$34

Gehl Z35 Excavator (SN 00700 and Before) Parts Manual 50940088 – PDF DOWNLOAD

Gehl Z35 Excavator (SN 00700 and Before) Parts Manual 50940088 – PDF DOWNLOAD

FILE DETAILS:

Gehl Z35 Excavator (SN 00700 and Before) Parts Manual 50940088 – PDF DOWNLOAD

Language : English

Pages : 285

Downloadable : Yes

File Type : PDF

Size: 144 MB

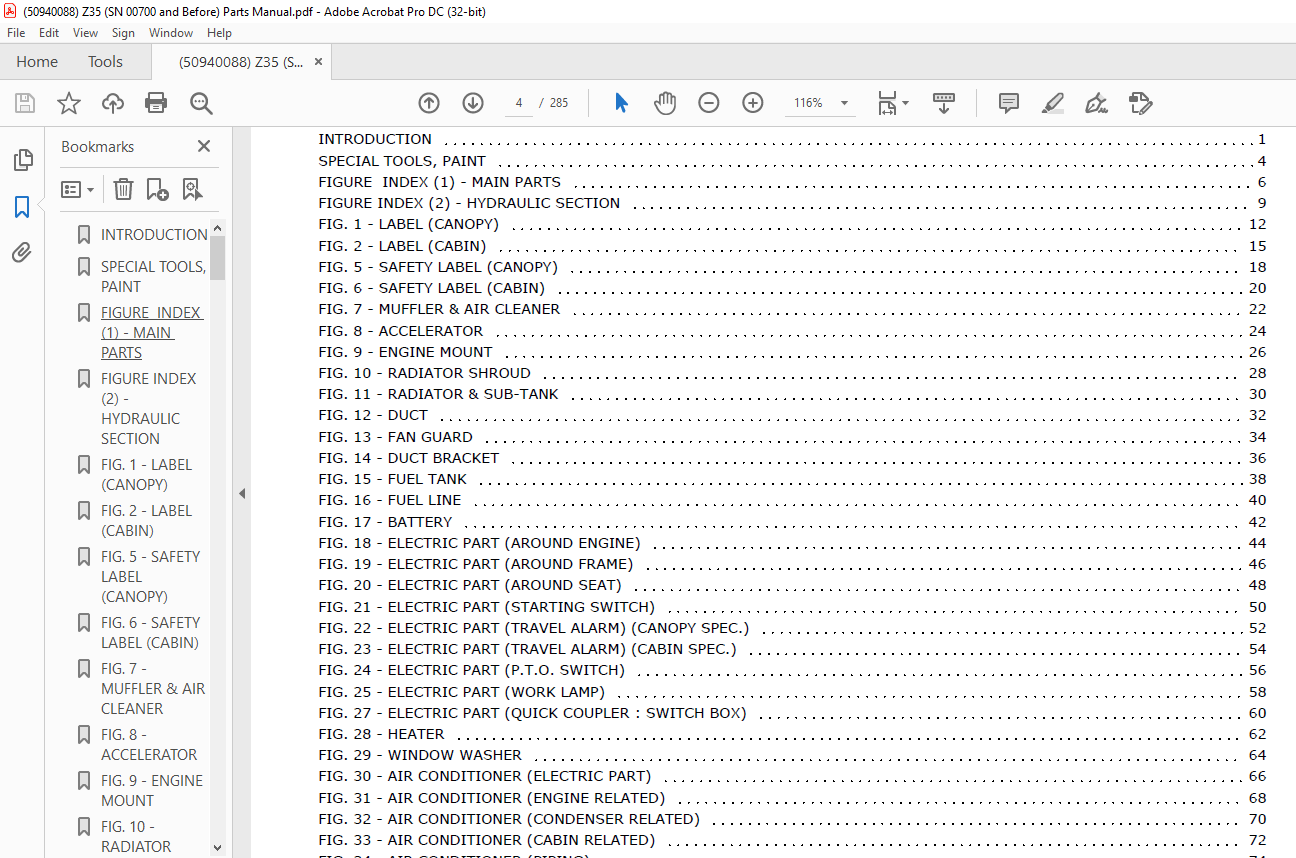

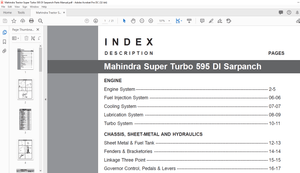

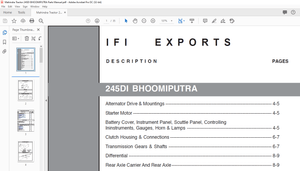

TABLE OF CONTENTS:

