$35

Haulotte Articulating Booms HA26 RTJ PRO – HA26 RTJ PRO SW Operator’s manual – PDF DOWNLOAD

Haulotte Articulating Booms HA26 RTJ PRO – HA26 RTJ PRO SW Operator’s manual – PDF DOWNLOAD

FILE DETAILS:

Haulotte Articulating Booms HA26 RTJ PRO – HA26 RTJ PRO SW Operator’s manual – PDF DOWNLOAD

Language : English

Pages :172

Downloadable : Yes

File Type : PDF

HA26 RTJ PRO – HA26 RTJ PRO SW –

HA80 RTJ O – HA80 RTJ PRO –

COLOR SCREEN DISPLAY

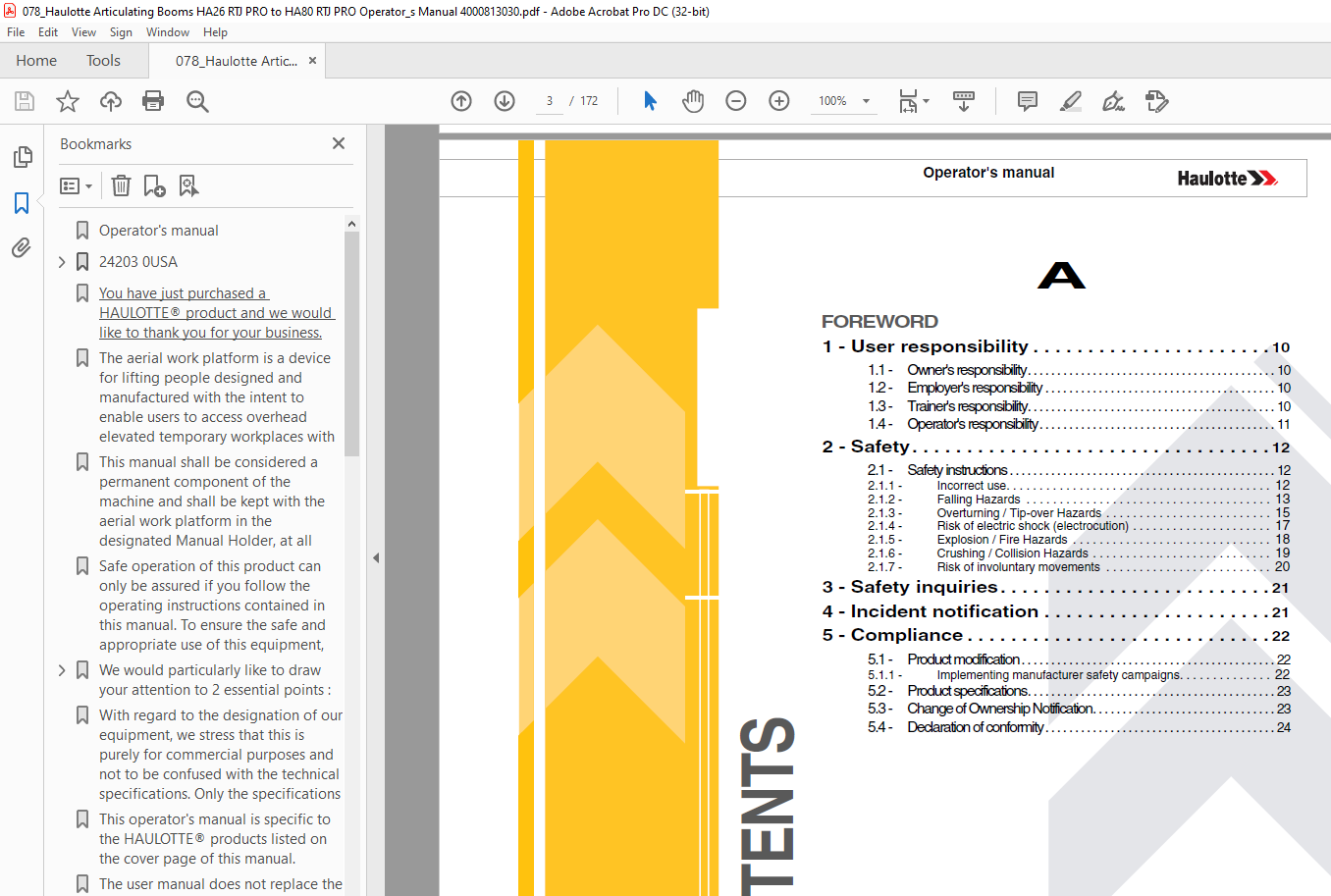

TABLE OF CONTENTS:

Haulotte Articulating Booms HA26 RTJ PRO – HA26 RTJ PRO SW Operator’s manual – PDF DOWNLOAD

