$34

Haulotte Forklift STAR 6P – STAR 13P Operator’s manual – PDF DOWNLOAD

Haulotte Forklift STAR 6P – STAR 13P Operator’s manual – PDF DOWNLOAD

FILE DETAILS:

Haulotte Forklift STAR 6P – STAR 13P Operator’s manual – PDF DOWNLOAD

Language : English

Pages :106

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Haulotte Forklift STAR 6P – STAR 13P Operator’s manual – PDF DOWNLOAD

Operator’s manual 1

24203 0 1

X 1

USA 1

A 3

Foreword 3

1 – User responsibility 10 3

11 – Owner’s responsibility 10 3

12 – Employer’s responsibility 10 3

13 – Trainer’s responsibility 10 3

14 – Operator’s responsibility 11 3

2 – Safety 12 3

21 – Safety instructions 12 3

211 – Incorrect use 12 3

212 – Falling Hazards 12 3

213 – Overturning / Tip-over Hazards 14 3

214 – Risk of electric shock (electrocution) 16 3

215 – Explosion / Fire Hazards 17 3

216 – Crushing / Collision Hazards 17 3

217 – Risk of involuntary movements 18 3

3 – Safety inquiries 19 3

4 – Incident notification 19 3

5 – Compliance 20 3

51 – Product modification 20 3

511 – Implementing manufacturer safety campaigns 20 3

52 – Product specifications 21 3

53 – Change of Ownership Notification 21 3

54 – Declaration of conformity 22 3

B 4

Familiarization 4

1 – General safety 25 4

11 – Intended use 25 4

12 – Decal content 26 4

13 – Symbols and colors 27 4

14 – Level of severity 27 4

15 – Symbols legend and definitions 28 4

2 – Models description 29 4

3 – Primary machine components 30 4

31 – Layout 30 4

32 – Maintenance support 32 4

33 – Picking tray 33 4

331 – Description 33 4

332 – Safety precautions 33 4

333 – Pre-use inspection 33 4

334 – Loading instructions 33 4

335 – Special decal 34 4

336 – Operation 34 4

337 – Cold weather operational recommendation 34 4

34 – Ground control box 35 4

341 – Layout 35 4

342 – HAULOTTE Activ’Screen 36 4

3421 – LCD screen 37 4

35 – Platform control box 42 4

351 – Layout 42 4

36 – Auxiliary control box 44 4

361 – Layout 44 4

4 – Performance Specifications 45 4

41 – Technical characteristics 45 4

42 – Working area / Range of motion 46 4

5 – Decals and markings locations 47 4

C 5

Pre-operation inspection 5

1 – Recommendations 53 5

2 – Working area assessment 53 5

3 – Inspection and Functional test 54 5

31 – Daily inspection 54 5

4 – Safety functional checks 58 5

41 – E-Stop button check 58 5

42 – Activation of controls 59 5

43 – Fault detector 59 5

431 – Buzzers test 59 5

432 – Motion alarm test 59 5

44 – Slope warning device 60 5

45 – Travel speed limitation 60 5

46 – Electronic variable speed drive 61 5

47 – On-board electronics 61 5

48 – Machine braking 61 5

49 – Wheel motor brake release 61 5

410 – Pothole protection system 61 5

411 – On-board charger 61 5

D 5

Operation instructions 5

1 – Operation 63 5

11 – Introduction 63 5

12 – Operation from the ground control box 64 5

13 – Operation from the platform control box 65 5

14 – Operation from the auxiliary control box 66 5

2 – Ground control box 67 5

21 – To start and stop the machine 67 5

22 – Movement control 67 5

23 – Additional controls 67 5

3 – Platform control box 68 5

31 – To start and stop the machine 68 5

32 – Drive and steer control 68 5

33 – Movement control 69 5

34 – Additional controls 69 5

4 – Auxiliary control box 70 5

41 – To start and stop the machine 70 5

42 – Movement control 70 5

5 – Rescue and emergency procedures 71 5

51 – Mast manual lowering procedure 71 5

6 – Transportation 72 6

61 – Transport configuration 72 6

62 – Machine stowage for transport – STAR 6 P – STAR 13 P 72 6

63 – Unloading 73 6

64 – Towing 73 6

641 – Electric brake release 74 6

65 – Storage 75 6

66 – Loading by ramp 76 6

67 – Unloading by ramp 76 6

68 – Loading and unloading with forklift 77 6

7 – Cold Weather Recommendations 78 6

71 – Environmental conditions 78 6

711 – Hydraulic oil 78 6

8 – Battery care and maintenance 79 6

81 – Battery recharge 79 6

811 – On-board charger 79 6

812 – Battery charging 81 6

82 – Battery care and maintenance 83 6

821 – Filling batteries 83 6

8211 – Procedure to fill the batteries manually – Option 84 6

8212 – Procedure to fill the batteries automatically – Option 86 6

822 – Desulfation charge 87 6

83 – Optimise battery life 88 6

E 6

General Specifications 6

1 – Machine dimensions 89 6

2 – Major component masses 90 6

3 – Acoustics and vibrations 90 6

4 – Wheel/Tire assembly 91 6

41 – Technical specifications 91 6

42 – Inspection and maintenance 91 6

421 – Procedure of replacement 92 6

F 7

Maintenance 7

1 – General 95 7

2 – Maintenance Schedule 96 7

3 – Inspection program 97 7

31 – General program 97 7

32 – Daily inspection 97 7

33 – Periodic inspection 98 7

34 – Reinforced inspection 98 7

35 – Major inspection 99 7

4 – Repairs and adjustments 100 7

G 7

Other information 7

1 – Conditions of warranty 101 7

2 – Subsidiary contact information 101 7

21 – California warning 102 7

H 7

Intervention register 7

1 – Intervention register 105 7

Foreword 9

You have just purchased a HAULOTTE® product and we would like to thank you for your business 9

The aerial work platform is a device for lifting people designed and manufactured with the intent to enable users to access overhead elevated temporary workplaces with the necessary tools and equipment All other uses or alterations/ modifications to 9

This manual shall be considered a permanent component of the machine and shall be kept with the aerial work platform in the designated Manual Holder, at all times 9

Safe operation of this product can only be assured if you follow the operating instructions contained in this manual To ensure the safe and appropriate use of this equipment, only trained personnel are authorised to use and carry out maintenance on 9

We would particularly like to draw your attention to 2 essential points : 9

• Comply with safety instructions 9

• use this equipment within the performance limits specified by this user manual 9

With regard to the designation of our equipment, we stress that this is purely for commercial purposes and not to be confused with the technical specifications Only the specifications in this manual should be used to study the suitability of the equ 9

This operator’s manual is specific to the HAULOTTE® products listed on the cover page of this manual 9

The user manual does not replace the necessary training that is required for all of this machine’s operators HAULOTTE® has compiled this manual to assist in safe and efficient operation of the products covered in the manual 9

The manual must be available to all operators and must be kept in a legible condition Additional copies can be ordered from HAULOTTE Services® 9

Stay Safe and keep working with HAULOTTE® ! 9

For online reference and to download the manuals for your machines HAULOTTE®, go to : 9

or, scan the QR Code below : 9

1 – User responsibility 10

11 – Owner’s responsibility 10

The owner (or hirer) has the obligation to : 10

All malfunctions and problems identified during the inspection shall be corrected before the aerial work platform is returned to service 10

12 – Employer’s responsibility 10

The employer (or plant superintendent) is required : 10

• Under the influence of drugs, alcohol, etc 10

• Subject to fits, convulsions, dizziness, etc 10

13 – Trainer’s responsibility 10

14 – Operator’s responsibility 11

The operator has the obligation to : 11

Operators must ensure that the inspections have been carried out by the owner and that they can use the machine for the purpose intended by the manufacturer 11

The operator has the obligation to stop using the machine in the event of malfunction or safety problems on the machine or in the work area and report the problem immediately to his/her supervisor 11

2 – Safety 12

21 – Safety instructions 12

211 – Incorrect use 12

212 – Falling Hazards 12

Before commencing operation : 12

To enter or exit from the platform : 13

When in the platform : 13

213 – Overturning / Tip-over Hazards 14

Before positioning and operating the machine : 14

Using the machine on a slope 15

WIND: the aerial work platform can be used up to the maximum wind speed indicated in the specifications in this manual To identify the local wind speed, use the Beaufort scale below, a wind gauge or an anemometer 15

Beaufort scale 15

214 – Risk of electric shock (electrocution) 16

The machine is not electrically insulated and does not provide protection from contact or proximity to electrically charged conductors 16

Always position all parts of the aerial work platform, the occupants, accessories and tools at a reasonable distance from power lines to ensure that no part of the work platform accidentally comes into contact with a power line 16

Apply local regulations pertaining to safety distances If this is not possible, follow the distances in the table below at a minimum : 16

Minimum safe approach distances 16

Keep away from the machine if it contacts energized power lines Personnel on the ground or in the platform must not touch or operate the machine until energized power lines are shut off 16

215 – Explosion / Fire Hazards 17

Always wear protective clothing and eye wear when working with batteries and power sources/systems 17

216 – Crushing / Collision Hazards 17

When in the platform : 17

• Check the driving direction with the help of the red or white arrows on the chassis and the platform control box 18

• Also note that when changing the driving direction (Forward <> Reverse) the joysticks or switches must return to the neutral position before reversing the drive direction and for movement to occur 18

• The occupants of the aerial work platform must wear personal protection equipment and comply with local regulations in force 18

• Operators must comply with the safety standards of the job site and the employer, as well as the applicable state regulations relating to the use of personal protective equipment 18

• All personal fall protection equipment (PFPE) must comply with current regulations, must be inspected and used in accordance with the manufacturer’s instructions 18

217 – Risk of involuntary movements 18

Never use a damaged or malfunctioning machine 18

Always respect the following rules : 18

3 – Safety inquiries 19

Inquiries relating to design criteria/specifications of a product, standards compliance, or overall machine safety should be sent to the HAULOTTE® PRODUCT SAFETY department 19

Each inquiry or request should include all relevant information; including contact name, telephone number, mailing address, email address, plus the machine model and serial number 19

The HAULOTTE® Product Safety department will evaluate each request/inquiry and will provide a written response 19

4 – Incident notification 19

Notify HAULOTTE® immediately when a HAULOTTE® product has been involved in an incident/ accident leading to personal injury or death, or when there is a major property damage 19

Connect to our website : wwwhaulottecom 19

5 – Compliance 20

51 – Product modification 20

It is strictly forbidden to modify a HAULOTTE® product Any modification may violate Haulotte design parameters, local regulations and industry standards 20

Any requests for modification must be formulated in writing (form) and be approved by the manufacturer 20

Do not hesitate to contact HAULOTTE Services®, should you have any questions relating to the issued bulletin(s) or with questions on the policy itself 20

511 – Implementing manufacturer safety campaigns 20

It is essential to implement the safety campaigns issued by the manufacturer All of these campaigns are accessible on our website 20

Connect to our website : wwwhaulottecom 20

52 – Product specifications 21

HAULOTTE® cannot be held liable for any changes to the technical characteristics/ specifications contained in this manual HAULOTTE® has a continuous improvement policy in place for its product range Given this policy, the Company reserves the rig 21

53 – Change of Ownership Notification 21

It is important and necessary to keep HAULOTTE Services® updated with current ownership of the machine This way, HAULOTTE® will be able to provide the necessary support for the product If you have sold or transferred this machine(s); it is your 21

Connect to our website : wwwhaulottecom 21

54 – Declaration of conformity 22

Declaration of conformity – Electric platforms 22

Declaration of conformity – Electric platforms 23

Familiarization 25

1 – General safety 25

11 – Intended use 25

Do not operate the product in the following situations : 25

• Check the allowable wind speed specified in the performace specifications tabulation 25

• Consult the Beaufort scale 25

12 – Decal content 26

The purpose of the labels on the machine is to alert the user to the conditions of use and risks related to aerial work platforms 26

Decals provide the following information : 26

Familiarize yourself with the decals and the hazard severity levels 26

The labels must be kept in good condition, otherwise they must be replaced 26

Familiarize yourself with the decals and their respective color codes 26

Additional decals can be ordered from HAULOTTE Services® 26

CE, UKCA and AS standards 26

ANSI and CSA standards 26

13 – Symbols and colors 27

Symbols and colors are used to alert the operator of safety precautions and/or to highlight important safety information 27

The following safety symbols are used throughout this manual to indicate specific hazards and the hazard severity level when operating or maintaining the Aerial Work Platform 27

14 – Level of severity 27

15 – Symbols legend and definitions 28

Symbols are used throughout this manual to depict hazards, avoidance measures and indicate when information is required 28

Refer to the following table to familiarize yourself with these symbols 28

2 – Models description 29

Legend 29

3 – Primary machine components 30

31 – Layout 30

STAR 6 P – STAR 13 P 30

Universal plug 31

32 – Maintenance support 32

The maintenance stand must be in place before any maintenance operation is begun 32

Placing the machine in maintenance configuration : 32

Putting in use position : 32

33 – Picking tray 33

331 – Description 33

This picking tray is designed as an attachment to the platform to transport parcels to and from elevated heights 33

332 – Safety precautions 33

Before using machine in the picking mode : 33

333 – Pre-use inspection 33

334 – Loading instructions 33

335 – Special decal 34

336 – Operation 34

refer to Section B 36 Auxiliary control box to perform the picking tray and mast movements 34

337 – Cold weather operational recommendation 34

For temperatures between 0 °C(32 °F) and – 20 °C(- 4 °F) : 34

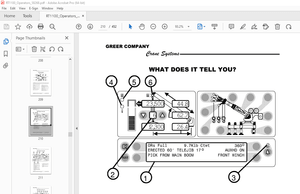

34 – Ground control box 35

341 – Layout 35

General view 35

Controls and indicators 35

342 – HAULOTTE Activ’Screen 36

Upon starting and during operation of the machine, the LCD screen “Activ’Screen” located on the ground control box displays in real time the machine operating status 36

HAULOTTE Activ’Screen 36

Controls and indicators 36

At startup : 37

At startup with the ground or platform controls selected; system initiates a self check : 37

Alarm status : 39

Alarm status displayed as applicable – samples shown below 39

Tilt : 39

Overload : 39

Low battery : 39

Recharge the batteries : 39

Fully recharge the batteries 39

Low battery water level : 40

Low water tank level : 40

Present fault : 40

35 – Platform control box 42

351 – Layout 42

General view – STAR 6 P – STAR 13 P 42

Controls and indicators 43

36 – Auxiliary control box 44

361 – Layout 44

General view 44

Controls and indicators 44

4 – Performance Specifications 45

41 – Technical characteristics 45

Use the table to select the right Haulotte machine for the job 45

CE, UKCA, AS, EAC, CSA and ANSI A9220 standards 45

42 – Working area / Range of motion 46

STAR 6 P – STAR 13 P 46

5 – Decals and markings locations 47

CE, UKCA, AS and EAC standards – 4000498770 H – STAR 6P – 1/2 47

CE, UKCA, AS and EAC standards – 4000498770 H – STAR 6P – 2/2 48

CE, UKCA, AS and EAC standards 49

ANSI and CSA standards – 4000498800 I – STAR 13P – 1/2 50

ANSI and CSA standards – 4000498800 I – STAR 13P – 2/2 51

ANSI and CSA standards 52

Pre-operation inspection 53

1 – Recommendations 53

The owner, the site manager, the supervisor and the operator are all responsible to ensure the machine is fit for the work it is to perform; ie that the machine is suitable to carry out the work in complete safety and in compliance with this Operat 53

Before using the machine, read the previous chapters in this manual Ensure that you have understood the following points : 53

• Safety precautions 53

• Operator’s responsibilities 53

• Conditions and the operating principles of the machine 53

2 – Working area assessment 53

Before any operation : 53

• Carry out a thorough inspection of the site to identify any potential risks within the work zone 53

• Take the necessary precautions to avoid collisions with other machinery within the work zone 53

Ensure that : 53

• The weather conditions (wind, rain, etc) allowing the machine to be used 53

• The ground withstands the weight of the machine and has not been affected by the poor weather conditions 53

• Check that the authorisations to work with the machine on the site in question have been obtained (g chemical product factories) 53

• Define a rescue plan for all the risks, including the risk of falls and crushing 53

3 – Inspection and Functional test 54

31 – Daily inspection 54

Each day before the beginning of a new work session and with each change of operator, the machine must be subjected to a visual inspection and a complete functional test 54

In case of loose fasteners, refer to torque table value in maintenance book 54

In case of leaks, replace the damaged part before use 54

In case of structural part deformation (cracks, broken weld, paint chips) replace the part before use 54

Sample of broken welds 54

We recommend these forms to be completed daily and stored to assist with your maintenance schedule 54

Each action is depicted in the daily inspection sheet using the following symbols 54

Use the detailed program below 54

4 – Safety functional checks 58

To protect the user and the machine, safety systems prevent the movement of the machine beyond its operating limits These safety systems when activated immobilize the machine and prevent further movement 58

The operator must be familiar with this technology and understand that is not a malfunction but an indication that the machine has reached an operation limit 58

Aerial Work platforms are equipped with three (ground, platform and auxiliary) control boxes which allow operators to safely use the machine A mast lowering device is provided on the chassis to assist in emergency situations Each control box is equ 58

The following checks describe the operation of the machine and the specific controls required 58

For the location and description of these controls : refer to Section B 34 and D 2 – Ground controls, B 35 and D 3 – Platform controls and B 36 and D 4 – for Auxiliary controls 58

41 – E-Stop button check 58

Ground control box E-stop button 58

Platform control box E-stop button 58

Auxiliary control box E-stop button 58

42 – Activation of controls 59

The enable switch must be active to allow any movement 59

The “Enable Switch” system depends on the machine configuration and will consist of one of the following : 59

43 – Fault detector 59

The machine is equipped with an on-board fault detection system, which indicates the type of fault to the operator 59

The fault is identified by a default code 59

The default code is displayed at the ground control box 59

According to the type of fault, the machine MAY switch into DOWNGRADEMODE mode and certain movements are prevented to maintain Operator’s safety 59

Do not use the machine until the fault has been corrected 59

431 – Buzzers test 59

From the ground control box 59

432 – Motion alarm test 59

44 – Slope warning device 60

From each control box, a buzzer alerts the operator that the machine is not folded/stowed and is positioned on a slope exceeding the slope allowed 60

When machine is on a slope greater than the rated slope, with extending structure out of the stowed position : 60

The lowering speeds are reduced 60

In this case, fully lower the platform and reposition the machine on level ground before raising the platform again 60

To check the tilt sensor at ground level, perform the following steps : 60

Daily check 60

45 – Travel speed limitation 60

Drive speed is proportional to control until the maximum speed is reached (machine in fully stowed position) 60

The only speed allowed when not in stowed position is microspeed (This speed is a default speed programed into the machine) 60

For Japan : 60

46 – Electronic variable speed drive 61

The machine is equipped with 2 electronic variable speed regulators configured for each function that manages the amount of power sent to each motor 61

47 – On-board electronics 61

The machine is equipped with a specific calculator configured for this machine’s functionalities 61

Do not interchange the Calculator (calibration restoration) between machines 61

48 – Machine braking 61

When electric power is cut off, the machine stops automatically 61

Performance levels may be reduced in the following situations : 61

Check that the brakes are applied automatically when the Drive joystick is released to the neutral position 61

49 – Wheel motor brake release 61

Each time a drive command is activated, electric power releases the brakes 61

410 – Pothole protection system 61

The machine is equipped with a pothole mechanism under the chassis that is deployed automatically when the platform is out of the stowed position 61

Check the system for damage and ensure that it deploys when the platform is raised 61

411 – On-board charger 61

Battery charging starts as soon as an external supply is connected to the battery charger 61

Operation instructions 63

1 – Operation 63

11 – Introduction 63

The lift platforms are fitted with three control boxes enabling users to use the machine in complete safety 63

An auxiliary device is available on the chassis to assist with the emergency rescue of people 63

Each control box is equipped with an E-Stop button, which allows operators to stop all movements, if necessary 63

Only trained and authorized personnel shall be permitted to operate this aerial work platform 63

Prior to operation : 63

12 – Operation from the ground control box 64

• The emergency stop on the ground control box is not pushed in 64

• The machine is switched on 64

• Ground control box is selected 64

• Beacon light (if fitted) 64

A buzzer beeps in the following conditions : 64

13 – Operation from the platform control box 65

• The E-stop buttons on both ground and platform control boxes are not pressed in 65

• Machine switched on at ground control box 65

• Platform control box selected from ground control box 65

• The “beetle-wing” doors are closed 65

A buzzer beeps in the following conditions : 65

• When the machine is switched on 65

14 – Operation from the auxiliary control box 66

• No E-stop button on any workstations is pressed in (ground, platform and auxiliary control boxes) 66

• Machine switched on at ground control box 66

• Platform control box selected from ground control box 66

• The “beetle-wing” doors are closed 66

2 – Ground control box 67

21 – To start and stop the machine 67

To shut-down the machine from the ground control box : 67

22 – Movement control 67

Press and hold ‘Enable switch’ button ( 9 ) to perform movements 67

Ground box controls (emergency station) 67

23 – Additional controls 67

For the machines equipped with beacon light : 67

3 – Platform control box 68

31 – To start and stop the machine 68

To start the machine : 68

At the ground control box : 68

At the platform : 68

To stop the machine (Only in the event of an emergency) : 68

32 – Drive and steer control 68

To operate driving/steering functions, move 2 position selector switch ( 112 ) to the right Activate driving selection indicator ( 111 ) Simultaneously operate drive joystick ( 108 ) with joystick trigger (Enable switch ( 123 )) pressed in and main 68

33 – Movement control 69

To operate Mast Extension / Retraction function, move 2 position selector switch ( 112 ) to the left Activate mast extension / retraction switch ( 110 ) Simultaneously operate joystick ( 108 ) with joystick trigger (Enable switch ( 123 )) pressed i 69

For Japan : Foot Switch ( 245 ) and joystick enable trigger ( 123 ) must be activated simultaneously for any function movement 69

Foot Switch (For Japan only) 69

34 – Additional controls 69

4 – Auxiliary control box 70

41 – To start and stop the machine 70

To start the machine : 70

At the ground control box : 70

At the auxiliary control box : 70

To stop the machine (Only in the event of an emergency) : 70

42 – Movement control 70

To raise and lower the tray, operate control ( 253 ) and hold down the Enable switch ( 247 ) To raise and lower the mast, operate control ( 254 ) while simultaneously holding down the Enable switch ( 247 ) 70

5 – Rescue and emergency procedures 71

In case of power loss or if an operating problem prevents the platform occupant from descending, a competent operator can perform the emergency procedures from the ground level 71

In an emergency, if the operator has to exit the platform while it is elevated, the transfer of the operator must respect the following recommendations : 71

• Exit onto a sturdy and safe structure 71

• The occupant(s) must ensure that 2 lanyards are used for security/safety One must be attached to the designated anchorage point on platform the occupant(s) is in and the other attached to the structure intended to get on 71

• Occupant(s) must exit the current platform through the normal access 71

51 – Mast manual lowering procedure 71

6 – Transportation 72

61 – Transport configuration 72

To climb the slope, move progressively the drive joystick ( 108 ) 72

If the slope is too steep, use a winch in addition to traction 72

Do not place yourself below or too close to the machine during loading 72

The machine must be completely in the stowed configuration : 72

62 – Machine stowage for transport – STAR 6 P – STAR 13 P 72

STAR 6 P – STAR 13 P 72

63 – Unloading 73

Before unloading, check that the machine is in good condition 73

To reinstate the system, lift the platform a few centimetres (inches) from the ground control box 73

To reinstate the system, lift the platform a few centimetres (inches) from the ground control box 73

64 – Towing 73

To tow a broken-down machine, release brake (Refer to Section D 641 – Electric brake release) 73

Perform this operation on flat ground with wheels chocked 73

In the towing configuration, the machine braking system is inactive Use a drawbar to avoid any risk of accident : 73

641 – Electric brake release 74

To tow a broken-down machine, the brakes can be released using the electric system 74

If the machine needs to be towed, the drive wheels brake release is located inside the battery bay (ground control box side) 74

To release the machine’s brakes, the following conditions must be met : 74

Hold brake switch upwards to activate the brake release 74

Push the brake release button for at least 3 s An audible signal (beep) sounds 74

Releasing the button disengages the brakes 74

The brakes are re-applied automatically when the brake release button : 74

65 – Storage 75

The machine must be parked in a protected, suitable area with the mast fully folded and the tray lowered Ensure there is no load in the platform and on the tray 75

Do not store or immobilise the machine when it is unfolded 75

Ensure all access panels, doors and side compartment covers are shut and secured 75

Turn the energizing key selector switch ( 92 ) at the ground control box to the “center” position to shut OFF the power 75

Remove the ignition key to prevent unauthorized operation of the machine 75

66 – Loading by ramp 76

67 – Unloading by ramp 76

1 Remove the tie downs 76

2 Start the machine 76

3 The ramp is in good condition and of sufficient capacity 76

68 – Loading and unloading with forklift 77

Unloading 77

7 – Cold Weather Recommendations 78

In extreme cold conditions, machines should be equipped with optional cold start kits 78

71 – Environmental conditions 78

711 – Hydraulic oil 78

External environmental conditions can reduce performance of the machine if the hydraulic oil temperature does not reach its optimum range 78

It is recommended to use the hydraulic oil according to weather condition Refer to the table below 78

8 – Battery care and maintenance 79

81 – Battery recharge 79

811 – On-board charger 79

The on-board charger is used to charge the semi-drive batteries The charger’s power is 750W-1000W and the maximum intensity is 10A for 220V – 240V and 110V networks Battery charging starts as soon as it is connected via the mains supply 79

Locations 80

812 – Battery charging 81

Duration of charge cycle : 81

The charge cycle stops automatically when charging is complete 81

It can take up to 24 hours for a full charge if the battery levels are very low (Charge status less than 5 %) 81

82 – Battery care and maintenance 83

821 – Filling batteries 83

The procedure described below only applies to open lead acide batteries 6 V open lead-acid battery blocks are composed of 3 2 V single cells connected together in series The cells are immersed in an electrolyte composed of 1/3 sulfuric acid and 2 83

Single-Point Watering System 84

Procedure : 85

1 Launch a full charge of the battery and check the charge indicator 85

2 Disconnect the batteries charger and put back the plug in its housing 85

3 Open the swing out trays on both sides 85

4 Immerse the filtered inlet ( 2 ) of the transparent hose ( 4 ) fitted with a hand pump ( 3 ) in a demineralized water canister (Supplied with the machine) 85

5 Press the hand pump ( 3 ) to prime it until the water rises in the hose ( 4 ) 85

6 Once the hand pump ( 3 ) is primed, remove the male connector ( 8 ) cap ( 7 ) from the black supply tube assembly 85

7 Connect the female connector ( 5 ) quick-hitch from the centralized filling system, including the hand-pump, to the male connector ( 8 ) 85

8 Press firmly on the hand pump to bring the distilled water to the batteries ( 1 ) 85

9 When the bulb ( 3 ) becomes resistant, this means that all the battery cells are filled appropriately 85

10 Then uncouple the female connector ( 5 ) from the male connector ( 8 ) filling tube by pressing on the yellow button ( 6 ), then replace the cap ( 7 ) on the machine hose 85

11 Close the battery compartment again 85

1 Open the swing out trays on both sides 86

2 Open the cap 86

3 Fill the can with demineralized water 86

4 Correctly close the plug and battery compartment 86

5 Fully recharge the batteries in order to restart an automatic filling or activate the automatic filling from the Activ’Screen of the ground control box 86

822 – Desulfation charge 87

Normal battery use leads to sulfatation of the lead plates during discharge (Formation of lead sulfate) Recharging the battery dissolves the lead sulfate The plates are desulfated 87

Moreover, sulfatation also appears if the battery self-discharges during storage in a low state- of-charge (< 70%) 87

As the battery ages, the lead sulfate may become harder and harder and increasingly difficult to eliminate by normal charging This leads to a loss of autonomy The desulfation charge is a way of regenerating the battery 87

Procedure : 87

Desulfation charge 87

83 – Optimise battery life 88

To optimize battery performance and life-time, you are advised to follow the recommendations below : 88

Keep the top of the batteries clean and dry Incorrect connection or corrosion may cause a high loss of power 88

General Specifications 89

1 – Machine dimensions 89

Stowed / Transport position : Configuration that takes the minimum floor space necessary for storage and / or delivery of the machine – Access position 89

CE, AS and EAC standards 89

ANSI and CSA standards 89

2 – Major component masses 90

3 – Acoustics and vibrations 90

The acoustics and vibrations specifications are based upon the following conditions : 90

• The airborne noise emissions at workstation are determined per European Directive 2006/42/CE 90

• The guaranteed sound power level LWA (displayed on the product) is determined per European Directive 2000/14/CE 90

• The vibrations transmitted by the machinery to the hand/arm system and to the whole body are determined per European Directive 2006/42/CE 90

4 – Wheel/Tire assembly 91

41 – Technical specifications 91

42 – Inspection and maintenance 91

Replace the wheels and the tires if any of the following conditions exist : 91

421 – Procedure of replacement 92

Reassembly of the wheel 93

1 Check that the shaft key is well positioned in the motor shaft 94

2 Mount the wheel on the motor shaft 94

3 Install the washer first then the nut 94

4 Tighten the wheel nut to the recommended torque : 250 Nm (184 ftlbs) 94

5 Add tightening until a groove of the nut is in coincidence with one hole of the shaft of the motoreducer 94

6 Insert the pin (2352101250) into its seating 94

7 Bend over the cotter pin legs to secure the nut 94

Maintenance 95

1 – General 95

As an owner and/or operator of Haulotte equipment, your Safety is of utmost importance to HAULOTTE® , which is why HAULOTTE® places such a high priority on product safety 95

INSPECTIONS are not only required by HAULOTTE®, but may also be required by industry standards and/or local regulations 95

To ensure your equipment continues to achieve the level of performance set in the factory, it is important to maintain it regularly We remind you that it is strictly forbidden to make any modifications Regular and timely inspections will reduce equ 95

Overview : 95

• Walk-around inspections take only a few minutes at the beginning and end of each shift – one of the best ways to prevent mechanical problems and safety hazards 95

What to Do : 95

• Use your senses: sight, smell, hearing and touch 95

Frequency : 95

• Check your machine periodically during your entire workday 95

• Make sure to do your inspection the same way every time 95

• Complete one of these inspections at the start and end of each shift 95

It is the owner’s responsibility to ensure the required maintenance as recommended by Haulotte is completed prior to the operation of the machine 95

If regular maintenance is not carried out, this may : 95

• Void the warranty 95

• Cause machine malfunction 95

• Reduce machine reliability and shorten its service life 95

• Jeopardize operator safety 95

HAULOTTE Services® technicians are specially trained to carry out extensive repairs, interventions or adjustments on the safety systems or elements of HAULOTTE® machines They carry genuine HAULOTTE spare parts and tools as required, and also provi 95

The inspection and maintenance table, identifies the role and the responsibilities of each party in periodical machine maintenance Section C 3 – Inspection and Functional test 95

2 – Maintenance Schedule 96

This section provides the necessary information needed to place the machine in safe operation In accordance with the regulations that are currently applicable, this machine is deisgned to have a 10 year life span in normal usage conditions The life 96

Severity of operating conditions may require a reduction in time between maintenance periods Machines that have been out of service or have not been in use for more than 3 months must undergo a periodic inspection before the machine is put back into 96

Maintenance must be carried out by a competent company or person familiar with mechanical procedures 96

Maintenance operations performed must be recorded in a register / log book of the machine 96

3 – Inspection program 97

31 – General program 97

The machine must be inspected on a regular basis at intervals of no less than once 1 per year The purpose of the inspection is to detect any defect which could lead to an accident during routine use of the machine Local standards and regulations ma 97

HAULOTTE® requires Reinforced and Major Inspections to be carried out on the product to extend its service life 97

Inspections must be carried out by a competent company or person 97

The inspection results must be recorded in the safety register or machine log book controlled and overseen by the company manager This register or machine log book and the list of competent repair persons must be made available to the government wor 97

32 – Daily inspection 97

The Daily inspection includes a visual inspection, operational checks and testing of the safety systems This must be conducted by the operator before using the machine 97

This inspection is the responsibility of the user Refer to Section C 31 – Daily inspection 97

33 – Periodic inspection 98

The Periodic inspection is a thorough evaluation of the operation and safety features of the machine 98

It must be conducted before the sale / resale of the machine and/or at least once every year 98

Local regulations may have specific requirements on frequency, and content of inspections 98

The severity of operating conditions may require frequent inspections 98

This inspection is the responsibility of the owner, and inspections must be carried out by a competent company or person 98

This inspection is in addition to the daily inspection 98

This inspection should also be conducted after : 98

34 – Reinforced inspection 98

The Reinforced inspection is a thorough evaluation of the machine’s structural components, to ensure proper functionality of the machine 98

This evaluation must occur at a frequency of 5000 hours or every 5 years 98

This inspection is the responsibility of the owner, and it must be conducted by a HAULOTTE Services® technician or by a competent company or person 98

This inspection includes : 98

35 – Major inspection 99

The Major inspection is a thorough evaluation of the machine’s integrity and proper functioning; after a normal service life of 10 years 99

This evaluation must take place after 10 years of operation and then repeated every 5 years thereafter 99

The severity of operating conditions may require frequent inspections 99

This inspection is the responsibility of the owner, and it must be conducted by a HAULOTTE Services® technician or by a competent company or person 99

This inspection includes : 99

4 – Repairs and adjustments100

Extensive repairs, interventions or adjustments on the safety systems or components must be performed by a HAULOTTE Services® technician Use original spare parts and components only100

HAULOTTE Services® will not take responsibility for any outcomes resulting from inferior services or repairs performed by other unauthorised personnel100

HAULOTTE® reminds that NO modifications SHALL be carried out without the written permission of HAULOTTE®100

Any unauthorised repairs/modifications will void HAULOTTE® warranty100

To check for safety campaigns, consult our website : wwwhaulottecom100

Other information101

1 – Conditions of warranty101

Our warranty conditions and extension contracts are now available on the websites of our sales network : wwwhaulottecom101

2 – Subsidiary contact information101

21 – California warning102

For the US destined machines (ANSI and CSA standards)102

For electric (battery operated) machines103

Intervention register105

1 – Intervention register105

The intervention register keeps a record of maintenance and repair work carried out inside or outside the maintenance programme105

For online reference and to download the manuals for your machines HAULOTTE®, go to : 1

or, scan the QR Code below : 1

IMAGES PREVIEW OF THE MANUAL: