$45

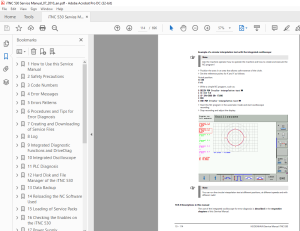

Heidenhain iTNC 530 Service Manual 2010 - PDF DOWNLOAD

Heidenhain iTNC 530 Service Manual 2010 - PDF DOWNLOAD

FILE DETAILS:

Heidenhain iTNC 530 Service Manual 2010 - PDF DOWNLOAD

Language :English

Pages :696

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Heidenhain iTNC 530 Service Manual 2010 - PDF DOWNLOAD

1 How to Use this Service Manual

1.1 Target Group

This Service Manual has been written for specialist electricians for service, maintenance and

commissioning.

Specialists who perform work on the electrical system of a machine tool and its components

must have the required technical knowledge and competence1.2 About this Manual

This Service Manual assists service personnel in the field in diagnosing and

correcting errors on machine tools controlled by iTNC 530.It includes:

Error messages and types of errors that indicate technical defects

Information on possible error causes

Descriptions of error diagnosis

Application descriptions of the diagnosis tools

Information on corrective action

Data backup instructions

Theoretical explanations of functions and their correlations

TABLE OF CONTENTS:

Heidenhain iTNC 530 Service Manual 2010 - PDF DOWNLOAD

1 How to Use this Service Manual 11

11 Target Group 11

12 About this Manual 11

Udpate service 12

13 Other Service Manuals 12

14 Other Documentation 12

15 Support 12

16 Service Training 12

17 Meaning of the Symbols Used in this Manual 13

18 Safety 13

2 Safety Precautions 15

21 Overview 15

Ground 15

Zero potential 15

Fundamental knowledge 15

Know-how and competence 15

Suitable tools 15

Safety precautions of the machine manufacturer 15

Regulations for power installations and instructions for safety and prevent- ion of accidents 15

Basic insulation 16

Vertical axes 16

Changes to entry values 16

Liability 16

3 Code Numbers 17

31 Introduction 17

32 Overview 17

33 Input of Code Numbers 18

Additional notes 19

4 Error Messages 21

41 Introduction 21

Type of error message 21

Display of the error message 22

Reaction of control and machine 24

Automatic generation of service files 24

42 HELP Key 25

43 ERR Key 26

44 CE Key 28

45 List of NC Error Messages 29

Complete list 29

Filtered list 29

5 Errors Patterns 55

51 Introduction 55

Static and nonstatic errors 55

Sporadic and nonsporadic errors 55

52 Overview of Possible Error Patterns 55

6 Procedures and Tips for Error Diagnosis 59

61 Introduction 59

62 Power Off and On 59

63 Sequence for Finding Serious Electrical Errors 60

Flowchart 61

64 Sequence for Finding Errors in the Control Loop 62

Integrated oscilloscope 62

Flowchart 63

Possible effects of contaminated, loose, defective encoders 64

65 Error Localization by Process of Interchange 65

Example: Interchange possibilities on iTNC 530 65

66 Error Localization by Process of Exclusion 66

Flowchart 67

67 Finding Position Differences of Direct and Indirect Encoder 68

Prerequisite 68

Integrated oscilloscope 68

Conclusion 69

68 Error Localization by Switching from Direct to Indirect Position Measurement 70

Prerequisite 70

Direct position measurement 70

Indirect position measurement 71

Flowchart 71

Conclusion 71

69 Notes and Tips 72

What is the cause of this error? 72

First steps 72

Visual inspection 72

Comparison with functioning machines or devices 72

Low voltages and polyfuses 73

Cables 73

Connectors and females 73

Terminals 73

Shielding and grounding 73

Sources of interference 74

Contamination 74

Temperature 75

Humidity 75

Shipping brace of the hard disk 75

7 Creating and Downloading of Service Files 77

71 Introduction 77

72 Automatic Generation of Service Files 78

73 Manual Generation of Service Files 78

74 Downloading of Service Files 79

8 Log 81

81 Introduction 81

82 Calling the Log 82

83 Overview of Log Entries 83

Entry of IP addresses 85

Entry of operating system error messages 85

Entry of NC programs 86

84 Log Entries at Program Cancelation 87

Considering the tool length 88

Calculating the REF position 88

9 Integrated Diagnostic Functions and DriveDiag 89

91 Introduction 89

92 Activation and Operation 90

Calling the drive diagnosis 90

Selecting the supply device 91

Operating the drive diagnosis 92

Calling the drive information 94

Calling DriveDiag 96

How to operate DriveDiag 97

93 For Error Diagnosis 98

10 Integrated Oscilloscope 99

101 Introduction 99

102 Activation and Settings100

Mode of operation101

Sample time101

Output102

Feed rate102

Channel 1 to 6102

Signals102

Trigger104

Trigger threshold104

Edge104

Pre-trigger104

103 Recording and Adjusting the Signals105

Vertical resolution105

Horizontal resolution107

Other soft keys108

Cursor information108

Specific for pre-triggering109

104 Saving and Loading Recordings110

105 For Error Diagnosis111

1051 Triggering on error marker111

1052 Circular interpolation test113

1053 Descriptions in this manual114

11 PLC Diagnosis115

111 Introduction115

Definition of PLC115

Tasks of the PLC115

Data exchange with the PLC115

PLC error messages115

Calling the PLC mode115

PLC main page116

PLC functions of the main menu117

112 Possible Causes of Errors118

General information118

Additionally for the use of PROFIBUS118

113 Diagnosis Tools in the PLC Mode119

1131 The TABLE function119

Call119

Checking the PLC inputs120

Conclusion121

Error localization PLC input122

Checking the PLC outputs123

Conclusion123

Meaning of the LEDs on the PLD 16-8123

Measuring circuit with test adapter for PLC inputs and outputs on the MC124

1132 The LOGIC diagram125

Call125

Selecting the operands125

Start of recording126

Saving the LOGIC DIAGRAM recording127

Calling the LOGIC DIAGRAM recording127

Further possibilities with the integrated oscilloscope127

1133 The TRACE function128

Call128

Selecting the PLC128

Evaluation128

1134 The WATCH LIST function129

Call129

Selecting symbolic operands in the WATCH LIST129

Selecting absolute operands in the WATCH LIST130

Saving the WATCH LIST file130

Calling a WATCH LIST file130

1135 The I / O - FORCE LIST131

Call131

Selecting inputs and outputs for the FORCE LIST131

Activating the I/O FORCE LIST132

Saving the I/O FORCE LIST file132

Calling an I/O FORCE LIST file132

Deactivating and exiting the I/O FORCE LIST132

1136 PROFIBUS diagnosis133

Call133

Soft keys for the PROFIBUS diagnosis134

Use for troubleshooting134

Log files135

114 Non-Volatile PLC Markers and Words136

Saving on hard disk136

Playing back the data into the RAM137

115 Overviews138

Overview of markers138

Overview of words144

Overview of operands146

116 Specifications147

1161 PLC inputs147

1162 Analog inputs148

1163 Inputs for thermistors148

1164 PLC outputs149

Output signals and addresses149

Supply voltage for PLC outputs149

12 Hard Disk and File Manager of the iTNC 530151

121 Introduction151

HDR and drive assembly151

122 Structure of the Hard Disk152

Single-processor control152

Dual-processor control152

123 Possible Causes of Error152

124 Test of Hard Disk153

No communication with the hard disk153

Communication with the hard disk153

With the single- processor control (without Windows)154

With the dual- processor control (with Windows)157

125 Setting the System Time159

With the single- processor control159

With the dual- processor control control161

126 Setting the Program Manager162

127 File Management of TNC Partition163

Calling the TNC partition163

Using the mouse163

Overview of the most important TNC file types164

Which file type is to be listed?164

File information164

128 File Management of PLC Partition165

Calling the PLC partition165

Using the mouse166

Overview of the most important PLCfile types166

Which file type is to be listed?167

File information167

13 Data Backup169

131 Introduction169

Backup recommended169

Data backup169

Available data interfaces169

Windows knowledge170

Authorization170

TNCremoNT data transfer software170

BINARY-to-ASCII conversion170

Protection from data tampering171

132 Connection Setup172

1321 Via Ethernet172

Requirements172

Management of the Ethernet interface on the iTNC 530172

Connection via your local network172

Connection establishment at the customer's (field service)172

Adjusting Ethernet settings on the laptop173

Adjusting Ethernet settings on the control175

TNCremoNT179

„Pinging"180

Meaning of the LEDs on the Ethernet data interface X26181

Restoring original settings181

1322 Via serial interface RS-232-C or RS-422182

Requirements182

Managing the serial data interfaces on the iTNC 530182

Connection setup182

Configuration of the serial interface on the iTNC183

TNCremoNT183

1323 Via USB185

Requirements185

Connecting the USB stick185

Disconnecting the USB stick185

133 Reading In and Out of Individual Files or Directories186

Connection setup186

Transferring data to the USB flash drive186

Transferring data from the USB flash drive188

Reading out data using TNCremoNT190

Reading in data using TNCremoNT191

134 Backup on an External Data Medium192

Connection setup192

Selecting the target drive on the laptop192

Creating target folder on laptop192

Selecting the control partition192

Call the back-up function193

Selecting the backup type193

Starting the backup194

135 Extracting Files from the Backup File196

136 Restoring Data197

Connection setup197

Backup file197

Starting the restoring procedure198

137 Cable Overview200

1371 Ethernet interface RJ45 connection200

1372 RS-232-C (V24)201

Accessories202

1373 RS-422 (V11)204

138 Operating Modes of the Data Interfaces205

1381 Overview of operating modes205

FE1205

EXT 1, EXT 2205

LSV-2:205

1382 Interface configuration and assignment of mode206

Calling the interface setup206

Operating mode / baud rate206

139 Drive Symbols207

14 Reloading the NC Software Used209

141 Introduction209

142 Preparations209

Test of Hard Disk209

Active NC software version and service pack209

Preparing the machine209

143 Proceeding up to NC Software 34049x-01 (Single-Processor Version)210

144 Proceeding as of NC Software 34049x-02 (Single-Processor Version)212

145 Proceeding for the Dual-Processor Version215

15 Loading of Service Packs219

151 Introduction219

Display on the screen219

152 Preparations220

Who provides the new Service Pack?220

Preparing the machine220

153 Execution up to NC Software 34049x-01 (Single and Dual Processor Version)221

Unzipping the ZIP File221

Access to the service pack files via the customer network221

Transferring files service packs from the laptop to the control221

Loading the service pack221

Functional test222

154 Execution as of NC Software 34049x-02 (Single-Processor Version)223

Unzipping the ZIP File223

Access to the service pack files via the customer network223

Loading the service pack223

Functional test225

155 Execution as of NC Software 34049x-02 (Dual-Processor Version)226

Unzipping the ZIP File226

Access to the service pack files via the customer network226

Loading the service pack226

Functional test228

16 Checking the Enables on the iTNC 530229

161 Introduction229

Closed EMERGENCY-STOP chain229

Acknowledgment control is ready230

Global drive enabling230

Drive enabling for axis groups230

Drives ready for operation230

Current and speed controller active231

Some machine parameters231

162 Examination232

Selecting the supply device232

1621 Checking the "Control is ready" output and input (EMERGENCY STOP chain)233

Fault: Message "Relay external DC voltage missing" permanently displayed233

Page from the integrated drive diagnosis234

Page from DriveDiag234

Excerpt from the basic circuit diagram235

Sliding switch on I/O module235

Error message: EMERGENCY STOP defective236

Bridge inserted238

1622 Checking the global drive enable I32, connector X42 / pin 33239

Page from the integrated drive diagnosis240

Page from DriveDiag240

Excerpt from the basic circuit diagram241

1623 Checking the drive enabling for the axis groups via connector X150 and X151 (if wired)242

Page from the integrated drive diagnosis242

Page from DriveDiag242

1624 Checking the readiness of the inverter system243

Pages from the integrated drive diagnosis243

Page from DriveDiag244

Page from the integrated drive diagnosis244

Page from DriveDiag245

Green READY LEDs on the drives245

Red LED SH1247

Red LED SH2247

1625 Checking PLC modules, markers and words248

17 Power Supply251

171 Power Supply for the iTNC 530251

1711 Introduction251

Power supply by UV 105252

Power supply by UVR253

Power supply by UV 105 B254

Power supply by UV 106 (B)255

1712 UV 105, UV 105 B256

Possible causes of error256

Troubleshooting UV 105 (B)256

Control of the LED READY UV256

5 V on auxiliary terminal256

Function of the fan256

Checking the supply voltages256

Uz of a non HEIDENHAIN inverter system257

Fuses in UV 105 (B)258

Corrective action259

Mounting the UV 105 (B)259

1713 UV 106, UV 106 B260

Possible causes of error260

Troubleshooting UV 106 (B)260

Control of the LED READY UV260

Function of the fan260

Checking the supply voltages260

Fuses in UV 106 (B)261

Corrective action261

Mounting the UV 106 (B)261

172 Power Supply for "Control-Is-Ready Signal"262

X34: Power supply for "Control-Is-Ready" signal output262

Error messages262

Troubleshooting263

173 Buffer Battery264

Introduction264

Message264

Checking the charge status of the "Gold cap"265

Replacing the buffer battery265

Position of the buffer battery265

Were any data lost?266

174 Information Menu267

Call267

Description267

175 Power Supply for PLC Outputs268

1751 Introduction268

Power consumption268

Nominal operating current per output268

1752 Supply voltage for PLC outputs on the MC269

X44: PLC supply voltage269

Error message269

Troubleshooting X44270

Fine wire fuses271

1753 Supply voltage for PLC outputs on the PL 4xx B272

Connection272

X9 to X14: Power supply272

X23: Supply voltage of the analog inputs of the PL 410 B273

Error273

Functional check273

1754 Supply voltage for PLC outputs on the PL 510274

Connection274

PLB 510 basic module274

PLD 16-8 input/ output module274

LED display275

Error275

Functional check275

176 Power Supply for the Display Units276

Errors276

Troubleshooting276

18 Encoder Interface277

181 Position Encoders277

1811 Introduction277

Position encoder inputs277

Monitoring of the position encoders277

Assignment of the position encoders278

EnDat encoders278

Memory areas in the EnDat encoder278

Signal type and input frequency278

Polyfuses278

1812 Possible causes of errors279

1813 Troubleshooting280

Example280

Example machine parameters280

Block diagram280

Flowchart281

1814 Possibilities with the integrated diagnosis or DriveDiag282

EnDat position encoder282

Position encoder test282

1815 Possibilities with the integrated oscilloscope283

1816 Corrective action286

Encoder components286

Control286

1817 Determining the field angle on linear motors, torque motors and synchronous spindles287

1818 Resetting the machine datum288

Individual axis288

Gantry axes with two position encoders290

1819 Restoring the spindle orientation292

182 Speed Encoders293

1821 Introduction293

Speed encoder inputs293

Monitoring of rotary encoders293

Assignment of speed encoders293

EnDat encoders294

Memory areas in the EnDat encoder294

Temperature sensor lines294

Polyfuses294

Different servicing294

1822 Possible causes of errors295

1823 Trouble shooting on the CC 422296

Example296

Example machine parameters296

Block diagram296

Flowchart297

1824 Trouble shooting on the CC 424 (B)298

Example298

Example machine parameters298

Notes and preliminary action298

Block diagram298

Flowchart299

1825 Possibilities with the integrated diagnosis or DriveDiag300

1826 Possibilities with the integrated oscilloscope301

1827 Corrective action304

Motor encoder in a synchronous motor304

Motor encoder in an asynchronous motor304

Control304

1828 Readjusting the trip dog for reference end position305

1829 Resetting the machine datum306

18210 Restoring the spindle orientation306

183 Error Codes for Encoders with EnDat Interface307

184 Further Examination of Position and Speed Encoders308

Introduction308

PWM 9308

PWT309

IK 215310

185 Position Measurement via Motor Encoder (Indirect Position Measurement)311

Note!311

Preliminary action312

Line count of the motor encoder312

Flowchart for individual axis313

Flowchart for axes with master-slave torque control314

186 Switching over the Position Display for Servicing315

Call315

Description of the settings315

19 Reference Run317

191 Definition317

Reference marks317

Machine datum317

Distance between the scale reference point and the machinedatum317

Spindle preset317

192 Traversing the Reference Marks318

193 Possible Causes of Errors318

194 Troubleshooting319

Examining the encoders319

Examining the reference mark319

Examining the switch signal of the trip dog319

195 Corrective Action320

196 Deselecting the Reference Run for Axes320

197 Retraction after an Error with Control Reset321

General information321

Tilted axes321

20 Interface to the Drives323

201 Digital PWM Interface323

2011 Introduction323

PWM outputs323

Assignment of the PWM outputs323

PWM frequency324

Single and double- speed control loops325

Power supply modules, power stages and motors325

Different servicing325

2012 Tables for power supply modules, power stages and motors326

Table of power supply modules326

Power module table328

Motor table330

2013 Possible causes of error332

2014 Sequence for finding errors in the control loop332

2015 Troubleshooting: Interchanging PWM outputs on the CC 422333

Modular setup with CC 422333

Example333

Example machine parameters333

Notes and preliminary action333

Block diagram334

Flowchart335

Next test335

2016 Troubleshooting: Interchanging PWM outputs on the CC 424 (B)336

Modular setup with CC 424 (B)336

Example336

Example machine parameters336

Notes and preliminary action336

Block diagram337

Flowchart338

Next test338

2017 Troubleshooting: Interchanging power modules or output stages of the same type339

Assumed configuration for two 1-axis modules340

Assumed configuration for one 2-axis module340

Example340

Block diagram for two 1-axis modules340

Flowchart for two 1-axis modules341

2018 Troubleshooting: Interchanging the HEIDENHAIN interface boards for the SIMODRIVE 611 system342

Boards of the same type342

Boards of different types342

2019 Corrective action343

Control343

Drive components343

Mechanics343

202 Analog Speed Command Interface344

2021 Introduction344

Analog speed value outputs344

Assignment of the speed value outputs344

2022 Possible causes of error344

2023 Sequence for finding errors in the control loop345

2024 Checking the analog speed command interface346

Observation with the integrated oscilloscope346

Error: No axis movement!346

Flowchart347

Battery box348

Measuring setup with test adapter348

Specifications of the analog channels348

2025 Adjusting the electrical offset (drift adjustment)349

Offset adjustment at the analog servo amplifier349

Offset fine adjustment in the control351

2026 Speed adjustment at the servo amplifier (tachometer adjustment)352

Suggestion how to perform the adjustment352

Comparison of noml and actl speed in the integrated oscilloscope353

2027 Corrective action354

Control354

Drive components354

Mechanics354

21 Visual Display Unit355

211 Introduction355

212 Possible Causes of Errors355

213 Troubleshooting356

VDU soft keys356

Monitor356

Rear view BF 150357

Rear view BF 120358

214 Corrective Action358

VDU soft keys358

Fan358

Front glass358

Monitor358

Control358

22 Keyboard Unit359

221 Introduction359

222 Front View of the Keyboard Units360

223 Possible Causes of Error362

224 Checking the Keys363

Correct operation?363

Visual inspection363

Does the control receive the key signal?363

Principle of the key matrix364

Flowchart364

Measuring setup with test adapter365

Test adapter replaces keyboard366

225 Checking the Potentiometers367

Potentiometer values in the PLC-TABLE367

Potentiometer values in the integrated oscilloscope367

Measuring setup with test adapter369

226 Checking the Touchpads370

Second USB interfaces370

Other mouse370

Touchpad on laptop370

227 Corrective Action371

Pushbuttons371

Potentiometer371

Control371

228 Key Matrix of the Keyboard Units372

TE 520 B TE 530 TE 530 B TE 535 Q372

TE 420383

229 Key Matrix of the Visual Units388

BF 150388

BF120 BF 150388

23 Machine Operating Panel389

231 Introduction389

232 Possible Causes of Errors390

233 Checking the Power Supply391

Measuring setup with test adapter391

234 Checking the Keys392

Correct operation?392

Visual inspection392

Does the control receive the key signal?392

Measuring setup with test adapter395

Test adapter replaces MB396

235 Checking the Outputs397

236 Corrective Action398

Pushbuttons398

Other MB components398

Control398

24 Handwheel399

241 Introduction399

242 Possible Causes of Errors400

243 Error Location on Portable Handwheel with HR 420 Display401

Control impaired?401

Visual inspection401

Functional check401

Power supply OK?401

Checking the keys403

Checking the potentiometers404

244 Error Diagnosis at HR 410 Portable Handwheel406

Control impaired?406

Visual inspection406

Functional check406

Power supply OK?406

Checking the keys408

245 Deselecting and Disconnecting the Portable Handwheel409

Dummy plug409

246 Error Diagnosis at Panel-Mounted Handwheels410

Power supply OK?410

Checking the switches411

Assignment of the switch positions to the PLC inputs411

247 Corrective Action412

Keys412

Cables and handwheel adapters412

Control412

25 Touch Probe413

251 Introduction413

Different touch probes413

Infrared transmission415

Touch probe cycles416

Pin layout416

Other information416

252 Possible Causes of Errors417

253 Error Diagnosis on TS Touch Probes418

Control impaired?418

Visual inspection418

Checking the LEDs418

Checking the "Ready" bridge419

Functional test420

254 Error Diagnosis on TT Touch Probes422

Control impaired?422

Visual inspection422

Checking the LEDs422

Checking the "Ready" bridge422

Functional test423

255 Error Diagnosis on Laser Touch Probe425

Control impaired?425

Visual inspection425

Checking the LEDs425

Checking the "Ready" bridge425

256 Deselecting and Disconnecting the Touch Probe426

257 Corrective Action427

Cleaning427

Readjusting the SE427

Exchange of components427

Recalibration427

Returning the touch probe427

Returning the control427

26 Important Features of HEIDENHAIN Components429

261 HEIDENHAIN Components in a Machine Tool429

262 Hardware Identification430

ID label430

Main computer430

HDR hard disk, SIK431

Controller units431

Power supply units432

Visual display units433

Keyboards434

Switching unit435

Machine operating panel435

Handwheels436

Touch probes438

PLC Expansion440

Encoders442

Inverters and motors442

Interface boards for the SIMODRIVE system 611D442

263 Display of Important System Information443

Calling the display443

Display for NC software 340420-xx to 340480-xx443

NC software443

PLC software444

Preset table444

Options444

DSP software444

Current controller software445

Display for NC Software as of 340490-xx (smarTNC programming interface)445

Feature Content Level445

27 Connector Designation and Layout447

271 Important Note447

272 MC and CC447

2721 Designation and position of connectors447

2722 Pin Layouts on the MC and CC457

X1 to X6, X35 to X38, X201 to X214: Position encoder 1 VPP457

X1 to X6, X35 to X38, X201 to X214: Position encoders with EnDat interface458

X8: Analog output 1 to 6459

X9: Analog output 7 to 13459

X12: Connection of the touch probe for workpiece measurement460

X13: Connection of the touch probe for tool measurement462

X15 to X20, X80 to X87: Speed encoder 1 VPP463

X15 to X20, X80 to X87: Speed encoder with EnDat interface464

X23: Handwheel input467

X26: Ethernet interface RJ45 connection467

X27: RS-232-C/V24 data interface468

X28: RS-422/V11 Data interface469

X30: Reference signal spindle469

X34: Power supply for “Control is ready”469

X41: PLC outputs on the MC 42x (B/C)470

X42: PLC inputs on the MC 42x (B/C)471

X44: PLC supply voltage472

X45: iTNC control panel473

X46: Machine operating panel474

X47: PLC expansion for PL 4xx B on the MC 422 (B/C)475

X47: PLC expansion for PL 510 to the MC 422 (B/C)476

X48: Analog input (PLC) on the MC 42x (B/C)477

X49: BF 120 flat-panel display478

X51 to X64: PWM-output480

X69: NC power supply and control signals481

X74: 5 V supply481

X127: RS-232-C/V24 data interface482

X128: RS-422/V11 data interface483

X141, X142: USB connection483

USB hub483

X147: PLC Expansion for PL 510 on the MC 420484

X149: BF 150 flat-panel display485

X150, X151: Drive controller enable for axis groups486

X169: NC supply voltage and control signals486

273 Power Supply Units487

2731 UV 105 power supply unit488

Connection overview UV 105488

X31: Power supply unit for UV 105489

Power supply of the UV 105 with UZ489

X69: NC supply voltage and control signals489

X74: 5 V connection of the UV 105489

2732 UV 105 B power supply unit490

Connection overview UV 105 B490

Connector on the front panel491

50-pin ribbon cable491

5V terminal on the front panel491

2733 UV 106 (B) power supply unit492

Connection overview UV 106 (B)492

X31: Power supply of the UV 106 (B)492

274 Monitors493

2741 Designation and position of connectors493

BF 120493

BF 150493

2742 Pin layouts494

X1: Power supply494

X2: Connection of the BF 120 to the MC494

X2: Connection of the BF 150 to the MC494

X3: Connection of the VDU soft keys to the iTNC operating panel494

275 Keyboard Units495

2751 Designation and position of connectors495

TE 420495

TE 520 B495

TE 530 (B)496

TE 535 Q496

2752 Pin layouts497

X1: Connection of the VDU soft keys to the iTNC operating panel497

X2: iTNC keyboard497

X9: USB interface for the mousepad497

276 BTS 1x0 Monitor/Keyboard Switch498

X1, X2, X4, X5 to X7: Monitor and keyboard connections498

X3: Switchover between the keyboards498

X8: Supply voltage for BTS 1x0498

277 Machine Operating Panel499

2771 Designation and position of connectors499

MB 420499

MB 520499

2772 Pin Layouts on MB 420499

X1: Connection to MC499

X2: Connection of NC start and NC stop key499

X3: PLC Inputs499

X4: PLC outputs500

2773 Pin layouts on MB 520500

X3: Connection to MC500

X10: To a transfer unit501

X11: Vacant PLC inputs501

X12: PLC outputs502

X13, X14, X15: Key connections502

278 Handwheels503

X23: Handwheel input503

2781 HR 4xx portable handwheel503

2782 HR 130 panel-mounted handwheel504

2783 HRA 110 handwheel adapter505

X1 to X3: Inputs on the HRA 110 for the HR 150 handwheels505

X23: Connection to MC 42x (B/C)506

X31: HRA 110 supply voltage506

279 Touch Probes507

Touch probes for workpiece measurement507

Touch probe for tool measurement507

2710 PLC Input/Output Units507

27101 Designation and position of connectors507

PL 405 B507

PL 410 B508

PL 510509

27102 PL 4xxB Pin Layouts510

X1: PLC expansion on the MC510

X2: PLC expansion PL 4xx B on the PL 410 B510

X3: PLC input PL 410 B and PL 405 B511

X4: PLC input PL 410 B and PL 405 B511

X5: PLC input PL 410 B512

X6: PLC input PL 410 B512

X7: PLC output PL 410 B513

X8: PLC output PL 410 B and PL 405 B513

X9 to X14: Power supply514

X15 to X18: Analog input on the PL 410 B514

X19 to X22: Connection for Pt 100 on the PL 410 B514

X23: Supply voltage for analog inputs of the PL 410 B515

27103 Pin layouts for PL 510516

X1: PLC expansion on the MC 422 (B)516

X1: PLC expansion on the MC 420516

X2: PLC expansion PL 510 on the PL 510516

X3: Supply voltage for logic516

X4 to X5: PLC inputs on the PL 510517

X6: PLC outputs on the PL 510518

X6: Power supply for the PLC outputs on PLD 16-8 input/ output module518

X15 to X18: Analog input on the PLA 4-4 analog module519

X19 to X22: Connection for Pt 100 on the PLA 4-4 analog module519

2711 Encoders520

27111 Position encoders520

Adapter connector TTL (HEIDENHAIN)/ 1 VPP521

Adapter connector TTL (SIEMENS) / 1 VPP521

Adapter connector 11 µAPP / 1 VPP522

27112 Speed encoders522

2712 Inverters and Motors522

2713 Interface Boards for the SIMODRIVE System 611D522

28 Exchange of HEIDENHAIN Components523

281 Important Information523

Which components may be exchanged in the field?523

What could be exchanged in addition?523

NC software update524

Export restrictions524

Windows license524

SIK525

Feature Content Level526

Electronic ID label526

MPNAMEMP527

ESD protection528

Information on possible errors529

ID numbers for service order529

Serial number for traceability529

Replacement units and spare parts530

Repair530

Checking after replacement of electrical components530

282 Exchange of the MC 422531

Preparing the machine531

Backup of non-volatile PLC markers and words531

Data backup531

Removing the Defective MC 422531

Shipping brace of the hard disk532

SIK533

Integrating the New MC 422534

Adapting the MPNAMEMP534

Setting date and time on the new MC 422534

Setting up the data interface534

Defining the NC software version534

Restoring the data535

Updating the machine parameter list535

Reset non-volatile PLC markers and words536

Restoring the original state of the machine536

Functional test536

Creating a machine backup536

Removing the defective MC 422536

283 Exchange of the Drive Assembly537

Preparing the machine537

If possible …537

Removing the defective drive assembly537

Shipping brace of the hard disk538

Integrating the new drive assembly538

Adapting the MPNAMEMP539

Setting date and time on the control539

Setting up the data interface539

Defining the NC software version539

Restoring the data539

Updating the machine parameter list540

If possible …541

Restoring the default settings on the machine541

Functional test541

Creating a machine backup541

Removing the defective drive assembly541

284 Exchange of the MC 422 B, MC 422 C, MC 420542

Preparing the machine542

Backup of Non-Volatile PLC Markers and Words542

Removing the defective MC 422 B (MC 422 C, MC 420)542

Mounting the new MC 422 B (MC 422 C, MC 420)542

Setting date and time on the new MC 422 B (MC 422 C, MC 420)542

Reset non-volatile PLC markers and words542

Restoring the original state of the machine543

Functional test543

Returning the defective MC 422 B (MC 422 C, MC 420)543

285 Exchange of the HDR544

Preparing the machine544

If possible …544

Removing the defective HDR545

Shipping brace of the HDR546

SIK547

Installing the new HDR547

Upgrading the main memory548

Adapting the MPNAMEMP548

Setting date and time on the control548

Setting up the data interface548

Defining the NC software version548

Restoring the data548

Updating the machine parameter list549

If possible …550

Restoring the original state of the machine550

Functional test550

Creating a machine backup550

Returning the defective HDR550

286 Exchange of the CC551

Preparing the machine551

Removing the defective CC551

Mounting the new CC551

Functional test551

Returnings the defective CC551

287 Exchange of the Buffer Battery552

288 Exchange of Other HEIDENHAIN Components553

Encoders553

Drive components and mechanics553

Cables553

Shielding and grounding553

Packaging553

289 Exchange of HEIDENHAIN Components in the SIMODRIVE System554

Version with D-sub connector554

Version with ribbon cable connector558

Compatibility of HEIDENHAIN interface boards and SIMODRIVE power modules559

29 Measuring, Testing and Inspection Equipment561

291 Important Notes561

292 Test Adapter562

Brief description562

Adapter cable to the test adapter563

293 PWM 9 Encoder Diagnostic Set566

Brief description566

Available functions567

294 PWT 10/17/18 Testing Unit568

Short description568

Available functions569

295 IK 215 Adjusting and Testing Package570

30 Machine Parameter571

301 Explanation571

302 The Machine Parameter Editor572

303 Meaning of the Machine Parameters579

304 List of Machine Parameters580

3041 Encoders and machines580

3042 Positioning586

3043 Operation with Velocity Feedforward Control592

3044 Operation with following error (servo lag)593

3045 Integrated speed and current control594

3046 Spindle603

3047 Integrated PLC606

3048 Configuration of the Data Interface609

3049 3-D touch probe611

30410 Tool Measurement with TT613

30411 Tapping616

30412 Display and operation617

30413 Color624

30414 Machining and Program Run627

30415 Hardware634

30416 Second spindle643

1 Annex: Principle of Function of the iTNC 530 Control645

11 Introduction645

12 The Control Loop645

The control loop for analog axes/ spindles645

The control loop for digital axes/ spindles646

Nominal and actual values for the controllers647

Cycle times647

Look ahead647

The interpolator648

The position controller648

Operation with following error648

kv factor during control with following error649

Interrelation of kv factor, feed rate, and following error649

Position control with velocity feedforward control650

Position control with velocity semifeedforward control651

The speed controller652

The current controller652

Double-speed control loops653

13 PWM Signals654

2 Annex: Principle of Function of the iTNC 530 Control657

3 Annex: Monitoring Functions661

31 Introduction661

32 During Start-Up661

EMERGENCY STOP test661

Time diagram662

Possible errors and error messages662

Possible causes of error662

Troubleshooting662

33 During Operation663

331 Position or servo lag monitoring664

Possible causes of error664

Difference between position at switch- on and shutdown664

Possible causes of error665

332 Nominal speed value monitoring666

Problem or error666

Possible remedies666

333 Movement monitoring667

Possible causes of error668

Possible causes of error for movement monitoring … B668

334 Standstill monitoring669

Possible causes of error669

335 Positioning window670

Possible error670

Possible causes of error670

Test for troubleshooting670

Axes in position670

Axes in motion671

336 Monitoring of the power supply unit672

Excessive voltage672

Possible causes of error672

Too low voltages672

Possible causes of error673

337 Temperature monitoring674

Temperature of the MC 42x (B/C)674

Motor temperature674

Heat sink temperature of the power module674

Possible causes of error674

338 Internal power supply and housing fan675

339 I2t monitoring676

General information676

Function676

Basics677

Settings and evaluation678

Limit values678

Machine parameters679

Interrogation through PLC module679

Temperature models679

Compatibility680

Possible causes of error680

3310 Actual utilization of drive motors681

3311 Status of HEIDENHAIN inverters682

Status signals that are already low- active or not available during control start-up682

3312 Controlling the motor brakes684

Automatic test of the motor brakes at switch-on685

3313 EMERGENCY STOP monitoring during operation687

Internal EMERGENCY STOP687

External EMERGENCY STOP via MC (I3)687

External EMERGENCY STOP via CC (axis releases)688

Index689

Contact696

S.M 6/3/2025