first read and study the safety information in this manual. Be sure that anyone who operates or works on the machine is familiar with the safety precautions. This includes providing translations of the warnings and instructions for operators who are not fluent in reading English.• It is essential that operators be thoroughly trained in the safe operation of the machine and load handling. Operators must not be physically or mentally impaired. Do not allow minors or unqualified personnel to operate the machine, or to be near the machine unless they are properly supervised. It is recommended that the operator be capable of obtaining a valid motor vehicle operator’s license.• Do not use the machine for any application or purpose other than those described in this manual, or in manuals supplied with any attachments used with the machine.• Use of the machine is subject to certain hazards that cannot be eliminated by mechanical means, but only by exercising intelligence, care and common sense. Such hazards include: hillside operation, overloading, load instability, poor maintenance, and using the machine for a purpose for which it was not intended or designed.• Manitou always takes operator’s safety into consideration during the design process. Guards and shields are provided, which protect the operator and bystanders from moving parts and other hazards. Operators must be alert, however, because some areas cannot be guarded or shielded without preventing or interfering with proper operation.• Different applications may require optional safety equipment. Users must evaluate the worksite hazards and equip the machine and the operator as necessary. The information in this manual does not replace any applicable safety rules and laws. Before operating the machine, learn the rules and laws for the local area. Make sure the machine is equipped as required according to these rules/laws.

TABLE OF CONTENTS:

Gehl VT320 Mustang Manitou 3200VT Track Loader Service Manual 50940548 – PDF DOWNLOAD

Table of Contents…………………………………………………………………………………. 3

Safety…………………………………………………………………………………………… 9

Safety Symbol and Signal Words………………………………………………………………….. 9

Safety Alert Symbol………………………………………………………………………… 9

Signal Words………………………………………………………………………………. 9

Mandatory Safety Shutdown Procedure……………………………………………………………… 10

Before Starting……………………………………………………………………………….. 10

During Operation………………………………………………………………………………. 11

Applications with Load-Handling Devices………………………………………………………….. 14

Parking the Machine……………………………………………………………………………. 15

Electrical Energy……………………………………………………………………………… 15

Maintenance and Service Safety Practices…………………………………………………………. 15

Battery Hazards……………………………………………………………………………….. 17

Fire Hazards………………………………………………………………………………….. 18

Additional Safety Equipment…………………………………………………………………….. 19

Crystalline Silica Exposure…………………………………………………………………….. 19

Transporting the Machine……………………………………………………………………….. 19

Lifting the Machine with a Crane………………………………………………………………… 19

Loading and Transporting the Machine…………………………………………………………….. 20

Safety Decals…………………………………………………………………………………. 20

New Decal Application………………………………………………………………………. 20

ANSI-Style Safety Decals……………………………………………………………………….. 21

Lifting the Machine using a Crane……………………………………………………………….. 23

Crane Lifting Preparation…………………………………………………………………… 23

Loading and Transporting the Machine on a Transport Vehicle………………………………………… 24

Loading and Securing the Machine…………………………………………………………….. 24

Introduction……………………………………………………………………………………… 27

Contents and Use of this Manual…………………………………………………………………. 27

Machine Orientation……………………………………………………………………………. 27

Component Identification……………………………………………………………………….. 28

Machine Model and Serial Number Locations………………………………………………………… 29

Component Serial Numbers……………………………………………………………………. 29

ROPS/FOPS Certification Label…………………………………………………………………… 29

Indicator and Operation Symbols…………………………………………………………………. 30

Machine Controls and Operation………………………………………………………………….. 31

Maintenance………………………………………………………………………………………. 33

Maintenance Schedule…………………………………………………………………………… 34

Checks, Cleaning and Inspection……………………………………………………………… 34

Leakage Check……………………………………………………………………………… 35

Lubrication and Filter Changes………………………………………………………………. 36

Functional Check…………………………………………………………………………… 36

Engine Maintenance…………………………………………………………………………….. 37

Engine Access……………………………………………………………………………… 37

Closing Engine Covers…………………………………………………………………… 37

Engine Oil………………………………………………………………………………… 38

Checking Engine Oil Level……………………………………………………………….. 38

Changing Engine Oil and Filter…………………………………………………………… 39

Engine Air Filters…………………………………………………………………………. 40

Changing Air Filter Elements………………………………………………………………… 41

Engine Cooling System………………………………………………………………………. 41

Checking Coolant Level………………………………………………………………….. 41

Cleaning Radiator Fins………………………………………………………………….. 42

Draining/Refilling Cooling System………………………………………………………… 42

Belt Maintenance…………………………………………………………………………… 43

Engine Accessory Belt…………………………………………………………………… 43

Air Conditioning Belt…………………………………………………………………… 44

Belt Installation………………………………………………………………………. 44

Diesel Exhaust Fluid (DEF) Service………………………………………………………………. 46

Diesel Exhaust Fluid (DEF) Level…………………………………………………………….. 46

DEF Dosing Unit Filter Replacement…………………………………………………………… 46

Fuel System Maintenance………………………………………………………………………… 48

Adding Fuel……………………………………………………………………………….. 48

Water Separator Inspection/Maintenance……………………………………………………….. 49

Changing Water Separator and Fuel Filter……………………………………………………… 50

Hydraulic System Maintenance……………………………………………………………………. 51

Checking Hydraulic Oil Level………………………………………………………………… 51

Changing Hydraulic Oil and Filter……………………………………………………………. 52

Hydraulic Hose Maintenance……………………………………………………………………… 54

Travel Motor Maintenance……………………………………………………………………….. 55

Travel Motor Gearbox Oil……………………………………………………………………. 55

Track Maintenance……………………………………………………………………………… 55

Track Replacement………………………………………………………………………….. 55

General Lubrication……………………………………………………………………………. 56

Tilting ROPS/FOPS……………………………………………………………………………… 57

Raising ROPS/FOPS………………………………………………………………………….. 57

Lowering ROPS/FOPS…………………………………………………………………………. 58

Electrical System……………………………………………………………………………… 59

Batteries…………………………………………………………………………………. 59

Using a Booster Battery (Jump-Starting)………………………………………………………. 60

Fuses and Relays…………………………………………………………………………… 60

Fuses/Relays…………………………………………………………………………… 60

Engine Compartment Relays/Fuses – (SN 330101 and Up)…………………………………………… 61

Engine Compartment Relays/Fuses – (SN 330100 and Before)……………………………………….. 62

Power-A-Tach Relay……………………………………………………………………… 63

Optional 14-Pin Connector Fuses/Relays……………………………………………………. 63

Rearview Camera Fuse……………………………………………………………………….. 63

Long-Term Storage……………………………………………………………………………… 64

Before Storage…………………………………………………………………………….. 64

After Storage……………………………………………………………………………… 64

Air Conditioning Maintenance……………………………………………………………………. 65

Air Conditioning Filters……………………………………………………………………. 65

Cab Air Filter…………………………………………………………………………. 65

Outside Air Intake Filter……………………………………………………………….. 65

Windshield Washer Reservoir…………………………………………………………………….. 66

Final Shutdown / Decommissioning………………………………………………………………… 66

Before Disposal……………………………………………………………………………. 66

Machine Disposal…………………………………………………………………………… 66

Engine…………………………………………………………………………………………… 67

General Information……………………………………………………………………………. 67

Engine Access…………………………………………………………………………………. 67

Closing Engine Covers………………………………………………………………………. 67

Deutz SerDia Connection/Software………………………………………………………………… 68

Engine Maintenance…………………………………………………………………………….. 69

Engine Cooling System………………………………………………………………………….. 69

Engine Removal/Installation…………………………………………………………………….. 69

Engine Removal…………………………………………………………………………….. 69

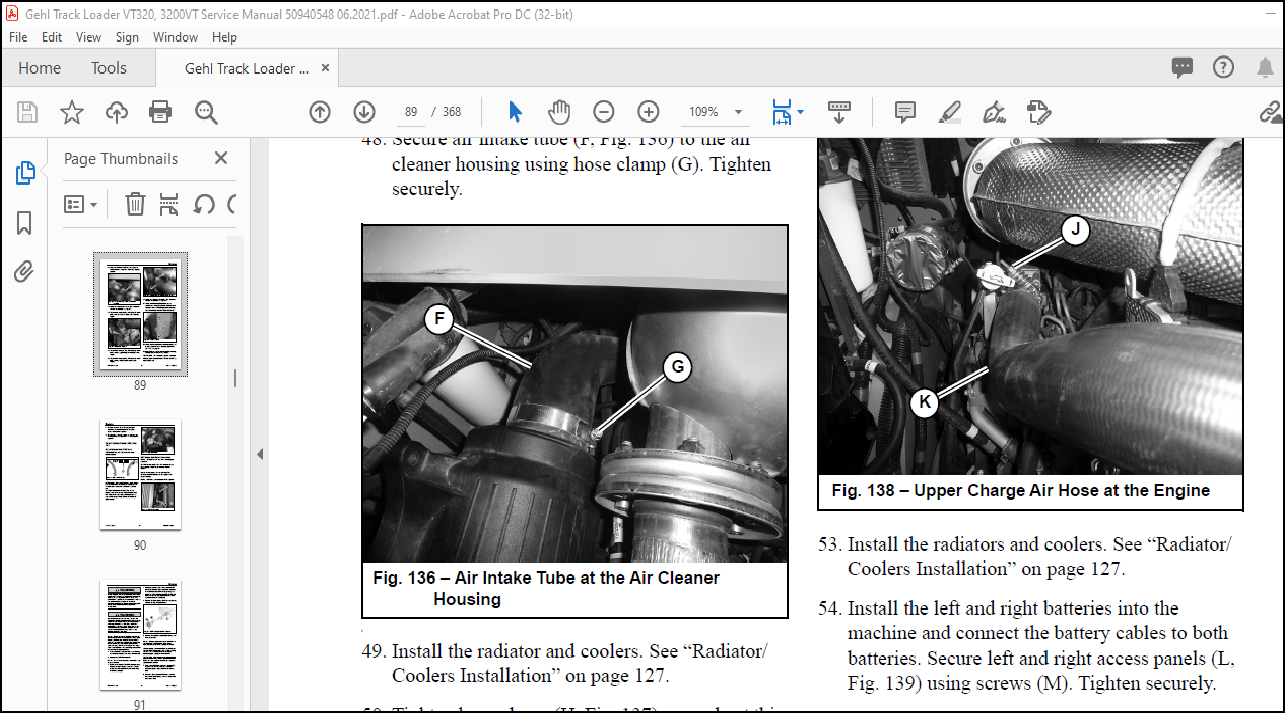

Engine Installation………………………………………………………………………… 79

Diesel Exhaust Fluid (DEF) Service………………………………………………………………. 90

Diesel Exhaust Fluid (DEF) Level…………………………………………………………….. 90

DEF Dosing Unit Filter Replacement…………………………………………………………… 90

Fuel System Maintenance………………………………………………………………………… 92

Adding Fuel……………………………………………………………………………….. 92

Water Separator Inspection/Maintenance……………………………………………………….. 93

Changing Water Separator and Fuel Filter……………………………………………………… 94

Engine Troubleshooting…………………………………………………………………………. 95

Engine Error Codes…………………………………………………………………………. 97

Cooling System…………………………………………………………………………………….115

General Information…………………………………………………………………………….115

Radiator/Coolers Removal………………………………………………………………………..119

Radiator/Coolers Installation……………………………………………………………………127

Hydrostatic Drive System……………………………………………………………………………135

General Information…………………………………………………………………………….135

General Hydraulic Service Notes………………………………………………………………….135

Hydraulic Oil Analysis………………………………………………………………………….135

Hydrostatic Drive Pump………………………………………………………………………….135

Hydrostatic Charge Pressure Test and Adjustment………………………………………………..138

Hydrostatic DA Pressure Test and Adjustment……………………………………………………138

Hydrostatic Pump Relief Valves…………………………………………………………………..139

Hydrostatic Pump High Pressure Test…………………………………………………………..140

Travel Drive Troubleshooting…………………………………………………………………….140

Travel Drive Joystick Lockout Valve Test………………………………………………………141

Neutral Centering Check/Adjustment……………………………………………………………….143

Straight Tracking Adjustment…………………………………………………………………….145

Forward Straight Tracking Adjustment………………………………………………………….145

Reverse Straight Tracking Adjustment………………………………………………………….146

Hydrostatic Pump Removal and Installation…………………………………………………………148

Hydrostatic Pump Removal…………………………………………………………………….148

Hydrostatic Drive Pump Installation…………………………………………………………..152

Hydrostatic Pump Drive Coupling Removal and Installation……………………………………………155

Installation……………………………………………………………………………….156

Travel Motors………………………………………………………………………………….156

Travel Motor Maintenance…………………………………………………………………….159

Travel Motor Removal/Installation…………………………………………………………….159

Travel Motor Removal…………………………………………………………………….159

Travel Motor Installation………………………………………………………………..161

Travel Drive High-Speed Troubleshooting…………………………………………………………..163

Travel Drive High-Speed (Pilot) Valve Test…………………………………………………….163

Tracks………………………………………………………………………………………..166

Rubber Track Use Cautions and Tips……………………………………………………………167

Sprocket Tooth Wear and Track Life……………………………………………………………168

Track Replacement…………………………………………………………………………..169

Track Removal…………………………………………………………………………..169

Track Installation………………………………………………………………………170

IdealTrax™ Track Tensioning System……………………………………………………………173

Track Tensioning Malfunctions………………………………………………………………..174

Track Tension Cylinder Internal Leakage Test……………………………………………….174

Track Tension (Pilot) Valve Test………………………………………………………….174

Parking (SAHR) Brake Malfunctions………………………………………………………………..175

Parking Brake (Pilot) Valve Test……………………………………………………………..176

Hydrostatic Drive System Troubleshooting………………………………………………………….179

Work Hydraulics……………………………………………………………………………………183

General Information…………………………………………………………………………….183

General Hydraulic Service Notes………………………………………………………………….183

Hydraulic Oil Analysis………………………………………………………………………….183

Hydraulic Hoses/Tubes……………………………………………………………………….190

Seals……………………………………………………………………………………..190

Main Pressure Test and Adjustment………………………………………………………………..190

Main Pressure Test………………………………………………………………………….190

Main Pressure Adjustment…………………………………………………………………….191

Hydraulic Gear Pump…………………………………………………………………………….192

Hydraulic Gear Pump Removal………………………………………………………………….193

Hydraulic Gear Pump Installation……………………………………………………………..194

Control Valve………………………………………………………………………………….195

Main Control Valve Removal…………………………………………………………………..196

Main Control Valve Installation………………………………………………………………196

Tilt/Lift Cylinder Circuits Components……………………………………………………………197

Tilt/Lift Cylinder Service/Tests…………………………………………………………………199

Inspection…………………………………………………………………………………199

Cylinder Rod/Base End Pressure Tests………………………………………………………….199

Tilt Cylinder Base End Pressure Test………………………………………………………199

Tilt Cylinder Rod End Pressure Test……………………………………………………….200

Lift Cylinder Base End Pressure Test………………………………………………………200

Lift Cylinder Rod End Pressure Test……………………………………………………….201

Lift/Tilt Relief Pressure Adjustment………………………………………………………….202

Cylinder Drift Tests………………………………………………………………………..203

Tilt Cylinder Drift Test…………………………………………………………………203

Lift Cylinder Drift Test…………………………………………………………………203

Cylinder Internal Leakage Tests………………………………………………………………203

Tilt Cylinder Internal Leakage Test……………………………………………………….203

Lift Cylinder Internal Leakage Test……………………………………………………….204

Cylinder Cycle Time Test…………………………………………………………………….204

Lower the Lift Arm………………………………………………………………………204

Raise the Lift Arm………………………………………………………………………205

Dump the Bucket/Attachment Hitch………………………………………………………….205

Roll the Bucket/Attachment Hitch Back……………………………………………………..205

Hydraulic Cylinder Disassembly/ Assembly………………………………………………………….206

Cylinder Disassembly………………………………………………………………………..206

Cylinder Assembly…………………………………………………………………………..206

Bleeding Air After Cylinder Installation………………………………………………………206

Work Hydraulics Tests and Solenoid Valves…………………………………………………………207

Hydraloc Safety Interlock Solenoid Valve Test………………………………………………….207

Self-Leveling Cancel (Disable) Valve and Test………………………………………………….210

Hydraglide…………………………………………………………………………………….212

Hydraglide/Float Valve Solenoid Test………………………………………………………….213

Hydraglide Accumulator………………………………………………………………………215

Solenoid Valve Disassembly/ Reassembly……………………………………………………………216

Work Hydraulics Troubleshooting………………………………………………………………….217

Hydraulic Schematic………………………………………………………………………………..219

(Gehl SN 0040301 and Up; Mustang SN 0060301 and Up; All Manitou)…………………………………….219

Hydraulic Schematic – (Gehl SN 0040300 and Before; Mustang SN 0060300 and Before)……………………..220

Electrical Control System…………………………………………………………………………..221

Electrical Control System General Information……………………………………………………..221

CAN System General Information……………………………………………………………….221

Control Modules………………………………………………………………………………..222

Machine Control Unit (MCU)…………………………………………………………………..222

Keypads……………………………………………………………………………………225

Engine Control Unit (ECU)……………………………………………………………………227

Display/Indicators/Controls………………………………………………………………….227

Multi-Function Display…………………………………………………………………..227

CAN System Service/Computer Connection……………………………………………………………228

J1939 Data Connector………………………………………………………………………..228

CAN/Computer Connection Harnesses…………………………………………………………….228

Service Adapter Harness………………………………………………………………….228

Deutz Engine CAN/Computer Connection Harness (SerDia)…………………………………………..229

Operation/Controller Area Network (CAN) Functional Organization……………………………………..230

Operation/CAN Function Organization Overview…………………………………………………..230

HydralocTM (Safety Interlock) Functional Detail………………………………………………..231

Ignition/Starting Functional Detail…………………………………………………………..232

Operation Functional Detail………………………………………………………………….234

Lift Arm Functional Detail…………………………………………………………………..235

Drive System Functional Detail……………………………………………………………….238

Auxiliary Hydraulics Functional Detail………………………………………………………..240

Warning Indicators Functional Detail………………………………………………………….242

Lighting Functional Detail…………………………………………………………………..244

Accessories and Options Functional Detail…………………………………………………………245

CAN/Control System Troubleshooting……………………………………………………………….249

Inputs/Outputs Detail……………………………………………………………………….249

Inputs Detail…………………………………………………………………………..249

Outputs Detail………………………………………………………………………….257

Indicator Lamp Troubleshooting…………………………………………………………………..267

Electrical System………………………………………………………………………………….269

Batteries……………………………………………………………………………………..269

Power Distribution……………………………………………………………………………..278

Power Distribution Module Fuse Socket Test…………………………………………………….278

Main Power Relay……………………………………………………………………………278

Relay Testing………………………………………………………………………………278

Machine Test……………………………………………………………………………278

Bench Test……………………………………………………………………………..278

Glow Relay Solenoid Test………………………………………………………………………..279

Power-A-Tach Relay Solenoid Test…………………………………………………………………280

Control Modules………………………………………………………………………………..281

Lighting………………………………………………………………………………………281

Work Light Bulb Replacement………………………………………………………………….281

Tail Light Bulb Replacement………………………………………………………………….282

Dome Light Bulb Replacement………………………………………………………………….283

Wire Harness Diagrams………………………………………………………………………………285

Chassis Wire Harness Diagram – (Gehl SN 0040301 and Up; Mustang SN 0060301 and Up; all Manitou)…………285

Chassis Wire Harness Diagram – (Gehl SN 0040300 and Before; Mustang SN 0060300 and Before)……………..287

Engine Wire Harness Diagram – (Gehl SN 0040301 and Up; Mustang SN 0060301 and Up; all Manitou)………….289

Engine Wire Harness Diagram – (Gehl SN 0040300 and Before; Mustang SN 0060300 and Before)………………292

ROPS/FOPS (Cab) Wire Harness Diagram – (Gehl SN 0040301 and Up; Mustang SN 0060301 and Up; all Manitou)….295

ROPS/FOPS (Cab) Wire Harness Diagram – (Gehl SN 0040300 and Before; Mustang SN 0060300 and Before)………296

Operator’s Seat Wire Harness Diagram – (Later Machines)…………………………………………….297

Operator’s Seat Wire Harness Diagram – (Early Machines)…………………………………………….299

Electrical Schematics………………………………………………………………………………301

Chassis – (Gehl SN 0040301 and Up; Mustang SN 0060301 and Up; all Manitou)……………………………301

Electrical Schematic – Chassis – (Gehl SN 0040300 and Before; Mustang SN 0060300 and Before)……………303

Electrical Schematic – Engine – (Gehl SN 0040301 and Up; Mustang SN 0060301 and Up; all Manitou)………..305

Electrical Schematic – Engine – (Gehl SN 0040300 and Before; Mustang SN 0060300 and Before)…………….307

Electrical Schematic – Rear Door…………………………………………………………………309

Electrical Schematic – ROPS/FOPS (Cab)……………………………………………………………310

Electrical Schematic – Seat……………………………………………………………………..311

Electrical Schematic – Road Lights……………………………………………………………….313

Electrical Schematic – 14-Pin Connector…………………………………………………………..314

Lift Arm………………………………………………………………………………………….315

Lift Arm Support……………………………………………………………………………….315

Engage Lift Arm Support……………………………………………………………………..315

Disengage Lift Arm Support…………………………………………………………………..316

Lift Arm Alignment Stops………………………………………………………………………..317

Tilt Stop Adjustment……………………………………………………………………………318

Lift Arm Removal……………………………………………………………………………….320

Lift Arm Installation…………………………………………………………………………..324

ROPS/FOPS/Cab……………………………………………………………………………………..327

Tilting ROPS/FOPS………………………………………………………………………………327

Raising ROPS/FOPS…………………………………………………………………………..327

Lowering ROPS/FOPS………………………………………………………………………….328

ROPS/FOPS Removal………………………………………………………………………………328

ROPS/FOPS Installation………………………………………………………………………….336

HVAC System……………………………………………………………………………………….343

Air Conditioning Refrigerant Recovery…………………………………………………………….347

Air Conditioning System Port Access…………………………………………………………..347

Air Conditioning System Charging…………………………………………………………………347

Specifications…………………………………………………………………………………….349

Fluids/Lubricants Types and Capacities……………………………………………………………349

Dimensions…………………………………………………………………………………….351

Payloads/Capacities…………………………………………………………………………….353

Weights……………………………………………………………………………………….354

Track Drive……………………………………………………………………………………354

Coolant Compound Table………………………………………………………………………….354

Engine………………………………………………………………………………………..355

Hydraulic System……………………………………………………………………………….356

General……………………………………………………………………………………356

Drive Hydraulics……………………………………………………………………………356

Pumps……………………………………………………………………………………..357

Cylinders………………………………………………………………………………….357

Forces and Cycle Times………………………………………………………………………358

Electrical System………………………………………………………………………………358

Sound Power/Pressure Levels……………………………………………………………………..358

Features………………………………………………………………………………………359

Standard Features………………………………………………………………………………359

Optional Features………………………………………………………………………………359

Common Materials and Densities…………………………………………………………………..360

Index…………………………………………………………………………………………….361

Torque Specifications………………………………………………………………………………365