$34

Haulotte Forklift SIGMA 16 – SIGMA 46 SIGMA 16 PRO – SIGMA 46 PRO Monochrome LCD Operator’s Manual

Haulotte Forklift SIGMA 16 – SIGMA 46 SIGMA 16 PRO – SIGMA 46 PRO Monochrome LCD Display Operator’s Manual – PDF DOWNLOAD

FILE DETAILS:

Haulotte Forklift SIGMA 16 – SIGMA 46 SIGMA 16 PRO – SIGMA 46 PRO Monochrome LCD Display Operator’s Manual – PDF DOWNLOAD

Language : English

Pages :136

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Haulotte Forklift SIGMA 16 – SIGMA 46 SIGMA 16 PRO – SIGMA 46 PRO Monochrome LCD Display Operator’s Manual – PDF DOWNLOAD

Operator’s manual 1

SIGMA 16 – SIGMA 46 – SIGMA 16 PRO – SIGMA 46 PRO 1

SIGMA 16 – SIGMA 46 SIGMA 16 PRO – SIGMA 46 PRO 1

USA 1

A 3

Foreword 3

1 – User responsibility 8 3

11 – Owner’s responsibility 8 3

12 – Employer’s responsibility 8 3

13 – Trainer’s responsibility 8 3

14 – Operator’s responsibility 9 3

2 – Safety 10 3

21 – Safety instructions 10 3

211 – Incorrect use 10 3

212 – Falling Hazards 11 3

213 – Overturning / Tip-over Hazards 13 3

214 – Risk of electric shock (electrocution) 15 3

215 – Explosion / Fire Hazards 16 3

216 – Crushing / Collision Hazards 17 3

217 – Risk of involuntary movements 18 3

3 – Safety inquiries 19 3

4 – Incident notification 19 3

5 – Compliance 20 3

51 – Product modification 20 3

511 – Implementing manufacturer safety campaigns 20 3

52 – Product specifications 21 3

53 – Change of Ownership Notification 21 3

54 – Declaration of conformity 22 3

B 3

Familiarization 3

1 – General safety 25 3

11 – Intended use 25 3

12 – Decal content 26 3

13 – Symbols and colors 28 3

14 – Level of severity 28 3

15 – Symbols legend and definitions 29 3

2 – Models description 30 3

3 – Primary machine components 32 3

31 – Layout 32 3

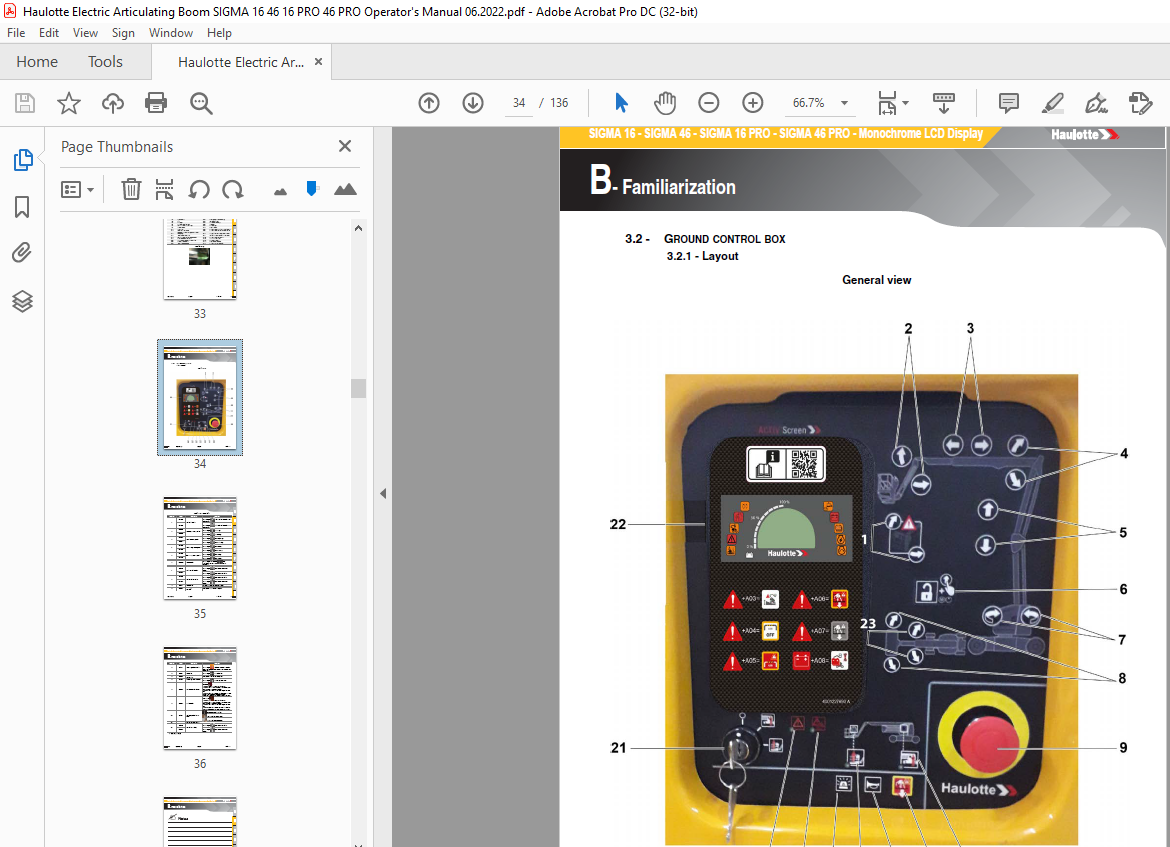

32 – Ground control box 34 3

321 – Layout 34 3

322 – HAULOTTE Activ’Screen 2 37 3

33 – Platform control box 54 3

331 – Layout 54 3

332 – Battery charging indicator (90) 56 3

333 – Display Panel (LED’S 101 – 116) 57 3

4 – Performance Specifications 59 3

41 – Technical characteristics 59 3

42 – Working area / Range of motion 61 3

5 – Decals and markings locations 63 3

C 4

Pre-operation inspection 4

1 – Recommendations 71 4

2 – Working area assessment 71 4

3 – Inspection and Functional test 72 4

31 – Daily inspection 72 4

4 – Safety functional checks 75 4

41 – E-Stop button check 75 4

42 – Activation of controls 75 4

43 – Fault detector 76 4

431 – Indicators/LED’s test 76 4

432 – Buzzers test 76 4

44 – Overload sensing system 77 4

45 – Slope warning device 77 4

46 – Travel speed limitation 78 4

47 – On-board electronics 78 4

D 4

Operation instructions 4

1 – Operation 79 4

11 – Introduction 79 4

12 – Major description 79 4

13 – Operation from the ground control box 80 4

14 – Operation from the platform control box 81 4

2 – Ground control box 83 4

21 – To start and stop the machine 83 4

22 – Movement control 84 4

23 – Additional controls 85 4

3 – Platform control box 86 4

31 – To start and stop the machine 86 4

311 – To start the machine 86 4

312 – To stop the machine 86 4

32 – Drive and steer control 87 4

33 – Movement control 88 4

34 – Additional controls 89 4

341 – Activ’ Lighting System 89 4

4 – Rescue and emergency procedures 90 4

41 – Main power supply failure 90 4

411 – Procedure 90 4

42 – To rescue operator in platform 91 4

421 – Operation of overriding system from ground control box 91 4

5 – Transportation 92 5

51 – Transport configuration 92 5

52 – Machine stowage for transport – SIGMA 16 – SIGMA 46 – SIGMA 16 PRO – SIGMA 46 PRO 93 5

53 – Unloading 95 5

54 – Towing 95 5

541 – Electric brake release 96 5

55 – Storage 98 5

56 – Lifting operation 99 5

6 – Cold Weather Recommendations 101 5

61 – Hydraulic oil 101 5

7 – Battery care and maintenance 102 5

71 – Battery recharge 102 5

711 – On-board charger 102 5

712 – Battery charging 103 5

72 – Battery care and maintenance 106 5

721 – Filling batteries 106 5

7211 – Procedure to fill the batteries manually – Option 107 5

7212 – Procedure to fill the batteries automatically – Option 109 5

722 – Desulfation charge 110 5

73 – Optimise battery life 111 5

E 5

General Specifications 5

1 – Machine dimensions 114 5

2 – Major component masses 116 5

3 – Acoustics and vibrations 116 5

4 – Wheel/Tire assembly 117 5

41 – Technical specifications 117 5

42 – Inspection and maintenance 117 5

5 – Options 119 5

51 – Swing gate 119 5

511 – Description 119 5

512 – Characteristics 119 5

513 – Safety precautions 119 5

514 – Pre-operation instructions 120 5

515 – Specific decals, optional 120 5

52 – Platform 121 5

53 – Plumber’s kit 122 5

531 – Description 122 5

532 – Characteristics 122 5

533 – Safety precautions 122 5

534 – Pre-operation inspection 123 5

535 – Operation 123 5

536 – Assembly – Dis-assembly 124 5

537 – Specific decals, optional 125 5

54 – Signalling cones holder 126 5

541 – Description 126 5

542 – Characteristics 126 5

543 – Safety precautions 126 5

544 – Pre-operation inspection 126 5

545 – Operation 127 5

546 – Assembly – Dis-assembly 128 5

55 – Neon tube holder 129 6

551 – Description 129 6

552 – Characteristics 129 6

553 – Safety precautions 129 6

554 – Pre-operation inspection 129 6

555 – Operation 130 6

556 – Assembly – Disassembly 131 6

56 – Activ’ Shield Bar – SECONDARY GUARDING SYSTEM 132 6

561 – Description 132 6

562 – Characteristics 132 6

563 – Safety precautions 133 6

564 – Pre-operation inspection 134 6

565 – Operation 135 6

566 – Specific decals 135 6

F 6

Maintenance 6

1 – General 137 6

2 – Maintenance Schedule 138 6

3 – Inspection program 139 6

31 – General program 139 6

32 – Daily inspection 139 6

33 – Periodic inspection 140 6

34 – Reinforced inspection 140 6

35 – Major inspection 141 6

4 – Repairs and adjustments 142 6

G 6

Other information 6

1 – Conditions of warranty 143 6

2 – Subsidiary contact information 143 6

21 – California warning 144 6

H 6

Intervention register 6

1 – Intervention register 147 6

Foreword 7

You have just purchased a HAULOTTE® product and we would like to thank you for your business 7

The aerial work platform is a device for lifting people designed and manufactured with the intent to enable users to access overhead elevated temporary workplaces with the necessary tools and equipment All other uses or alterations/ modifications to 7

This manual shall be considered a permanent component of the machine and shall be kept with the aerial work platform in the designated Manual Holder, at all times 7

Safe operation of this product can only be assured if you follow the operating instructions contained in this manual To ensure the safe and appropriate use of this equipment, only trained personnel are authorised to use and carry out maintenance on 7

We would particularly like to draw your attention to 2 essential points : 7

With regard to the designation of our equipment, we stress that this is purely for commercial purposes and not to be confused with the technical specifications Only the specifications in this manual should be used to study the suitability of the equ 7

This operator’s manual is specific to the HAULOTTE® products listed on the cover page of this manual 7

The user manual does not replace the necessary training that is required for all of this machine’s operators HAULOTTE® has compiled this manual to assist in safe and efficient operation of the products covered in the manual 7

The manual must be available to all operators and must be kept in a legible condition Additional copies can be ordered from HAULOTTE Services® 7

Stay Safe and keep working with HAULOTTE® ! 7

For online reference and to download the manuals for your machines HAULOTTE®, go to : 7

https://wwwetechnical-informationcom 7

or, scan the QR Code below : 7

1 – User responsibility 8

11 – Owner’s responsibility 8

12 – Employer’s responsibility 8

13 – Trainer’s responsibility 8

14 – Operator’s responsibility 9

2 – Safety 10

21 – Safety instructions 10

211 – Incorrect use 10

212 – Falling Hazards 11

213 – Overturning / Tip-over Hazards 13

Beaufort scale 14

214 – Risk of electric shock (electrocution) 15

Minimum safe approach distances 15

215 – Explosion / Fire Hazards 16

216 – Crushing / Collision Hazards 17

217 – Risk of involuntary movements 18

3 – Safety inquiries 19

4 – Incident notification 19

5 – Compliance 20

51 – Product modification 20

511 – Implementing manufacturer safety campaigns 20

52 – Product specifications 21

53 – Change of Ownership Notification 21

54 – Declaration of conformity 22

Declaration of conformity – Electric platforms 22

Declaration of conformity – Electric platforms 23

Familiarization 25

1 – General safety 25

11 – Intended use 25

12 – Decal content 26

CE, UKCA, AS and EAC standards – Label warning risk 26

CE, UKCA, AS and EAC standards – Label informing about an important function of the machine 26

ANSI and CSA standards 27

13 – Symbols and colors 28

14 – Level of severity 28

15 – Symbols legend and definitions 29

2 – Models description 30

Legend 30

3 – Primary machine components 32

31 – Layout 32

SIGMA 16 – SIGMA 46 – SIGMA 16 PRO – SIGMA 46 PRO 32

Universal plug 33

32 – Ground control box 34

321 – Layout 34

General view 34

Controls and indicators 35

322 – HAULOTTE Activ’Screen 2 0

HAULOTTE Activ’Screen 2 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

Controls and indicators 0

33 – Platform control box 0

331 – Layout 0

General view 0

Controls and indicators 0

332 – Battery charging indicator (90) 44

Battery charge status 44

333 – Display Panel (LED’S 101 – 116) 45

Upper control box display 45

4 – Performance Specifications 47

41 – Technical characteristics 47

CE, UKCA, AS, EAC, CSA and ANSI A9220 standards 47

42 – Working area / Range of motion 49

SIGMA 16 – SIGMA 46 49

SIGMA 16 PRO – SIGMA 46 PRO 50

5 – Decals and markings locations 51

CE, UKCA, AS and EAC standards – 4001102610 F – SIGMA 16 51

CE, UKCA, AS and EAC standards – 4001102620 F – SIGMA 16 PRO 52

CE, UKCA, AS and EAC standards 53

ANSI and CSA standards – 4001102950 F – SIGMA 46 55

ANSI and CSA standards – 4001102960 F – SIGMA 46 PRO 56

ANSI and CSA standards 57

Pre-operation inspection 59

1 – Recommendations 59

2 – Working area assessment 59

3 – Inspection and Functional test 60

31 – Daily inspection 60

Sample of broken welds 60

Electric articulated platforms 61

Electric articulated platforms 62

4 – Safety functional checks 63

41 – E-Stop button check 63

Ground control box E-stop button 63

Platform control box E-stop button 63

42 – Activation of controls 63

43 – Fault detector 64

431 – Indicators/LED’s test 64

From the ground control box 64

From the platform control box 64

432 – Buzzers test 64

From the ground control box 64

44 – Overload sensing system 65

45 – Slope warning device 65

To check the tilt sensor at ground level 65

46 – Travel speed limitation 66

47 – On-board electronics 66

Operation instructions 67

1 – Operation 67

11 – Introduction 67

12 – Major description 67

13 – Operation from the ground control box 68

14 – Operation from the platform control box 69

2 – Ground control box 71

21 – To start and stop the machine 71

22 – Movement control 72

Ground box controls (emergency station) 72

23 – Additional controls 73

3 – Platform control box 74

31 – To start and stop the machine 74

311 – To start the machine 74

312 – To stop the machine 74

32 – Drive and steer control 75

33 – Movement control 76

Foot Switch 76

34 – Additional controls 77

341 – Activ’ Lighting System 77

4 – Rescue and emergency procedures 78

41 – Main power supply failure 78

411 – Procedure 78

Manual repair – Marking (30) 78

42 – To rescue operator in platform 79

421 – Operation of overriding system from ground control box 79

5 – Transportation 80

51 – Transport configuration 80

52 – Machine stowage for transport – SIGMA 16 – SIGMA 46 – SIGMA 16 PRO – SIGMA 46 PRO 81

Turntable rotation pin – Locked 81

Turntable rotation pin – Unlocked 81

Machine stowing 82

Loading characteristics 82

53 – Unloading 83

54 – Towing 83

541 – Electric brake release 84

55 – Storage 86

56 – Lifting operation 87

Procedure for the use of slings 88

6 – Cold Weather Recommendations 89

61 – Hydraulic oil 89

7 – Battery care and maintenance 90

71 – Battery recharge 90

711 – On-board charger 90

Locations 90

712 – Battery charging 91

Machine settings / Machine configuration / Option setting / Battery charge configuration 91

Machine settings / Machine configuration / Option setting / Battery charge configuration 92

Charge screen 93

72 – Battery care and maintenance 94

721 – Filling batteries 94

7211 – Procedure to fill the batteries manually – Option 95

Single-Point Watering System 95

1 Launch a full charge of the battery and check the charge indicator 96

2 Disconnect the batteries charger and put back the plug in its housing 96

3 Unlock both locks 96

4 Remove the covers 96

5 Immerse the filtered inlet ( 2 ) of the transparent hose ( 4 ) fitted with a hand pump ( 3 ) in a demineralized water canister(Supplied with the machine) 96

6 Press the hand pump ( 3 ) to prime it until the water rises in the hose ( 4 ) 96

7 Once the hand pump ( 3 ) is primed, remove the male connector ( 8 ) cap ( 7 ) from the black supply tube assembly 96

8 Connect the female connector ( 5 ) quick-hitch from the centralized filling system, including the hand-pump, to the male connector ( 8 ) 96

9 Press firmly on the hand pump to bring the distilled water to the batteries ( 1 ) 96

10 When the bulb ( 3 ) becomes resistant, this means that all the battery cells are filled appropriately 96

11 Then uncouple the female connector ( 5 ) from the male connector ( 8 ) filling tube by pressing on the yellow button ( 6 ), then replace the cap ( 7 ) on the machine hose 96

12 Close the machine covers 96

13 Do not let the can to connect after filling is finished because this could cause the batteries to overfill 96

14 Place the cover in the correct position on the batteries 96

15 Unlock both locks on each side of the battery container 96

7212 – Procedure to fill the batteries automatically – Option 97

1 Open the cap 97

2 Fill the can with demineralized water 97

3 Close the cap properly 97

4 Fully recharge the batteries in order to restart an automatic filling or activate the automatic filling from the Activ’Screen of the ground control box 97

Navigation in the menus : 97

722 – Desulfation charge 98

73 – Optimise battery life 99

General Specifications101

1 – Machine dimensions102

Stowed / Transport position : Configuration that takes the minimum floor space necessary for storage and / or delivery of the machine – Access position – SIGMA 16 – SIGMA 46 – SIGMA 16 PRO – SIGMA 46 PRO102

2 – Major component masses104

3 – Acoustics and vibrations104

4 – Wheel/Tire assembly105

41 – Technical specifications105

42 – Inspection and maintenance105

5 – Options107

51 – Swing gate107

511 – Description107

Swing gate107

512 – Characteristics107

513 – Safety precautions107

514 – Pre-operation instructions108

515 – Specific decals, optional108

Location of the decals108

52 – Platform109

Technical specifications109

Sliding bar109

Swing gate109

53 – Plumber’s kit110

531 – Description110

532 – Characteristics110

533 – Safety precautions110

534 – Pre-operation inspection111

535 – Operation111

Strapping example(s)111

536 – Assembly – Dis-assembly112

537 – Specific decals, optional113

Location of the decals113

54 – Signalling cones holder114

541 – Description114

542 – Characteristics114

543 – Safety precautions114

544 – Pre-operation inspection114

545 – Operation115

546 – Assembly – Dis-assembly116

55 – Neon tube holder117

551 – Description117

552 – Characteristics117

553 – Safety precautions117

554 – Pre-operation inspection117

555 – Operation118

556 – Assembly – Dis-assembly119

56 – Activ’ Shield Bar – SECONDARY GUARDING SYSTEM120

561 – Description120

562 – Characteristics120

563 – Safety precautions121

564 – Pre-operation inspection122

565 – Operation123

566 – Specific decals123

Location of the decals123

Activ’ Shield Bar instructions – CE, UKCA, AS and EAC standards124

Activ’ Shield Bar instructions – ANSI and CSA standards124

Maintenance125

1 – General125

2 – Maintenance Schedule126

3 – Inspection program127

31 – General program127

32 – Daily inspection127

33 – Periodic inspection128

34 – Reinforced inspection128

35 – Major inspection129

4 – Repairs and adjustments130

Other information131

1 – Conditions of warranty131

2 – Subsidiary contact information131

21 – California warning132

For the US destined machines (ANSI and CSA standards)132

For electric (battery operated) machines133

Intervention register135

1 – Intervention register135

IMAGES PREVIEW OF THE MANUAL: