$37

Haulotte Forklift OPTIMUM 8 – OPTIMUM 1931 E MAINTENANCE BOOK Manual – PDF DOWNLOAD

Haulotte Forklift OPTIMUM 8 – OPTIMUM 1931 E MAINTENANCE BOOK Manual – PDF DOWNLOAD

FILE DETAILS:

Haulotte Forklift OPTIMUM 8 – OPTIMUM 1931 E MAINTENANCE BOOK Manual – PDF DOWNLOAD

Language : English

Pages :224

Downloadable : Yes

File Type : PDF

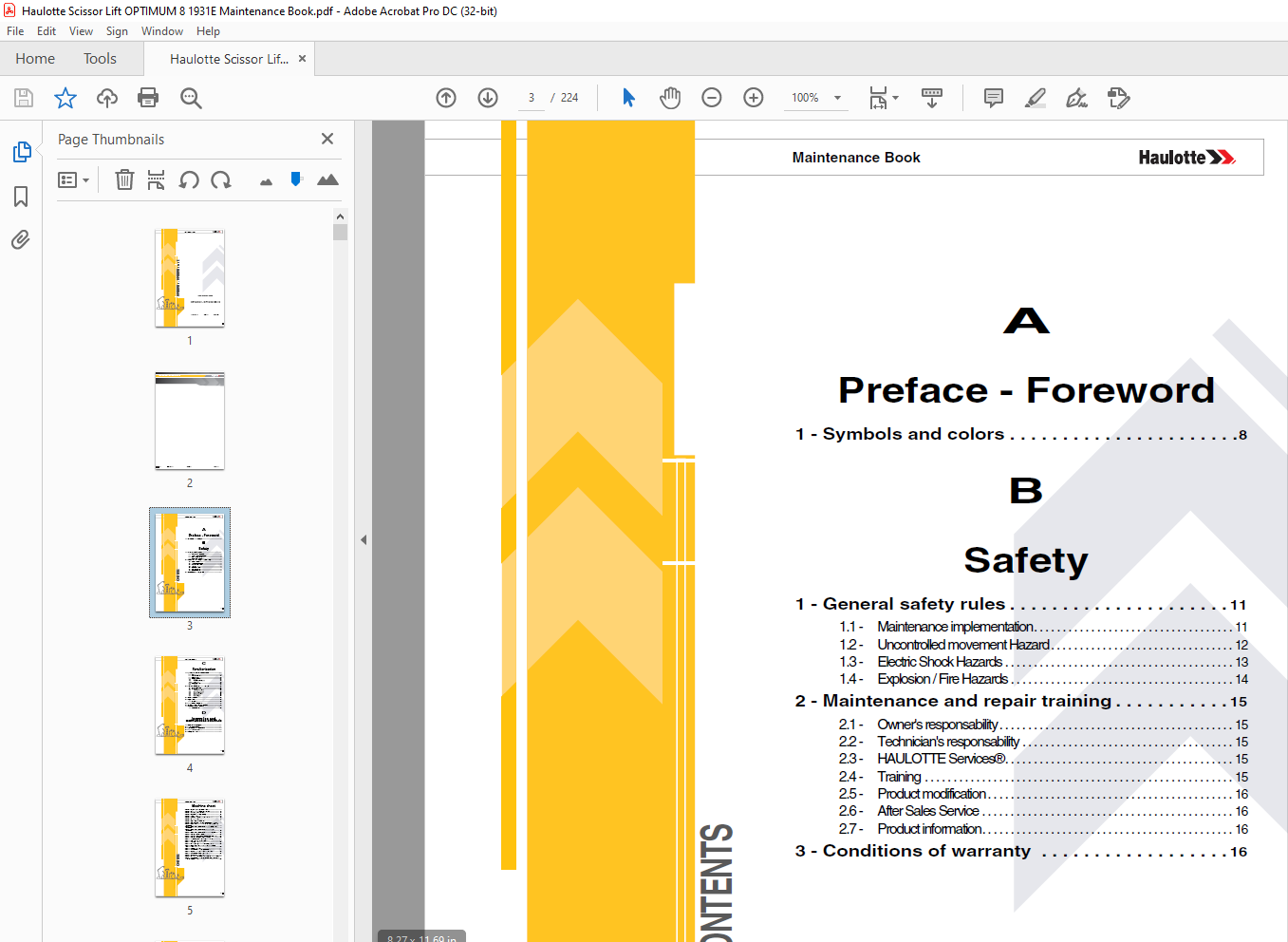

TABLE OF CONTENTS:

Haulotte Forklift OPTIMUM 8 – OPTIMUM 1931 E MAINTENANCE BOOK Manual – PDF DOWNLOAD

Preface – Foreword

1 – Symbols and colors 8

B

Safety

1 – General safety rules 11

11 – Maintenance implementation 11

12 – Uncontrolled movement Hazard 12

13 – Electric Shock Hazards 13

14 – Explosion / Fire Hazards 14

2 – Maintenance and repair training 15

21 – Owner’s responsability 15

22 – Technician’s responsability 15

23 – HAULOTTE Services® 15

24 – Training 15

25 – Product modification 16

26 – After Sales Service 16

27 – Product information 16

3 – Conditions of warranty 16

4

Maintenance Book

C

Familiarization

1 – Primary machine components 18

11 – Layout 18

12 – Maintenance support 20

13 – Extension deck 21

14 – Ground control box 22

141 – Layout 22

142 – HAULOTTE Activ’Screen 23

1421 – LCD screen 24

15 – Platform control box 28

151 – Layout 28

2 – List of actuators and sensors 30

21 – Sensors and actuators 30

22 – Sensors detail 32

221 – Limit switch for potholes 32

222 – Sensor – Steering angle 33

223 – Angle transducers 34

224 – Pressure transducer 35

225 – Slope sensor 36

226 – Battery charger 36

3 – Consumables 37

4 – Ingredient 37

41 – Hydraulic oil 37

5 – Lubrication diagram 38

6 – Greasing points localization 39

7 – Machine specifications 40

71 – Movement speed 40

D

Inspection and

maintenance schedule

1 – Inspection program 41

2 – Daily inspection 41

3 – Preventive maintenance 42

4 – Periodic inspection 45

5 – Major inspection 47

5

CONTENTS

Maintenance Book

Machine sheet

MS0001 – Structural part inspection 49

MS0002 – Pins and bearing inspection 53

MS0003 – Cylinder inspection 57

MS0004 – Braking test procedure 61

MS0005 – Torque Values 63

MS0020 – Hoses inspection – Replacement 67

MS0025 – Electrical wiring 69

MS0072 – Pressure adjustment 71

MS0073 – Scissor arms screw – Periodical checks 73

MS0084 – Removal / Replacement of motor reducer

assembly 75

MS0090 – Removal / replacement of steering pivot

assembly 79

MS0095 – Removal / replacement of platform

assembly 85

MS0096 – Removal / replacement of Scissor pack 91

MS0097 – Calibration steering 101

MS0098 – Calibration Load management system 105

MS0099 – Calibration arm angle sensors 109

MS0102 – Tires (Tyres) – Wheel replacement 113

MS0106 – HAULOTTE Activ’Screen 119

MS0133 – Universal plug 131

MS0174 – Platform extension lock assembly 133

MS0175 – Removal – Replacement of the motor/

pump assembly 137

MS0176 – Hydraulic filter 141

MS0177 – Assembly electro-brake unit 145

MS0178 – Brake unit protection installation 155

MS0179 – Assembly moto – reducer 161

MS0242 – Check of tilt sensor 173

MS0245 – Dismantling/Reassembling the Tilt Sensor 179

MS0283 – Assembly electro-brake unit (For the Asia-

Pacific market only) 187

6

Maintenance Book

E

Trouble shooting and

diagram

1 – Trouble shooting 195

11 – Recommendations 195

12 – Description 195

13 – Requirements 195

14 – Failures list 196

141 – List of failures per category 198

2 – Electric diagram 215

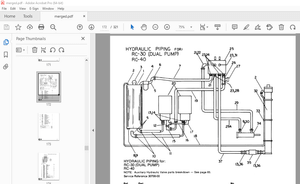

3 – Hydraulic diagram 221

F

Records

1 – Intervention register 223

Familiarization

1 – Primary machine components 18

11 – Layout 18

12 – Maintenance support 20

13 – Extension deck 21

14 – Ground control box 22

141 – Layout 22

142 – HAULOTTE Activ’Screen 23

1421 – LCD screen 24

15 – Platform control box 28

151 – Layout 28

2 – List of actuators and sensors 30

21 – Sensors and actuators 30

22 – Sensors detail 32

221 – Limit switch for potholes 32

222 – Sensor – Steering angle 33

223 – Angle transducers 34

224 – Pressure transducer 35

225 – Slope sensor 36

226 – Battery charger 36

3 – Consumables 37

4 – Ingredient 37

41 – Hydraulic oil 37

5 – Lubrication diagram 38

6 – Greasing points localization 39

7 – Machine specifications 40

71 – Movement speed 40

D

Inspection and

maintenance schedule

1 – Inspection program 41

2 – Daily inspection 41

3 – Preventive maintenance 42

4 – Periodic inspection 45

5 – Major inspection 47

5

CONTENTS

Maintenance Book

Machine sheet

MS0001 – Structural part inspection 49

MS0002 – Pins and bearing inspection 53

MS0003 – Cylinder inspection 57

MS0004 – Braking test procedure 61

MS0005 – Torque Values 63

MS0020 – Hoses inspection – Replacement 67

MS0025 – Electrical wiring 69

MS0072 – Pressure adjustment 71

MS0073 – Scissor arms screw – Periodical checks 73

MS0084 – Removal / Replacement of motor reducer

assembly 75

MS0090 – Removal / replacement of steering pivot

assembly 79

MS0095 – Removal / replacement of platform

assembly 85

MS0096 – Removal / replacement of Scissor pack 91

MS0097 – Calibration steering 101

MS0098 – Calibration Load management system 105

MS0099 – Calibration arm angle sensors 109

MS0102 – Tires (Tyres) – Wheel replacement 113

MS0106 – HAULOTTE Activ’Screen 119

MS0133 – Universal plug 131

MS0174 – Platform extension lock assembly 133

MS0175 – Removal – Replacement of the motor/

pump assembly 137

MS0176 – Hydraulic filter 141

MS0177 – Assembly electro-brake unit 145

MS0178 – Brake unit protection installation 155

MS0179 – Assembly moto – reducer 161

MS0242 – Check of tilt sensor 173

MS0245 – Dismantling/Reassembling the Tilt Sensor 179

MS0283 – Assembly electro-brake unit (For the Asia-

Pacific market only) 187

6

Maintenance Book

E

Trouble shooting and

diagram

1 – Trouble shooting 195

11 – Recommendations 195

12 – Description 195

13 – Requirements 195

14 – Failures list 196

141 – List of failures per category 198

2 – Electric diagram 215

3 – Hydraulic diagram 221

F

Records

1 – Intervention register 223

IMAGES PREVIEW OF THE MANUAL: