$34

Gehl Z35 GEN2 Compacat Excavator Parts Manual 50940278 – PDF DOWNLOAD

Gehl Z35 GEN2 Compacat Excavator Parts Manual 50940278 – PDF DOWNLOAD

FILE DETAILS:

Gehl Z35 GEN2 Compacat Excavator Parts Manual 50940278 – PDF DOWNLOAD

Language : English

Pages : 424

Downloadable : Yes

File Type : PDF

Size: 28.4 MB

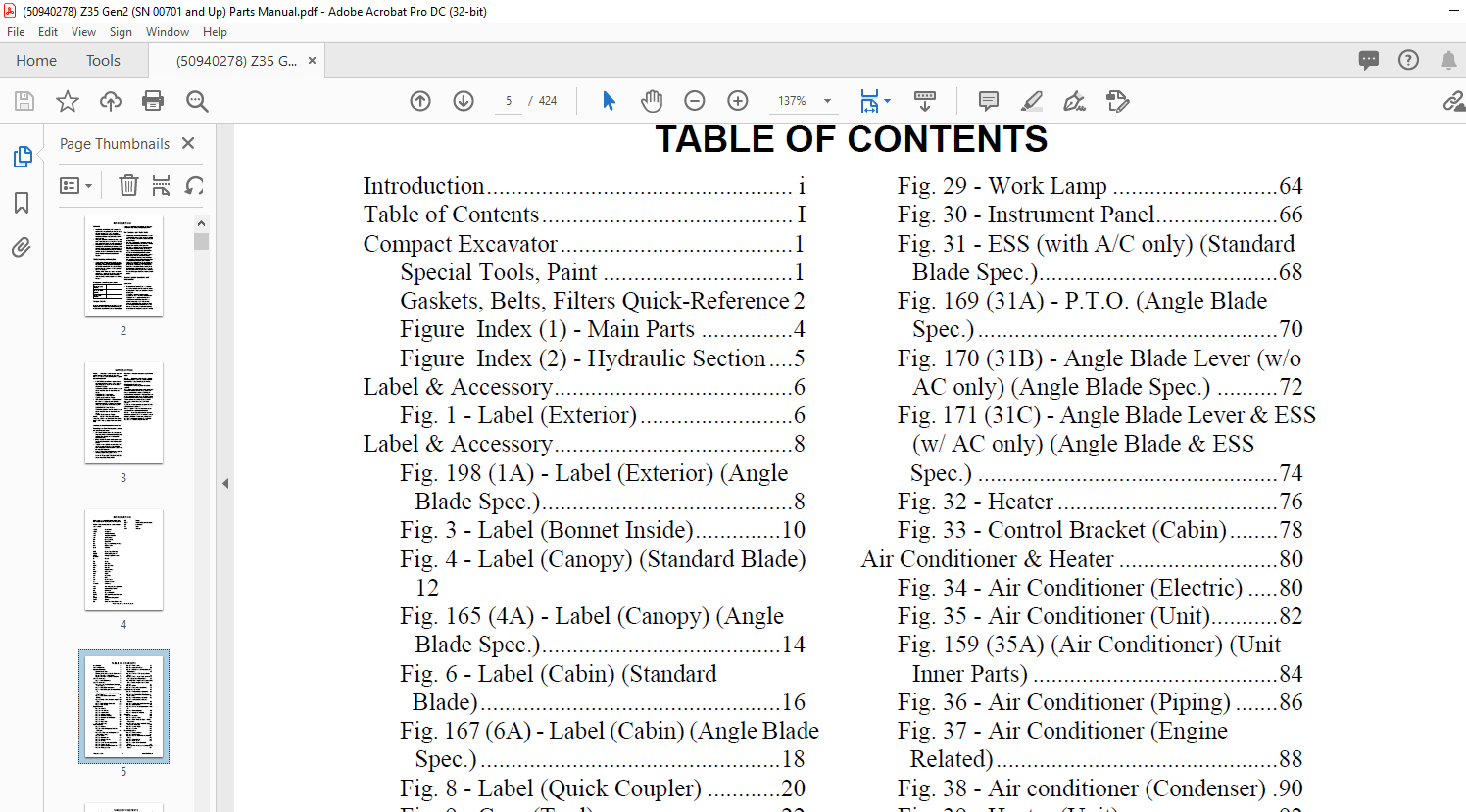

TABLE OF CONTENTS:

Gehl Z35 GEN2 Compacat Excavator Parts Manual 50940278 – PDF DOWNLOAD

Introduction i

Table of Contents I

Compact Excavator 1

Special Tools, Paint 1

Gaskets, Belts, Filters Quick-Reference 2

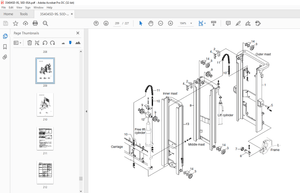

Figure Index (1) – Main Parts 4

Figure Index (2) – Hydraulic Section 5

Label & Accessory 6

Fig 1 – Label (Exterior) 6

Label & Accessory 8

Fig 198 (1A) – Label (Exterior) (Angle

Blade Spec ) 8

Fig 3 – Label (Bonnet Inside) 10

Fig 4 – Label (Canopy) (Standard Blade)

12

Fig 165 (4A) – Label (Canopy) (Angle

Blade Spec ) 14

Fig 6 – Label (Cabin) (Standard

Blade) 16

Fig 167 (6A) – Label (Cabin) (Angle Blade

Spec ) 18

Fig 8 – Label (Quick Coupler) 20

Fig 9 – Case (Tool) 22

Engine Related 24

Fig 10 – Muffler 24

Fig 11 – Air Cleaner 26

Fig 12 – Accelerator 28

Fig 13 – Engine Mount 30

Fig 14 – Radiator Shroud 32

Fig 15 – Radiator & Oil-Cooler 34

Fig 16 – Duct 36

Fig 17 – Fuel Tank 38

Fig 18 – Fuel Line 40

Electrical Parts 42

Fig 19 – Battery 42

Fig 20 – Around Engine (SN before

M00806) 44

Fig 197 (20A) – Around Engine (SN

M00806 and later) 46

Fig 21 – Horn 48

Fig 22 – Seat Mount 50

Fig 23 – Guide Harness 52

Fig 24 – Starter 54

Fig 25 – Auto Deceleration (A/D) 56

Fig 26 – Travel Buzzer 58

Fig 27 – Quick Coupler:Switch Box 60

Fig 28 – Canopy Lamp 62

Fig 29 – Work Lamp 64

Fig 30 – Instrument Panel 66

Fig 31 – ESS (with A/C only) (Standard

Blade Spec ) 68

Fig 169 (31A) – P T O (Angle Blade

Spec ) 70

Fig 170 (31B) – Angle Blade Lever (w/o

AC only) (Angle Blade Spec ) 72

Fig 171 (31C) – Angle Blade Lever & ESS

(w/ AC only) (Angle Blade & ESS

Spec ) 74

Fig 32 – Heater 76

Fig 33 – Control Bracket (Cabin) 78

Air Conditioner & Heater 80

Fig 34 – Air Conditioner (Electric) 80

Fig 35 – Air Conditioner (Unit) 82

Fig 159 (35A) (Air Conditioner) (Unit

Inner Parts) 84

Fig 36 – Air Conditioner (Piping) 86

Fig 37 – Air Conditioner (Engine

Related) 88

Fig 38 – Air conditioner (Condenser) 90

Fig 39 – Heater (Unit) 92

Fig 160 (39A) – Heater (Unit Inner Parts)

94

Fig 40 – Heater (Piping) 96

Fig 41 – Duct (A/C, Heater) 98

Traveling 100

Fig 42 – Sprocket 100

Fig 43 – Idler & Adjust 102

Fig 44 – Track Roller (Y Spec – Before

May 2014) 104

Fig 164 (44A) – Track Roller (K Spec –

May 2014 and later) 106

Fig 45 – Carrier Roller 108

Fig 46 – Crawler 110

Control Equipment 112

Fig 47 – Mount (Valve) 112

Fig 48 – Travel Lever 114

Fig 206 (48A) – Travel Pedals (Folding

Type) 116

Fig 49 – Swing Pedal 118

Fig 50 – Pedal Cover 120

Fig 51 – Blade Lever (Standard

Blade) 122

Fig 172 (51A) – Blade Lever (Angle Blade

Spec ) 124

50940278/BP0318 II Printed in U S A

TABLE OF CONTENTS

Fig 52 – Arm Rest 126

Fig 53 – Lock Lever & Stand 128

Frame 130

Fig 54 – Track Frame 130

Fig 55 – Counterweight 132

Fig 163 (55A) – Additional Weight 134

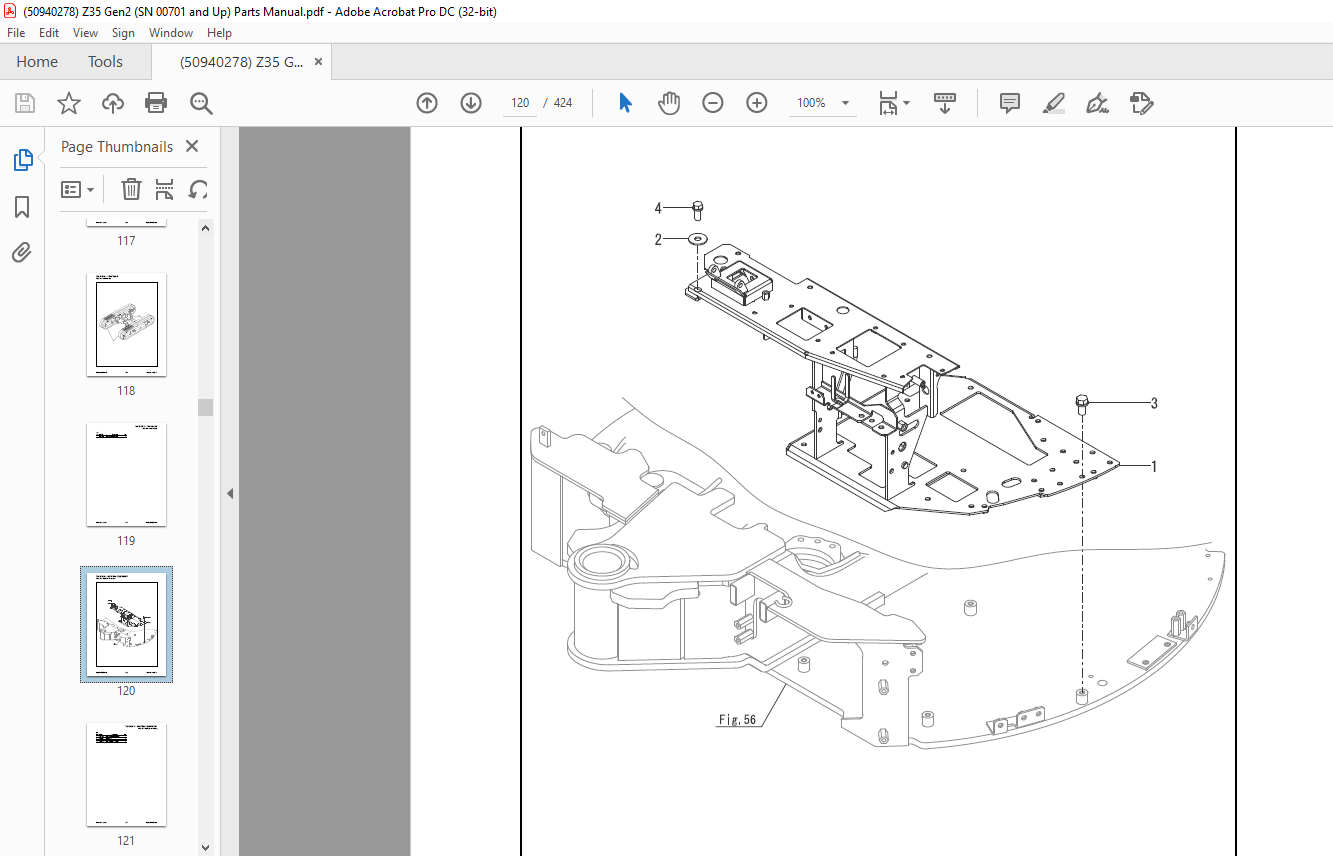

Fig 56 – Turning Frame 136

Fig 57 – Turning Bearing 138

Cover 140

Fig 58 – Cover (Multi) 140

Fig 60 – Cover (Upper) 142

Fig 61 – Cover (Turning Frame) 144

Fig 62 – Cover (Track Frame) 146

Fig 63 – Guard (Frame) 148

Fig 64 – Cover (Frame Front) 150

Around Seat 152

Fig 65 – Step (Cabin) 152

Fig 66 – Step (Canopy) 154

Fig 67 – Cover (Lever) 156

Fig 68 – Cover (Monitor, w/

Canopy) 158

Fig 69 – Cover (Monitor, w/Cabin) 160

Fig 70 – Seat Mount 162

Fig 71 – Seat Mount (Cover) 164

Fig 72 – Seat 166

Fig 73 – Seat (Inner Parts) 168

Fig 74 – Handrail (w/Canopy) 170

Bonnet 172

Fig 75 – Bonnet (Rear) 172

Fig 77 – Bonnet (Front) 174

Fig 78 – Bonnet (Left) 176

Fig 80 – Bonnet (Right) 178

Canopy 180

Fig 82 – Canopy 180

Canopy / Cabin 182

Fig 83 – Mount 182

Cabin 184

Fig 84 – Window Washer 184

Fig 85 – Cabin (Body) 186

Fig 86 – Cabin (Door:1) 188

Fig 87 – Cabin (Door:2) 190

Fig 88 – Cabin (Front Window:1) 192

Fig 89 – Cabin (Front Window:2) 194

Fig 90 – Cabin (Glass) 196

Fig 91 – Cabin (Rear Cover) 198

Fig 92 – Cabin (Electric Parts) 200

Fig 93 – Cabin (Accessory Parts) 202

Fig 94 – Rearview Mirror 204

Fig 95 – Mount (Cabin) 206

Fig 96 – Box (Cabin Heater Spec ) 208

Hydraulic Oil Equipment 210

Fig 97 – Hyd Oil Pump Mount 210

Fig 98 – Hyd Oil Pump 212

Fig 99 – Hyd Oil Pump (ESS Spec ) (with

A/C only) 214

Fig 100 – Boom Cylinder (Y SPEC )—

Early Machines 216

Fig 200 (100A) – Boom Cylinder (K

SPEC )—Later Machines 218

Fig 101 – Arm Cylinder (Y SPEC )—Early

Machines 220

Fig 201 (101A) – Arm Cylinder (K

SPEC )—Later Machines 222

Fig 102 – Bucket Cylinder (Y Spec )—

Early Machines 224

Fig 202 (102A) – Bucket Cylinder (K

Spec )—Later Machines 226

Fig 103 – Swing Cylinder (Y Spec )—Early

Machines 228

Fig 203 (103A) – Swing Cylinder (K

Spec )—Later Machines 230

Fig 104 – Lift Cylinder (Standard Blade)

(Y Spec )—Early Machines 232

Fig 204 (104A) – Lift Cylinder (Standard

Blade) (K Spec )—Later

Machines 234

Fig 205 (104B) – Lift Cylinder (Angle

Blade Spec ) 236

Fig 173 (104A) – Angle Cylinder (Angle

Blade Spec ) 238

Fig 105 – Travel Motor (Standard

Blade) 240

Fig 174 (105A) – Travel Motor (Angle

Blade Spec ) 242

Fig 106 – Turning Motor 244

Fig 107 – Swivel Joint (Y Spec ) (SN

Before M00730) (Standard Blade) 246

Fig 108 – Swivel Joint (N Spec ) (SN

M00730 & Later) (Standard

Blade) 248

Fig 175 (108A) – Swivel Joint (Angle

Blade Spec ) 250

Fig 109 – Control Valve (1/7) (Standard

Blade) 252

Fig 110 – Control Valve (2/7) (Standard

Blade) 254

Printed in U S A III 50940278/BP0318

TABLE OF CONTENTS

Fig 111 – Control Valve (3/7) (Standard

Blade) 256

Fig 112 – Control Valve (4/7) (Standard

Blade) 258

Fig 113 – Control Valve (5/7) (Standard

Blade) 260

Fig 114 – Control Valve (6/7) (Standard

Blade) 262

Fig 115 – Control Valve (7/7) (Standard

Blade) 264

Fig 176 (115A) – Control Valve (1/8)

(Angle Blade Spec ) 266

Fig 177 (115B) – Control Valve (2/8)

(Angle Blade Spec ) 268

Fig 178 (115C) – Control Valve (3/8)

(Angle Blade Spec ) 270

Fig 179 (115D) – Control Valve (4/8)

(Angle Blade Spec ) 272

Fig 180 (115E) – Control Valve (5/8)

(Angle Blade Spec ) 274

Fig 181 (115F) – Control Valve (6/8)

(Angle Blade Spec ) 276

Fig 182 (115G) – Control Valve (7/8)

(Angle Blade Spec ) 278

Fig 183 (115H) – Control Valve (8/8)

(Angle Blade Spec ) 280

Fig 116 – Joystick Control (Right) 282

Fig 117 – Joystick Control (Left) 284

Fig 118 – 2-Way Valve (Standard

Blade) 286

Fig 184 (118A) – 2-Way Valve (Angle

Blade Spec ) 288

Fig 119 – Solenoid Valve (ESS:PTO) (with

A/C only) 290

Fig 120 – Solenoid Valve (PTO) 292

Fig 185 (120A) – Solenoid Valve (P T O 2)

(Angle Blade Spec ) 294

Fig 186 (120B) – Solenoid Valve Bracket

(P T O 2) (Angle Blade Spec ) 296

Fig 121 – Hyd Oil Tank 298

Fig 142 – Quick Coupler (Hitch

Cylinder) 300

Hydraulic Oil Piping 302

Fig 122 – Tank-Pump, C/V 302

Fig 123 – C/V-Turning Motor 304

Fig 124 – C/V:Fitting1 (Standard

Blade) 306

Fig 187 (124A) – CV:Fitting1 (Angle

Blade Spec ) 308

Fig 125 – C/V:Fitting 2 (Standard

Blade) 310

Fig 188 (125A) – CV:Fitting 2 (Angle

Blade Spec ) 312

Fig 126 – C/V-Return, Drain 314

Fig 127 – C/V-Boom Bulkhead,

Swing 316

Fig 128 – C/V-Boom Cylinder 318

Fig 129 – Hyd Oil Piping (C/V-Swivel

Joint) (Standard Blade) 320

Fig 189 (129A) – Hyd Oil Piping (Control

Valve-Swivel Joint) (Angle Blade

Spec ) 322

Fig 130 – Hyd Oil Piping (Track Frame)

(Standard Blade) 324

Fig 190 (130A) – Hyd Oil Piping (Track

Frame) (Angle Blade Spec ) 326

Fig 131 – Hyd Oil Piping (Arm Cylinder,

Bucket Cylinder) 328

Fig 133 – Hyd Oil Piping (P T O :C/VBoom)

330

Fig 134 – Hyd Oil Piping (P T O :Boom-

Arm End) 332

Fig 136 – Hyd Oil Piping (P T O :Solenoid

Valve) (Standard Blade) 334

Fig 191 (136A) – Hyd Oil Piping

(P T O :Solenoid Valve) (Angle Blade

Spec ) 336

Fig 137 – Hyd Oil Piping (P T O :Solenoid

Valve, ESS) (Standard Blade) (with A/C

only) 338

Fig 192 (137A) – Hyd Oil Piping

(P T O :Solenoid Valve, ESS) (Angle

Blade Spec ) (with A/C only) 340

Fig 193 (137B) – Hyd Oil Piping

(P T O2:Angle Blade) (Angle Blade

Spec ) 342

Fig 138 – Control Piping (1) (Standard

Blade) 344

Fig 194 (138A) – Control Piping (1) (Angle

Blade Spec ) 346

Fig 139 – Control Piping (2) 348

Fig 140 – Accumulator 350

Fig 141 – Greasing 352

Fig 143 – Quick Coupler (Hyd Oil

Piping:1) 354

50940278/BP0318 IV Printed in U S A

TABLE OF CONTENTS

Fig 145 – Quick Coupler (Hyd Oil

Piping:2) 356

Fig 147 – Quick Coupler (Body) 358

Implement 358

Fig 149 – Boom Bracket 360

Fig 151 – Boom 362

Fig 153 – Arm 364

Fig 155 – Bucket Arm & Link 366

Fig 157 – Blade (Standard) 368

Fig 195 (157A) – Blade (Angle Blade

Spec ) 370

Fig 161 – Radio Kit (option) 372

Hydraulic Quick-Connect Couplers 374

DESCRIPTION:

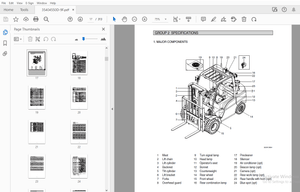

Gehl Z35 GEN2 Compacat Excavator Parts Manual 50940278 – PDF DOWNLOAD

Serial Numbers 00701 and Up

General:

•MANITOU AMERICAS, INC. reserves the right to make changes or improvements in the design or construction of any part of the machine without incurring the obligation to install such changes on any previously delivered machines.• This parts manual should not be used as a technical data reference; it uses simplified illustrations and does not detail servicing procedures.

Parts Ordering Information:

• When ordering service parts, specify the correct part number, full description and quantity required, as well as the machine and engine model and serial numbers. For your safety and continued proper operation, use only genuine GEHL service parts.• “Right”, “left”, “front” and “back” are determined from a position sitting on the operator’s seat and facing forward, and the excavator “house” rotated so that the blade is also facing forward.

Torque Charts:

Standard attaching hardware torque values are provided on the inside back cover, and some torque values may be shown in illustrations. Metric torque values are shown in Newton-meters, and are converted to foot-pounds by multiplying by 0.738.

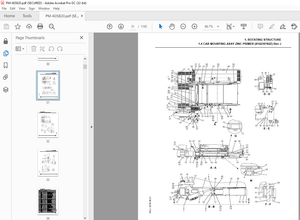

Illustrations and Parts Lists:

• Not all parts shown in the illustrations may be included in the parts listings; some are not serviced separately or are not included on engines sold in all areas.• Ref. Nos. shown in the parts listings without part numbers are shown for reference purposes only and are not available for purchase.• Boxes or brackets may be used in some illustrations to indicate assemblies (part groupings), or in some cases to highlight different versions of individual parts or assemblies.• Text references may be present on some illustrations to provide additional information.• Some illustrations will contain circled letters or a circled combination of letters and numbers in addition to the regular number callouts. These special callouts may be used to identify hydraulic port locations which are marked on components, or to identify the two ends of a hose, tube, or other part that is shown split in the illustration. They may also be used to indicate a common reference point when different versions of components are shown on the illustration.

IMAGES PREVIEW OF THE MANUAL: