$33

Gleaner NA Harvesting 3000 Corn Header Service Manual – PDF DOWNLOAD

Gleaner NA Harvesting 3000 Corn Header Service Manual – PDF DOWNLOAD

FILE DETAILS:

Gleaner NA Harvesting 3000 Corn Header Service Manual – PDF DOWNLOAD

Language : English

Pages : 316

Downloadable : Yes

File Type : PDF

Size: 60.4 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gleaner NA Harvesting 3000 Corn Header Service Manual – PDF DOWNLOAD

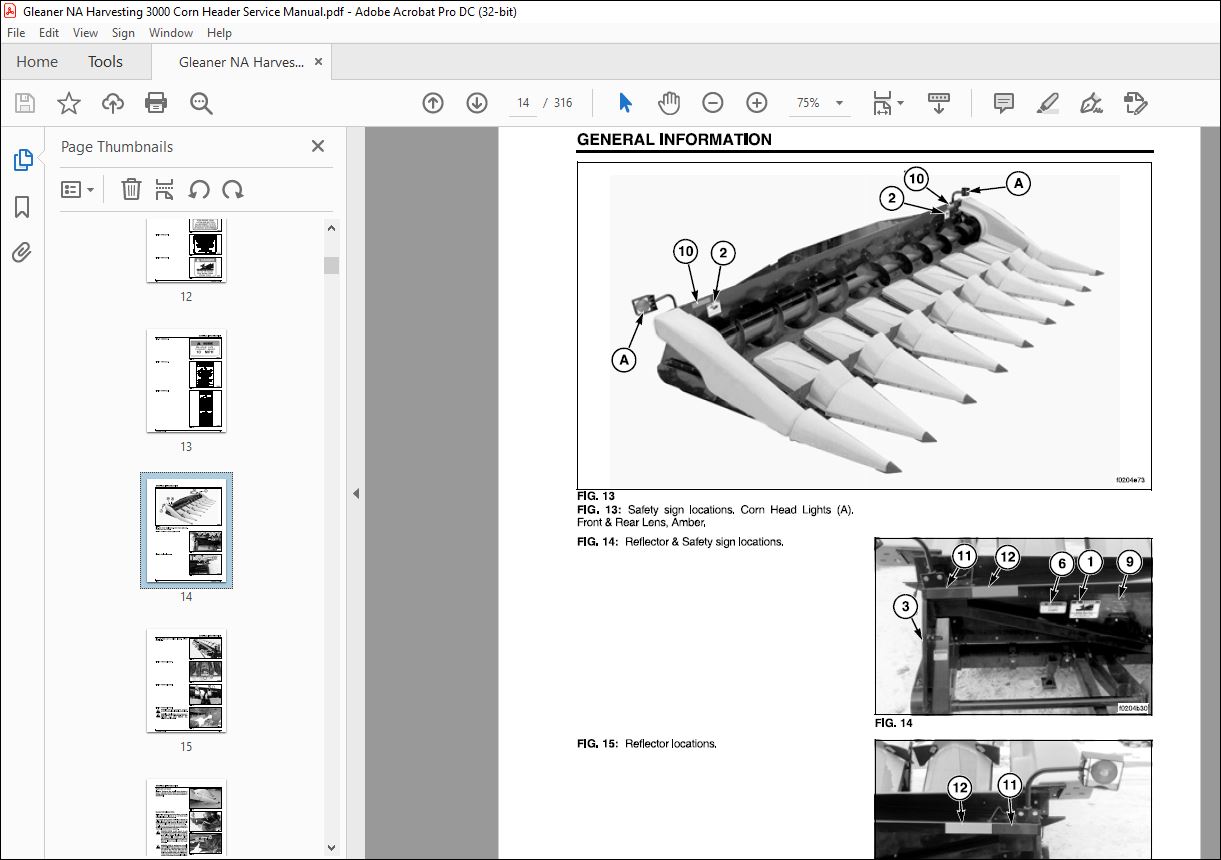

GENERAL INFORMATION:

Safety Precautions:

Read and understand this section of your service manual, the operator’s manuals for the combine, and for all the attachments before operating the combine. Learn how to operate the combine and header and how to use the controls properly. Do not allow anyone to operate the combine without proper instruction and training.

- The Right Hand and Left Hand side is determined by facing in the direction of forward travel. IT IS TOO LATE TO REMEMBER WHAT SHOULD HAVE BEEN DONE AFTER THE ACCIDENT HAS HAPPENED.

- For you safety and the safety of others, follow all the safety precautions and instructions in the manuals and on the decals affixed to the combine and its attachments. Personal injury or death may result if these precautions are not followed.

• READ the Operator’s Manuals carefully to acquaint yourself with the Corn Head and combine. Operating unfamiliar equipment can cause accidents.• ALWAYS shift transmission to neutral, stop engine, set brake and remove start key before leaving the operator’s station, or before permitting anyone to inspect, clean, lubricate, adjust or repair any part of the combine or its attachments, unless otherwise specifically recommended in the Operator’s Manual.• NEVER permit anyone to work under the Corn Head or feeder housing or between the Corn Head and combine UNLESS the header lift cylinder stop is fully engaged on the lift ram, the engine is stopped, the brake is set, the key is removed from the start switch, and the Corn Head is latched securely to the feeder housing.• NEVER permit the operator or another person to engage or disengage the header lift cylinder stop UNLESS the combine engine is stopped, the brake is set, and the key is removed from the start switch while that person is between the Corn Head and the combine or under the feeder housing to move the header lift cylinder stop.• BE SURE that everyone is clear of the combine before starting the engine and mechanism or it’s attachments.

TABLE OF CONTENTS:

Gleaner NA Harvesting 3000 Corn Header Service Manual – PDF DOWNLOAD

GENERAL INFORMATION 1-3

Safety Alert Symbol 1-3

Signal Words 1-3

Safety Precautions 1-4

Road and Highway Operation 1-6

Safety Decals, Lights, and Reflectors 1-7

Right and Left Hand 1-12

Header Lift Cylinder Stop 1-12

SHIELDS 1-14

Attaching Corn Head to Combine 1-21

Leveling Header 1-26

Specifications 1-27

Lubrication and Service 1-31

SETTING UP INSTRUCTIONS 1-39

General 1-39

Shipping Angles 1-40

Shipping Stands 1-41

Preparation 1-42

Inner Gathering Sheets 1-43

Inner Divider Points 1-45

Outer Fenders 1-47

Extremity Lights 1-50

Corn Head Hopper Bottom Deflector Plate 1-51

Setup to Fit Transverse Corn Head on Conventional or Axial Combine 1-52

Setup to Fit Conventional or Axial Corn Head on Transverse Combine 1-57

ADJUSTMENTS 2-3

Troubleshooting 2-4

Inner Gather Assembly 2-5

Outer Fenders 2-8

Divider Points 2-12

Divider Point Storage 2-13

Row Unit 2-14

Gather Chain 2-17

Stripper Plates 2-20

Snapping Rolls 2-24

Grass Knives 2-26

Slip Clutches 2-27

Auger Height Adjustment 2-28

Row Unit Drive Chain Idler 2-30

Unit Drive Cross Shaft 2-32

Inner Gather Assembly Height Adjustment 2-33

ROW SPACING CHANGES 2-34

Fender and Inner Gather Assemblies 2-35

Row Units 2-37

Assembly 2-41

SERVICE – GENERAL 3-3

Divider Points 3-3

Inner Gathering Sheets 3-10

Fenders (Outer Gathering Sheets) 3-21

Lateral Tilt (Option) 3-36

PTO Drive Shaft (Left Hand and Right Hand) 3-41

Main Drive Shaft Group Left and Right Hand 3-52

Conveyor Drive Chain 3-66

Spiral Conveyor 3-71

Row Unit Drive Left and Right Hand 3-84

Torque Limiter – Row Unit 3-93

Adjustable Stripper Plates 3-97

SERVICE – FRAME GROUP 4-3

Conveyor 4-3

Hanger Weldment 4-6

Hopper Deflector and Inner Bottom Extension 4-11

Conveyor Stripper Angles 4-16

Spiral Conveyor Back 4-21

Spiral Conveyor Bottom 4-26

SERVICE – ROW UNIT 5-3

Unit Frame and Gearbox 5-3

Row Unit Frame Repair 5-20

Input Housing – Gearbox 5-30

Output Housing – Gearbox 5-40