Gehl Z35 Excavator (SN 00700 and Before) Parts Manual 50940088 – PDF DOWNLOAD

INTRODUCTION 1

SPECIAL TOOLS, PAINT 4

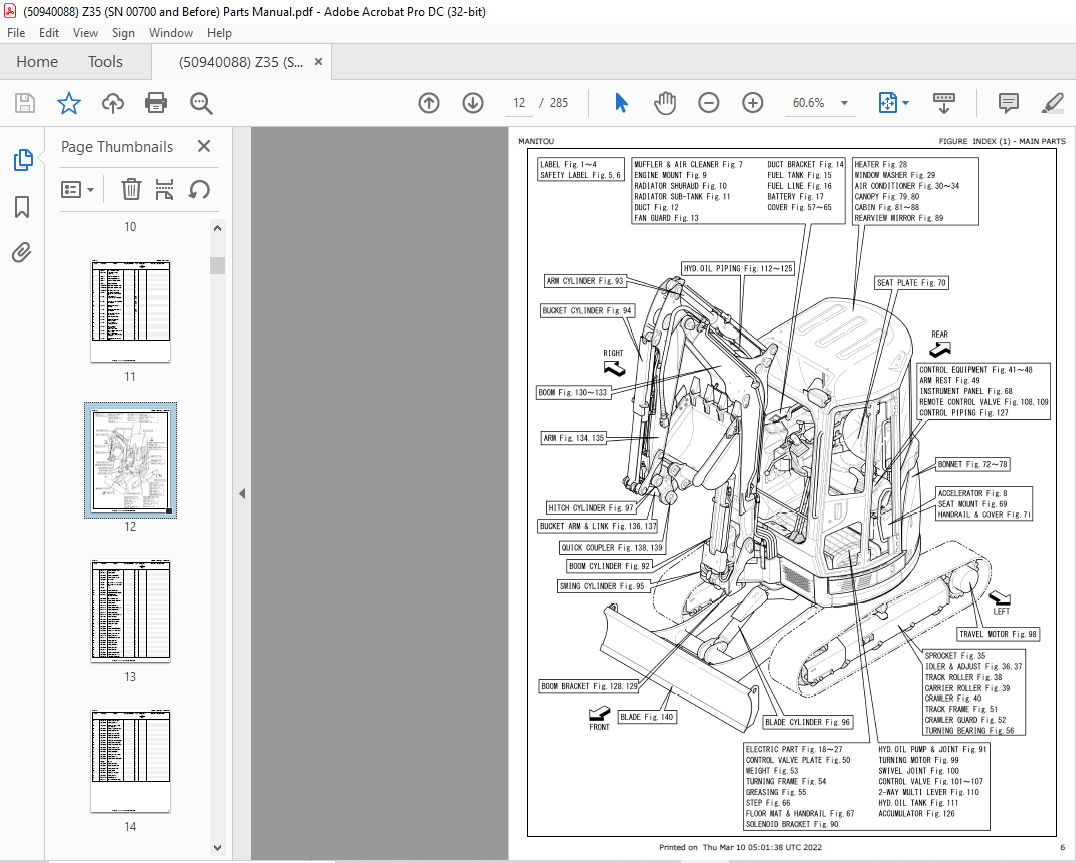

FIGURE INDEX (1) – MAIN PARTS 6

FIGURE INDEX (2) – HYDRAULIC SECTION 9

FIG. 1 – LABEL (CANOPY) 12

FIG. 2 – LABEL (CABIN) 15

FIG. 5 – SAFETY LABEL (CANOPY) 18

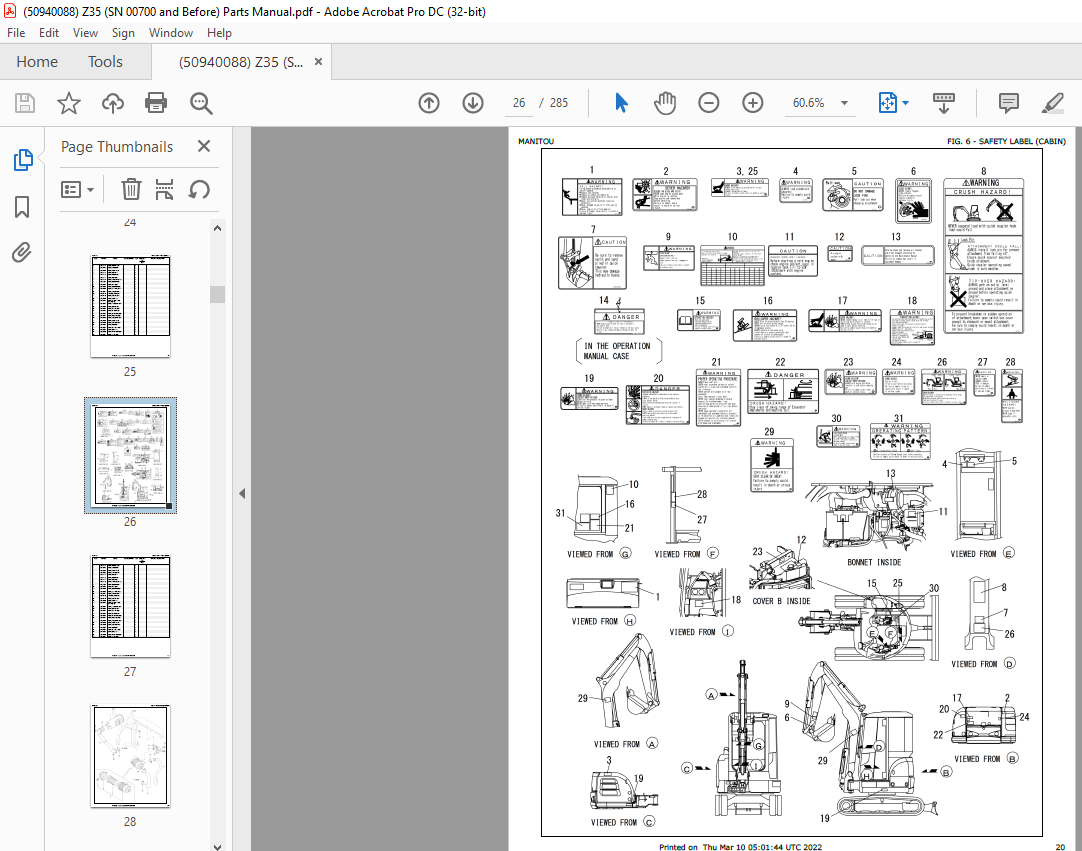

FIG. 6 – SAFETY LABEL (CABIN) 20

FIG. 7 – MUFFLER & AIR CLEANER 22

FIG. 8 – ACCELERATOR 24

FIG. 9 – ENGINE MOUNT 26

FIG. 10 – RADIATOR SHROUD 28

FIG. 11 – RADIATOR & SUB-TANK 30

FIG. 12 – DUCT 32

FIG. 13 – FAN GUARD 34

FIG. 14 – DUCT BRACKET 36

FIG. 15 – FUEL TANK 38

FIG. 16 – FUEL LINE 40

FIG. 17 – BATTERY 42

FIG. 18 – ELECTRIC PART (AROUND ENGINE) 44

FIG. 19 – ELECTRIC PART (AROUND FRAME) 46

FIG. 20 – ELECTRIC PART (AROUND SEAT) 48

FIG. 21 – ELECTRIC PART (STARTING SWITCH) 50

FIG. 22 – ELECTRIC PART (TRAVEL ALARM) (CANOPY SPEC.) 52

FIG. 23 – ELECTRIC PART (TRAVEL ALARM) (CABIN SPEC.) 54

FIG. 24 – ELECTRIC PART (P.T.O. SWITCH) 56

FIG. 25 – ELECTRIC PART (WORK LAMP) 58

FIG. 27 – ELECTRIC PART (QUICK COUPLER : SWITCH BOX) 60

FIG. 28 – HEATER 62

FIG. 29 – WINDOW WASHER 64

FIG. 30 – AIR CONDITIONER (ELECTRIC PART) 66

FIG. 31 – AIR CONDITIONER (ENGINE RELATED) 68

FIG. 32 – AIR CONDITIONER (CONDENSER RELATED) 70

FIG. 33 – AIR CONDITIONER (CABIN RELATED) 72

FIG. 34 – AIR CONDITIONER (PIPING) 74

FIG. 35 – SPROCKET 77

FIG. 36 – IDLER & ADJUST (RUBBER CRAWLER SPEC.) 79

FIG. 37 – IDLER & ADJUST (IRON CRAWLER SPEC.) 81

FIG. 38 – TRACK ROLLER 83

FIG. 39 – CARRIER ROLLER 85

FIG. 40 – CRAWLER 87

FIG. 41 – CONTROL EQUIPMENT (LOCK LEVER & STAND : RIGHT) 89

FIG. 42 – CONTROL EQUIPMENT (LOCK LEVER & STAND : LEFT) 91

FIG. 43 – CONTROL EQUIPMENT (TRAVEL LEVER) 93

FIG. 44 – CONTROL EQUIPMENT (BLADE LEVER) 95

FIG. 45 – CONTROL EQUIPMENT (TRAVEL PEDAL) 97

FIG. 46 – CONTROL EQUIPMENT (SWING PEDAL) 99

FIG. 47 – CONTROL EQUIPMENT (LOW-HIGH PEDAL) 101

FIG. 48 – CONTROL EQUIPMENT (P.T.O. PEDAL) 103

FIG. 49 – ARM REST 105

FIG. 50 – CONTROL VALVE PLATE 107

FIG. 51 – TRACK FRAME 109

FIG. 52 – CRAWLER GUARD (IRON CRAWLER SPEC.) 111

FIG. 53 – WEIGHT 113

FIG. 54 – TURNING FRAME 115

FIG. 55 – GREASING 117

FIG. 56 – TURNING BEARING 119

FIG. 57 – COVER (LINK) 121

FIG. 58 – MULTI COVER & FRAME GUARD 123

FIG. 60 – COVER (TAIL PIPE) 125

FIG. 61 – COVER (QUICK COUPLER SPEC.) 127

FIG. 62 – COVER (BONNET) 129

FIG. 63 – COVER (TURNING FRAME) 131

FIG. 64 – COVER (TRACK FRAME) 133

FIG. 65 – COVER (SEAT MOUNT) 135

FIG. 66 – STEP 137

FIG. 67 – FLOOR MAT & HANDRAIL 139

FIG. 68 – INSTRUMENT PANEL 141

FIG. 69 – SEAT MOUNT 143

SEAT 146

FIG. 70 – SEAT PLATE 148

FIG. 71 – HANDRAIL & COVER 150

FIG. 72 – BONNET (1) 152

FIG. 74 – BONNET (2) 154

FIG. 75 – BONNET (3) 156

FIG. 77 – BONNET (4) 158

FIG. 79 – CANOPY 160

FIG. 81 – CABIN (BODY) 162

FIG. 82 – CABIN (GLASS) 164

FIG. 83 – CABIN (ACCESSORY) 167

FIG. 84 – CABIN (ELECTRIC PART) 169

FIG. 85 – CABIN DOOR (FRONT) 171

FIG. 86 – CABIN DOOR (REAR) 173

FIG. 87 – CABIN (COVER) 175

FIG. 88 – CABIN (FITTING) 177

FIG. 89 – REARVIEW MIRROR 179

FIG. 90 – SOLENOID BRACKET (P.T.O. SPEC.) 181

FIG. 91 – HYD. OIL PUMP & JOINT (QUICK COUPLER SPEC.) 183

FIG. 92 – BOOM CYLINDER 186

FIG. 93 – ARM CYLINDER 189

FIG. 94 – BUCKET CYLINDER 192

FIG. 95 – SWING CYLINDER 194

FIG. 96 – BLADE CYLINDER 196

FIG. 97 – HITCH CYLINDER (QUICK COUPLER) 198

FIG. 98 – TRAVEL MOTOR 200

FIG. 99 – TURNING MOTOR 203

FIG. 100 – SWIVEL JOINT 206

FIG. 101 – CONTROL VALVE (1/7) 208

FIG. 102 – CONTROL VALVE (2/7) 211

FIG. 103 – CONTROL VALVE (3/7) 213

FIG. 104 – CONTROL VALVE (4/7) 215

FIG. 105 – CONTROL VALVE (5/7) 217

FIG. 106 – CONTROL VALVE (6/7) 219

FIG. 107 – CONTROL VALVE (7/7) 221

FIG. 108 – REMOTE CONTROL VALVE (LEFT) 223

FIG. 109 – REMOTE CONTROL VALVE (RIGHT) 225

FIG. 110 – 2-WAY MULTI LEVER 227

FIG. 111 – HYD. OIL TANK 229

FIG. 112 – HYD. OIL PIPING (TANK-PUMP, CONTROL VALVE) 232

FIG. 113 – HYD. OIL PIPING (CONTROL VALVE-TURNING MOTOR) 234

FIG. 114 – HYD. OIL PIPING (CONTROL VALVE : FITTING) 236

FIG. 115 – HYD. OIL PIPING (CONTROL VALVE – BOOM, SWING) 238

FIG. 116 – HYD. OIL PIPING (CONTROL VALVE – BOOM CYLINDER) 240

FIG. 117 – HYD. OIL PIPING (CONTROL VALVE – SWIVEL JOINT) 242

FIG. 118 – HYD. OIL PIPING (TRACK FRAME) 244

FIG. 119 – HYD. OIL PIPING (BOOM) 246

FIG. 120 – HYD. OIL PIPING (P.T.O. : SOLENOID-CONTROL VALVE) 248

FIG. 121 – HYD. OIL PIPING (P.T.O. : CONTROL VALVE-BOOM) 250

FIG. 122 – HYD. OIL PIPING (P.T.O. : BOOM-ARM END) 252

FIG. 124 – HYD. OIL PIPING (QUICK COUPLER) 254

FIG. 126 – ACCUMULATOR 256

FIG. 127 – CONTROL PIPING 258

FIG. 128 – BOOM BRACKET 260

FIG. 130 – BOOM 262

FIG. 132 – BOOM (COVER) 264

FIG. 134 – ARM 266

FIG. 136 – BUCKET ARM & LINK 268

FIG. 138 – QUICK COUPLER 270

FIG. 140 – BLADE 272

HYDRAULIC QUICK-CONNECT COUPLERS 274

TORQUE SPECIFICATIONS 276

DESCRIPTION:

Gehl Z35 Excavator (SN 00700 and Before) Parts Manual 50940088 – PDF DOWNLOAD

General:

•MANITOU AMERICAS, INC. reserves the right to make changes or improvements in the design or construction of any part of the machine without incurring the obligation to install such changes on any previously delivered machines.• This parts manual should not be used as a technical data reference; it uses simplified illustrations and does not detail servicing procedures.

Parts Ordering Information:

• When ordering service parts, specify the correct part number, full description and quantity required, as well as the machine and engine model and serial numbers. For your safety and continued proper operation, use only genuine GEHL service parts.• “Right”, “left”, “front” and “back” are determined from a position sitting on the operator’s seat and facing forward, and the excavator “house” rotated so that the blade is also facing forward.

Torque Charts:

Standard attaching hardware torque values are provided on the inside back cover, and some torque values may be shown in illustrations. Metric torque values are shown in Newton-meters, and are converted to foot-pounds by multiplying by 0.738.

Illustrations and Parts Lists:

• Not all parts shown in the illustrations may be included in the parts listings; some are not serviced separately or are not included on engines sold in all areas.• Ref. Nos. shown in the parts listings without part numbers are shown for reference purposes only and are not available for purchase.• Boxes or brackets may be used in some illustrations to indicate assemblies (part groupings), or in some cases to highlight different versions of individual parts or assemblies.• Text references may be present on some illustrations to provide additional information.• Some illustrations will contain circled letters or a circled combination of letters and numbers in addition to the regular number callouts. These special callouts may be used to identify hydraulic port locations which are marked on components, or to identify the two ends of a hose, tube, or other part that is shown split in the illustration. They may also be used to indicate a common reference point when different versions of components are shown on the illustration.

IMAGES PREVIEW OF THE MANUAL: