$33

Gleaner EU 9255 DynaFlex Draper Header Operator’s Manual 71483068B – PDF DOWNLOAD

Gleaner EU 9255 DynaFlex Draper Header Operator’s Manual 71483068B – PDF DOWNLOAD

FILE DETAILS:

Gleaner EU 9255 DynaFlex Draper Header Operator’s Manual 71483068B – PDF DOWNLOAD

Language : English

Pages : 199

Downloadable : Yes

File Type : PDF

Size: 27 MB

TABLE OF CONTENTS:

Gleaner EU 9255 DynaFlex Draper Header Operator’s Manual 71483068B – PDF DOWNLOAD

1 1 Introduction 9

1 1 1 Safety symbol 9

1 1 2 Safety messages 9

1 1 3 Information messages 9

1 1 4 Safety signs 9

1 1 5 A word to the operator 10

1 1 6 This manual 11

1 2 Operation 12

1 2 1 General information 12

1 2 2 Prepare for operation 13

1 2 3 Personal protective equipment 14

1 2 4 Seat instructions 14

1 2 5 Shield and guards 15

1 2 6 Exhaust warning 15

1 2 7 Flying debris 16

1 2 8 Handrails 16

1 2 9 Agricultural chemicals 16

1 3 Travel on public roads 17

1 4 Maintenance 19

1 4 1 General maintenance information 19

1 4 2 Fire prevention and first aid 20

1 4 3 High pressure leaks 21

1 4 4 Accumulator safety 22

1 4 5 Tire safety 22

1 4 6 Replacement parts 23

1 5 Cylinder stops 24

1 5 1 Engaging the stop for the reel lift cylinder 24

1 5 2 Disengaging the stop for the reel lift cylinder 24

1 5 3 Header lift cylinder stop 25

1 6 Shields 26

1 6 1 Draper drive shields 26

1 6 2 Auger shaft shield 26

1 6 3 End shields 27

1 6 4 Divider shield 27

1 6 5 Reel drive shield 28

1 6 6 Flying debris 29

1 7 Safety and informational signs 30

1 7 1 Warning – Operators manual 34

1 7 2 Warning – Hydraulic fluid pressure 34

1 7 3 Warning – Entanglement hazard 34

1 7 4 Warning – Crushing hazard 35

1 7 5 Warning – Crushing hazard 35

1 7 6 Informational decals 35

2 1 Introduction 41

2 1 1 Units of measurement 41

2 1 2 Replacement parts 41

2 1 3 Intended use 41

2 1 4 Recommended header/combine usage 41

2 1 5 Proper disposal of waste 41

2 2 Machine identification 42

2 2 1 Serial number plate 42

2 2 2 Serial number description 42

3 1 Checklists 47

3 1 1 Daily checklist 47

3 1 2 Before each season checklist 47

3 1 3 End of season checklist 47

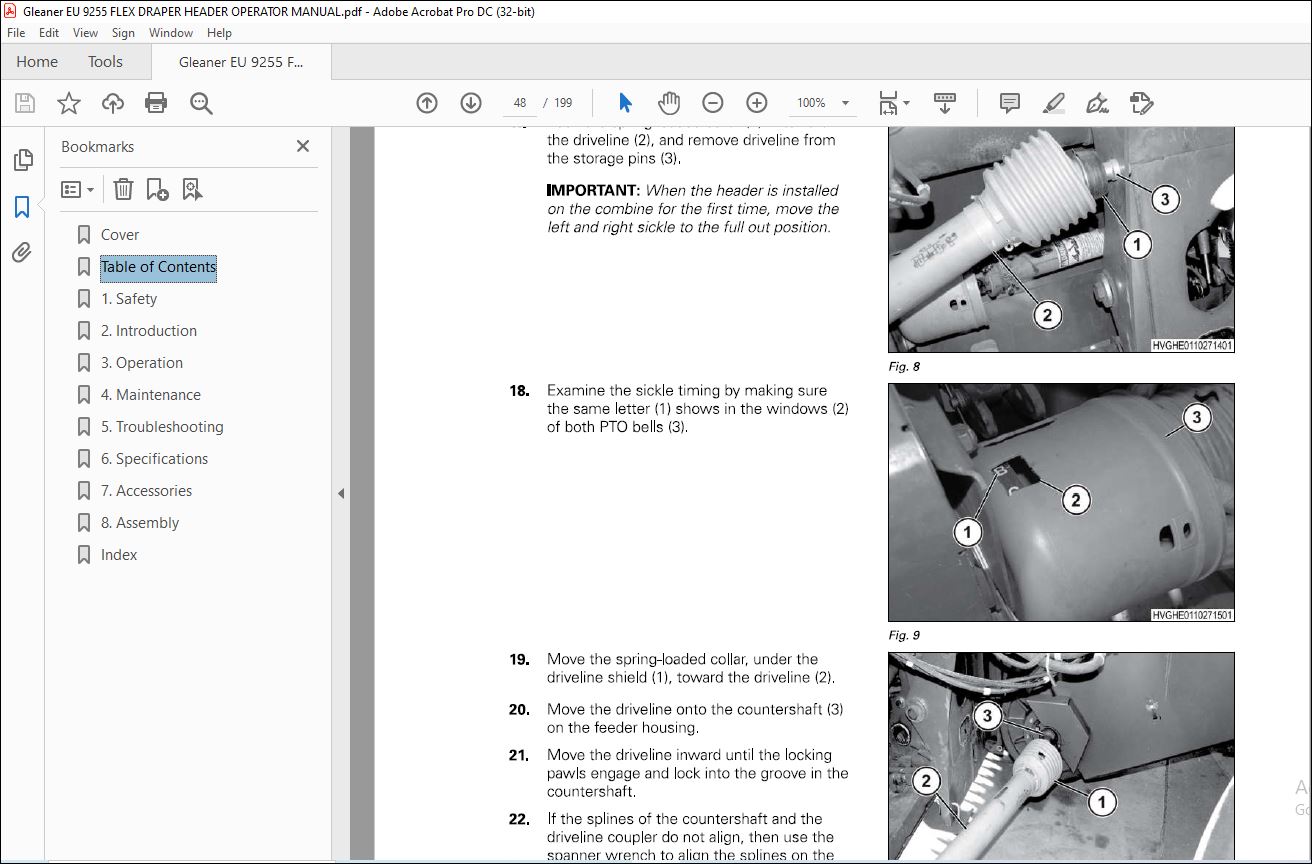

3 2 Setting up the combine 48

3 2 1 Required kits to install the header on the combines 48

3 2 2 Break in the header 49

3 2 3 Check the draper belt 49

3 2 4 Parking stands 49

3 3 Install the header 50

3 4 Remove the header 53

3 5 Reel 55

3 5 1 Reel position 55

3 5 2 Reel speed 57

3 5 3 Reel speed sensors 58

3 6 Tine pitch 59

3 6 1 Adjust the tine pitch 59

3 7 Header control sensors 60

3 7 1 Drag rod sensors 60

3 7 2 Cutterbar sensors 60

3 8 Header pitch 62

3 8 1 Adjust the header pitch – 2009 and later axial combines 62

3 8 2 Adjust header pitch – 2003 to 2008 axial combines 63

3 9 Cutterbar 64

3 9 1 Recommended cutterbar flex pressure 64

3 9 2 Adjust the cutterbar flex pressure – 2009 and later axial combine 64

3 9 3 Lock and unlock the cutterbar 64

3 10 Sickle storage 66

3 11 Header extremity lights 67

3 12 Flighting filler 68

3 13 Center crop deflector 69

3 14 Header transport kit 70

3 14 1 Put the header transport into field position 70

3 14 2 Position from field to transport 76

3 14 3 Connect the header transport to the hitch 76

4 1 Lubrication and maintenance 79

4 1 1 Lubrication details 79

4 1 2 Gear box oil level 83

4 2 Sealed chain 85

4 2 1 Lubricate and clean the sealed chain 85

4 2 2 Roller chain maintenance 85

4 2 3 Roller chain don’ts 86

4 2 4 Adjust the roller chain 87

4 3 Drive belts 88

4 3 1 Care of the drive belts 88

4 3 2 Adjust main drive belt tension 88

4 3 3 Adjust the center draper drive belt tension 89

4 3 4 Adjust auger drive belt tension 90

4 4 Draper maintenance 91

4 4 1 Draper care 91

4 4 2 Adjust left and right draper tension 91

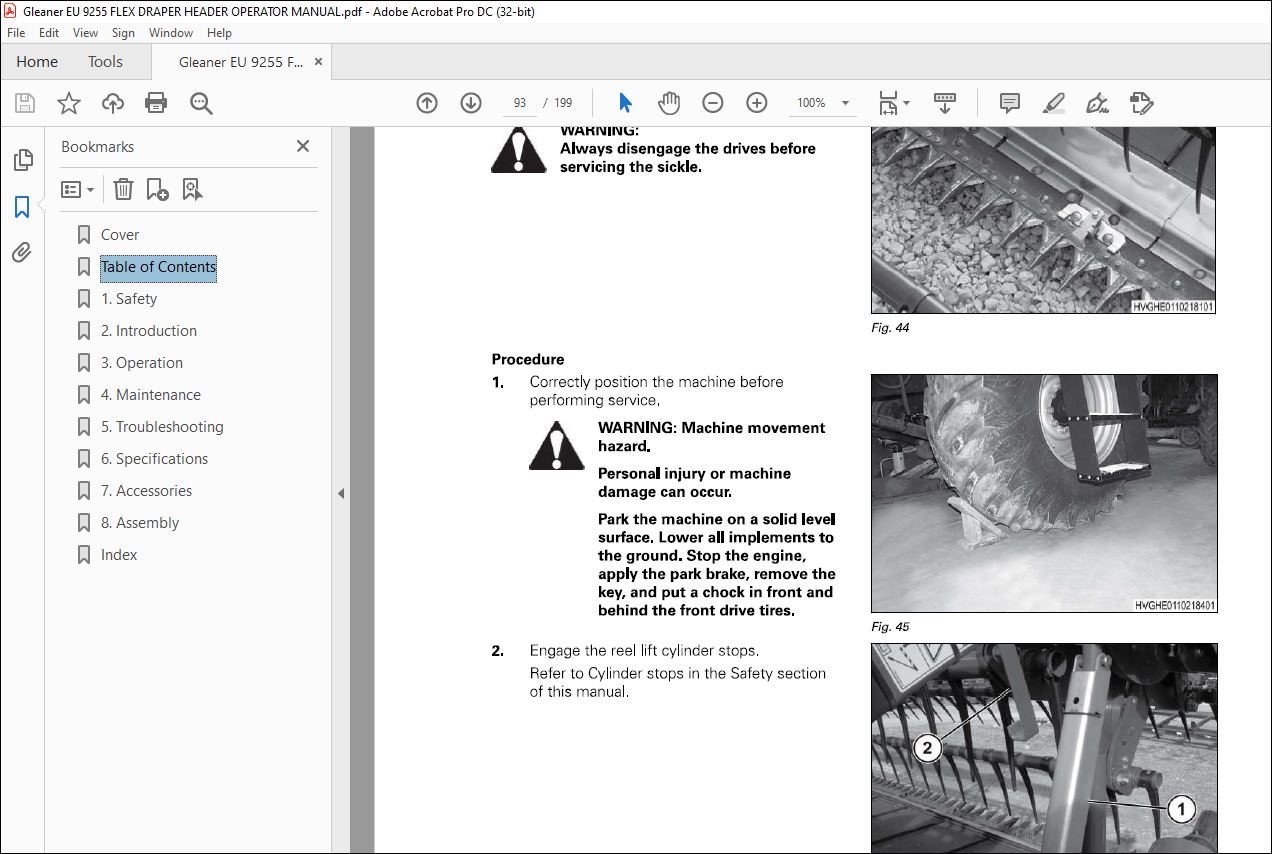

4 4 3 Remove the draper 92

4 4 4 Adjust the draper roller scraper 92

4 4 5 Adjust the flotation spring for the center deck 93

4 5 Reel 94

4 5 1 Replace the reel tines 94

4 5 2 Adjust the minimum reel lift height 94

4 5 3 Synchronize the reel lift arms 95

4 6 Cutterbar 96

4 6 1 Remove the sickle 96

4 6 2 Inspect the sickle 99

4 6 3 Install the sickle 102

4 6 4 Adjust the hold down pressure for the standard sickle 110

4 6 5 Adjust the sickle register 111

4 6 6 Replace the standard sickle sections 111

4 6 7 Replace the SCH sickle sections 118

4 6 8 Guards wear plates knife back rollers for SCH and hold downs 126

4 6 9 Set the sickle time 139

4 6 10 Replace the shear bolt for the sickle drive 139

4 7 Sensor adjustment and calibration 141

4 7 1 Calibrate the automatic header height control (AHHC) 141

4 7 2 Calibrate the header sensor 141

4 7 3 Adjust the reel speed sensors 141

4 7 4 Adjust the drag rod sensors 141

4 7 5 Adjust and measure the cutterbar sensors 143

4 7 6 Verify the cutterbar sensor adjustment 145

4 8 Torque the transport wheel 146

4 9 Hydraulics 147

4 9 1 Bleed the reel lift cylinders 147

4 9 2 Bleed the cutterbar flotation cylinders 147

4 9 3 Bleed the header pitch cylinders 147

4 9 4 Hydraulic schematic 148

4 10 Electrical 150

4 10 1 Wiring diagram 150

5 1 Cutterbar 155

5 2 Reel 157

5 3 Draper 158

6 1 Dimensions and weights 163

6 1 1 Header depth 163

6 1 2 Header width 164

6 1 3 Weight 164

6 2 Pick up reel 165

6 3 Reel drive 166

6 4 Reel height control 167

6 5 Cutterbar 168

6 6 Sickle 169

6 7 Header tilt 170

6 8 Drapers 171

6 8 1 Side drapers 171

6 8 2 Center drapers 171

6 9 Center conveyor 172

6 10 General lubrication 173

6 11 Wheels 174

6 12 Header transport 175

6 13 Bolt torque values 176

6 14 Conversion table 178

7 1 Reel divider 183

7 2 Divider rod 184

8 1 Header assembly 187

8 1 1 Remove the shipping stand 187

8 1 2 Set the reel lift cylinders 189

8 1 3 Set the reel 189

8 1 4 Remove the bracket and wire 191

8 1 5 Install the left hand and right hand draper 192

8 1 6 Install the center draper 194

8 2 Pre-delivery checklist 196

8 3 Delivery checklist 197

Index

DESCRIPTION:

Gleaner EU 9255 DynaFlex Draper Header Operator’s Manual 71483068B – PDF DOWNLOAD

Introduction:

The operating and maintenance instructions in this manual are assembled from field testing and other data.

The information is written for general conditions. Make adjustments as necessary for specific conditions.

2.1.1 Units of measurement:

Measurements are given in metric units followed by the equivalent in US units. Hardware sizes are given in

millimeters for metric hardware and inches for US hardware.

2.1.2 Replacement parts:

To receive your parts quickly, have the following information:

Correct part description and part number

Model number of the machine

Serial number of the machine

2.1.3 Intended use:

This machine is designed solely for use in customary agricultural operations.

Do not use this machine for any application or purpose other than those described in this manual. The

manufacturer accepts no liability for damage or injury resulting from misuse of this machine.

Compliance with the conditions of operation, service and repair as specified by the manufacturer constitute

essential elements for the intended use of this machine.

This machine should be operated, serviced and repaired only by qualified persons familiar with its

characteristics and familiar with the relevant safety rules and procedures.

All generally recognized safety regulations and road traffic regulations must be obeyed at all times.

Any unauthorized modifications performed on this machine will relieve the manufacturer of all liability for

any resulting damage or injury.

2.1.4 Recommended header/combine usage:

The DynaFlex™ header is recommended for use in beans, peas, cereal grains, and low bearing crops. The

DynaFlex header can be used with the cutterbar locked in the rigid or in the float position depending on the

application.

2.1.5 Proper disposal of waste:

Improper disposal of waste can pollute the environment and ecology. A few examples of potentially

harmful equipment waste can include, but not limited to, items such as oil, fuel, coolant, brake fluid, filters,

battery chemicals, tires, etc.

Use leak proof containers when draining fluids. Do not use food or beverage containers to collect waste

fluids, as food or beverage container(s) may mislead someone into drinking from them.

Do not pour or spill waste onto the ground, down a drain, or into any water source.

Air conditioning refrigerants escaping into the air can damage the Earth ‘s atmosphere. Government

regulations may require a certified air conditioning service center to recover and recycle used air

conditioning refrigerants.

IMAGES PREVIEW OF THE MANUAL: