$36

Gehl Z80 800Z Compact Excavator Service Manual 50940113 – PDF DOWNLOAD

Gehl Z80 800Z Compact Excavator Service Manual 50940113 – PDF DOWNLOAD

FILE DETAILS:

Gehl Z80 800Z Compact Excavator Service Manual 50940113 – PDF DOWNLOAD

Language : English

Pages : 698

Downloadable : Yes

File Type : PDF

Size: 43.1 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gehl Z80 800Z Compact Excavator Service Manual 50940113 – PDF DOWNLOAD

General Cautions for Maintenance Work

1-1 Correct Work

Correct work means the quickest possible completion of according to the correct procedures and the specified standards.

It is important when conducting certain operations always to bear in mind the equipment, tools, gauges, materials, oil

and grease, etc. that you must have ready, as well as items to be checked, adjusted, or disassembled, and cautions

to watch out for.

1-2 Safety Precautions

(1) Never attempt servicing while engine is running or immediately after stopping operation.

(2) Wear work cloths, safety shoes and helmet.

(3) Check the equipment and tools before use. Especially, be sure to check the crane, lifting equipment and tools.

(4) When working together with other persons, allocate everyone’s share of job, arrange the signals and act in concert

with the other persons.

(5) The operation of the crane and slinging work must be performed by qualified persons.

(6) Do not enter or pass under the raised load.

(7) Lift and support the massive parts by crane before removing the installation bolts.

(8) Disconnect cables from battery before repairing the electric system.

(9) Remove the battery when welding the machine.

1-3 Preparations

(1) Check the service record of the machine. (That is, check how many months or hours the machine has been

used since the preceding overhaul, what was the trouble then and what parts were replaced.)

(2) Have all servicing tools ready, i.e., tools, measuring devices (which have received periodic maintenance), containers,

oil & grease, etc.

(3) Have the service literature (operation manual, parts catalog, etc.) ready.

TABLE OF CONTENTS:

Gehl Z80 800Z Compact Excavator Service Manual 50940113 – PDF DOWNLOAD

GENERAL CAUTIONS FOR MAINTENANCE WORK

1-1 Correct Work 1-1

1-2 Safety Precautions 1-1

1-3 Preparations 1-1

1-4 Cautions for Disassembly and Reassembly 1-1

1-5 Cautions for Removal and Installation of Hydraulic Equipment 1-2

1-6 Cautions for Removal and Installation of Hydraulic Piping 1-2

1-7 Cautions for Handling Seals 1-3

1-8 Correct Installation of Hydraulic Hose 1-3

1-9 Specifications of Hydraulic Hose 1-6

1-10 Air Release of Hydraulic Equipment 1-11

CHAPTER 2

TECHNICAL DATA

2-1 Specifications 2-1-1

2-2 Outline Drawing and Working Area 2-2-1

2-2-1 Quick Coupler 2-2-1

2-3 Weight List of Main Parts 2-3-1

2-4 Lifting Capacity List 2-4-1

2-4-1 Z80/800Z Quick Coupler Spec 2-4-1

CHAPTER 3

SERVICE STANDARDS

3-1 Machine Performance 3-1-1

3-2 Engine 3-2-1

3-3 Undercarriage 3-3-1

3-3-1 Rubber Crawler Specifications 3-3-1

3-3-2 Steel Crawler Specifications 3-3-2

3-3-3 Common Specifications of Steel & Rubber Crawlers 3-3-3

3-4 Controls 3-4-1

3-5 Hydraulic Equipment 3-5-1

3-5-1 Hydraulic Cylinders 3-5-1

3-6 Implement 3-6-1

3-6-1 Front Attachments 3-6-1

3-6-2 Blade Moving Device 3-6-2

3-6-3 Bucket Teeth 3-6-2

3-7 List of Tightening Torque 3-7-1

3-7-1 Machine 3-7-1

3-7-2 Engine 3-7-4

3-7-3 Tightening Torque for General Bolts and Nuts 3-7-5

3-7-4 Hydraulic Fitting 3-7-6

CONTENTS

CHAPTER 4

ENGINE

4-1 Engine 4-1-1

4-1-1 Safety Precautions 4-1-1

4-1-2 Introduction 4-1-21

4-1-3 Special Service Tools 4-1-22

4-1-4 Measuring Instruments 4-1-25

4-1-5 4-Valve Cylinder Head 4-Valve Cylinder Head Components 4-1-27

4-1-6 Measuring and Adjusting Valve Clearance 4-1-44

4-1-7 Crankshaft and Camshaft Components 4-1-48

4-1-8 EGR System 4-1-75

4-2 Fuel System 4-2-1

4-2-1 Before You Begin Servicing 4-2-1

4-2-2 Introduction 4-2-6

4-2-3 Special Service Tools 4-2-9

4-2-4 Measuring Instruments 4-2-9

4-2-5 Fuel System Diagram 4-2-10

4-2-6 Fuel System Components 4-2-11

4-2-7 Fuel Injection Pump 4-2-13

4-2-8 Fuel Injectors 4-2-29

4-3 Cooling System 4-3-1

4-3-1 Before You Begin Servicing 4-3-1

4-3-2 Introduction 4-3-3

4-3-3 Cooling System Diagram 4-3-3

4-3-4 Engine Coolant Pump Components 4-3-4

4-3-5 Engine Coolant System Check 4-3-5

4-3-6 Engine Coolant Pump 4-3-5

4-4 Lubrication System 4-4-1

4-4-1 Before You Begin Servicing 4-4-1

4-4-2 Introduction 4-4-3

4-4-3 Lubrication System Diagram 4-4-3

4-4-4 Checking Engine Oil Pressure 4-4-4

4-4-5 Trochoid Oil Pump 4-4-4

4-5 Starter Motor 4-5-1

4-5-1 Before You Begin Servicing 4-5-1

4-5-2 Introduction 4-5-3

4-5-3 Starter Motor Specifications 4-5-3

4-5-4 Starter Motor Troubleshooting 4-5-4

4-5-5 Starter Motor Components 4-5-5

4-5-6 Starter Motor 4-5-6

4-6 Alternator 4-6-1

4-6-1 Before You Begin Servicing 4-6-1

4-6-2 Introduction 4-6-4

4-6-3 Alternator Specifications 4-6-4

4-6-4 Alternator Troubleshooting 4-6-5

4-6-5 Alternator Components 4-6-6

CONTENTS

4-6-6 Alternator Wiring Diagram 4-6-7

4-6-7 Alternator Standard Output 4-6-8

4-6-8 Alternator 4-6-9

4-7 Electronic Control System 4-7-1

4-7-1 Engines available with the electronic control system 4-7-1

4-7-2 Before You Begin Servicing 4-7-1

4-7-3 Main Electronic Control Components and Features 4-7-4

4-8 Electric Wiring 4-8-1

4-8-1 Electric Wiring Precautions 4-8-1

4-9 Failure Diagnosis 4-9-1

4-9-1 Special Service Tools 4-9-1

4-9-2 Troubleshooting By Measuring Compression Pressure 4-9-2

CHAPTER 5

HYDRAULIC SYSTEM

5-1 Outline 5-1-1

5-1-1 Control Valve Operation 5-1-3

5-1-2 Additional Operation of Control Valve 5-1-4

5-2 Hydraulic Circuit Schematic 5-2-1

5-2-1 US spec 5-2-1

5-2-2 AS/NZ spec 5-2-2

5-2-3 KR spec 5-2-3

5-2-4 AYR spec 5-2-4

5-3 Circuit Operation 5-3-1

5-3-1 Boom 5-3-1

5-3-2 Arm 5-3-3

5-3-3 Bucket 5-3-4

5-3-4 Swing 5-3-5

5-3-5 Boom Swing 5-3-6

5-3-6 Blade 5-3-7

5-3-7 Travel 5-3-8

5-3-8 Non-deviation Travel (with Boom, Arm, Bucket or Boom Swing Operation) 5-3-10

5-3-9 Simultaneous Operation of Boom Up and Arm Retract 5-3-11

5-3-10 Simultaneous Operation of Boom Up and Bucket 5-3-12

5-3-11 Simultaneous Operation of Boom Up and Swing 5-3-13

5-3-12 Simultaneous Operation of Arm and Bucket 5-3-14

5-3-13 Hydraulic P T O 5-3-15

5-3-14 Travel Alarm 5-3-16

5-3-15 4th P T O 5-3-17

5-3-16 Quick Coupler 5-3-18

5-3-17 Auto Deceleration 5-3-19

5-4 Pressure Adjustment 5-4-1

5-4-1 Relief Valves 5-4-1

5-4-2 Swing Brake Valve 5-4-3

5-4-3 Cut-off Valve 5-4-4

CONTENTS

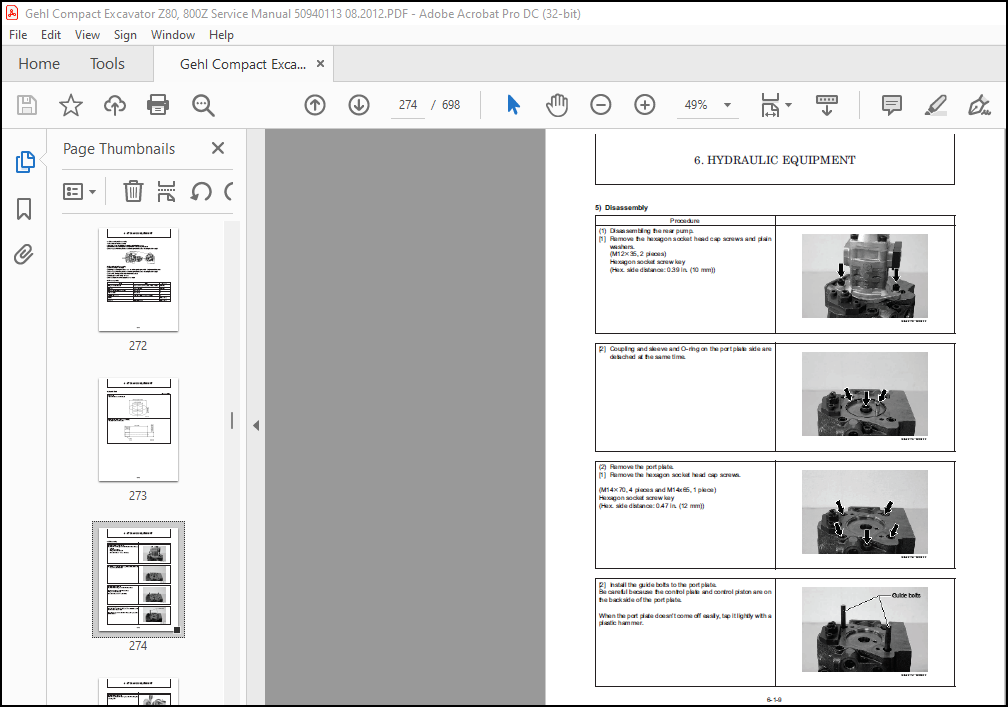

CHAPTER 6

HYDRAULIC EQUIPMENT

6-1 Hydraulic Pump 6-1-1

6-2 Control Valve 6-2-1

6-2-1 Main Control Valve 6-2-1

6-2-2 Disassembly 6-2-10

6-2-3 Cleaning 6-2-21

6-2-4 Checking 6-2-21

6-2-5 Reassembly 6-2-21

6-2-6 Servicing Procedure for Relief Valve 6-2-26

6-2-7 Installation 6-2-30

6-2-8 Running 6-2-30

6-2-9 Troubleshooting 6-2-31

6-3 Pilot Valve 6-3-1

6-3-1 Remote Control Valve 6-3-1

6-3-2 Travel Pilot Valve 6-3-10

6-3-3 Blade and Boom Swing Pilot Valve 6-3-32

6-4 Swing Motor 6-4-1

6-4-1 Overview 6-4-1

6-4-2 Description of Functions and Operation 6-4-2

6-4-3 Precautions for Handling 6-4-14

6-4-4 Troubleshooting 6-4-15

6-4-5 Employment Tool 6-4-21

6-4-6 Disassembly Procedure 6-4-24

6-4-7 Assembly Procedure 6-4-37

6-4-8 Quality Check After Reassembly 6-4-54

6-5 Travel Motor 6-5-1

6-5-1 Product Overview 6-5-1

6-5-2 External Dimensions 6-5-2

6-5-3 Basic Configuration and Drawing 6-5-3

6-5-4 Operating Description 6-5-9

6-5-5 Troubleshooting 6-5-22

6-5-6 Service outline 6-5-24

6-5-7 Disassembly 6-5-31

6-5-8 Service Standard 6-5-49

6-5-9 Assembly 6-5-51

6-5-10 Performance Confirmation Test 6-5-69

6-6 Cutoff Valve 6-6-1

6-7 P T O Solenoid Valve 6-7-1

6-8 Quick Coupler Solenoid Valve 6-8-1

6-9 Pilot Check Valve (Quick Coupler spec ) 6-9-1

6-10 Holding Valve (AS/NZ spec ) 6-10-1

CONTENTS

CHAPTER 7

ADJUSTMENT AND REPAIR

7-1 Electric Equipment of the Machine 7-1-1

7-1-1 Parts Layout of Electrical Equipment 7-1-1

7-1-2 Monitor and Alarm Systems 7-1-6

7-1-3 Wiring Diagram 7-1-16

7-1-4 Circuit Description of Engine Start, Stop and Battery Charging 7-1-20

7-1-5 Electronic Control 7-1-22

7-1-6 Removal and Reinstallation of Engine 7-1-31

7-1-7 Removal and Reinstallation of Starter Motor 7-1-39

7-1-8 Removal and Reinstallation of Radiator and Oil cooler 7-1-40

7-1-9 Removal and Reinstallation of Fan Belt and Compressor Driving Belt 7-1-43

7-1-10 Removal and Reinstallation of Fuel Injection Pump 7-1-44

7-1-11 Removal and Reinstallation of ECU 7-1-46

7-2 Undercarriage 7-2-1

7-2-1 Outline 7-2-1

7-2-2 Compatibility of Main Parts 7-2-1

7-2-3 Points of Reassembly (Rubber Crawler Type) 7-2-2

7-2-4 Points of Reassembly (Steel Crawler Type) 7-2-3

7-2-5 Removal and Reinstallation of Crawler 7-2-4

7-2-6 Disassembly and Reassembly of Steel Crawler 7-2-8

7-2-7 Disassembly and Reassembly of Front Idler 7-2-10

7-2-8 Disassembly and Reassembly of Track Roller 7-2-12

7-2-9 Installation of Floating Seal 7-2-14

7-2-10 Drawings of Jigs 7-2-15

7-2-11 Disassembly and Reassembly of Carrier Roller 7-2-17

7-3 Controls 7-3-1

7-3-1 Control Lever 7-3-1

7-3-2 Travel Lever 7-3-2

7-3-3 Adjustment of Lock Lever 7-3-3

7-4 Swing Bearing 7-4-1

7-4-1 Removal and Reinstallation of Swing Bearing 7-4-1

7-5 Hydraulic Equipment 7-5-1

7-5-1 Removal and Reinstallation of Hydraulic Pump 7-5-1

7-5-2 Removal and Reinstallation of Control Valve 7-5-6

7-5-3 Removal and Reinstallation of Remote Control Valves 7-5-8

7-5-4 Removal and Reinstallation of Blade Pilot Valve 7-5-10

7-5-5 Removal and Reinstallation of Travel Pilot Valve 7-5-11

7-5-6 Removal and Reinstallation of Boom Swing Pilot Valve 7-5-12

7-5-7 Removal and Reinstallation of Solenoid Valve 7-5-13

7-5-8 Removal and Reinstallation of P T O Solenoid Valve 7-5-14

7-5-9 Removal and Reinstallation of Line Filter 7-5-15

7-5-10 Removal and Reinstallation of Accumulator 7-5-16

7-5-11 Removal and Reinstallation of Swing Motor 7-5-17

7-5-12 Removal and Reinstallation of Swivel Joint 7-5-19

7-5-13 Disassembly and Reassembly of Swivel Joint 7-5-22

CONTENTS

7-5-14 Disassembly and Reassembly of Hydraulic Cylinders 7-5-25

7-5-15 Hydraulic Oil Tank 7-5-51

7-5-16 Piping Layout 7-5-55

7-6 Implement 7-6-1

7-6-1 Removal and Reinstallation of Implement 7-6-1

7-6-2 Quick Coupler 7-6-9

7-7 Cabin 7-7-1

7-7-1 Removal and Reinstallation of Cabin 7-7-1

7-7-2 Disassembly and Reassembly of Cabin 7-7-3

7-7-3 Removal and Reinstall of Cabin Glasses 7-7-16

7-8 Air Conditioner 7-8-1

7-8-1 Removal and Reinstallation of Air Conditioner 7-8-1

CHAPTER 8

PERIODIC INSPECTION AND SERVICING

8-1 List of Periodic Inspection and Servicing 8-1

CHAPTER 9

FUEL, LUBE OIL AND GREASE RECOMMENDED

9 Fuel, Lube Oil and Grease Recommended 9-1

CHAPTER 10

TROUBLESHOOTING

10-1 Non-breakdowns 10-1-1

10-1-1 Natural Release of Bucket 10-1-1

10-1-2 Discontinuous Arm Movement 10-1-1

10-1-3 Thermal Shock of Travel Motor 10-1-2

10-1-4 Elongation of Boom Swing Cylinder on 60 degrees Swing 10-1-3

10-1-5 Time Lag on Travel Speed Switching 10-1-4

10-1-6 Fluctuation in Oil Level of Hydraulic Oil Tank due to Temperature Change 10-1-5

10-1-7 Operation of Quick Coupler Cylinder 10-1-6

10-2 Troubleshooting 10-2-1

10-2-1 Machine and Engine 10-2-1

10-2-2 Electrical Equipment on Panel 10-2-23

CHAPTER 11

REFERENCE DATA

11-1 Specifications for Attachment 11-1