$34

Haulotte Forklift HA16RTJ – HA16RTJ O – HA16RTJ PRO Operator’s Manual – PDF DOWNLOAD

Haulotte Forklift HA16RTJ – HA16RTJ O – HA16RTJ PRO Operator’s Manual – PDF DOWNLOAD

FILE DETAILS:

Haulotte Forklift HA16RTJ – HA16RTJ O – HA16RTJ PRO Operator’s Manual – PDF DOWNLOAD

Language : English

Pages :130

Downloadable : Yes

File Type : PDF

HA16RTJ – HA16RTJO – HA16RTJ PRO –

HA46RTJO – HA46RTJ PRO —

MONOCHROME LCD DISPLAY

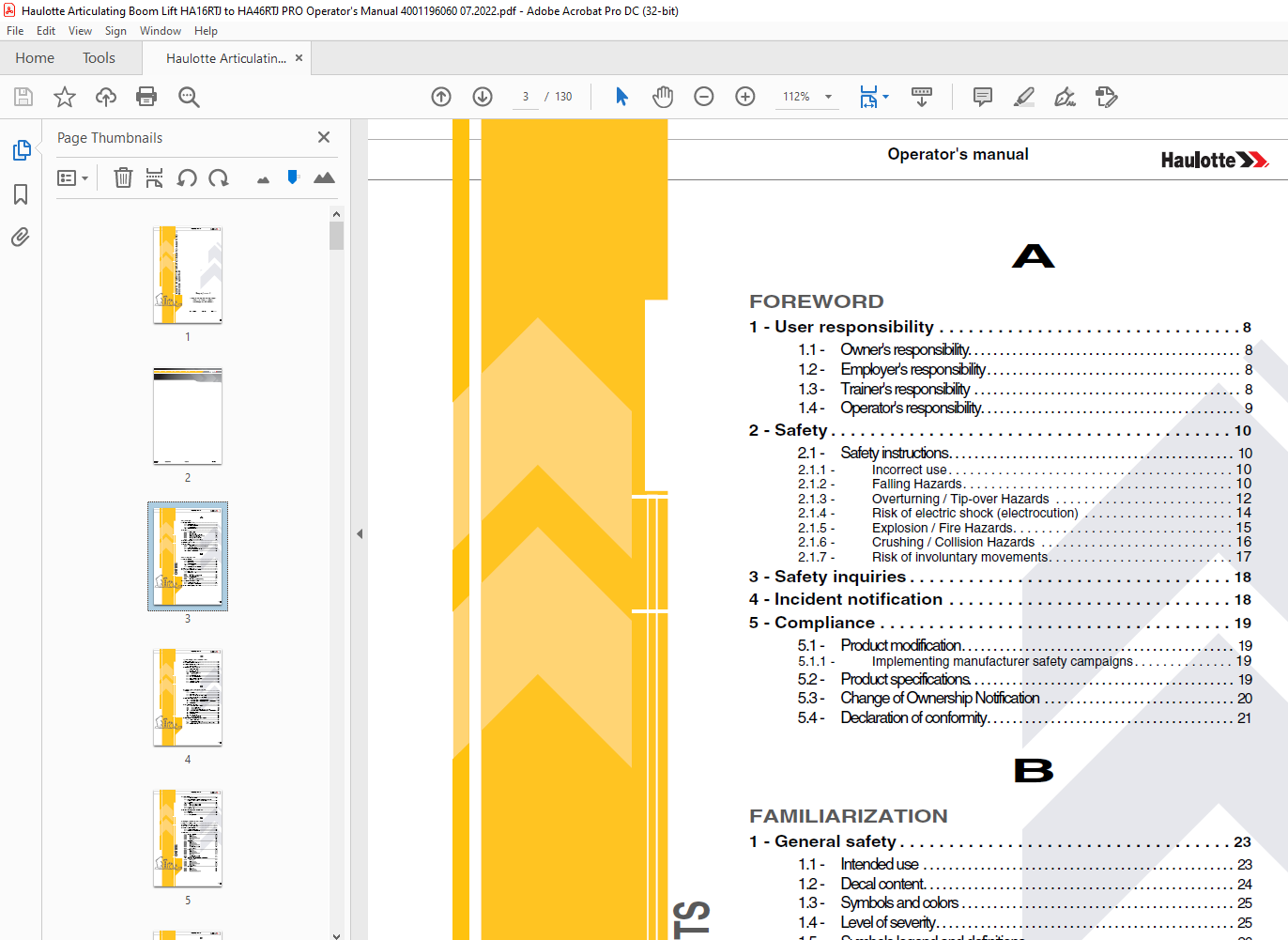

TABLE OF CONTENTS:

Haulotte Forklift HA16RTJ – HA16RTJ O – HA16RTJ PRO Operator’s Manual – PDF DOWNLOAD

FOREWORD

1 – User responsibility 8

11 – Owner’s responsibility 8

12 – Employer’s responsibility 8

13 – Trainer’s responsibility 8

14 – Operator’s responsibility 9

2 – Safety 10

21 – Safety instructions 10

211 – Incorrect use 10

212 – Falling Hazards 10

213 – Overturning / Tip-over Hazards 12

214 – Risk of electric shock (electrocution) 14

215 – Explosion / Fire Hazards 15

216 – Crushing / Collision Hazards 16

217 – Risk of involuntary movements 17

3 – Safety inquiries 18

4 – Incident notification 18

5 – Compliance 19

51 – Product modification 19

511 – Implementing manufacturer safety campaigns 19

52 – Product specifications 19

53 – Change of Ownership Notification 20

54 – Declaration of conformity 21

B

FAMILIARIZATION

1 – General safety 23

11 – Intended use 23

12 – Decal content 24

13 – Symbols and colors 25

14 – Level of severity 25

15 – Symbols legend and definitions 26

2 – Models description 27

3 – Primary machine components 28

31 – Description 28

32 – Ground control box 30

321 – Layout 30

322 – Display Panel (LED’S 1 – 10) 34

3221 – Fault and alarm codes 36

33 – Platform control box 38

331 – Layout 38

332 – Display Panel (LED’S 101 – 117) 41

4 – Performance Specifications 44

41 – Technical characteristics 44

42 – Working area / Range of motion 49

5 – Decals and markings locations 50

4

Operator’s manual

C

PRE-OPERATION INSPECTION

1 – Recommendations 63

2 – Working area assessment 63

3 – Inspection and Functional test 64

31 – Daily inspection 64

4 – Safety functional checks 67

41 – E-Stop button check 67

42 – Activation of controls 68

43 – Fault detector 68

431 – Indicators/LED’s test 68

432 – Buzzers test 68

44 – Automatic engine cut-out 69

45 – Overload sensing system 69

46 – Oscillating axles (If equipped) 69

47 – Slope warning device 70

48 – Travel speed limitation 71

49 – On-board electronics 71

D

OPERATION INSTRUCTIONS

1 – Operation 73

11 – Introduction 73

12 – Major description 73

13 – Operation from the ground control box 73

14 – Operation from the platform control box 75

2 – Ground control box 77

21 – To start and stop the machine – Diesel engine 77

22 – To start and stop the machine – Petrol / gas (Propane) Engine 78

23 – Movement control 79

3 – Platform control box 81

31 – To start and stop the machine 81

311 – To start the machine 81

312 – To stop the engine 81

313 – If engine is stopped by Stop Emission System 81

32 – To start and stop the machine – Petrol / gas (Propane) Engine 82

33 – Drive and steer control 83

34 – Movement control 84

35 – Additional controls 85

351 – Stop Emission System 85

352 – Activ’ Lighting System 85

4 – Rescue and emergency procedures 86

41 – In case of power loss 86

42 – To rescue operator in platform 87

421 – Operation of overriding system from ground control box 87

43 – No power available 88

5

CONTENTS

Operator’s manual

5 – Transportation 89

51 – Transport configuration 89

52 – Machine stowage for transport – HA16RTJ – HA16RTJO –

HA16RTJ PRO – HA46RTJO – HA46RTJ PRO 90

53 – Unloading 91

54 – Towing 92

541 – Disengaging the drive hubs 92

542 – Re-engaging the drive hubs 92

55 – Storage 93

56 – Lifting operation 94

6 – Cold Weather Recommendations 95

61 – Engine oil 95

62 – Hydraulic oil 96

63 – Preheating operation 96

E

GENERAL SPECIFICATIONS

1 – Machine dimensions 98

2 – Major component masses 100

3 – Acoustics and vibrations 100

4 – Wheel/Tire assembly 101

41 – Technical specifications 101

42 – Inspection and maintenance 101

5 – Options 103

51 – On-board generator 103

511 – Description 103

512 – Characteristics 103

513 – Safety precautions 103

514 – Pre-operation inspection 104

515 – Operation 104

52 – Glazier’s kit 105

521 – Description 105

522 – Characteristics 105

523 – Safety precautions 105

524 – Pre-operation inspection 105

525 – Operation 106

526 – Assembly / Dis-assembly 107

527 – Specific decals 108

53 – Plumber’s kit 109

531 – Description 109

532 – Characteristics 109

533 – Safety precautions 109

534 – Pre-operation inspection 110

535 – Operation 110

536 – Assembly – Dis-assembly 111

537 – Specific decals, optional 112

54 – Activ’ Shield Bar – SECONDARY GUARDING

SYSTEM (If fitted) 113

541 – Description 113

542 – Characteristics 113

543 – Safety precautions 114

544 – Pre-operation inspection 115

545 – Operation 115

546 – Specific decals 116

55 – Swing gate 117

551 – Description 117

552 – Characteristics 117

553 – Safety precautions 117

554 – Pre-operation instructions 117

6

Operator’s manual

F

MAINTENANCE

1 – General 119

2 – Maintenance Schedule 120

3 – Inspection program 121

31 – General program 121

32 – Daily inspection 122

33 – Periodic inspection 122

34 – Reinforced inspection 122

35 – Major inspection 123

4 – Repairs and adjustments 124

G

OTHER INFORMATION

1 – Conditions of warranty 125

2 – Subsidiary contact information 125

21 – California warning 126

H

INTERVENTION REGISTER

1 – Intervention register 129

IMAGES PREVIEW OF THE MANUAL: