$33

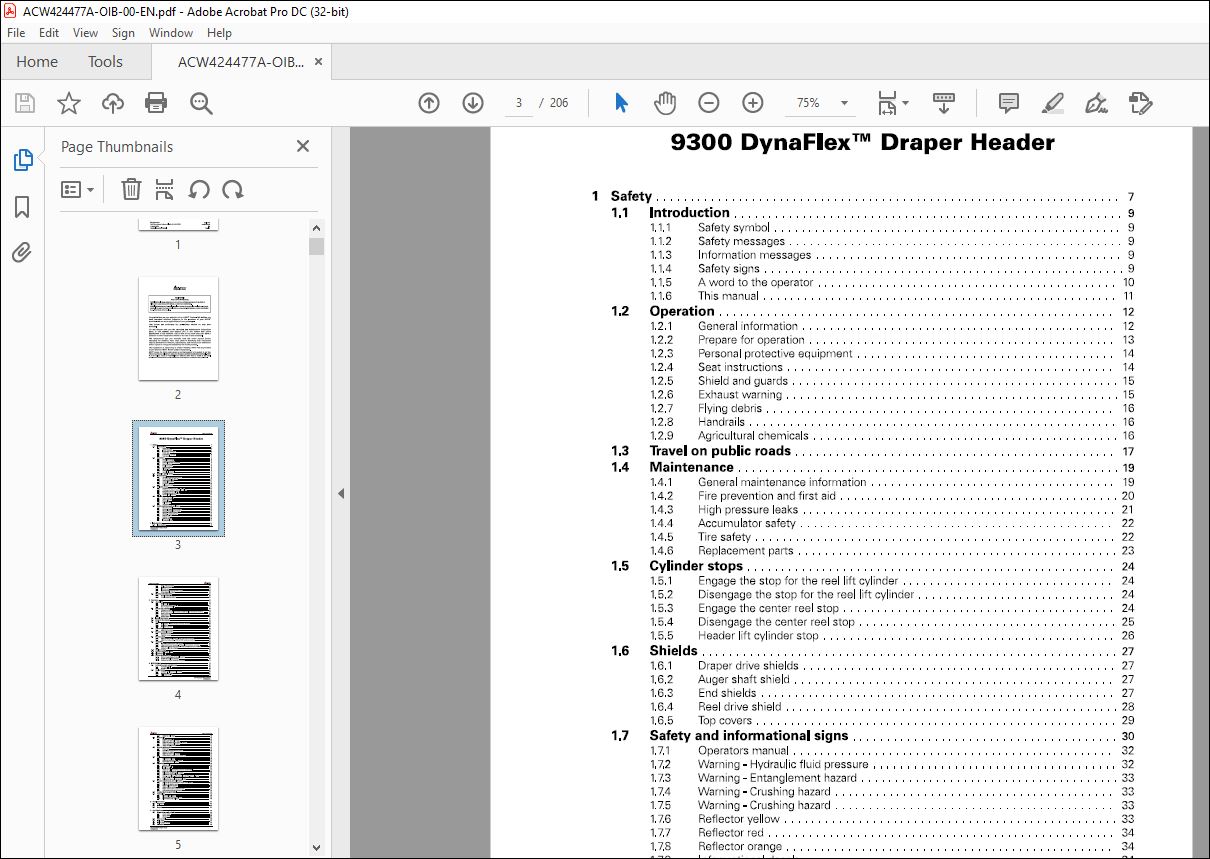

Gleaner EU 9300 Series 9325 9330 9335 9340 DynaFlex Draper Header Operator’s Manual ACW424477A – PDF

Gleaner EU 9300 Series 9325 9330 9335 9340 DynaFlex Draper Header Operator’s Manual ACW424477A – PDF DOWNLOAD

FILE DETAILS:

Gleaner EU 9300 Series 9325 9330 9335 9340 DynaFlex Draper Header Operator’s Manual ACW424477A – PDF DOWNLOAD

Language : English

Pages : 206

Downloadable : Yes

File Type : PDF

Size: 34.1 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gleaner EU 9300 Series 9325 9330 9335 9340 DynaFlex Draper Header Operator’s Manual ACW424477A – PDF DOWNLOAD

A word to the operator:

- It is your responsibility to read and understand the safety section in this manual and the manual for all implements before you operate this machine. You are responsible for your safety. Good safety procedures prevent injury to you and the persons around you.

- Make the information in the safety section of this manual a part of your safety procedure. This safety section is written only for this type of machine. Safety is your responsibility. You can prevent injury and death.

- This safety section gives basic safety examples that can occur during the operation and maintenance of your machine. This safety section is not a replacement for safety instruction in other sections of this manual.

- Injury or death can occur if the safety instruction is not obeyed. Learn how to operate the machine and how to use the controls correctly. Do not operate the machine if you do not know how to operate the machine. Do not let persons operate the machine that do not know how to operate the machine.

- Follow all safety instructions in the manuals and on the safety signs on the machine, the implements, and the attachments.

- Use only approved attachments and implements.

- Make sure that your machine has the correct equipment that is necessary by the local regulations.

Operation:

General information:

When parking, park the machine on a solid level surface and lower the header to the ground. Put all controls in neutral and apply the park brake. Stop the engine and take the key with you. Make sure the machine is in the proper operating condition according to the Operator Manual.

- Always operate the machine with the control console turned on. Do not dismount from moving machinery. Stay off slopes too steep for operation.

- Be aware of the size of the machine and have enough space available to allow for operation. Use extra care and reduce speed when operating on hillsides or near ditches or embankments especially with a full grain tank to avoid rollover. Travel speed must be such that complete control and machine stability is maintained at all times.

- Shift to a lower gear before descending a steep hill. Regulate ground speed to field conditions, and maintain control at all times. Do not dismount from moving machinery.

- Avoid contact with electrical power lines. Always put the grain tank unloader tube in the transport position and lower radio aerial before moving the machine near electrical wires. Contact with electrical power lines can cause electrical shock, resulting in very serious injury or death.

Prepare for operation:

- Read and understand the operating instructions and precautions in this manual before you operate or

perform service on the machine. - Make sure that you know and understand the positions and operations of all controls. Make sure that all

controls are in neutral and the parking brake is applied before you start the machine. - Make sure that all persons are a sufficient distance from your area of work before you start or operate the

machine. Do checks on the controls and learn all controls in an area clear of persons and objects before

you start work with the machine. Know the dimensions of the machine and have sufficient space available

for operation. Do not operate the machine at high speeds around persons, buildings, other equipment, etc.

Always use correct procedures when you do tasks around and operate the machine. Do not let children or

persons who do not know how to operate the machine operate the machine. Keep other persons away

from your area of work. Do not let other persons ride on the machine. - Make sure that the machine is in the good mechanical condition. Make sure that the machine has the

correct equipment as necessary by local regulations. - All equipment has a limit. Make sure you understand the speed, brakes, steering, stability, and load

characteristics of this equipment before you start.

Gleaner EU 9300 Series 9325 9330 9335 9340 DynaFlex Draper Header Operator’s Manual ACW424477A – PDF DOWNLOAD

1 Safety 7

1 1 Introduction 9

1 1 1 Safety symbol 9

1 1 2 Safety messages 9

1 1 3 Information messages 9

1 1 4 Safety signs 9

1 1 5 A word to the operator 10

1 1 6 This manual 11

1 2 Operation 12

1 2 1 General information 12

1 2 2 Prepare for operation 13

1 2 3 Personal protective equipment 14

1 2 4 Seat instructions 14

1 2 5 Shield and guards 15

1 2 6 Exhaust warning 15

1 2 7 Flying debris 16

1 2 8 Handrails 16

1 2 9 Agricultural chemicals 16

1 3 Travel on public roads 17

1 4 Maintenance 19

1 4 1 General maintenance information 19

1 4 2 Fire prevention and first aid 20

1 4 3 High pressure leaks 21

1 4 4 Accumulator safety 22

1 4 5 Tire safety 22

1 4 6 Replacement parts 23

1 5 Cylinder stops 24

1 5 1 Engage the stop for the reel lift cylinder 24

1 5 2 Disengage the stop for the reel lift cylinder 24

1 5 3 Engage the center reel stop 24

1 5 4 Disengage the center reel stop 25

1 5 5 Header lift cylinder stop 26

1 6 Shields 27

1 6 1 Draper drive shields 27

1 6 2 Auger shaft shield 27

1 6 3 End shields 27

1 6 4 Reel drive shield 28

1 6 5 Top covers 29

1 7 Safety and informational signs 30

1 7 1 Operators manual 32

1 7 2 Warning – Hydraulic fluid pressure 32

1 7 3 Warning – Entanglement hazard 33

1 7 4 Warning – Crushing hazard 33

1 7 5 Warning – Crushing hazard 33

1 7 6 Reflector yellow 33

1 7 7 Reflector red 34

1 7 8 Reflector orange 34

1 7 9 Informational decals 34

2 Introduction 39

2 1 Introduction 41

9300 DynaF/ex™ Draper Header

ACW424477A

Table of contents , •AGCO

Your Agriculture Company

2 1 1 Units of measurement 41

2 1 2 Replacement parts 41

2 1 3 Intended use 41

2 1 4 Recommended header/combine usage 41

2 1 5 Proper disposal of waste 41

2 2 Machine identification 42

2 2 1 Serial number plate 42

2 2 2 Serial number description 42

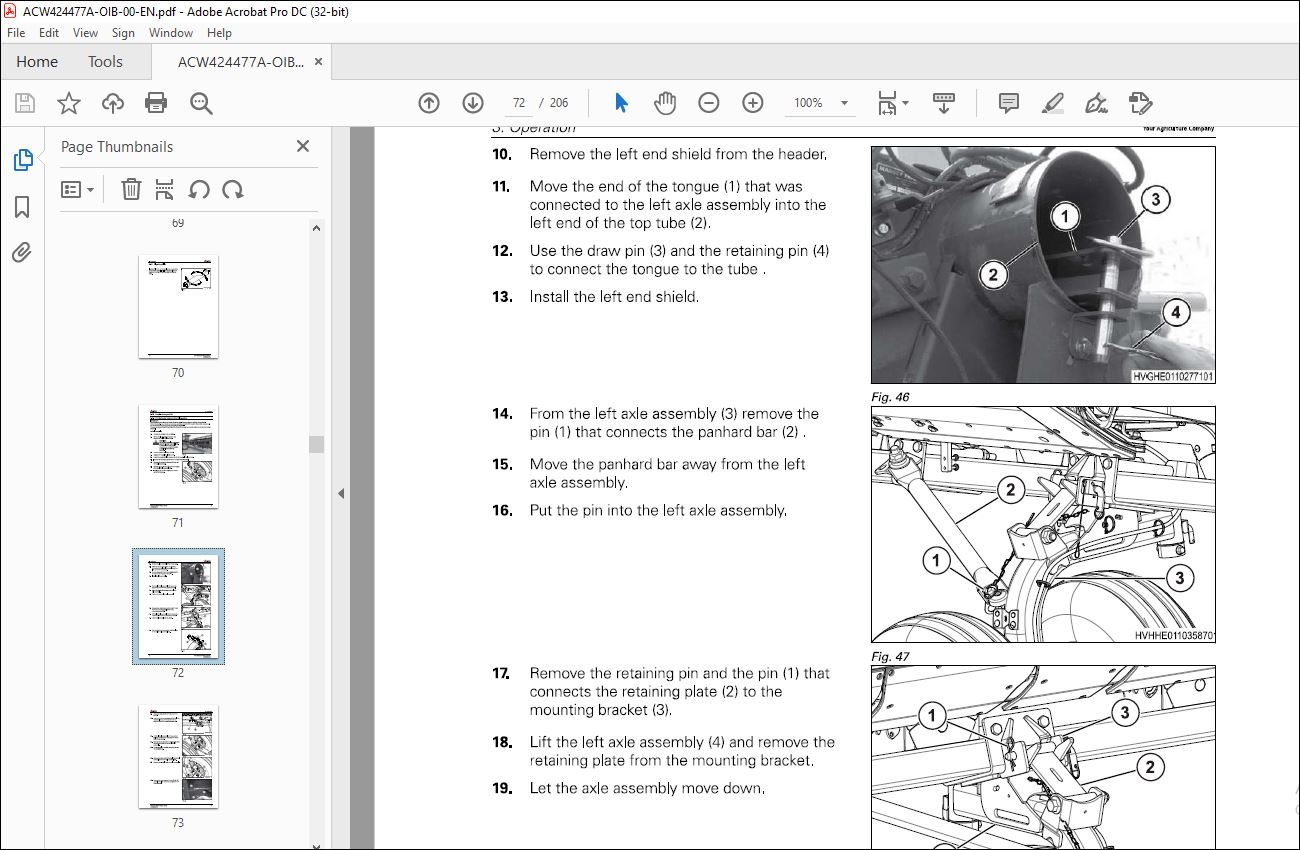

3 Operation 45

3 1 Checklists 47

3 1 1 Daily checklist 47

3 1 2 Before each season checklist 47

3 1 3 End of season checklist 47

3 2 Set up the combine 48

3 2 1 Configure a header 48

3 2 2 Required kits to install the header on 2003 and later transverse combines 49

3 2 3 Break in the header 50

3 2 4 Check draper belt 50

3 2 5 Parking stands 50

3 3 Install the header 51

3 4 Remove the header 54

3 5 Reel 56

3 5 1 Reel position – 2003 and after transverse combines 56

3 5 2 Reel speed 57

3 5 3 Reel speed sensors 58

3 6 Tine pitch 59

3 6 1 Adjust the tine pitch 59

3 7 Header control sensors 60

3 7 1 Drag rod sensors 60

3 7 2 Cutterbar sensors 60

3 8 Header pitch 62

3 8 1 Adjust header pitch – 2016 and later transverse combines 62

3 8 2 Adjust the header pitch – 2003 to 2015 transverse combines 63

3 9 Cutterbar 65

3 9 1 Recommended cutterbar flex pressure 65

3 9 2 Adjust cutterbar flex pressure – 2016 and later transverse combines 65

3 9 3 Adjust the cutterbar flex pressure – 2003 to 2015 transverse combines 65

3 9 4 Lock and unlock the cutterbar 66

3 10 Sickle storage 68

3 11 Header extremity lights 69

3 12 Flighting filler 70

3 13 Header transport kit 71

3 13 1 Put the header transport into field position 71

3 13 2 Position from field to transport 77

3 13 3 Connect the header transport to the hitch 78

4 Maintenance 79

4 1 Lubrication and maintenance 81

4 1 1 Lubrication details 81

4 1 2 Gear box oil level 85

4 2 Sealed chain 87

4 2 1 Lubricate and clean the sealed chain 87

4 2 2 Maintain roller chains 87

4 2 3 Roller chain don’ts 87

9300 DynaF!ex™ Draper Header

ACW424477A

AGCO

v ,,k,IM,Company Table of contents

4 2 4 Adjust the roller chain 88

4 3 Drive belts 89

4 3 1 Maintain drive belts 89

4 3 2 Adjust main drive belt tension 89

4 3 3 Adjust the center draper drive belt tension 90

4 3 4 Adjust auger drive belt tension 91

4 3 5 Adjust variable speed belt 91

4 4 Draper maintenance 92

4 4 1 Draper care 92

4 4 2 Adjust left and right draper tension 92

4 4 3 Remove the draper 93

4 4 4 Adjust the draper roller scraper 93

4 4 5 Adjust flotation spring for the center deck 94

4 5 Reel 95

4 5 1 Replace the reel tines 95

4 5 2 Adjust the minimum reel lift height 95

4 5 3 Synchronize the reel lift arms 96

4 6 Cutterbar 98

4 6 1 Remove sickle 98

4 6 2 Inspect the sickle 101

4 6 3 Install the sickle 103

4 6 4 Adjust the hold-down pressure for the standard sickle 111

4 6 5 Adjust the sickle register 112

4 6 6 Replace the standard sickle sections 112

4 6 7 Replace the SCH sickle sections 119

4 6 8 Guards, wear plates, knife back rollers for SCH, and hold-downs 127

4 6 9 Set the sickle time 140

4 6 10 Replace the shear bolt for the sickle drive 140

4 7 Sensor adjustment and calibration 142

4 7 1 Calibrate the automatic header height control (AHHC) 142

4 7 2 Calibrate the header sensor 142

4 7 3 Adjust reel speed sensors 142

4 7 4 Adjust drag rod sensors 142

4 7 5 Adjust and measure cutterbar sensors 144

4 7 6 Verify cutterbar sensor adjustment 146

4 8 Torque the transport wheel 148

4 9 Hydraulics 149

4 9 1 Bleed reel lift cylinders 149

4 9 2 Bleed cutterbar flotation cylinders 149

4 9 3 Bleed header pitch cylinders 149

5 Troubleshooting 151

5 1 Cutterbar 153

5 2 Reel 156

5 3 Draper 157

6 Specifications 161

6 1 Dimensions and weights 163

6 1 1 Header depth 163

6 1 2 Header width 164

6 1 3 Weights 164

6 2 Pick up reel 165

6 3 Reel drive 166

6 4 Reel height control 167

6 5 Cutterbar 168

9300 DynaF/ex™ Draper Header

ACW424477A

Table of contents , •AGCO

Your Agriculture Company

6 6 Sickle 169

6 7 Header tilt 170

6 8 Drapers 171

6 8 1 Side drapers 171

6 8 2 Center drapers 171

6 9 Center conveyor 172

6 10 General lubrication 173

6 11 Wheels 174

6 12 Header transport 175

6 13 Bolt torque values 176

6 14 Conversion table 178

7 Accessories 181

7 1 Reel divider 183

7 2 Divider rod 184

7 3 Center crop deflector 185

7 4 Stabilizer wheels 186

8 Assembly 187

8 1 Header assembly 189

8 1 1 Remove the shipping stand 189

8 1 2 Set the reel lift cylinders 191

8 1 3 Set the reel 192

8 1 4 Remove the bracket and wire 194

8 1 5 Install the left hand and right hand draper 195

8 1 6 Install the center draper 197

8 2 Pre-delivery checklist 199

8 3 Delivery checklist 200

9 Index 201