Operator’s manual 1

Foreword 3

1 – User responsibility 10 3

11 – Owner’s responsibility 10 3

12 – Employer’s responsibility 10 3

13 – Trainer’s responsibility 10 3

14 – Operator’s responsibility 11 3

2 – Safety 12 3

21 – Safety instructions 12 3

211 – Incorrect use 12 3

212 – Falling Hazards 13 3

213 – Overturning / Tip-over Hazards 15 3

214 – Risk of electric shock (electrocution) 17 3

215 – Explosion / Fire Hazards 18 3

216 – Crushing / Collision Hazards 19 3

217 – Risk of involuntary movements 20 3

3 – Safety inquiries 21 3

4 – Incident notification 21 3

5 – Compliance 22 3

51 – Product modification 22 3

511 – Implementing manufacturer safety campaigns 22 3

52 – Product specifications 23 3

53 – Change of Ownership Notification 23 3

54 – Declaration of conformity 24 3

B 4

Familiarization 4

1 – General safety 27 4

11 – Intended use 27 4

12 – Decal content 28 4

13 – Symbols and colors 29 4

14 – Level of severity 29 4

15 – Symbols legend and definitions 30 4

2 – Models description 31 4

3 – Primary machine components 32 4

31 – Layout 32 4

32 – Ground control box 34 4

321 – Layout – Color screen display 34 4

322 – HAULOTTE Activ’Screen 2 38 4

33 – Platform control box 60 4

331 – Layout 60 4

332 – Display Panel (LED’S 101 – 117) 63 4

34 – DPF (Diesel Particle Filter) (If equipped) 65 4

341 – Kubota engine 65 4

342 – Kohler engine 68 4

343 – Automatic regeneration 72 4

344 – Manual regeneration 72 4

345 – To inhibit regeneration 72 4

346 – To stop manual regeneration 72 4

4 – Performance Specifications 73 4

41 – Technical characteristics 73 4

42 – Engine specifications 76 4

421 – Kubota engines 76 4

422 – Perkins engines 78 4

423 – Kohler engines 78 4

43 – Working area / Range of motion 79 4

5 – Decals and markings locations 80 4

C 5

Pre-operation inspection 5

1 – Recommendations 97 5

2 – Working area assessment 97 5

3 – Inspection and Functional test 98 5

31 – Daily inspection 98 5

4 – Safety functional checks 101 5

41 – E-Stop button check 101 5

42 – Activation of controls 102 5

43 – Fault detector 102 5

431 – Indicators/LED’s test 102 5

432 – Buzzers test 103 5

44 – Automatic engine cut-out 103 5

45 – Overload sensing system 103 5

46 – Oscillating axles (If equipped) 104 5

47 – Slope warning device 104 5

48 – Travel speed limitation 105 5

49 – On-board electronics 105 5

410 – Load selection system (if fitted) 106 5

D 6

Operation instructions 6

1 – Operation 107 6

11 – Introduction 107 6

12 – Major description 107 6

13 – Operation from the ground control box 108 6

14 – Operation from the platform control box 110 6

2 – Ground control box 112 6

21 – To start and stop the machine – Diesel engine 112 6

22 – To start and stop the machine – Petrol / gas (Propane) Engine 113 6

23 – Movement control 114 6

24 – Additional controls 115 6

3 – Platform control box 116 6

31 – To start and stop the machine 116 6

311 – To start the machine 116 6

3111 – To stop the engine 116 6

3112 – If engine is stopped by Stop Emission System 116 6

32 – Drive and steer control 117 6

33 – Movement control 118 6

34 – Additional controls 119 6

341 – Stop Emission System 119 6

342 – Activ’ Lighting System 119 6

343 – Dual load selector (if fitted) 120 6

4 – Rescue and emergency procedures 121 6

41 – In case of power loss 121 6

42 – To rescue operator in platform 122 6

43 – Operation of overriding system from ground control box 123 6

44 – No power available 123 6

5 – Transportation 124 6

51 – Transport configuration 124 6

52 – Machine stowage for transport – HA26 RTJ O/PRO 125 6

53 – Unloading 126 6

54 – Towing 126 6

541 – Disengaging the drive hubs 127 6

542 – Re-engaging the drive hubs 127 6

55 – Storage 128 6

56 – Lifting operation 129 6

6 – Cold Weather Recommendations 131 6

61 – Engine oil 132 6

62 – Hydraulic oil 132 6

E 7

General Specifications 7

1 – Machine dimensions 134 7

2 – Major component masses 136 7

3 – Acoustics and vibrations 137 7

4 – Wheel/Tire assembly 138 7

41 – Technical specifications 138 7

42 – Inspection and maintenance 138 7

5 – Options 141 7

51 – On-board generator 141 7

511 – Description 141 7

512 – Characteristics 141 7

513 – Safety precautions 141 7

514 – Pre-operation inspection 141 7

515 – Operation 142 7

52 – Glazier’s kit 143 7

521 – Description 143 7

522 – Characteristics 143 7

523 – Safety precautions 143 7

524 – Pre-operation inspection 143 7

525 – Operation 144 7

526 – Assembly / Dis-assembly 145 7

527 – Specific decals 146 7

53 – Welder’s kit 147 7

531 – Description 147 7

532 – Characteristics 147 7

533 – Safety precautions 147 7

534 – Pre-operation inspection 147 7

535 – Operation 147 7

536 – Assembly – Dis-assembly 148 7

537 – Specific decals 149 7

54 – Plumber’s kit 150 7

541 – Description 150 7

542 – Characteristics 150 7

543 – Safety precautions 150 7

544 – Pre-operation inspection 150 7

545 – Operation 151 7

546 – Assembly – Dis-assembly 152 7

547 – Specific decals, optional 153 7

55 – Activ’ Shield Bar – SECONDARY GUARDING SYSTEM (If fitted) 154 7

551 – Description 154 7

552 – Characteristics 154 7

553 – Safety precautions 155 7

554 – Pre-operation inspection 156 7

555 – Operation 156 7

556 – Specific decals 157 7

56 – Swing gate 158 7

561 – Description 158 7

562 – Characteristics 158 7

563 – Safety precautions 158 7

564 – Pre-operation instructions 158 7

57 – Sand tires 159 7

571 – Technical specifications 159 7

572 – Inspection and maintenance 159 7

573 – Specific decal(s) 160 7

F 8

Maintenance 8

1 – General 161 8

2 – Maintenance Schedule 162 8

3 – Inspection program 163 8

31 – General program 163 8

32 – Daily inspection 163 8

33 – Periodic inspection 164 8

34 – Reinforced inspection 164 8

35 – Major inspection 165 8

4 – Repairs and adjustments 166 8

G 8

Other information 8

1 – Conditions of warranty 167 8

2 – Subsidiary contact information 167 8

21 – California warning 168 8

H 8

Intervention register 8

1 – Intervention register 171 8

Foreword 9

You have just purchased a HAULOTTE® product and we would like to thank you for your business 9

The aerial work platform is a device for lifting people designed and manufactured with the intent to enable users to access overhead elevated temporary workplaces with the necessary tools and equipment All other uses or alterations/ modifications to 9

This manual shall be considered a permanent component of the machine and shall be kept with the aerial work platform in the designated Manual Holder, at all times 9

Safe operation of this product can only be assured if you follow the operating instructions contained in this manual To ensure the safe and appropriate use of this equipment, only trained personnel are authorised to use and carry out maintenance on 9

We would particularly like to draw your attention to 2 essential points : 9

• Comply with safety instructions 9

• use this equipment within the performance limits specified by this user manual 9

With regard to the designation of our equipment, we stress that this is purely for commercial purposes and not to be confused with the technical specifications Only the specifications in this manual should be used to study the suitability of the equ 9

This operator’s manual is specific to the HAULOTTE® products listed on the cover page of this manual 9

The user manual does not replace the necessary training that is required for all of this machine’s operators HAULOTTE® has compiled this manual to assist in safe and efficient operation of the products covered in the manual 9

The manual must be available to all operators and must be kept in a legible condition Additional copies can be ordered from HAULOTTE Services® 9

Stay Safe and keep working with HAULOTTE® ! 9

For online reference and to download the manuals for your machines HAULOTTE®, go to : 9

https://wwwe-technical-informationcom 9

or, scan the QR Code below : 9

1 – User responsibility 10

11 – Owner’s responsibility 10

The owner (or hirer) has the obligation to : 10

All malfunctions and problems identified during the inspection shall be corrected before the aerial work platform is returned to service 10

12 – Employer’s responsibility 10

The employer (or plant superintendent) is required : 10

• Under the influence of drugs, alcohol, etc 10

• Subject to fits, convulsions, dizziness, etc 10

13 – Trainer’s responsibility 10

14 – Operator’s responsibility 11

The operator has the obligation to : 11

Operators must ensure that the inspections have been carried out by the owner and that they can use the machine for the purpose intended by the manufacturer 11

The operator has the obligation to stop using the machine in the event of malfunction or safety problems on the machine or in the work area and report the problem immediately to his/her supervisor 11

2 – Safety 12

21 – Safety instructions 12

211 – Incorrect use 12

212 – Falling Hazards 13

Before commencing operation : 13

To enter or exit from the platform : 13

When in the platform : 14

213 – Overturning / Tip-over Hazards 15

Before positioning and operating the machine : 15

Using the machine on a slope 16

WIND: the aerial work platform can be used up to the maximum wind speed indicated in the specifications in this manual To identify the local wind speed, use the Beaufort scale below, a wind gauge or an anemometer 16

Beaufort scale 16

214 – Risk of electric shock (electrocution) 17

The machine is not electrically insulated and does not provide protection from contact or proximity to electrically charged conductors 17

Always position all parts of the aerial work platform, the occupants, accessories and tools at a reasonable distance from power lines to ensure that no part of the work platform accidentally comes into contact with a power line 17

Apply local regulations pertaining to safety distances If this is not possible, follow the distances in the table below at a minimum : 17

Minimum safe approach distances 17

Keep away from the machine if it contacts energized power lines Personnel on the ground or in the platform must not touch or operate the machine until energized power lines are shut off 17

215 – Explosion / Fire Hazards 18

216 – Crushing / Collision Hazards 19

When in the platform : 19

• When turret is slewed/rotated 180°, the platform is now facing the rear of the machine 19

• Check the driving direction with the help of the red or white arrows on the chassis and the platform control box 19

• Also note that when changing the driving direction (Forward <> Reverse) the joysticks or switches must return to the neutral position before reversing the drive direction and for movement to occur 19

• The occupants of the aerial work platform must wear personal protection equipment and comply with local regulations in force 20

• Operators must comply with the safety standards of the job site and the employer, as well as the applicable state regulations relating to the use of personal protective equipment 20

• All personal fall protection equipment (PFPE) must comply with current regulations, must be inspected and used in accordance with the manufacturer’s instructions 20

217 – Risk of involuntary movements 20

Never use a damaged or malfunctioning machine 20

Always respect the following rules : 20

3 – Safety inquiries 21

Inquiries relating to design criteria/specifications of a product, standards compliance, or overall machine safety should be sent to the HAULOTTE® PRODUCT SAFETY department 21

Each inquiry or request should include all relevant information; including contact name, telephone number, mailing address, email address, plus the machine model and serial number 21

The HAULOTTE® Product Safety department will evaluate each request/inquiry and will provide a written response 21

4 – Incident notification 21

Notify HAULOTTE® immediately when a HAULOTTE® product has been involved in an incident/ accident leading to personal injury or death, or when there is a major property damage 21

Connect to our website : wwwhaulottecom 21

5 – Compliance 22

51 – Product modification 22

It is strictly forbidden to modify a HAULOTTE® product Any modification may violate Haulotte design parameters, local regulations and industry standards 22

Any requests for modification must be formulated in writing (form) and be approved by the manufacturer 22

Do not hesitate to contact HAULOTTE Services®, should you have any questions relating to the issued bulletin(s) or with questions on the policy itself 22

511 – Implementing manufacturer safety campaigns 22

It is essential to implement the safety campaigns issued by the manufacturer All of these campaigns are accessible on our website 22

Connect to our website : wwwhaulottecom 22

52 – Product specifications 23

HAULOTTE® cannot be held liable for any changes to the technical characteristics/ specifications contained in this manual HAULOTTE® has a continuous improvement policy in place for its product range Given this policy, the Company reserves the rig 23

53 – Change of Ownership Notification 23

It is important and necessary to keep HAULOTTE Services® updated with current ownership of the machine This way, HAULOTTE® will be able to provide the necessary support for the product If you have sold or transferred this machine(s); it is your 23

Connect to our website : wwwhaulottecom 23

54 – Declaration of conformity 24

Declaration of conformity – Thermal platforms 24

Declaration of conformity – Thermal platforms 25

Familiarization 27

1 – General safety 27

11 – Intended use 27

Do not operate the product in the following situations : 27

• Check the allowable wind speed specified in the performace specifications tabulation 27

• Consult the Beaufort scale 27

12 – Decal content 28

The purpose of the labels on the machine is to alert the user to the conditions of use and risks related to aerial work platforms 28

Decals provide the following information : 28

Familiarize yourself with the decals and the hazard severity levels 28

The labels must be kept in good condition, otherwise they must be replaced 28

Familiarize yourself with the decals and their respective color codes 28

Additional decals can be ordered from HAULOTTE Services® 28

CE, UKCA and AS standards 28

ANSI and CSA standards 28

13 – Symbols and colors 29

Symbols and colors are used to alert the operator of safety precautions and/or to highlight important safety information 29

The following safety symbols are used throughout this manual to indicate specific hazards and the hazard severity level when operating or maintaining the Aerial Work Platform 29

14 – Level of severity 29

15 – Symbols legend and definitions 30

Symbols are used throughout this manual to depict hazards, avoidance measures and indicate when information is required 30

Refer to the following table to familiarize yourself with these symbols 30

2 – Models description 31

Legend 31

3 – Primary machine components 32

31 – Layout 32

HA26 RTJ O – HA26 RTJ O SW – HA26 RTJ PRO – HA26 RTJ PRO SW – HA80 RTJ O – HA80 RTJ PRO 32

Universal plug 33

32 – Ground control box 34

321 – Layout – Color screen display 34

General view 34

Controls and indicators 35

322 – HAULOTTE Activ’Screen 2 38

Upon starting and during operation of the machine, the LCD screen “Activ’Screen” located on the ground control box displays in real time the machine operating status 38

HAULOTTE Activ’Screen 2 38

On initial start-up of the machine or after 3 day of inactivity, the following screens are displayed in order 39

Controls and indicators 39

Controls and indicators 40

Controls and indicators 41

Controls and indicators 42

Controls and indicators 43

Controls and indicators 44

Controls and indicators 45

Controls and indicators 46

Controls and indicators 48

Controls and indicators 49

Controls and indicators 50

Controls and indicators 51

Controls and indicators 52

Controls and indicators 53

Controls and indicators 54

Controls and indicators 55

Controls and indicators 56

Controls and indicators 57

Controls and indicators 58

33 – Platform control box 60

331 – Layout 60

General view 60

Controls and indicators 61

332 – Display Panel (LED’S 101 – 117) 63

Upper control box display 63

34 – DPF (Diesel Particle Filter) (If equipped) 65

341 – Kubota engine 65

Kubota engine 65

342 – Kohler engine 68

Kohler engine 68

4 different ways of regeneration are possible 70

343 – Automatic regeneration 72

The automatic regeneration occurs during normal machine usage without any interruption 72

When automatic regeneration is on-going : 72

1 icon lights up on ground control box 72

2 DPF activation icon HL302 / LED107 on the platform control box display lights up 72

344 – Manual regeneration 72

1 Park the machine in a safe stowed position outside location and away from other equipment 72

2 Check that the fuel level icon on the ground control box doesn’t light-up 72

3 Put the engine hood in closed position 72

4 Press the regeneration button on the ground control box and hold for 5 seconds 72

5 When regeneration is initiated, the regeneration icon on the ground control box starts blinking 72

6 Engine speed increases to 2300 rpm 72

7 The regeneration cycle will take approximately 15 min 72

8 When regeneration is complete, all engine lights on the ground control box are turned off Engine speed is automatically decreased to idle speed 72

345 – To inhibit regeneration 72

To inhibit regeneration (indoors or in explosive atmosphere), press button on ground control box and hold for 5 seconds The regeneration is inhibited until cancellation To activate regeneration, press the button again during 5 seconds When the r 72

346 – To stop manual regeneration 72

Use this function only in case of emergency 72

Regeneration process can be stopped by : 72

Or 72

Or 72

4 – Performance Specifications 73

41 – Technical characteristics 73

Use the table to select the right Haulotte machine for the job 73

CE, UKCA, AS, EAC, CSA and ANSI A9220 standards 73

42 – Engine specifications 76

421 – Kubota engines 76

For China only : 77

HA26 RTJ O – HA26 RTJ PRO – Kubota Engine 77

422 – Perkins engines 78

423 – Kohler engines 78

43 – Working area / Range of motion 79

HA26 RTJ O – HA26 RTJ O SW – HA26 RTJ PRO – HA26 RTJ PRO SW – HA80 RTJ O – HA80 RTJ PRO 79

5 – Decals and markings locations 80

CE, UKCA and AS standards – 4000558090 E 80

CE, UKCA and AS standards 81

CE, UKCA and AS standards 84

EAC standard – 4000558120 E 88

EAC standard 89

EAC standard 92

ANSI and CSA standards – 4000558140 G 94

ANSI and CSA standards 95

Pre-operation inspection 97

1 – Recommendations 97

The owner, the site manager, the supervisor and the operator are all responsible to ensure the machine is fit for the work it is to perform; ie that the machine is suitable to carry out the work in complete safety and in compliance with this Operat 97

Before using the machine, read the previous chapters in this manual Ensure that you have understood the following points : 97

• Safety precautions 97

• Operator’s responsibilities 97

• Conditions and the operating principles of the machine 97

2 – Working area assessment 97

Before any operation : 97

• Carry out a thorough inspection of the site to identify any potential risks within the work zone 97

• Take the necessary precautions to avoid collisions with other machinery within the work zone 97

Ensure that : 97

• The weather conditions (wind, rain, etc) allowing the machine to be used 97

• The ground withstands the weight of the machine and has not been affected by the poor weather conditions 97

• Check that the authorisations to work with the machine on the site in question have been obtained (g chemical product factories) 97

• Define a rescue plan for all the risks, including the risk of falls and crushing 97

3 – Inspection and Functional test 98

31 – Daily inspection 98

Each day before the beginning of a new work session and with each change of operator, the machine must be subjected to a visual inspection and a complete functional test 98

In case of loose fasteners, refer to torque table value in maintenance book 98

In case of leaks, replace the damaged part before use 98

In case of structural part deformation (cracks, broken weld, paint chips) replace the part before use 98

Sample of broken welds 98

We recommend these forms to be completed daily and stored to assist with your maintenance schedule 98

Each action is depicted in the daily inspection sheet using the following symbols 98

Use the detailed program below 98

Articulated and telescopic fuel-powered aerial work platforms 99

Articulated and telescopic fuel-powered aerial work platforms100

4 – Safety functional checks101

To protect the user and the machine, safety systems prevent the movement of the machine beyond its operating limits These safety systems when activated immobilize the machine and prevent further movement101

The operator must be familiar with this technology and understand that is not a malfunction but an indication that the machine has reached an operation limit101

Aerial Work platforms are equipped with two control boxes which allow operators to safely use the machine An auxiliary system (Overriding system) is available on the ground control box in order to rescue anyone trapped on the platform101

The following checks describe the operation of the machine and the specific controls required101

For the location and description of these controls : refer to section B 32 and D 2 – Ground control box and B 33 and D 3 – Platform control box101

41 – E-Stop button check101

Ground control box E-stop button101

Platform control box E-stop button101

42 – Activation of controls102

The enable foot pedal (enable switch) must be activated to allow any movement102

The “Enable Switch” system depends on the machine configuration and will consist of one of the following :102

43 – Fault detector102

The machine is equipped with an on-board fault detection system, which indicates the type of fault to the operator102

The fault is identified by a default code102

The default code is displayed at the ground control box102

According to the type of fault, the machine MAY switch into DOWNGRADEMODE mode and certain movements are prevented to maintain Operator’s safety102

Do not use the machine until the fault has been corrected102

431 – Indicators/LED’s test102

From the ground control box102

From the platform control box102

432 – Buzzers test103

From the ground control box103

44 – Automatic engine cut-out103

The engine automatically cuts out in the following conditions :103

45 – Overload sensing system103

If the platform load exceeds the maximum allowed load, no movement is possible from the 2 control boxes103

At ground and platform control boxes a buzzer sounds and an indicator light warns the operator103

To return the machine to normal operation remove weight from the platform until the load is below the maximum allowed load103

Daily check that the LED’s illuminate when the machine is switched on :103

A periodic inspection of this device must be performed according to the recommendation in Maintenance Schedule103

46 – Oscillating axles (If equipped)104

To improve the driving capability on rough terrain, the front axle is equipped with an oscillating mechanism When the extending structure is retracted and is in the stowed position, oscillating mechanism is unlocked to adapt itself to the features o104

A visual inspection must be performed to ensure the absence of leaks from the oscillating cylinder and associated plumbing connections including the hydraulic hoses104

A periodic inspection of this device must be conducted according to the recommendation in the maintenance schedule104

47 – Slope warning device104

From each control box, a buzzer alerts the operator that the machine is not folded/stowed and is positioned on a slope exceeding the slope allowed104

When machine is on a slope greater than the rated slope, with extending structure out of the stowed position :104

The lowering speeds are reduced104

In this case, fully lower the platform and reposition the machine on level ground before raising the platform again104

To check the tilt sensor at ground level, perform the following steps :104

To check the tilt sensor at ground level104

48 – Travel speed limitation105

Drive Speed Selector switch ( 45 ) at the platform control provides a 2 speed selection (high or low)105

All driving speeds are authorised when extending structure of the machine is in stowed position (transport configuration) Drive speed is proportional to the movement of the drive joystick ( 33 ) Adjust position of Jib to enhance field of vision dur105

Whatever the position of the drive speed selector switch ( 45 ) on the platform control box, the drive speed is limited when the machine is unfolded105

Daily check that the speed is limited to less than 1 km/h (06 mph) when :105

49 – On-board electronics105

The machine is equipped with a specific calculator configured for this machine’s functionalities105

Do not interchange the Calculator (calibration restoration) between machines105

410 – Load selection system (if fitted)106

The machine is equipped with a selector load capacity (250 kg (550 lbs) or 350 kg (770 lbs)) In case that the capacity 350 kg (770 lbs) is selected, the work area is automatically limited106

Refer to Section B 42 – Working area / Range of motion106

Daily check :106

• Switch on the machine106

• Pull out the E-Stop buttons at the ground and platform boxes106

• Start the engine106

• Fully stow the machine on flat ground with the boom fully retracted106

• Check that the load selector ( 82 ) on the platform control box is on 350 kg (770 lbs)106

• The LED ( 117 ) at platform display panel lights up106

• Turn the load selector ( 82 ) on 350 kg (770 lbs)106

• Extend the telescoping boom106

• Boom extension stops automatically when the LED ( 113 ) lights up106

• Raise the boom until the indicator/LED ( 113 ) light turns off106

• Fully extend the telescoping boom106

• Lower the boom Lowering stops automatically, indicator/LED ( 113 ) lights106

• Retract the telescoping boom106

• Lower the boom106

• The indicator/LED ( 113 ) goes out106

Operation instructions107

1 – Operation107

11 – Introduction107

Only trained and authorized personnel shall be permitted to operate this aerial work platform107

Prior to operation :107

12 – Major description107

All the machines are equipped with :107

13 – Operation from the ground control box108

• The E-stop buttons on both ground and platform control boxes are not pressed in (Deactivated)108

• To switch ON the machine, turn the Control box activation key switch ( 22 ) at the ground control box on ground control box position 108

• With engine running, the selector ( 6 ) functions as an Enable Switch only108

• With engine stopped, the selector ( 6 ) functions as the Enable Switch and activates the back-up unit (emergency pump)108

• When power is switched on109

• Overload109

• Slope if machine is out of stowed position109

• Hydraulic oil overheating109

• Movement buzzer option109

• Drive buzzer option109

For petrol / gas machines :109

14 – Operation from the platform control box110

• The E-stop buttons on both ground and platform control boxes are not pressed in110

• To switch ON the machine, turn the Control box activation key switch ( 22 ) at the ground control box to platform control box position 110

• Overriding system not activated110

• When power is switched on111

• Overload111

• Machine elevated on a slope greater than the rated slope111

2 – Ground control box112

21 – To start and stop the machine – Diesel engine112

To shut-down the machine from the ground control box :112

22 – To start and stop the machine – Petrol / gas (Propane) Engine113

To shut-down the machine from the ground control box :113

23 – Movement control114

Ground box controls (emergency station)114

24 – Additional controls115

For the machines equipped with beacon light :115

3 – Platform control box116

31 – To start and stop the machine116

311 – To start the machine116

At the ground control box :116

At the platform control box :116

32 – Drive and steer control117

Before driving, locate the green / red orientation arrows on the chassis These will determine the direction in which the machine is traveling117

Push the drive control joystick ( 33 ) in the direction corresponding to the directional arrows117

33 – Movement control118

Foot Switch118

34 – Additional controls119

341 – Stop Emission System119

The machine is equipped with the innovative Stop Emission System that automatically stops the engine after 90 s of inactivity Engine can be restarted by pressing the ‘enable switch’ foot pedal ( C42 )119

342 – Activ’ Lighting System119

Refer to Section B 33 – Platform control box119

This option means that the operator will be able to safely load (or unload) the machine onto the truck119

Located on the turntable, boom and platform, the Activ’ Lighting System system lights up the controls and surrounding areas of the machine Users can then safely move the machine119

343 – Dual load selector (if fitted)120

To safely utilize the working area/range of motion, follow the below steps and as shown in the illustrations :120

1 If boom lowering is cut-off, then retract the boom to recover the lowering movement120

2 If boom telescoping is cut off, lift the boom to recover the boom telescoping movement120

4 – Rescue and emergency procedures121

41 – In case of power loss121

In case of loss of the main power source, the secondary (back-up) power unit, powered by the starting battery, allows movements to be controlled from both the ground and platform control boxes121

As the electric pump has limited power, it is advisable to reach the ground in the most direct manner possible121

The use of the electric pump is exclusively reserved for lowering the boom in emergency situations only You are advised to retract the telescope before lowing the boom121

Depending on the control box in use, push and hold the back-up/auxiliary power switch ( 6 ) at ground box or switch ( 41 ) at platform box Retract the boom and lower it by using switches ( 3 ) and ( 4 ) at ground box or switch ( 54 ) and joystick ( 121

In an emergency, if the operator has to exit the platform while it is elevated, the transfer of the operator must respect the following recommendations :121

42 – To rescue operator in platform122

In a situation where an operator located in the platform needs to be rescued (for example in case of illness, injury or trapped against a structure making the control box inaccessible), the rescue personel at ground level needs to obtain rapid and di122

HAULOTTE® has implemented a control system for safely lowering the operator to the ground in the event of an emergency to enable him to receive the neccessary treatment122

Procedure :122

43 – Operation of overriding system from ground control box123

Procedure :123

44 – No power available123

In case of loss of the main power and the secondary power unit not functioning, do not attempt to activate any function movement using hydraulic manifold unless trained and authorized by HAULOTTE Services® All safety functions are no longer active123

5 – Transportation124

51 – Transport configuration124

Do not place yourself below or too close to the machine during loading124

The machine must be completely in the stowed configuration :124

To climb the slope, select low driving speed124

If the slope is too steep, use a winch in addition to the low speed drive124

52 – Machine stowage for transport – HA26 RTJ O/PRO125

Turntable rotation enabled125

Turntable rotation disabled125

Machine stowing125

53 – Unloading126

Before unloading, check that the machine is in good condition126

To reinstate the system, lift the jib a few centimetres (inches) using the ground control box126

54 – Towing126

To tow a broken-down machine, disconnect the wheel drive hubs126

Perform this operation on flat ground with wheels chocked126

In the towing configuration, the machine braking system is inactive Use a drawbar to avoid any risk of accident :126

541 – Disengaging the drive hubs127

542 – Re-engaging the drive hubs127

Machine is now in the normal driving mode127

55 – Storage128

Machine must be parked in a protected/designated area with the boom in a stowed configuration, however the boom can be raised but must not be extended Make sure there is no load in the platform128

Do not store or immobilise the machine when it is unfolded128

Ensure all access panels, doors and side compartment covers are shut and secured128

Turn the control box activation key switch ( 22 ) at the ground control box to the extreme left to shut OFF the power128

Ensure that the turntable rotation locking pin is shifted to the disabled position (Refer to Section D 52 – Machine layout)128

Remove the ignition key to prevent unauthorized operation of the machine128

56 – Lifting operation129

During loading / unloading operation with an overhead crane, it is important to respect the following :129

Lifting configuration with slings130

6 – Cold Weather Recommendations131

In cold weather conditions, allow engine to run for at least 5 min to warm up ; before operating any function thereby preventing any damage to the hydraulic system131

In extreme cold conditions, machines should be equipped with optional cold start kits131

Attempting to start engine when temperature is in the negative range, may require the use of a booster battery131

If engine fails to start, do not crank for an extended time Allow starter to “cool off” for a few minutes before attempting again If engine fails after several attempts, refer to the engine maintenance manual131

61 – Engine oil132

The correct SAE viscosity grade of oil is determined by the minimum ambient temperature during cold engine start-up, and the maximum ambient temperature during engine operation132

Generally, use the highest viscosity oil that is available to meet the requirement for the temperature at start-up132

Classification API132

62 – Hydraulic oil132

External environmental conditions can reduce performance of the machine if the hydraulic oil temperature does not reach its optimum range132

It is recommended to use the hydraulic oil according to weather condition Refer to the table below132

General Specifications133

1 – Machine dimensions134

Stowed position : Access position134

Transport position : Configuration that takes the minimum floor space necessary for storage and / or delivery of the machine134

2 – Major component masses136

3 – Acoustics and vibrations137

The acoustics and vibrations specifications are based upon the following conditions :137

• The airborne noise emissions at workstation are determined per European Directive 2006/42/CE137

• The guaranteed sound power level LWA (displayed on the product) is determined per European Directive 2000/14/CE137

• The vibrations transmitted by the machinery to the hand/arm system and to the whole body are determined per European Directive 2006/42/CE137

4 – Wheel/Tire assembly138

41 – Technical specifications138

42 – Inspection and maintenance138

Wheels replacement must be made in the following cases :138

Procedure of replacement :140

5 – Options141

51 – On-board generator141

511 – Description141

The optional socket on the platform is supplied by a hydraulically powered generator The generator is located in the engine compartment The generator is activated by a switch on the platform control box The power output and voltage available at t141

512 – Characteristics141

513 – Safety precautions141

514 – Pre-operation inspection141

515 – Operation142

Power on :142

Power off :142

52 – Glazier’s kit143

521 – Description143

This attachment is an assembly designed to transport panels The assembly comprises of a tray that extends along the length of the floor The panel(s) should be placed in the tray and secured to the guard rail with a strap (not supplied)143

522 – Characteristics143

523 – Safety precautions143

524 – Pre-operation inspection143

525 – Operation144

Strapping example(s) – Large panel144

Strapping example(s) – Small panel144

526 – Assembly / Dis-assembly145

Tray145

527 – Specific decals146

Location of the decals146

53 – Welder’s kit147

531 – Description147

This carrier is designed for installing a welder (model type Miller CS280) on the carrier installed on the platform The welder unit must be correctly attached to the carrier using the supplied flanges147

532 – Characteristics147

533 – Safety precautions147

534 – Pre-operation inspection147

535 – Operation147

536 – Assembly – Dis-assembly148

537 – Specific decals149

Location of the decals149

54 – Plumber’s kit150

541 – Description150

This attachment is an assembly designed to transport pipes and tubes The assembly comprises of 2 cradles securely attached to the platform The load (material) should be placed in both the cradles and secured with a strap (not supplied)150

542 – Characteristics150

543 – Safety precautions150

544 – Pre-operation inspection150

545 – Operation151

Strapping example(s)151

546 – Assembly – Dis-assembly152

547 – Specific decals, optional153

Location of the decals153

55 – Activ’ Shield Bar – *1 SECONDARY GUARDING SYSTEM (If fitted)154

551 – Description154

552 – Characteristics154

553 – Safety precautions155

554 – Pre-operation inspection156

555 – Operation156

If the Activ’ Shield Bar is pushed forward, all movements are stopped The horn sounds and the warning blue light flashes Only movements to move away from the entrapment are authorised156

To re-set the Activ’ Shield Bar, release the activation bar, the Foot Switch and controls Then, re-press the Foot Switch156

Care must be taken during all operations to prevent collision and entrapment against structures156

556 – Specific decals157

Location of the decals157

Activ’ Shield Bar instructions157

56 – Swing gate158

561 – Description158

“SWING GATE” consists of a laterally mounted pivoting ½ gate with closing latch, which enables a better access to platform Spring loaded hinges and a latching mechanism allows the gate to swing inwards only158

Swing gate158

562 – Characteristics158

Width of the gate : 500 mm / 1968 in158

563 – Safety precautions158

564 – Pre-operation instructions158

57 – Sand tires159

571 – Technical specifications159

572 – Inspection and maintenance159

Replace the wheels and the tires if any of the following conditions exist :159

Procedure of replacement :160

573 – Specific decal(s)160

If you use this option, the following decals must replace the standard decals of the machine Refer to Section B 5 – Decals and markings locations :160

Maintenance161

1 – General161

As an owner and/or operator of Haulotte equipment, your Safety is of utmost importance to HAULOTTE® , which is why HAULOTTE® places such a high priority on product safety161

INSPECTIONS are not only required by HAULOTTE®, but may also be required by industry standards and/or local regulations161

To ensure your equipment continues to achieve the level of performance set in the factory, it is important to maintain it regularly We remind you that it is strictly forbidden to make any modifications Regular and timely inspections will reduce equ161

Overview :161

• Walk-around inspections take only a few minutes at the beginning and end of each shift – one of the best ways to prevent mechanical problems and safety hazards161

What to Do :161

• Use your senses: sight, smell, hearing and touch161

Frequency :161

• Check your machine periodically during your entire workday161

• Make sure to do your inspection the same way every time161

• Complete one of these inspections at the start and end of each shift161

It is the owner’s responsibility to ensure the required maintenance as recommended by Haulotte is completed prior to the operation of the machine161

If regular maintenance is not carried out, this may :161

• Void the warranty161

• Cause machine malfunction161

• Reduce machine reliability and shorten its service life161

• Jeopardize operator safety161

HAULOTTE Services® technicians are specially trained to carry out extensive repairs, interventions or adjustments on the safety systems or elements of HAULOTTE® machines They carry genuine HAULOTTE spare parts and tools as required, and also provi161

The inspection and maintenance table, identifies the role and the responsibilities of each party in periodical machine maintenance Section C 3 – Inspection and Functional test161

2 – Maintenance Schedule162

This section provides the necessary information needed to place the machine in safe operation In accordance with the regulations that are currently applicable, this machine is deisgned to have a 10 year life span in normal usage conditions The life162

Severity of operating conditions may require a reduction in time between maintenance periods Machines that have been out of service or have not been in use for more than 3 months must undergo a periodic inspection before the machine is put back into162

Maintenance must be carried out by a competent company or person familiar with mechanical procedures162

Maintenance operations performed must be recorded in a register / log book of the machine162

3 – Inspection program163

31 – General program163

The machine must be inspected on a regular basis at intervals of no less than once 1 per year The purpose of the inspection is to detect any defect which could lead to an accident during routine use of the machine Local standards and regulations ma163

HAULOTTE® requires Reinforced and Major Inspections to be carried out on the product to extend its service life163

Inspections must be carried out by a competent company or person163

The inspection results must be recorded in the safety register or machine log book controlled and overseen by the company manager This register or machine log book and the list of competent repair persons must be made available to the government wor163

32 – Daily inspection163

The Daily inspection includes a visual inspection, operational checks and testing of the safety systems This must be conducted by the operator before using the machine163

This inspection is the responsibility of the user Refer to Section C 31 – Daily inspection163

33 – Periodic inspection164

The Periodic inspection is a thorough evaluation of the operation and safety features of the machine164

It must be conducted before the sale / resale of the machine and/or at least once every year164

Local regulations may have specific requirements on frequency, and content of inspections164

The severity of operating conditions may require frequent inspections164

This inspection is the responsibility of the owner, and inspections must be carried out by a competent company or person164

This inspection is in addition to the daily inspection164

This inspection should also be conducted after :164

34 – Reinforced inspection164

The Reinforced inspection is a thorough evaluation of the machine’s structural components, to ensure proper functionality of the machine164

This evaluation must occur at a frequency of 5000 hours or every 5 years164

This inspection is the responsibility of the owner, and it must be conducted by a HAULOTTE Services® technician or by a competent company or person164

This inspection includes :164

35 – Major inspection165

The Major inspection is a thorough evaluation of the machine’s integrity and proper functioning; after a normal service life of 10 years165

This evaluation must take place after 10 years of operation and then repeated every 5 years thereafter165

The severity of operating conditions may require frequent inspections165

This inspection is the responsibility of the owner, and it must be conducted by a HAULOTTE Services® technician or by a competent company or person165

This inspection includes :165

4 – Repairs and adjustments166

Extensive repairs, interventions or adjustments on the safety systems or components must be performed by a HAULOTTE Services® technician Use original spare parts and components only166

HAULOTTE Services® will not take responsibility for any outcomes resulting from inferior services or repairs performed by other unauthorised personnel166

HAULOTTE® reminds that NO modifications SHALL be carried out without the written permission of HAULOTTE®166

Any unauthorised repairs/modifications will void HAULOTTE® warranty166

To check for safety campaigns, consult our website : wwwhaulottecom166

Other information167

1 – Conditions of warranty167

Our warranty conditions and extension contracts are now available on the websites of our sales network : wwwhaulottecom167

2 – Subsidiary contact information167

21 – California warning168

For the US destined machines (ANSI and CSA standards)168

For the engine powered machines destined to the US market (Standards ANSI and CSA)169

Intervention register171

1 – Intervention register171

The intervention register keeps a record of maintenance and repair work carried out inside or outside the maintenance programme171

For online reference and to download the manuals for your machines HAULOTTE®, go to : 1

https://wwwetechnical-informationcom 1

or, scan the QR Code below : 1

IMAGES PREVIEW OF THE MANUAL:’