$30

Gleaner NA Harvesting 3200 Series 3206 3206C 3212F 3212FC Corn Header Service Manual 79037206A – PDF

Gleaner NA Harvesting 3200 Series 3206 3206C 3212F 3212FC Corn Header Service Manual 79037206A – PDF DOWNLOAD

FILE DETAILS:

Gleaner NA Harvesting 3200 Series 3206 3206C 3212F 3212FC Corn Header Service Manual 79037206A – PDF DOWNLOAD

Language : English

Pages : 126

Downloadable : Yes

File Type : PDF

Size: 17.6 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Gleaner NA Harvesting 3200 Series 3206 3206C 3212F 3212FC Corn Header Service Manual 79037206A – PDF DOWNLOAD

General information:

1.1.1 Introduction to this service manual:

This service manual gives information from engineering tests, operating data, and the latest service

techniques at the time of publication. Read this service manual carefully before doing any service on the

machine.

The photos and illustrations used in this service manual were current at the time of publication. Production

changes can cause machines to vary from the photos and the illustrations. The manufacturer reserves the

right to redesign and change machines as necessary without notification.

Machine movement when in normal use determines right-hand and left-hand.

1.1.2 Units of measurement:

Measurements are given in metric units followed by the equivalent in US units. Hardware sizes are given in

millimeters for metric hardware and inches for US hardware.

1.1.3 Table of contents:

This manual has a table of contents at the front. The table of contents shows the divisions. The individual

divisions also have a table of contents.

1.1.4 Page numbers:

All pages have two numbers, such as 01-25. The first number shows the division. The second number

shows the page in the division.

Page numbers occur on the lower right-hand or lower left-hand corner of each page.

1.1.5 Intended use:

This machine is designed solely for use in customary agricultural operations.

Do not use this machine for any application or purpose other than those described in this manual. The

manufacturer accepts no liability for damage or injury resulting from misuse of this machine.

Compliance with the conditions of operation, service and repair as specified by the manufacturer constitute

essential elements for the intended use of this machine.

This machine should be operated, serviced and repaired only by qualified persons familiar with its

characteristics and familiar with the relevant safety rules and procedures.

All generally recognized safety regulations and road traffic regulations must be obeyed at all times.

Any unauthorized modifications performed on this machine will relieve the manufacturer of all liability for

any resulting damage or injury.

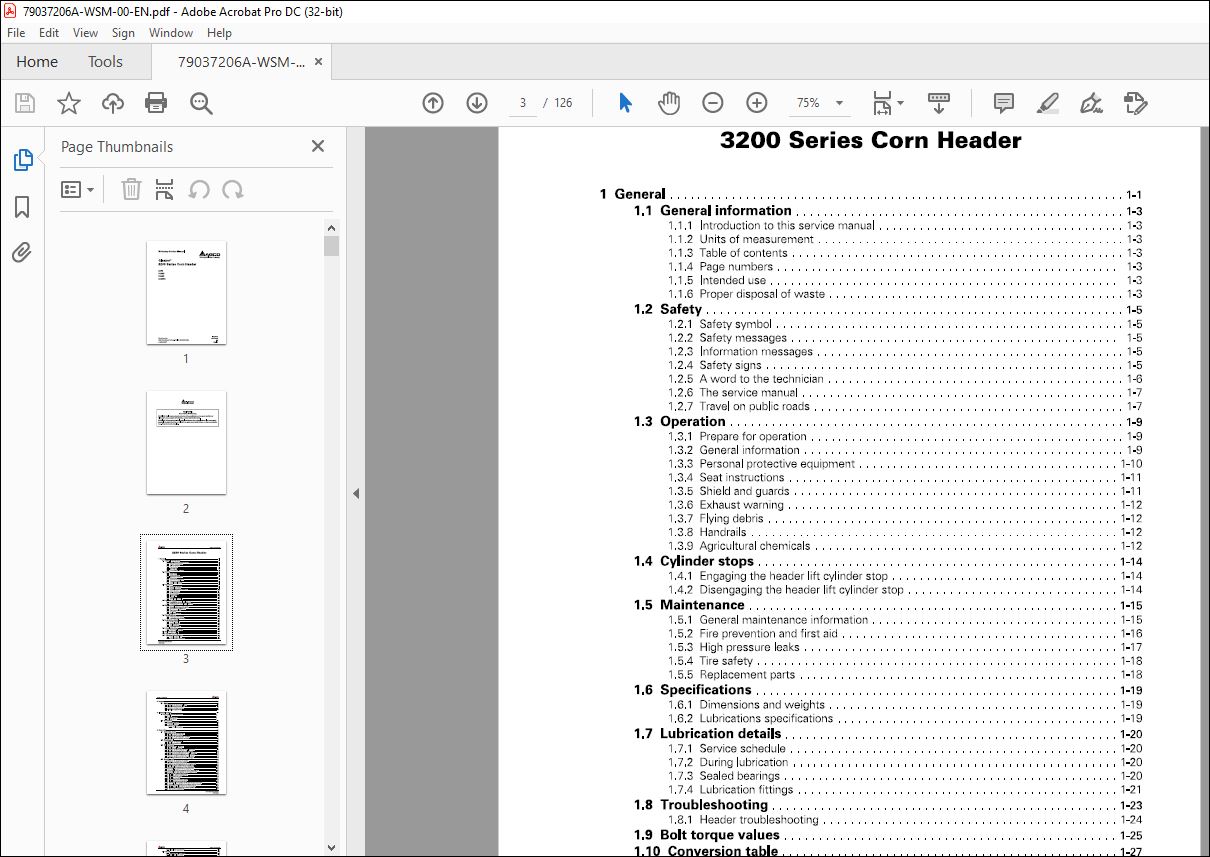

TABLE OF CONTENTS:

Gleaner NA Harvesting 3200 Series 3206 3206C 3212F 3212FC Corn Header Service Manual 79037206A – PDF DOWNLOAD

1 General 1-1

1 1 General information 1-3

1 1 1 Introduction to this service manual 1-3

1 1 2 Units of measurement 1-3

1 1 3 Table of contents 1-3

1 1 4 Page numbers 1-3

1 1 5 Intended use 1-3

1 1 6 Proper disposal of waste 1-3

1 2 Safety 1-5

1 2 1 Safety symbol 1-5

1 2 2 Safety messages 1-5

1 2 3 Information messages 1-5

1 2 4 Safety signs 1-5

1 2 5 A word to the technician 1-6

1 2 6 The service manual 1-7

1 2 7 Travel on public roads 1-7

1 3 Operation 1-9

1 3 1 Prepare for operation 1-9

1 3 2 General information 1-9

1 3 3 Personal protective equipment 1-10

1 3 4 Seat instructions 1-11

1 3 5 Shield and guards 1-11

1 3 6 Exhaust warning 1-12

1 3 7 Flying debris 1-12

1 3 8 Handrails 1-12

1 3 9 Agricultural chemicals 1-12

1 4 Cylinder stops 1-14

1 4 1 Engaging the header lift cylinder stop 1-14

1 4 2 Disengaging the header lift cylinder stop 1-14

1 5 Maintenance 1-15

1 5 1 General maintenance information 1-15

1 5 2 Fire prevention and first aid 1-16

1 5 3 High pressure leaks 1-17

1 5 4 Tire safety 1-18

1 5 5 Replacement parts 1-18

1 6 Specifications 1-19

1 6 1 Dimensions and weights 1-19

1 6 2 Lubrications specifications 1-19

1 7 Lubrication details 1-20

1 7 1 Service schedule 1-20

1 7 2 During lubrication 1-20

1 7 3 Sealed bearings 1-20

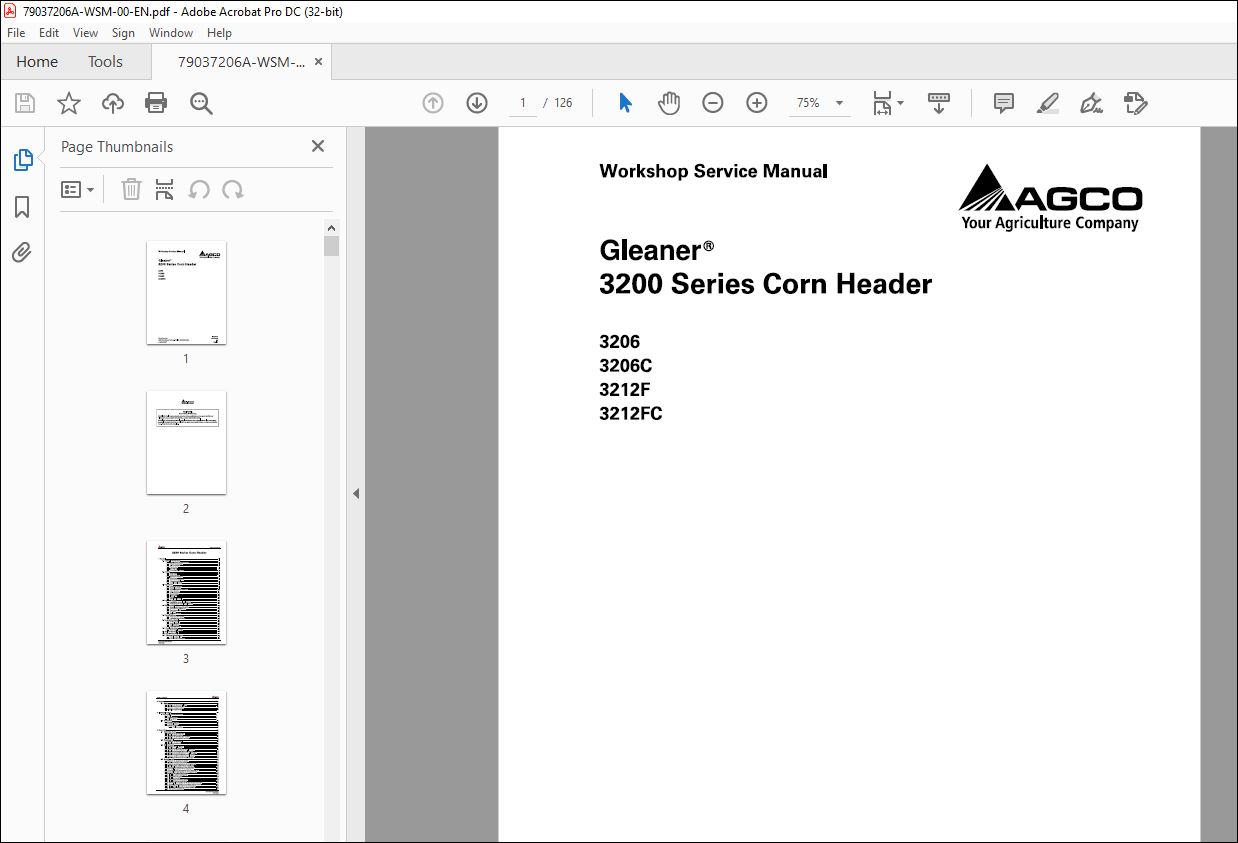

1 7 4 Lubrication fittings 1-21

1 8 Troubleshooting 1-23

1 8 1 Header troubleshooting 1-24

1 9 Bolt torque values 1-25

1 10 Conversion table 1-27

1 11 Machine identification 1-30

1 11 1 Serial number plate 1-30

1 11 2 Serial number description 1-30

3200 Series Corn Header

79037206A

Table of contents , •AGCO

Your Agriculture Company

2 Augers 2-1

2 1 Auger 2-3

2 1 1 Remove the auger safety clutch 2-3

2 1 2 Install the auger safety clutch 2-4

2 1 3 Remove the auger bearing 2-4

2 1 4 Install the auger bearing 2-6

3 Electrical system 3-1

3 1 Basic troubleshooting procedures 0

3 1 1 Tools 0

3 1 2 Continuity check 0

3 1 3 Voltage check 0

3 2 Connectors 3-3

3 2 1 Check a connector 3-3

3 2 2 Terminal numbers 3-3

3 2 3 Pins and sockets 3-4

3 2 3 1 Dielectric grease 3-5

4 Row units 4-1

4 1 Gathering chain 4-3

4 1 1 Remove the gathering chain 4-3

4 1 2 Install the gathering chain 4-3

4 1 3 Remove the gathering chain tensioner 4-3

4 1 4 Install the gathering chain tensioner 4-4

4 2 Snapping roll 4-5

4 2 1 Remove the snapping roll 4-5

4 2 2 Install the snapping roll 4-5

4 3 Stalk chopper 4-6

4 3 1 Remove the stalk chopper 4-6

4 3 2 Install the stalk chopper 4-7

4 3 3 Remove the first bearing for the stalk chopper 4-9

4 3 4 Install the first bearing for the stalk chopper 4-11

4 3 5 Remove the second bearing for the stalk chopper 4-13

4 3 6 Install the second bearing for the stalk chopper 4-14

4 3 7 Remove the third bearing for the stalk chopper 4-15

4 3 8 Install the third bearing for the stalk chopper 4-18

4 4 Snapping unit 4-20

4 4 1 Remove the snapping unit gearbox 4-20

4 4 2 Install the snapping unit gearbox 4-21

4 4 3 Remove the input gearbox for the snapping unit 4-23

4 4 4 Install the input gearbox for the snapping unit 4-23

4 4 5 Disassemble the gearbox for the snapping unit 4-24

4 4 6 Assemble the gearbox for the snapping unit 4-29

4 4 7 Disassemble the input gearbox for the snapping unit 4-34

4 4 8 Assemble the input gearbox for the snapping unit 4-37

4 4 9 Remove the primary input gearbox 4-39

4 4 10 Install the primary input gearbox 4-40

4 4 11 Remove the hex shaft 4-40

4 4 12 Install the hex shaft 4-41

4 4 13 Remove the main output gearbox 4-42

4 4 14 Install the main output gearbox 4-43

4 4 15 Disassemble the gearbox for the primary input and output 4-44

4 4 16 Assemble the gearbox for the primary input and output 4-47

4 4 17 Remove the hollow shaft for the input gearbox 4-49

4 4 18 Install the hollow shaft for the input gearbox 4-50

4 4 19 Remove the snapping unit 4-51

4 4 20 Install the snapping unit 4-53

4 5 Snout 4-55

4 5 1 Remove the plastic divider 4-55

4 5 2 Install the plastic divider 4-56

4 6 Automatic header height control 4-57

4 6 1 Remove the automatic header height control (AH HC) assembly 4-57

4 6 2 Install the automatic header height control (AHHC) assembly 4-57

4 6 3 Remove the electronic sensor 4-58

4 6 4 Install the electronic sensor 4-58

4 6 5 Remove the gas strut 4-58

4 6 6 Install the gas strut 4-59

4 6 7 Remove the globe joint and rod 4-59

4 6 8 Install the globe joint and rod 4-59

4 6 9 Calibrate the automatic header height control (AHHC) 4-61

5 Special tools 5-1

5 1 Special tools 5-3

6 Diagrams 6-1

6 1 Electrical schematic 6-3

6 2 Hydraulic schematics 6-4

6 2 1 Hydraulic folding schematic 6-4

6 2 2 Hydraulic unfolding schdematic 6-6

7 Index lndex-1