$38

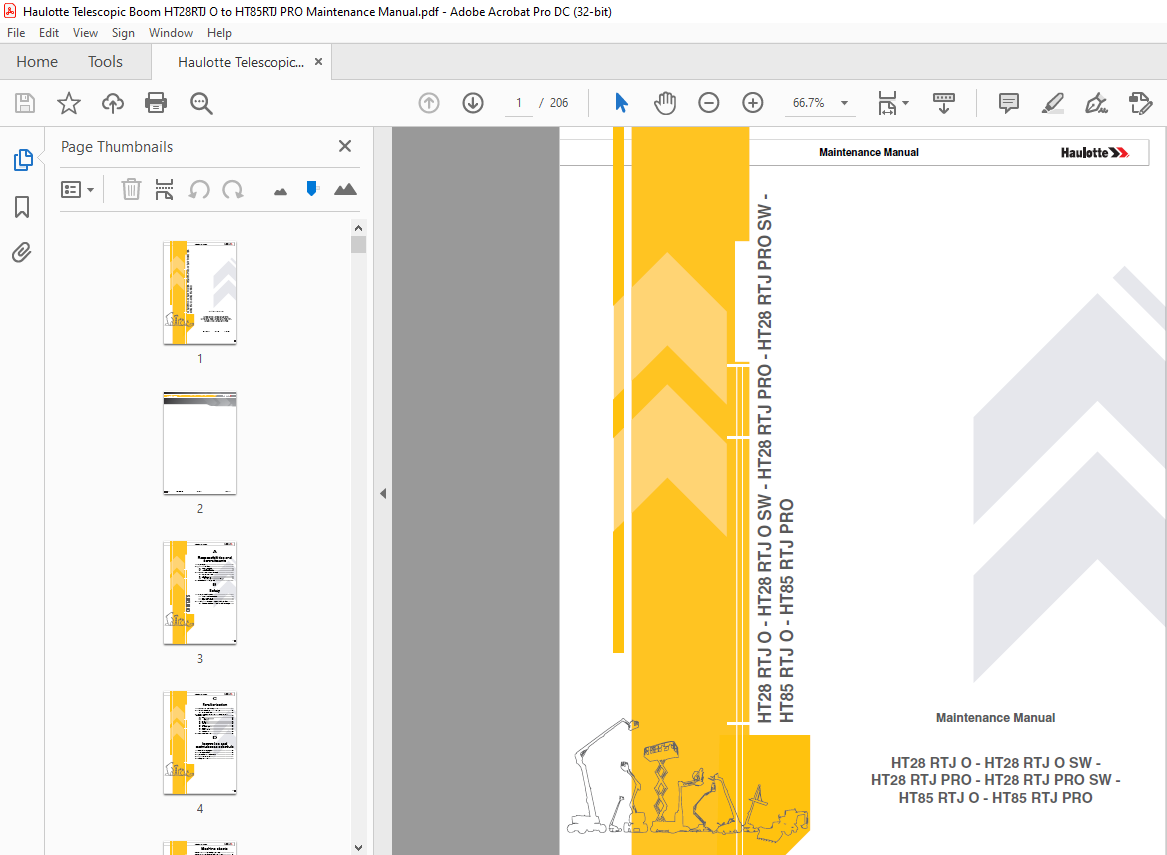

Haulotte Forklift HT28 RTJ O – HT28 RTJ O SW – HT28 RTJ PRO – HT28 RTJ PRO SW –

Haulotte Forklift HT28 RTJ O – HT28 RTJ O SW – HT28 RTJ PRO – HT28 RTJ PRO SW – HT85 RTJ O – HT85 RTJ PRO Maintenance Manual – PDF DOWNLOAD

FILE DETAILS:

Haulotte Forklift HT28 RTJ O – HT28 RTJ O SW – HT28 RTJ PRO – HT28 RTJ PRO SW – HT85 RTJ O – HT85 RTJ PRO Maintenance Manual – PDF DOWNLOAD

Language : English

Pages :206

Downloadable : Yes

File Type : PDF

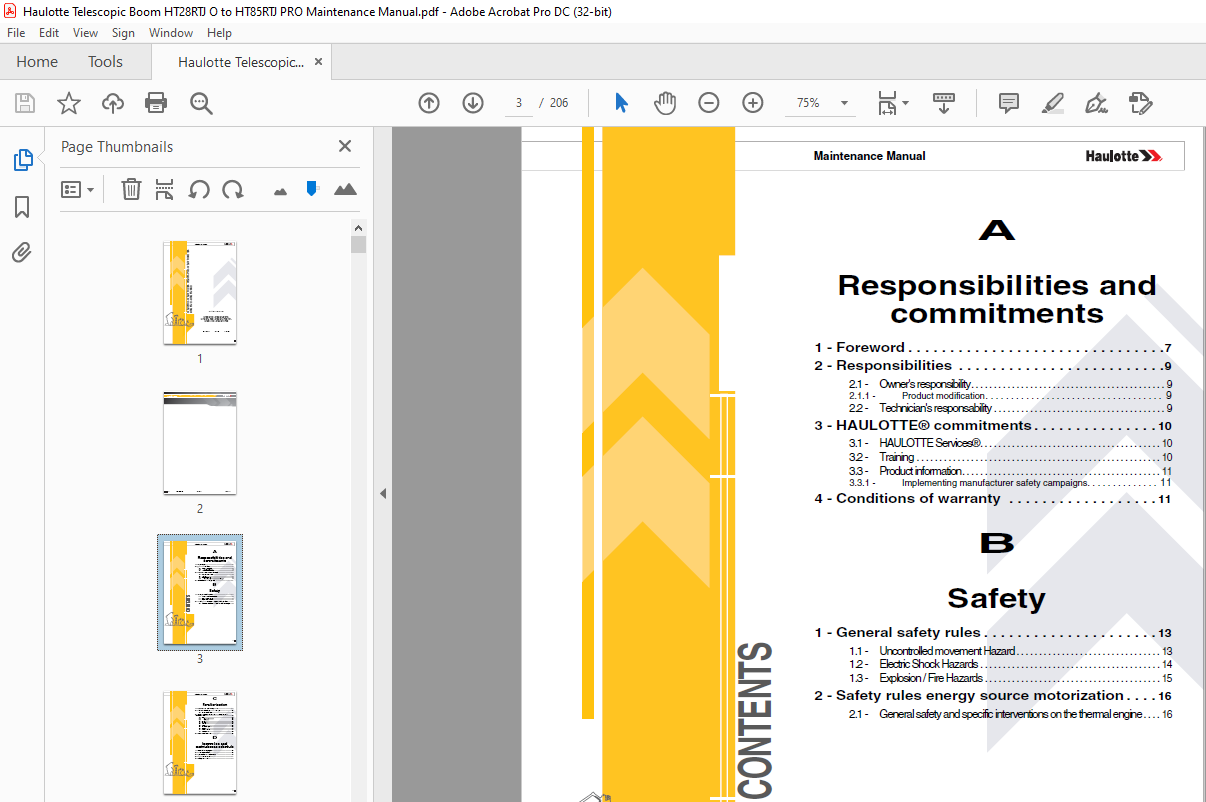

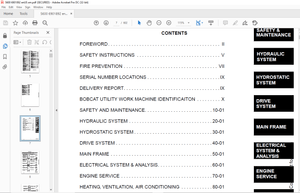

TABLE OF CONTENTS:

Haulotte Forklift HT28 RTJ O – HT28 RTJ O SW – HT28 RTJ PRO – HT28 RTJ PRO SW – HT85 RTJ O – HT85 RTJ PRO Maintenance Manual – PDF DOWNLOAD

Responsibilities and

commitments

1 – Foreword 7

2 – Responsibilities 9

21 – Owner’s responsibility 9

211 – Product modification 9

22 – Technician’s responsability 9

3 – HAULOTTE® commitments 10

31 – HAULOTTE Services® 10

32 – Training 10

33 – Product information 11

331 – Implementing manufacturer safety campaigns 11

4 – Conditions of warranty 11

B

Safety

1 – General safety rules 13

11 – Uncontrolled movement Hazard 13

12 – Electric Shock Hazards 14

13 – Explosion / Fire Hazards 15

2 – Safety rules energy source motorization 16

21 – General safety and specific interventions on the thermal engine 16

4

Maintenance Manual

C

Familiarization

1 – HAULOTTE Activ’Screen 2 17

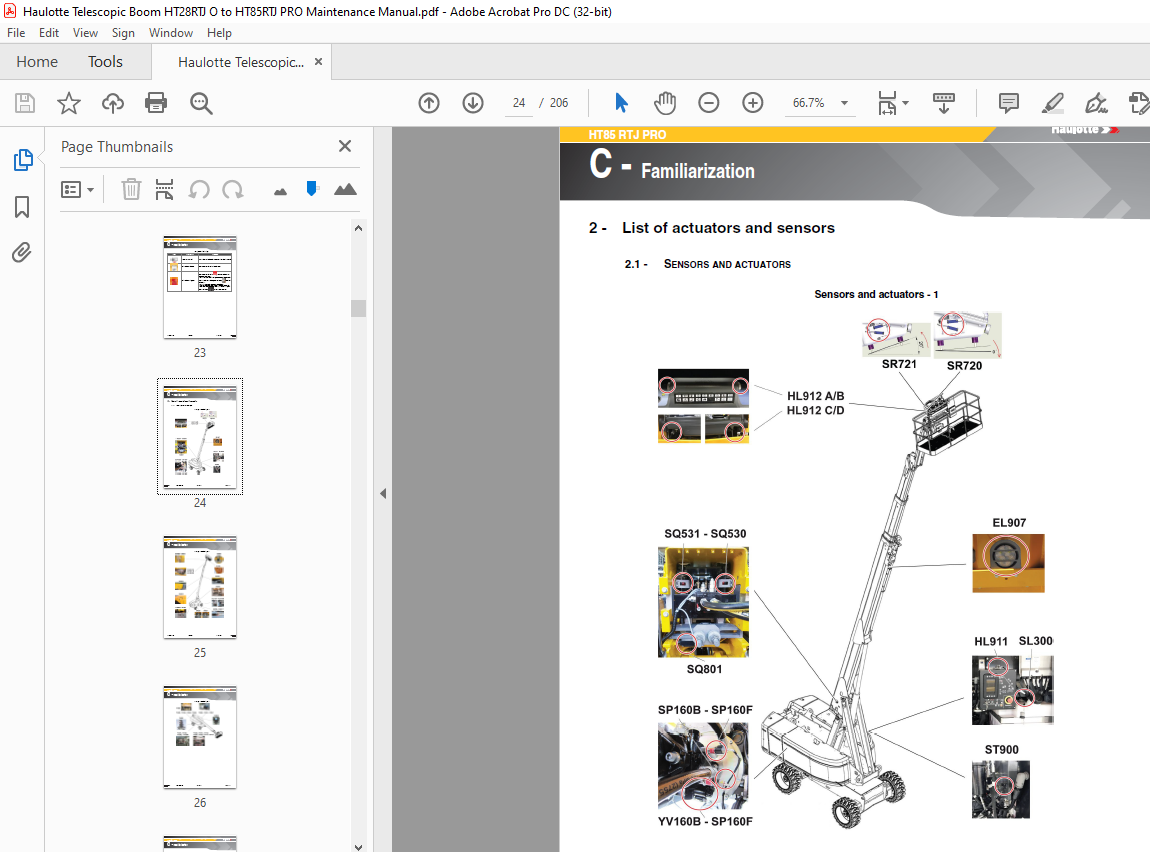

2 – List of actuators and sensors 24

21 – Sensors and actuators 24

3 – Consumables (Oils – Fuels – Engine oil –

Coolant level) 29

31 – Fuel 29

311 – General Specifications 30

312 – Other fuels 30

32 – Engine oil 30

33 – Hydraulic oil 31

34 – Gear motor oil 32

35 – Coolant 32

36 – Cylinder storage oil 32

37 – Grease 33

38 – Marine protection 33

39 – Consumables 34

4 – Movement speed 35

D

Inspection and

maintenance schedule

1 – Inspection program 37

2 – Daily inspection 37

3 – Preventive maintenance 38

4 – Periodic inspection 44

5 – Major inspection 46

5

CONTENTS

Maintenance Manual

Machine sheets

MP0001 – Wheel tightening procedure 47

MP0002A – Wheel reducer level procedure 51

MP0003C – Procedure for checking the level of

engine oil – Kubota engine 55

MP0003J – Procedure for checking the level of

engine oil – Deutz TCD 2,2 engine 59

MP0004C – Replacing the engine oil filter –

Kubota engine 63

MP0004L – Replacing the engine oil filter –

Deutz TCD 2,2 engine 65

MP0005I – Diesel filter replacement –

Kubota V2607 engine 69

MP0005J – Diesel filter replacement –

Deutz TCD 2,2 engine 73

MP0006 – Hydraulic oil filter replacement 77

MP0007 – Procedure for checking engine

belt tension – Kubota engine 79

MP0010 – Air filter replacement –

Kubota / Deutz TCD 2,2 engine 81

MP0011 – Wear pad check 85

MP0013 – Hydraulic tank level 87

MP0014 – Emptying the hydraulic tank 91

MP0015 – Load cell tightness check 95

MP0016 – Rotary cylinder tightness check 97

MP0017 – Checking the platform 99

MP0018 – Slew ring clearance check 103

MP0019 – Torque tightening of the slew ring 105

MP0020 – Emptying the diesel tank 107

MP0021A – Draining the cooling circuit –

Kubota engine 109

MP0021F – Draining the cooling circuit –

Deutz TCD 2,2 engine 113

MP0023 – Starter battery inspection 117

MP0024 – Checking the bushings and pins 121

MP0025 – Checking the condition of belts 125

MP0026E – Checking and cleaning the fuel filter –

Kubota engine 127

MP0026F – Checking and cleaning the fuel filter –

Deutz TCD 2,2 engine 129

MP0027 – Steering system greasing 131

MP0028 – Greasing the pads 133

MP0029 – Jib cylinder lubrication 135

6

Maintenance Manual

MP0030E – Cleaning of air cleaner element –

Kubota engine 137

MP0030I – Cleaning of air cleaner element –

Deutz TCD 2,2 engine 139

MP0031A – Coolant level – Kubota engine 141

MP0031C – Coolant level – Deutz TCD 2,2 engine 143

MP0032C – Replace the belt – Kubota engine 145

MP0032H – Replace the belt – Deutz TCD 2,2 engine 147

MP0034 – Check the condition of cables 149

MP0035 – Check the tension of cables 151

MP0036A – Drain the engine oil – Kubota engine 155

MP0036G – Drain the engine oil –

Deutz TCD 2,2 engine 159

MP0038 – Movement reducer level 163

MP0039 – Drain the movement reducer 165

MP0043B – Draining the wheel reducer 167

MP0044 – Greasing the turntable rotation gearbox 171

MS0238 – Links to engine manufacturer manuals –

Fuel-powered machines 173

MS0285 – Maintenance implementation 175

E

Electric and hydraulic

diagrams

1 – Electric diagram 178

2 – Hydraulic diagram 190

F

Records

1 – Intervention register 205

IMAGES PREVIEW OF THE MANUAL: