$33

Gleaner EU S9 Series S96 S97 S98 Combine with AP84 & AP98 Engine Service Manual 79037181F – PDF

Gleaner EU S9 Series S96 S97 S98 Combine with AP84 & AP98 Engine Service Manual 79037181F – PDF DOWNLOAD

FILE DETAILS:

Gleaner EU S9 Series S96 S97 S98 Combine with AP84 & AP98 Engine Service Manual 79037181F – PDF DOWNLOAD

Language : English

Pages : 461

Downloadable : Yes

File Type : PDF

Size: 61.5 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gleaner EU S9 Series S96 S97 S98 Combine with AP84 & AP98 Engine Service Manual 79037181F – PDF DOWNLOAD

A word to the operator:

- It is your responsibility to read and understand the safety section in this manual and the manual for all implements before you operate this machine. You are responsible for your safety. Good safety procedures prevent injury to you and the persons around you.

- Make the information in the safety section of this manual a part of your safety procedure. This safety section is written only for this type of machine. Safety is your responsibility. You can prevent injury and death.

- This safety section gives basic safety examples that can occur during the operation and maintenance of your machine. This safety section is not a replacement for safety instruction in other sections of this manual.

- Injury or death can occur if the safety instruction is not obeyed. Learn how to operate the machine and how to use the controls correctly. Do not operate the machine if you do not know how to operate the machine. Do not let persons operate the machine that do not know how to operate the machine.

- Follow all safety instructions in the manuals and on the safety signs on the machine, the implements, and the attachments.

- Use only approved attachments and implements.

- Make sure that your machine has the correct equipment that is necessary by the local regulations.

This manual:

- This manual covers general safety practices for this machine. The operator manual must always be kept

with the machine. - Right-hand and left-hand, as used in this manual, are determined by facing the direction the machine will

travel when in use. - The photos, illustrations, and data used in this manual were current at the time of printing, but due to

possible in-line production changes, your machine can vary slightly in detail. The manufacturer reserves the

right to redesign and change the machine as necessary without notification.

Operation:

Prepare for operation:

- Read and understand all operating instructions and precautions in this manual before operating or servicing

the machine. - Make sure you know and understand the positions and operations of all controls. Make certain all controls

are in neutral and the park brake is applied before starting the machine. Make sure the steering wheel is

centered and locked. - Make certain all people are well away from your area of work before starting and operating the machine.

Check and learn all controls in an area clear of people and obstacles before starting your work. Be aware of

the machine size and have enough space available to allow for operation. Never operate the machine at

high speeds in crowded places. - Emphasize the importance of using correct procedures when working around and operating the machine.

Do not let children or unqualified persons operate the machine. Keep others, especially children, away from

your area of work. Do not permit others to ride on the machine. - Make sure the machine is in the proper operating condition as stated in the Operator Manual. Make sure

the machine has the correct equipment required by local regulations. - All equipment has a limit. Make sure you understand the speed, brakes, steering, stability, and load

characteristics of this equipment before you start.

TABLE OF CONTENTS:

Gleaner EU S9 Series S96 S97 S98 Combine with AP84 & AP98 Engine Service Manual 79037181F – PDF DOWNLOAD

1 1 Introduction 17

1 1 1 Safety alert symbol 17

1 1 2 Safety messages 17

1 1 3 Informational messages 17

1 1 4 Safety signs 17

1 1 5 A word to the operator 18

1 1 6 This manual 19

1 2 Operation 20

1 2 1 Prepare for operation 20

1 2 2 General information 20

1 2 3 Personal protective equipment 21

1 2 4 Emergency exit 22

1 2 5 Seat instructions 22

1 2 6 Shield and guards 23

1 2 7 Exhaust warning 23

1 2 8 Flying debris 24

1 2 9 Handrails 24

1 2 10 Agricultural chemicals 24

1 3 Travel on public roads 25

1 4 Maintenance 27

1 4 1 General maintenance information 27

1 4 2 Fire prevention and first aid 28

1 4 3 High pressure leaks 29

1 4 4 Engine safety 30

1 4 5 Fuel safety 31

1 4 5 1 Ultra-low sulfur diesel 32

1 4 6 Battery safety 32

1 4 7 Accumulator safety 33

1 4 8 Replacement parts 33

1 5 Safety and informational signs 34

1 5 1 Danger – Crushing hazard 37

1 5 2 Danger – Crushing hazard 37

1 5 3 Danger – Electrical hazard 37

1 5 4 Danger – Entanglement hazard 37

1 5 5 Danger – Entanglement hazard 38

1 5 6 Danger – Explosion hazard 38

1 5 7 Danger – Shearing hazard 38

1 5 8 Warning – Burn hazard 38

1 5 9 Warning – Bystander alert 39

1 5 10 Warning – Bystander alert 39

1 5 11 Warning – Crushing hazard 39

1 5 12 Warning – Entanglement hazard 39

1 5 13 Warning – Entanglement hazard 40

1 5 14 Warning – Fall hazard 40

1 5 15 Warning – Flying objects hazard 40

1 5 16 Warning – Operators manual 40

1 5 17 Warning – Seat belt 41

1 5 18 Warning – Seat belt 41

1 5 19 Warning – Shearing hazard 41

1 5 20 Warning – Shearing hazard 41

59 Series Combine

Warning – Glass break hazard 42

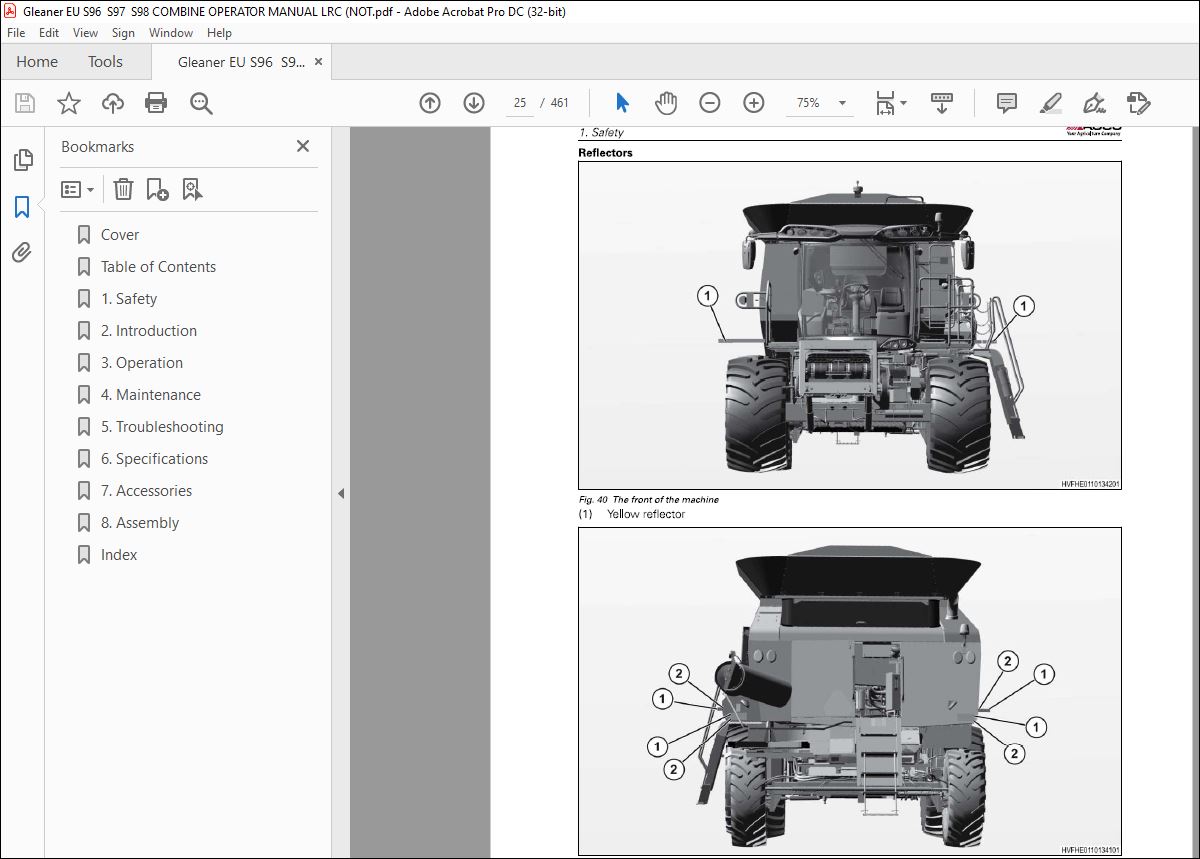

Slow Moving Vehicle (SMV) sign 42

Tire usage sign 42

Exit sign 42

2 1 Introduction 45

2 1 1 Units of measurement 45

2 1 2 Replacement parts 45

2 1 3 Intended use 45

2 1 4 Proper disposal of waste 45

2 2 Machine identification 46

2 2 1 Serial number plate 46

2 2 2 Engine serial number 47

2 2 3 Serial number description 47

2 2 4 Terminal software information 47

2 3 How the combine works 49

2 3 1 Headers 50

2 4 Header lift cylinder stop 51

2 4 1 Engage the header lift cylinder stop 51

2 4 2 Disengage the header lift cylinder stop 51

2 5 Component access 53

2 5 1 Remove the feeder house shield 53

2 5 2 Install the feeder house shield 53

2 5 3 Open the left-hand lower shield 54

2 5 4 Close the left-hand lower shield 54

2 5 5 Open the left-hand upper shield 54

2 5 6 Close the left-hand upper shield 55

2 5 7 Open the right-hand lower shield 55

2 5 8 Close the right-hand lower shield 56

2 5 9 Open the right-hand upper shield 56

2 5 10 Close the right-hand upper shield 57

2 5 11 Remove the mud shield 57

2 5 12 Install the mud shield 57

2 5 13 Lower the right-hand step 58

2 5 14 Open the elevator access panel 58

2 5 15 Open the rotary radiator screen 59

2 5 16 Open the engine cover 59

2 5 17 Close the engine cover 60

2 5 17 1 Access the threshing and the separating cage 61

3 1 Checklists 69

3 1 1 New machine break-in 69

3 1 2 New engine break-in 69

3 1 3 Daily checklist 69

3 1 4 Before each season checklist 70

3 2 Engine 71

3 2 1 Starting the engine 71

3 2 2 Cold weather starting 72

3 2 3 Stop the engine 72

3 2 4 Engine break-in 72

3 2 5 Engine operation with no load or low load 73

3 3 Hydrostatic transmission 74

3 3 1 Transmission gear selection 74

3 3 2 Ground speed lever 74

3 3 3 Warm-up procedure 74

3 3 4 Move the machine forward 74

3 3 5 Move the machine rearward 75

3 3 6 Stop the machine 75

3 3 7 Rear wheel assist (RWA) 75

3 4 Towing 77

3 4 1 Tow the header 77

3 4 2 Tow the machine 77

3 5 Machine transporting checklists 78

3 5 1 Machine preparation for driving on public roads 78

3 5 2 Machine preparation for transporting on a trailer 78

3 6 Pull the machine from the mud 79

3 6 1 Pull the machine forward from the mud 79

3 6 2 Pull the machine rearward from the mud 79

3 7 Ladder 81

3 7 1 Cab ladder 81

3 7 2 Engine platform ladder 81

3 7 3 Grain tank ladder 82

3 8 Fire extinguisher 83

3 8 1 Fire extinguisher 83

3 9 Storage compartment 84

3 9 1 Storage compartment 84

3 9 2 Field settings main screen 84

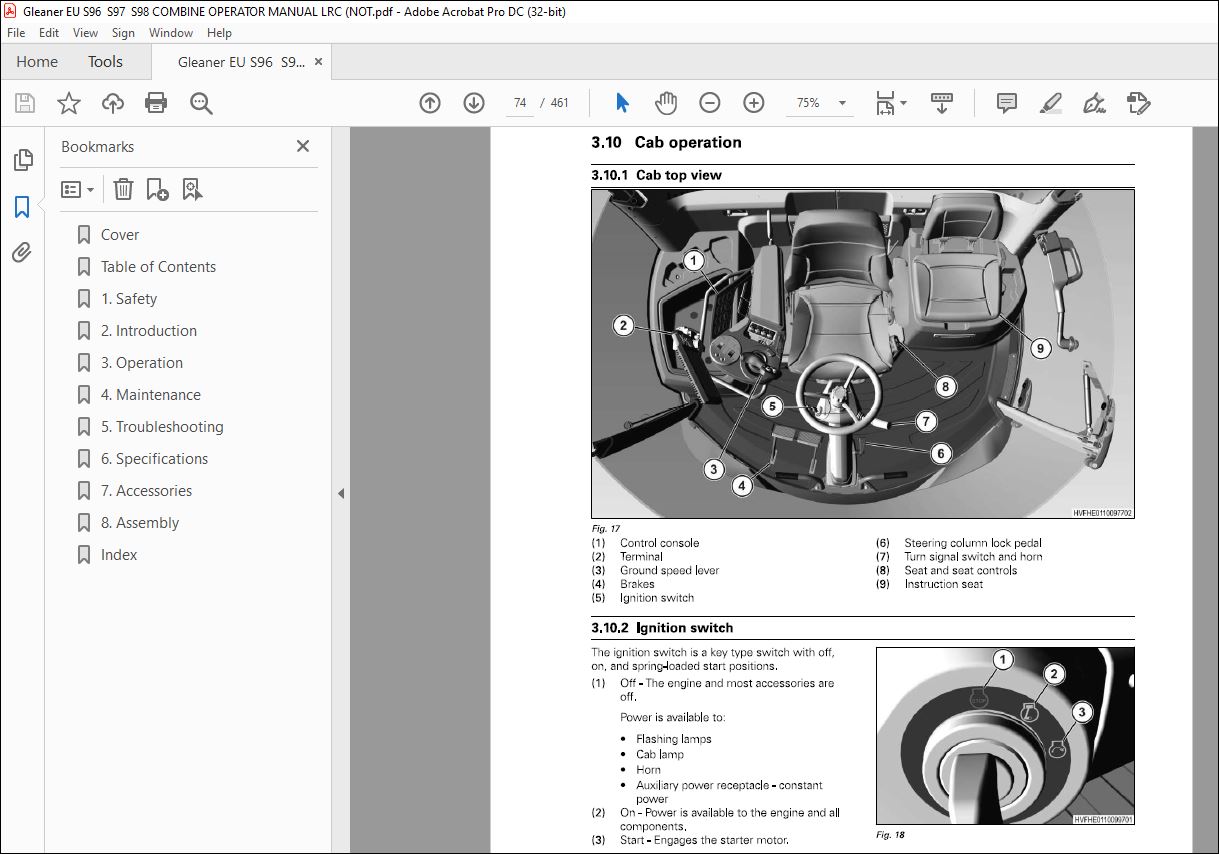

3 10 Cab operation 85

3 10 1 Cab top view 85

3 10 2 Ignition switch 85

3 10 3 Turn signals and row finder lamps 86

3 10 4 Horn 86

3 10 5 Trailer lamp malfunction indicator 87

3 10 6 Fuel level 87

3 10 7 Cab interior lamp 87

3 10 8 Cab storage 88

3 10 9 Cooler, if equipped 88

3 10 10 Auxiliary power sockets 89

3 10 11 Front shade 89

3 10 12 Radio 89

3 10 13 Brake pedals 90

3 10 14 Adjust the steering column fore and aft 90

3 10 15 Adjust the steering column tilt 90

3 10 16 Adjust the steering column up and down 91

3 10 17 Park brake 91

3 10 18 Power mirrors 92

3 10 19 Windscreen wiper 92

3 11 Console controls 93

3 11 1 Console controls 93

3 11 2 Engine speed dial 94

3 11 3 Ground speed lever controls 95

3 11 4 Header controls 96

3 11 5 Header engage switch 96

3 11 6 Park brake switch 97

3 11 7 Rear wheel assist switch 97

3 11 8 Thresher engage switch 97

3 11 9 Transport mode 98

3 12 Machine lamps 99

3 12 1 Lamp control panel 99

3 12 2 Field lamps and headlamps 99

3 12 3 Rear work and ladder lamps 100

3 12 4 Exit lamps 100

3 12 5 Beacon lamps 101

3 12 6 Row finder lamps 101

3 12 7 Flashing warning lamps 102

3 12 8 Service lamps 102

3 13 Terminal operation 104

3 13 1 Terminal settings 104

3 13 2 Terminal overview 104

3 13 3 Data transfer 105

3 13 4 Adjust the terminal 105

3 13 5 Video 105

3 13 6 Software upgrade 105

3 13 7 Terminal basics 106

3 13 7 1 Terminal display 106

3 13 7 2 External control panel 106

3 13 7 3 Screen layout 107

3 13 7 4 Navigation – control by touch 107

3 13 7 5 Navigation-quickjumps 108

3 13 7 6 Navigation – control with external control panel 108

3 13 7 7 Clean the terminal screen 108

3 13 7 8 Day/night mode on the terminal 108

3 13 7 9 Icon descriptions 109

3 14 Main screen overview 112

3 14 1 Customize the main screen 112

3 15 Combine dashboard 114

3 15 1 View alarms 114

3 15 2 Remove alarms 115

3 16 Machine settings and data 116

3 16 1 Configure a header 116

3 16 2 Change the header settings 118

3 16 3 Change the crop setting recommendations 118

3 16 4 Change the settings for cruise ground speed 118

3 16 5 Change the reel settings 119

3 16 6 Change the yield settings 120

3 16 7 Change the loss system settings 121

64 59 Series Combine

3 16 8 Shaft speeds screen 122

3 16 8 1 Change the shaft speeds settings 122

3 16 9 Change the system features 123

3 16 10 Combine maintenance information 124

3 16 11 Counters 124

3 16 12 Chaff spreader on/off 125

3 16 13 Engine reversing fan on/off 126

Calibrations 127

3 17 1 Calibrate the multifunction armrest 127

3 17 2 Calibrate the header 127

3 17 3 Calibrate the reel 128

3 17 4 Calibrate the processor and cleaning system 128

3 17 5 Calibrate the manual shaft 129

Info+ 131

3 18 1 Harvest data 131

3 18 2 Losses 132

3 18 3 Header 132

3 18 4 Engine 132

3 18 5 Engine 2 133

3 18 6 Shafts 133

3 18 7 Chopper 133

Camera 134

3 19 1 Show the camera on the terminal 134

3 19 2 Change between multiple cameras 134

3 19 3 Open the camera full-screen image 135

3 19 4 Adjust the brightness 135

3 19 5 Adjust the contrast 135

3 19 6 Adjust the color saturation 136

Terminal management main page 137

3 20 1 Menu overview of administration 137

3 20 2 Data exchange 138

3 20 2 1 Transfer data for a USB external memory device 138

3 20 3 ISOBUS information 139

3 20 3 1 ISOBUS and task controller switches 140

3 20 4 Position ISOBUS application on the terminal 140

3 20 4 1 Display without I SOBUS implement or device 141

3 20 4 2 Display with one ISOBUS implement or device 142

TaskDoc 143

TaskDoc menu overview 143

TaskDoc information 143

TaskDoc main menu 145

Data settings 146

Add a task 147

Save a task 148

Copy a task 148

Select a task 149

Add categories to a task 150

Delete categories from a task 151

Filter by categories 152

On-board computer 153

3 21 12 1 Open the on-board computer 154

3 21 12 2 Setacountertoofforon 154

3 21 13 Memory space monitoring 155

3 21 14 Delete all TaskDoc data 155

3 21 15 Starting the system test 156

3 21 16 System test results 156

Auto-Guide 159

59 Series Combine

Table of contents , •AGCO

Your Agriculture Company

3 22 1 General Guidance Information 159

3 22 1 1 Global Navigation Satellite System (GNSS) 159

3 22 1 2 How the Global Navigation Satellite System (GNSS) works 159

3 22 1 3 Global Navigation Satellite System (GNSS) components 159

3 22 1 4 Satellite reception 159

3 22 1 5 Signal interruption 160

3 22 1 6 Static and dynamic accuracy (satellite drift) 160

3 22 1 7 Convergence time 160

3 22 1 8 Conditions of use and application possibilities 160

3 22 1 9 Restrictions 161

3 22 1 10 Switch-off limits 161

3 22 1 11 Glossary 161

3 22 2 Quick start 166

3 22 2 1 Guidance system menu tree 166

3 22 2 2 Guidance system info 167

3 22 2 3 Guidance system main menu 167

3 22 2 4 Field settings main screen 168

3 22 2 5 Steering settings 168

3 22 2 6 Guidance system menu tree 169

3 22 2 7 System screen 170

3 22 3 Map view 171

3 22 3 1 Show the map view on the terminal 171

3 22 3 2 Map view on the main terminal screen 172

3 22 3 3 Full screen map view menu tree 173

3 22 3 4 Full screen map view screen 173

3 22 3 5 Information bar 176

3 22 3 6 Set a marker 179

3 22 3 7 Marker settings 180

3 22 3 8 Change the worked area settings 180

3 22 4 Start-up 181

3 22 4 1 Automatic guidance switch 181

3 22 4 2 Correction signals 182

3 22 4 3 WAAS/EGNOS 182

3 22 4 4 Configure the internal modem correction signal 183

3 22 4 5 Configure the tailback 184

3 22 4 6 Autonomous correction source 185

3 22 4 7 Field settings 185

3 22 4 8 Wayline 189

3 22 5 Troubleshooting 193

3 22 5 1 Guidance system troubleshooting 193

3 23 System check 196

3 23 1 Check the feeder house position sensor 196

3 23 2 Set the header break point 196

3 23 3 Check the elevator speed sensor 197

3 23 4 Check the ground speed sensor 198

3 23 5 Fieldstar yield monitor 198

3 23 5 1 Check the moisture sensor 198

3 23 5 2 Set the yield point 198

3 23 5 3 Calibrate the yield sensor 199

3 24 Configure the terminal for the Agleader yield monitor 200

3 24 1 Start calibration screen 201

3 24 2 Run screen 201

3 24 3 Calibration screen 202

3 24 4 Diagnostic screen 202

3 24 5 Calibrations 203

3 24 5 1 Do the vibration calibration 203

3 24 5 2 Calibrate yield 204

3 24 5 3 Calibrate the moisture 205

66 59 Series Combine

79037181F

AGCO

Your Agriculture Company Table of contents

3 24 5 4 Calibrate the temperature 206

3 24 5 5 Change the crop type 206

3 24 5 6 Change the crop density 207

3 24 5 7 Change the yield type 207

3 25 Leaf screen 208

3 25 1 Cleaning fan leaf screen 208

3 25 2 Open the cleaning fan leaf screen 208

3 25 3 Close the cleaning fan leaf screen 209

3 25 4 Transmission leaf screen 209

3 25 5 Open the transmission leaf screen 209

3 25 6 Close the transmission leaf screen 210

3 26 Feeder 211

3 26 1 Header electro-magnetic clutch 211

3 26 2 Operate the header/feeder reverser 212

3 26 3 Set the feeder speed 212

3 26 4 Set the feeder speed for the corn headers 213

3 27 Variable speed corn header drive 215

3 28 Threshing cylinder 216

3 28 1 Cylinder drive 216

3 28 2 Cylinder gearbox shift lever 216

3 28 3 Cylinder reverser tool 217

3 28 4 Use the cylinder reverser tool 217

3 29 Threshing 218

3 29 1 Filler bars 218

3 29 2 Concave wires 218

3 29 3 Separator cage cover 218

3 29 4 Install the separator cage cover 219

3 29 5 Remove the separator cage cover 219

3 30 Cleaning system 221

3 30 1 Cleaning shoe 221

3 30 2 Cleaning shoe tailboard 221

3 30 3 Open the cleaning shoe tailboard 221

3 30 4 Close the cleaning shoe tailboard 222

3 30 5 Adjustable chaffer 222

3 30 6 Optional chatters 223

3 30 7 Adjustable sieve 224

3 30 8 Adjust the sieve and chaffer 224

3 30 9 Optional sieves 225

3 30 10 Cleaning fan 225

3 30 11 Light seeds kit 226

3 31 Grain tank 227

3 31 1 Grain tank cross auger cover 227

3 31 2 Grain tank unloading system 227

3 31 3 Grain tank level sensors 228

3 31 4 Grain tank sample 228

3 31 5 Grain tank extensions 228

3 31 6 Open the grain tank extensions 228

3 31 7 Close the grain tank extensions 229

3 31 8 Yield sensor 229

3 31 9 Mositure sensor 230

3 32 Discharge system 231

3 32 1 Hydraulic straw spreader 231

3 32 2 Straw spreader guard 231

3 32 3 Chaff spreader 231

3 32 4 Move the chaff spreader to the maintenance position 232

3 32 5 Straw chopper 232

3 32 6 Adjust the straw chopper speed 232

59 Series Combine

79037181F

67

Table of contents , •AGCO

Your Agriculture Company

3 32 7 Fine cut knife 235

3 32 8 Engage the fine cut knife assembly 235

3 32 9 Disengage the fine cut knife assembly 236

3 33 Stone trap 237

3 33 1 Open the stone trap door 237

3 33 2 Close the stone trap door 238

3 34 Seat 239

3 34 1 Seat belts 239

3 34 2 Instructor seat 239

3 34 3 Deluxe operator seat 240

3 34 4 Standard operator seat 240

3 35 Climate control system 241

3 35 1 Operation 241

3 35 2 Automatic mode 241

3 35 3 Manual fan mode 242

3 35 4 Defog mode 242

3 36 Hydraulic system 244

3 36 1 Hydraulic system overview 244

3 36 2 Hydraulic pump 244

3 36 3 Steering priority valve 245

3 36 4 Hydraulic single point connector 245

3 36 5 Hydraulic accumulator 246

3 36 6 Accumulator valve 246

3 36 7 Lateral tilt valve 247

3 36 8 Main hydraulic control valve port location 247

3 36 9 Main hydraulic control valve solenoid and speed adjustment location 248

3 36 10 Park brake control valve 249

3 37 Headers 251

3 37 1 Install the header to the combine 251

3 37 2 Remove the header from the combine 253

3 38 Initial combine settings 255

3 39 Performance adjustments 257

3 39 1 Adjustment procedure tips 257

3 39 2 Corn header harvesting tips 259

3 39 3 Additional help 260

3 40 Field service tips 261

4 1 Service schedule 277

4 2 General information 281

4 2 1 Inspection during lubrication 281

4 2 2 Sealed bearings 281

4 2 3 After service work 281

4 3 Lubrication points 282

4 3 1 Left-hand side of machine 282

4 3 2 Right-hand side of machine 286

4 3 3 Automatic lubrication 291

4 4 Roller chain maintenance 294

4 5 Engine oil 295

4 5 1 Check the engine oil level 295

4 5 2 Change the engine oil and filter 295

4 6 Engine air filter 297

4 6 1 Clean the engine air cleaner screen 297

4 6 2 Aspirated air pre-cleaner 297

4 6 3 Air filter restriction switch 298

4 6 4 Engine air filters 298

4 6 5 Clean the primary element 298

4 6 6 Replace the primary element 298

4 6 7 Replace the secondary element 299

4 7 Fuel system 300

4 7 1 Fuel fill location 300

4 7 2 Fuel handling 300

4 7 3 Fuel valve 301

4 7 4 Fuel vent breather 301

4 7 5 How to remove the water from the fuel system 301

4 7 6 Replace the fuel filters 302

4 7 7 Replace the auxiliary fuel filter 303

4 7 8 Bleed the fuel system 303

4 8 Engine belts 304

4 8 1 Belt maintenance 304

4 8 2 Belt adjustment 304

4 8 3 Aspirator drive belt 304

4 8 4 Remove the aspirator drive belt 305

4 8 5 Install the aspirator drive belt 307

4 8 6 Compressor drive belt 307

4 8 7 Remove the compressor drive belt 308

4 8 8 Install the air conditioning compressor drive belt 309

4 8 9 Remove the alternator belt 309

4 8 10 Install the alternator belt 311

4 9 Engine cooling system 313

4 9 1 Engine cooling fan 313

4 9 2 Engine cooling system coolant 313

4 9 3 Coolant level 313

4 9 4 Coolant mixture 314

4 9 5 Change the engine coolant 314

4 10 Air conditioning system 317

4 10 1 Compressor 317

59 Series Combine

79037181F

273

Table of contents , •AGCO

Your Agriculture Company

4 10 2 Condensor 317

4 11 Cab air filter 318

4 11 1 Primary cab air filter 318

4 11 2 Cab recirculation filter 318

4 11 3 Clean the cab air filter 318

4 12 Clean the windscreen 320

4 13 Hydraulic system 321

4 13 1 Hydraulic oil level 321

4 13 2 Change the suction filter for the propel pump 321

4 13 3 Change the hydro return filter 322

4 13 4 Change the hydraulic oil 323

4 13 5 Remove air from the hydraulic system 325

4 13 6 Check the accumulator gas pressure 326

4 13 7 Hydrostatic oil cooler 327

4 14 Electrical system 328

4 14 1 Battery 328

4 14 2 Access the batteries from the engine compartment 328

4 14 3 Access the batteries from the outside of the machine 329

4 14 4 Battery disconnect switch 329

4 14 5 Battery jump post 330

4 14 6 Start the engine with a booster battery 330

4 14 7 Alternator 331

4 14 8 Starter 331

4 14 9 Lighting system and reflector maintenance 331

4 14 10 Replace the standard front work lamp bulbs 331

4 14 11 Replace the dome lamp 332

4 14 12 Adjust the cab lamp 332

4 14 13 EDT diagnostics connectors 333

4 15 Ground locations 334

4 16 Front electrical distribution center 336

4 16 1 HCDM1 336

4 16 2 EXT controller 337

4 17 Rear electrical distribution center 338

4 17 1 Fuse block 338

4 17 1 1 PDC 339

4 17 1 2 HCDM2 340

4 18 Cab electrical distribution center 342

4 18 1 CEDC 342

4 19 Transmission 345

4 19 1 Check the transmission fluid level 345

4 19 2 Change the transmission fluid 345

4 20 Final drive 347

4 20 1 Check the final drive fluid level 347

4 20 2 Change the final drive fluid 347

4 21 Cylinder gearbox 349

4 21 1 Check the cylinder gearbox fluid level 349

4 21 2 Change the cylinder gearbox fluid 349

4 22 Wheels and tires 351

4 22 1 Tire pressure 351

4 22 2 Wheel bolt torque 351

4 22 3 Dual tires 351

4 22 4 Sidehill use 351

4 22 5 Care of tires 351

4 22 6 Tire repair 352

4 22 7 Remove the front drive wheel 352

4 22 8 Install the front drive wheel 353

274 59 Series Combine

79037181F

AGCO

Your Agriculture Company Table of contents

4 22 9 Remove the rear wheel 353

4 22 10 Install the rear wheel 354

4 23 Con caves 356

4 23 1 Remove the concaves 356

4 23 2 Install the concaves 357

4 23 3 Levell ing the concaves 358

4 23 4 Remove the concave wires 360

4 23 5 Install the concave wires 360

4 23 6 Remove the concave filler plates 361

4 23 7 Install the concave filler plates 361

4 24 Chaffer and sieve 363

4 24 1 Remove the chaffer 363

4 24 2 Install the chaffer 364

4 24 3 Remove the sieve 364

4 24 4 Install the sieve 365

4 25 Chopper knives 367

4 25 1 Remove the chopper knives 367

4 25 2 Install the chopper knives 368

4 26 Drive alignment 369

4 26 1 Sheave Alignment 369

4 26 2 Idler Alignment 369

4 27 Drive belts and chains 371

4 27 1 Care of Belts 371

4 27 2 V-Belt Installation 371

4 27 3 Care of Chains 371

4 28 Left-hand drives 373

4 28 1 Main drive idler spring 373

4 28 2 Adjust the main drive idler 373

4 28 3 Left-hand pivot shaft drive idler spring 374

4 28 4 Adjust the left-hand pivot shaft drive idler spring 374

4 28 5 Unloader drive idler spring 375

4 28 6 Adjust the unloader drive idler 375

4 28 7 Adjust the shoe drive 376

4 28 8 Adjust the impeller drive idler spring 376

4 28 9 Adjust the straw chopper idler spring 377

4 28 10 Adjust the clean grain elevator idler 377

4 29 Right-hand drives 379

4 29 1 Adjust the separator drive idler spring 379

4 29 2 Elevator jackshaft idler spring 379

4 29 3 Adjust the elevator jackshaft idler spring 379

4 29 4 Variable speed cylinder drive belt 380

4 29 5 Adjust the rear feed conveyor drive idler spring 380

4 29 6 Adjust the tailings return drive idler 381

4 29 7 Tail ings return drive idler spring 381

4 29 8 Adjust the cleaning fan and accelerator roll belt 382

4 29 9 Adjust the unloader drive belt, if equipped 382

4 29 10 Adjust the unloader drive chain, if equipped 383

4 30 Feederhouse 385

4 30 1 Adjust the single speed header drive idler spring 385

4 30 2 Adjust the variable speed header drive idler 385

4 30 3 Adjust the right pivot shaft idler spring 386

4 30 4 Feed conveyor chains 386

4 30 5 Front feed conveyor 387

4 30 6 Adjust the feed conveyor chain springs 387

4 30 7 Remove or add chain half-links to the front feed conveyor chain 388

4 30 8 Remove or add chain half-links to the rear feed conveyor chain 388

4 30 9 Adjust the feeder reverser drive chain 389

59 Series Combine

79037181F

275

Table of contents , •AGCO

Your Agriculture Company

4 30 10 Feed drum blocks 390

4 30 11 Adjust the feed drum blocks 390

4 31 Accelerator rolls 391

4 31 1 Adjust the accelerator rolls 391

4 32 Shoe guides 392

4 32 1 Adjust the cleaning shoe guides 392

4 33 Grain elevators 393

4 33 1 Adjust the clean grain elevator conveyor chain 393

4 33 2 Adjust the tailings elevator conveyor chain 393

4 34 Grain tank 394

4 34 1 Cross auger cover 394

4 34 2 Adjust the cross auger cover 394

4 35 Grain tank unloader 395

4 35 1 Adjust the swing cylinder 395

4 35 2 Unloader tube swing proximity sensor 395

4 35 3 Adjust the cradle proximity sensor 395

4 36 Chaff spreader 397

4 36 1 Adjust the chaff spreader board 397

4 37 Straw spreader 398

4 37 1 Straw spreader paddles 398

4 38 Rotary radiator screen adjustment 399

4 39 Sensors and switches 400

4 39 1 Sensors and switches locations and specificiations 400

4 40 Speed adjustment 402

4 40 1 Adjust the header lift speed 402

4 40 2 Adjust the header lowering speed 402

4 40 3 Adjust the chaff spreader speed 403

4 40 4 Adjust the rotary screen speed 404

4 41 Axles 405

4 41 1 Front Axle 405

4 41 2 Rear Axle 405

4 41 3 Adjust the standard rear axle tread width 405

4 41 4 Adjust the rear wheel assist axle tread width 407

4 41 5 Wheel adjustment 408

4 41 5 1 Adjust the rear wheel assist wheel stops 408

4 41 5 2 Adjust the standard rear axle wheel stop 409

4 41 5 3 Adjust the wheel toe-in 409

4 42 Brakes 411

4 42 1 Master cylinder reservoir 411

4 42 2 Adjust the master cylinder 411

4 42 3 Adjust the parking brake 412

4 43 Storage 413

4 43 1 Preparation for use after storage 413

4 44 Seed loss 415

4 44 1 Grain loss 415

4 44 2 Corn loss 417

5 1 Engine troubleshooting 423

5 2 Hydrostatic propulsion troubleshooting 424

5 3 Terminal troubleshooting 426

5 4 Yield sensor troubleshooting 427

5 5 Fieldstar troubleshooting 429

5 6 Agleader yield monitor troubleshooting 430

5 7 Moisture sensor troubleshooting 431

6 1 General specifications 435

Dimensions 435

Weight specifications 436

Wheel torque specifications 436

Machine system specifications 437

Cab specifications 439

Climate control specifications 439

Brake specifications 440

Electrical specifications 440

Engine specifications 440

Hydraulic system specifications 441

Lubrication specifications 442

Lubricating oil quality requirements 443

Coolant quality requirements 443

Fuel quality requirements 444

6 1 14 1 Biodiesel blends 445

Machine drive specifications 446

Machine lamp specifications 447

Steering axle specifications 448

Tire specifications 448

6 1 18 1 Drive tires 448

6 1 18 2 Dual drive tires 449

6 1 18 3 Rear wheel assist steering tires 449

7 1 Accessories 453

8 1 Assembly 457

8 1 1 Unload the machine 457

8 1 2 Tire pressure 457

8 1 3 Check the wheel nut torque 457

8 1 4 Adjust the cab mirrors 457

8 1 5 Connect the hydraulic driven straw spreader 457

8 1 6 Install the fire extinguisher 458

8 1 7 Install the unloader auger spout 459

8 1 8 Lower the straw spreader guard 459

8 1 9 Wash the machine 459