$36

Gleaner EU 9255 DynaFlex Draper Header Service Manual 79036985A – PDF DOWNLOAD

Gleaner EU 9255 DynaFlex Draper Header Service Manual 79036985A – PDF DOWNLOAD

FILE DETAILS:

Gleaner EU 9255 DynaFlex Draper Header Service Manual 79036985A – PDF DOWNLOAD

Language : English

Pages : 629

Downloadable : Yes

File Type : PDF

Size: 145 MB

TABLE OF CONTENTS:

Gleaner EU 9255 DynaFlex Draper Header Service Manual 79036985A – PDF DOWNLOAD

GENERAL INFORMATION

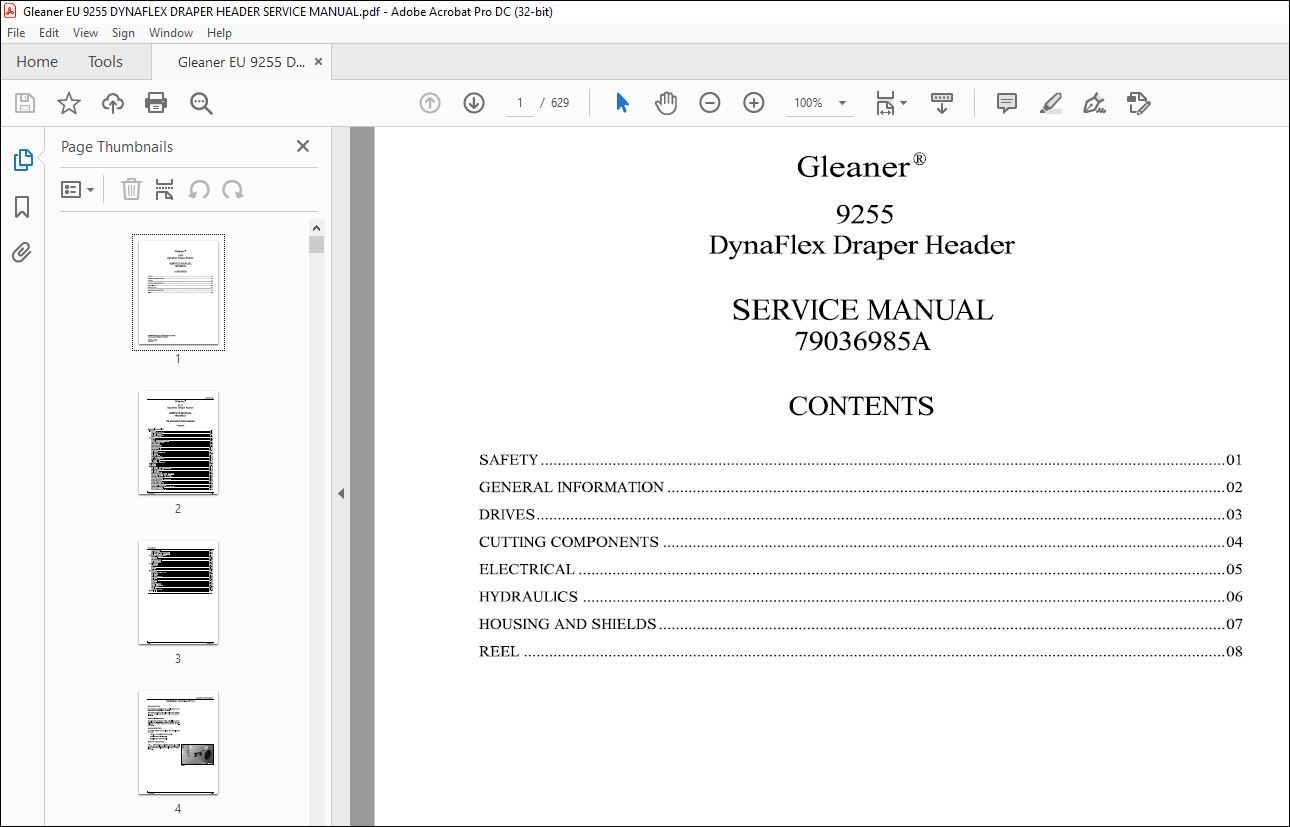

Gleaner®

9255

DynaFlex Draper Header

SERVICE MANUAL

79036985A

02 – General Information

Contents

Contents

Introduction 02-1

Units of Measurement 02-1

Replacement Parts 02-1

Machine Identification 02-1

Machine Usage 02-2

Operation 02-3

Checklists 02-3

Variable Speed Drive Lockout 02-4

Feeder Chain Speed 02-4

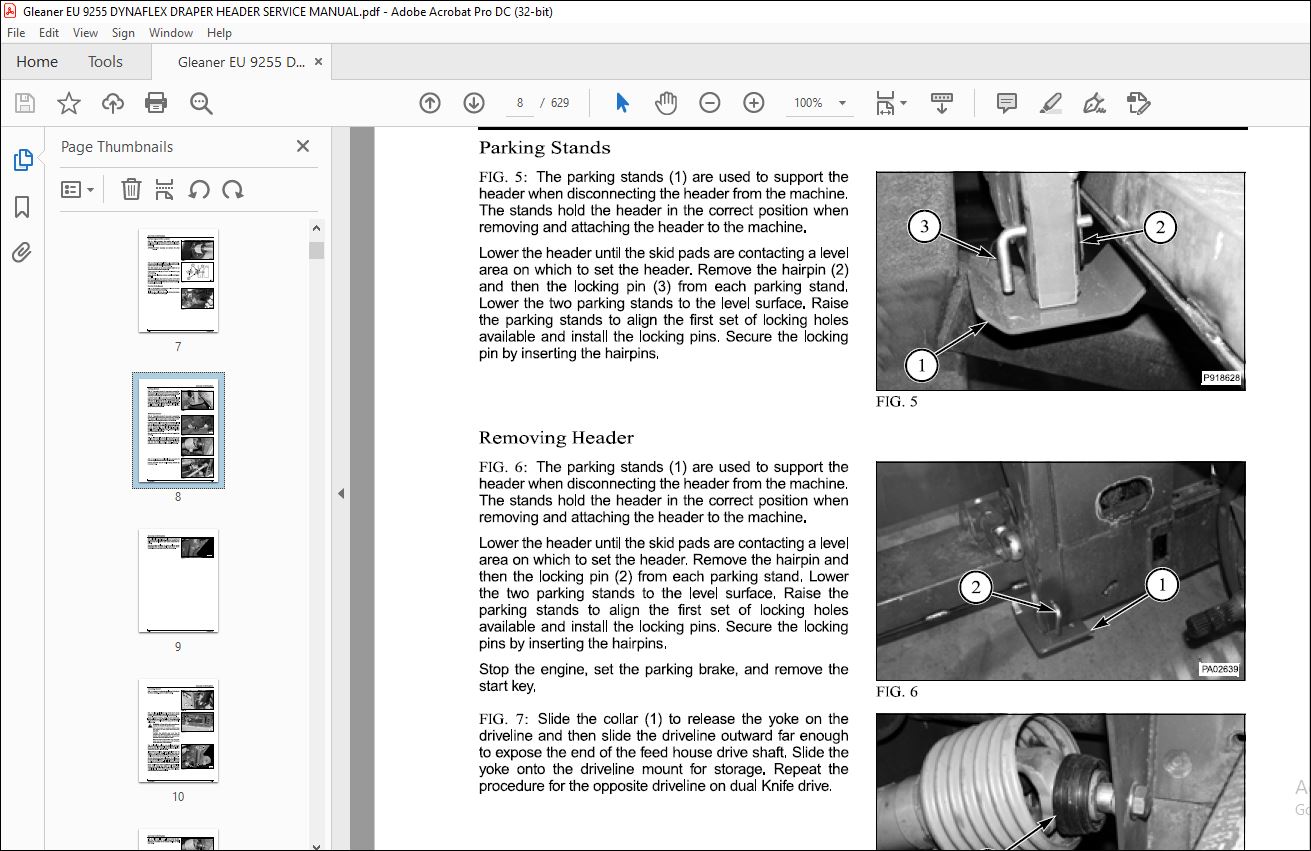

Parking Stands 02-5

Removing Header 02-5

Attaching Header 02-7

Extremity Lights 02-10

Header Break-In 02-11

Draper Care 02-11

Unplugging the Header 02-11

Reel Speed 02-12

Draper Speed 02-12

Tine Replacement 02-12

Completing Packages 02-13

Sickle Storage 02-15

Flighting Fillers 02-15

Cutterbar Float Lockout 02-15

Reel Divider 02-16

Divider Rod 02-17

Adjustments 02-18

Reel Lift Cylinder Synchronization 02-18

Reel Height (Leveling) 02-19

Reel Position 02-20

Reel Motor Chain 02-21

Recommended Cutterbar Flex Pressure 02-22

Adjusting Cutterbar Flex Pressure 02-22

Cutterbar Flex System – Bleeding Air 02-24

Tine Pitch Adjustment 02-25

Header (Cutterbar) Tilt Adjustment 02-25

Auger Adjustment 02-27

Header Height Control 02-28

Draper Tension (Side) 02-32

Draper Tension (Center) 02-33

Counter Balance Spring – Center Deck 02-33

Side Draper Drive Belt 02-34

Center Draper Drive Belt 02-36

79036985A 02-i

Contents

Auger Drive Belt 02-37

Reel Speed Sensor Adjustment 02-39

Sickle Timing – Dual Knife Drive 02-39

Lubrication and Maintenance 02-41

General Information 02-41

Lube Decal 02-48

Lubrication Chart 02-49

Lubrication Details 02-49

Reel Drive Chain 02-55

Troubleshooting 02-56

Cutterbar 02-56

Reel 02-61

Draper 02-62

Auger 02-62

Specifications 02-64

Dimensions and Weights 02-64

Pick-Up Reel 02-65

Reel Drive 02-66

Reel Height Control 02-66

Cutterbar 02-66

Sickle 02-66

Header Tilt 02-67

Drapers 02-67

Center Conveyor 02-67

General Lubrication 02-67

Tire Pressure 02-68

Wheels 02-68

Header Transport 02-68

Special tools 02-69

INDEX 02-71

02-ii 79036985A

DRIVES

Gleaner®

9255

DynaFlex Draper Header

SERVICE MANUAL

79036985A

03 – Drives

Contents

Contents

Side Draper Drive Belt 03-1

Removal 03-1

Installation 03-3

Center Draper Drive Belt 03-5

Removal 03-5

Installation 03-7

Auger Drive Belt 03-8

Removal 03-8

Installation 03-9

Draper (Main) Drive {Left and Right} 03-11

Removal 03-11

Disassembly 03-18

Assembly 03-20

Installation 03-23

Draper Drive {Left and Right) 03-29

Removal 03-29

Installation 03-35

Auger Drive 03-43

Removal 03-43

Installation 03-47

Torque Limiter (Auger) 03-52

Center Draper Drive Shaft 03-55

Removal 03-55

Clutch {Torque Limiter) – Center Draper 03-59

Installation 03-63

Center Draper Drive Gearcase 03-67

Removal 03-67

Installation 03-70

Components (Gearcase) 03-74

Disassembly 03-76

Inspection 03-78

Assembly 03-79

Sickle (Right Angle) Drive Box 03-87

Removal 03-87

Installation 03-90

Components (Gearbox) 03-92

Special Tools 03-94

Disassembly 03-95

Inspection 03-98

Assembly 03-99

Sickle Drive Gearbox 03-103

Removal 03-103

79036985A 03-i

Contents

Installation 03-105

Components (Gearbox) 03-110

Disassembly and Assembly 03-112

Power Take Off Drive Shafts 03-131

Disassembly 03-131

Inspection 03-136

Assembly 03-136

U-Joint Drive Shaft Assembly- Sickle 03-143

Components 03-143

Removal 03-144

Inspection 03-147

Installation 03-148

U-Joint Replacement 03-150

INDEX 03-157

04 – Cutting Components

Contents

Contents

Sickle Replacement 04-1

Removal 04-1

Inspection 04-6

Installation 04-8

Sickle (Standard) Hold Down Pressure 04-17

Sickle Register 04-17

Sickle Timing – Dual Knife Drive 04-18

Sickle Section Replacement 04-19

Standard Sickle Sections 04-19

SCH Sickle Sections 04-27

Guards, Wear Plates, SCH Knife Back Rollers, and Hold-Downs 04-36

Standard Sickle 04-38

SCH Sickle 04-43

Removal 04-43

Installation 04-44

INDEX 04-49

05 – Electrical

Contents

Contents

Introduction 05-1

Basic Troubleshooting Procedures 05-1

Basic Checks 05-2

Tools 05-3

Multimeter 05-4

Sensor Tester 05-5

General Testing Procedures 05-6

Visual Inspection 05-6

Continuity Check 05-6

Voltage Check 05-6

Testing For Open Circuits 05-7

Testing For Short Circuits 05-7

Testing For High Resistance 05-7

Wiring Diagram 05-8

Wiring Diagram Color Code 05-8

Feeder Harness Connector Numbers 05-9

Wiring Diagram 05-10

Splice Reference Chart 05-13

Electrical Schematic 05-15

Electrical Schematic Legand 05-16

Electrical Components 05-18

Location 05-18

Adjustments 05-20

Testing 05-21

Solenoid Tests 05-27

Visual Test 05-27

Voltage Test 05-27

Coil Test 05-27

Lighting Tests 05-28

INDEX 05-29

06 – Hydraulics

Contents

Contents

General Information 06-1

Header HyDraulic Schematic 06-3

Reel Lift Hydraulic Schematic 06-5

Cutterbar Float Hydraulic Schematic 06-7

Reel Drive Hydraulic Schematic 06-9

Header Interface Hydraulic Tilt Schematic 06-11

FloaUReel Valve Assembly 06-13

Operating Modes 06-14

O-ring and Backup Rings 06-14

Removal 06-15

Disassembly 06-18

Inspection 06-19

Assembly 06-21

Installation 06-22

Troubleshooting 06-25

Accumulator 06-29

Removal 06-29

Installation 06-32

Special Tools 06-35

Check Charge Pressure 06-35

Discharging 06-35

Charging 06-36

Float Cylinders 06-36

Removal 06-36

Installation 06-40

Float Cylinder – Middle Inner Tilt Arm 06-42

Float Cylinder – Outer Tilt Arm 06-44

Reel Relief Valve 06-45

Removal 06-45

Disassembly 06-46

Assembly 06-46

Installation 06-46

Adjusting the reel relief valve 06-47

Reel Motor 06-48

Disassembly 06-48

Assembly 06-51

Timing Procedure 06-55

Reel Lift Cylinders 06-57

Reel Lift Master Cylinder 06-57

Reel Lift Slave Cylinder 06-60

Header Interface Tilt Cylinder 06-62

Disassembly 06-62

79036985A 06-i

Contents

Inspection 06-63

Assembly 06-64

INDEX 06-65

07 – Housing and Shields

Contents

Contents

Hydraulic Interface Group 07-1

Removal 07-2

Installation 07-4

Tilt Cylinder 07-7

Center Deck Group 07-12

Center Draper (Belt) 07-14

Center Deck 07-18

Disassembly 07-28

Assembly 07-37

Side Canvas and Roller Group 07-51

Side Draper (Belt) 07-53

Drive Roller 07-60

Idler Roller 07-83

Feather Sheet Groups 07-89

Feather Sheets 07-91

Belt Guides 07-93

Belt Supports – Rear 07-96

Skid Plate and Cutterbar Group 07-100

Plastic Skid Replacement 07-103

Removal 07-103

Installation 07-108

Tilt Arm Group 07-114

Removal 07-117

Installation 07-135

Auger Group 07-157

Removal 07-158

Disassembly 07-161

Assembly 07-162

Installation 07-163

Shields Group 07-166

Divider Shield 07-166

End Shield 07-175

Drives Shield 07-180

End Panels Group 07-183

Removal 07-183

Installation 07-186

08 – Reel

Contents

Contents

Reel 08-1

Removal 08-1

Inspection 08-4

Installation 08-6

Removing the tine tube 08-9

Tine Replacement 08-9

Installing the tine tube 08-10

Troubleshooting 08-11

Reel Carrier Assembly 08-12

Left 08-12

Right 08-14

Reel Support Arm 08-19

Removal 08-19

Installation 08-21

Reel Actuator 08-24

Removal 08-24

Assembly and Installation 08-25

Reel Lift Cylinders 08-27

Synchronizing Lift Cylinders 08-27

Removal 08-30

Installation 08-32

Single Point Mobile Connector (Header) 08-34

Reel Drive (Hydraulic) 08-35

Reel Speed Pickup 08-37

Motor 08-41

INDEX 08-47

DESCRIPTION:

Gleaner EU 9255 DynaFlex Draper Header Service Manual 79036985A – PDF DOWNLOAD

GENERAL INFORMATION:

INTRODUCTION:

The information contained in this manual covers service information for the DynaFlex™ Header. The header operator’s manual as well as the machine operator’s manual must be kept at hand for reference at all times.

Units of Measurement:

Measurements are given in metric units followed by the equivalent in U.S. units. Hardware sizes are given in

millimeters for metric hardware and inches for U.S. hardware.

Replacement Parts:

To receive efficient service, always give the following information:

• Correct part description or part number.

• Model number of the machine.

• Serial number of the machine.

IMAGES PREVIEW OF THE MANUAL: